Home

Week Five : Electronics Production

Already I have explained my Engineering background was Mechanical, So I dont have a good knowledge on Electrical Electronics. So I was excited this week to learn new technology.

Our instructor Vinod has given a wonderful session on the basic Electrical and Electronics.

Yadu also given a great idea on milling machine.He also gave an idea how to use tool bit without wear and tear.

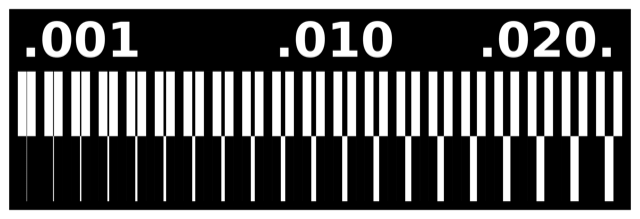

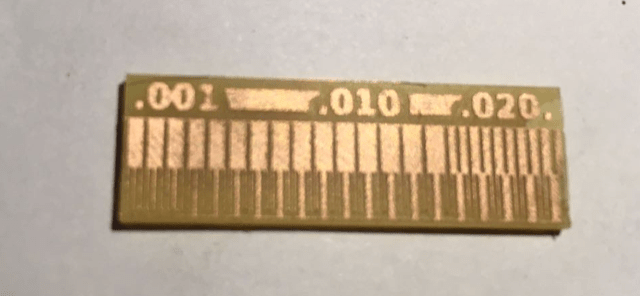

Characterizing the specification of our PCB production process

while characterizing we found that our milling tool bit is only able to mark trace upto 0.20, It doesnt have the accuracy to mill the thickness of 0.001 and 0.01.

Software : Offline FabModules

Input Format : Image(.png)

Output Pocess : Roland mill(.rml)

Select Tool : PCB(1/64) - for Milling

Select Tool : PCB(1/32) - for Cutting

Set Axis : Set X, Y & Z

Select Machine : MDX-20

Calculate

Sending : Send

Found out that machine is not able to make trace of thickness "0.01" and "0.001" due to wear and tear of tool bit and aging of machine

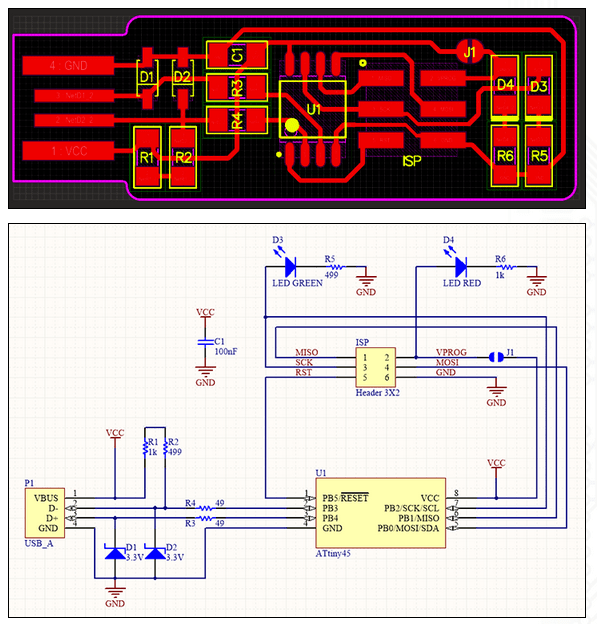

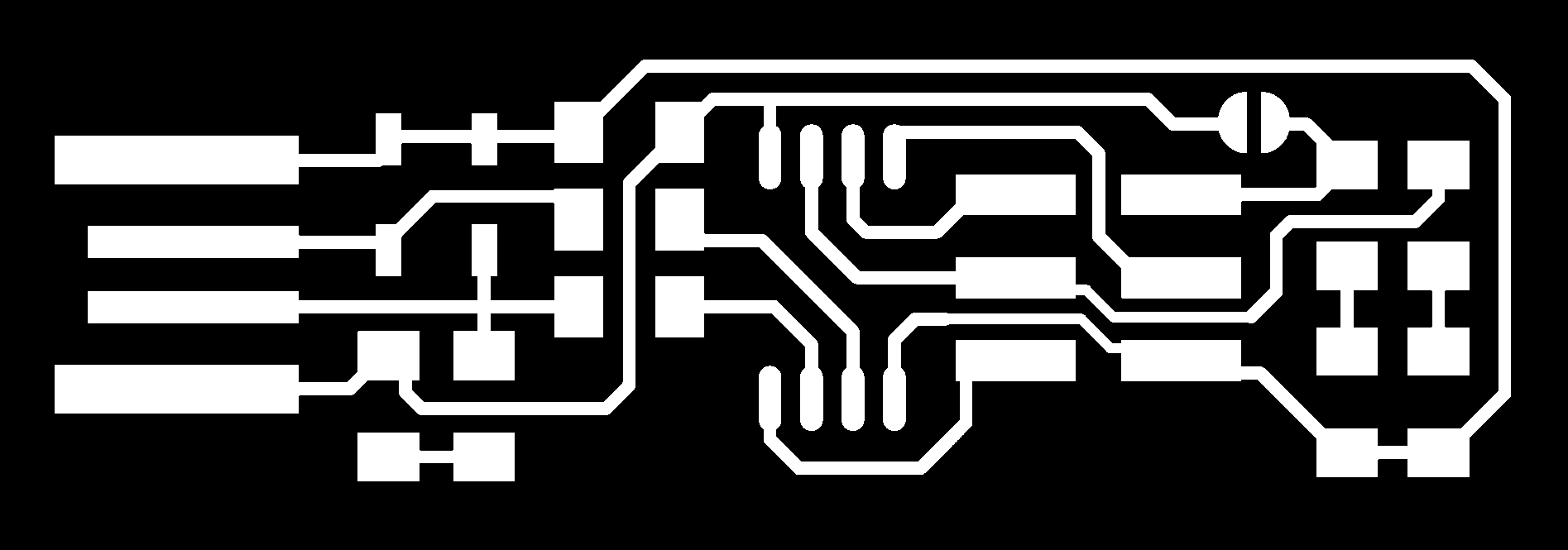

Making an Circuit Programmer

I chose Brian's website for making an in circuit programmer

Design Files

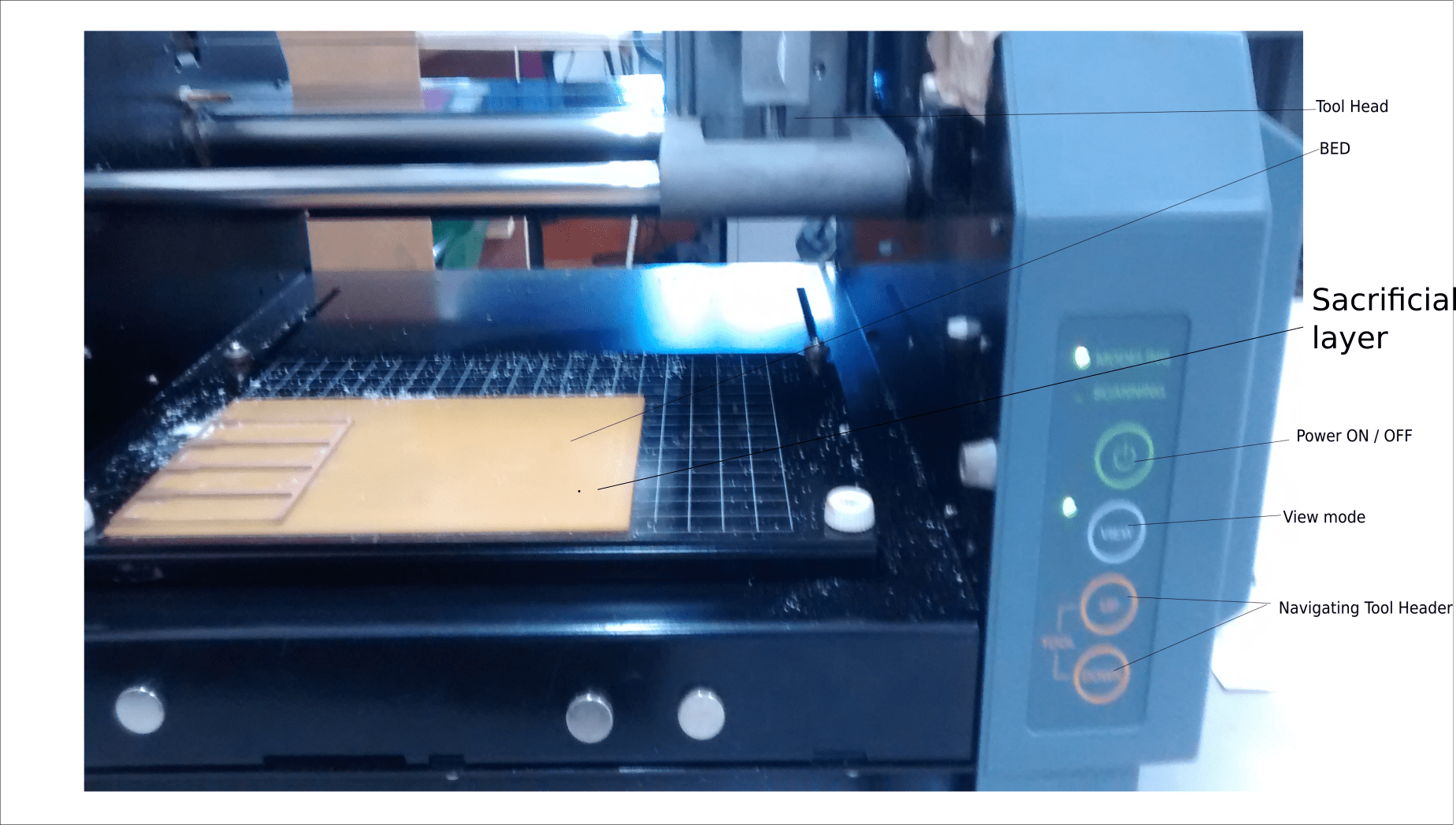

Milling Machine

Milling machine is used to machine flat surface.Here we used to mill tracks and cut the PCB(Printed Circuit Board).There are single side PCB's,double sided PCB's as well as multi layered PCB's available.

In single side PCB's we have a copper layer above a substrate of non conducting layer.In double sided PCB's we have two layers of copper at top and bottom of the substrate whereas in multi layered PCB's we have alternating layers of copper between substate layers

Machine we are using is Roland Modella MDX-20

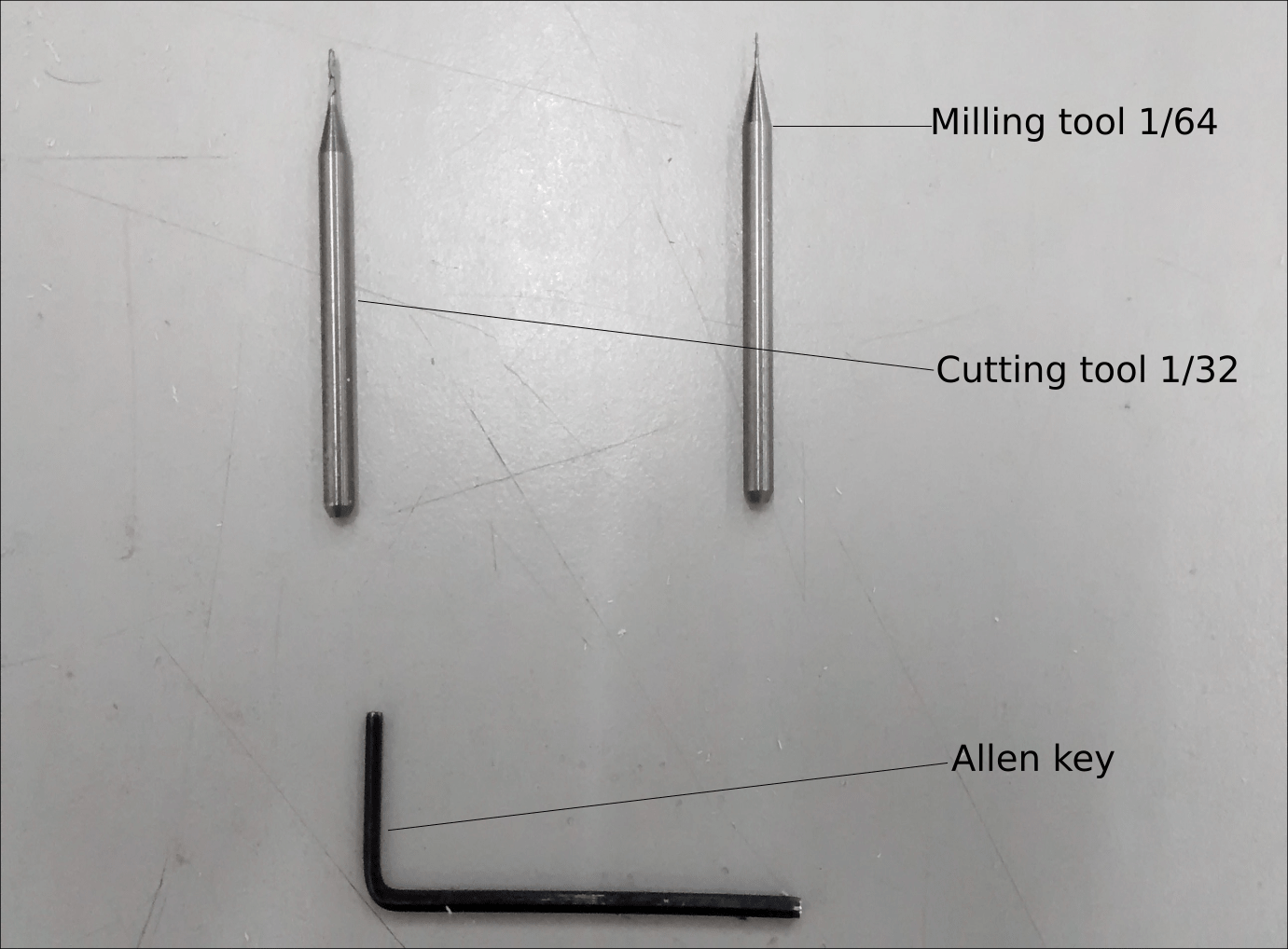

Tools used in Milling Machine

We use two types of tool in milling machine for milling tracks and cutting process.

Tools used are shown in image below.

(1/64) - for Milling

(1/32) - for Cutting

Fixing the copper board on the table

Double sided tape is applied to the copper board and set the board on the bed

Software used in Milling Machine- MDX-20

Software : Offline FabModules

Setting X,Y& Z axis in Milling Machine- MDX-20

First set the tool and give the cordinates for X,Y & Z in FABMODULES and move

Then adjust the tool so that tool touches the bed and Calculate and Send

Setting Tool to Zero- MDX-20

Now going to the Rolland Modella MDX-20, there is a bed to keep the PCB for machining. Before starting it is really important to have the bed levelled, Even a 1mm level difference is a huge difference when it comes to milling the PCBs, it will result in broken endmills or uneven PCB surface. The bed should be flat and steady to make the right cut on the copper surface. So our Instructor took of the bed and cleaned its surface, he set up the bed

While sticking the PCB to the board, we should make sure that there are no air bubbles or dirt, otherwise it could affect the depths of the cut

Fixing the tool bit to the tool head , allen-key is used to tighten and loosen the tool from the tool head. And we should make sure that the tool is fixed properly, otherwise it would broke the tool during machining. The tool must be tightened slowly and alternatly on both sides so that it ends at the center and the length of the tool to the cutting surface should be half or less than half to avoid vibration of the tool

The machine bed has to be first inspected for any bends and deformations. If any bends are observed, the copper blanks should be mounted away from the deformed areas. If the blanks are mounted on an uneven surface, the depth of milling and cutting will vary across different areas and can result in an improper operation

First I have pressed the view button on the machine.The plate will come front and the head will move to right

Load the 1/64 inch bit to the head,Put a sponge above the bed inorder to save the tool tip from breaking during the tighting process

Use the allen Key to tighten the tool bit in head

Now press the view button again to move to (0,0)position

Give the cordinates for X,Y & Z in FABMODULES and move the tool head using arrow key downwards towards material

Check the Z axis and adjust the tool bit using allen key,so that tool touches the PCB material for milling / cutting

After setting these X,Y & Z axis,load the png file to Mill / Cut and Calculate and then SEND

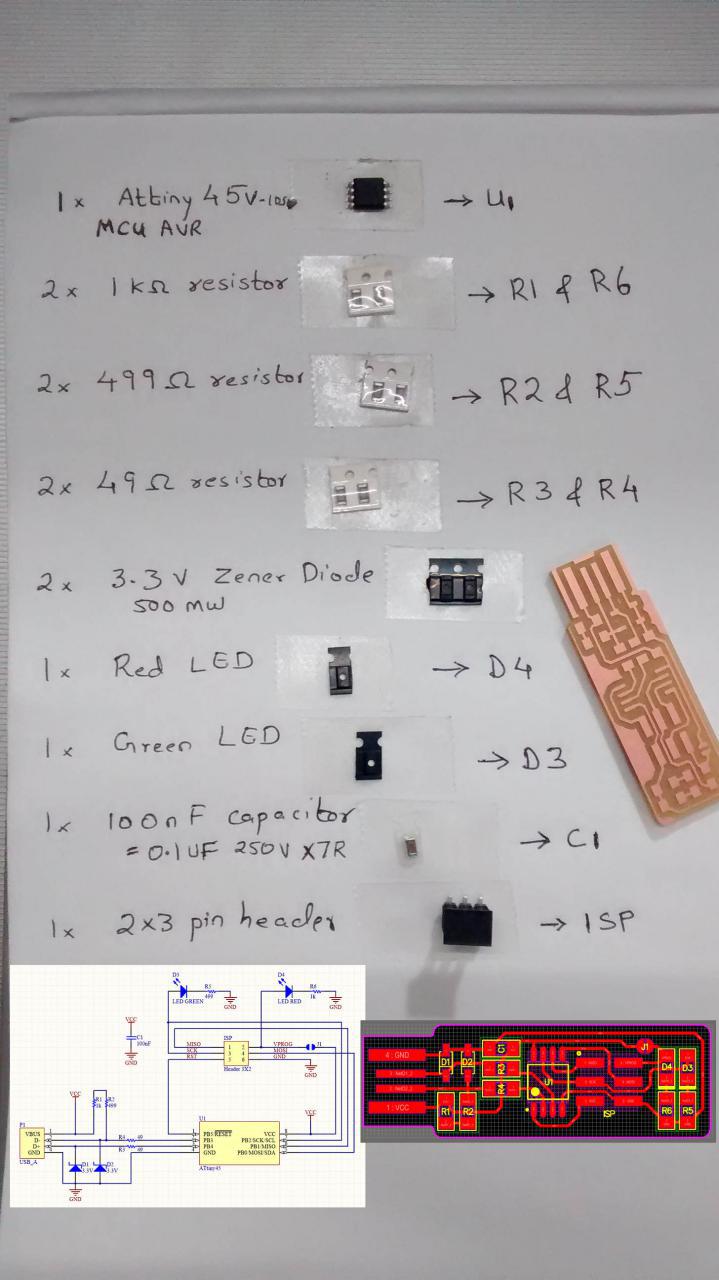

Components Used for making my ISP

Microcontroller - ATtiny45

Resistor R1 & R6 - 1 Kilo-Ohm

Resistor R2 & R5 - 499 Ohm

Resistor R3 & R4 - 49 Ohm

Zener Diode 3.3V

ISP - 2*3 PinHeader

Capacitor - 100nF

LEDs - Red & Green

Switch

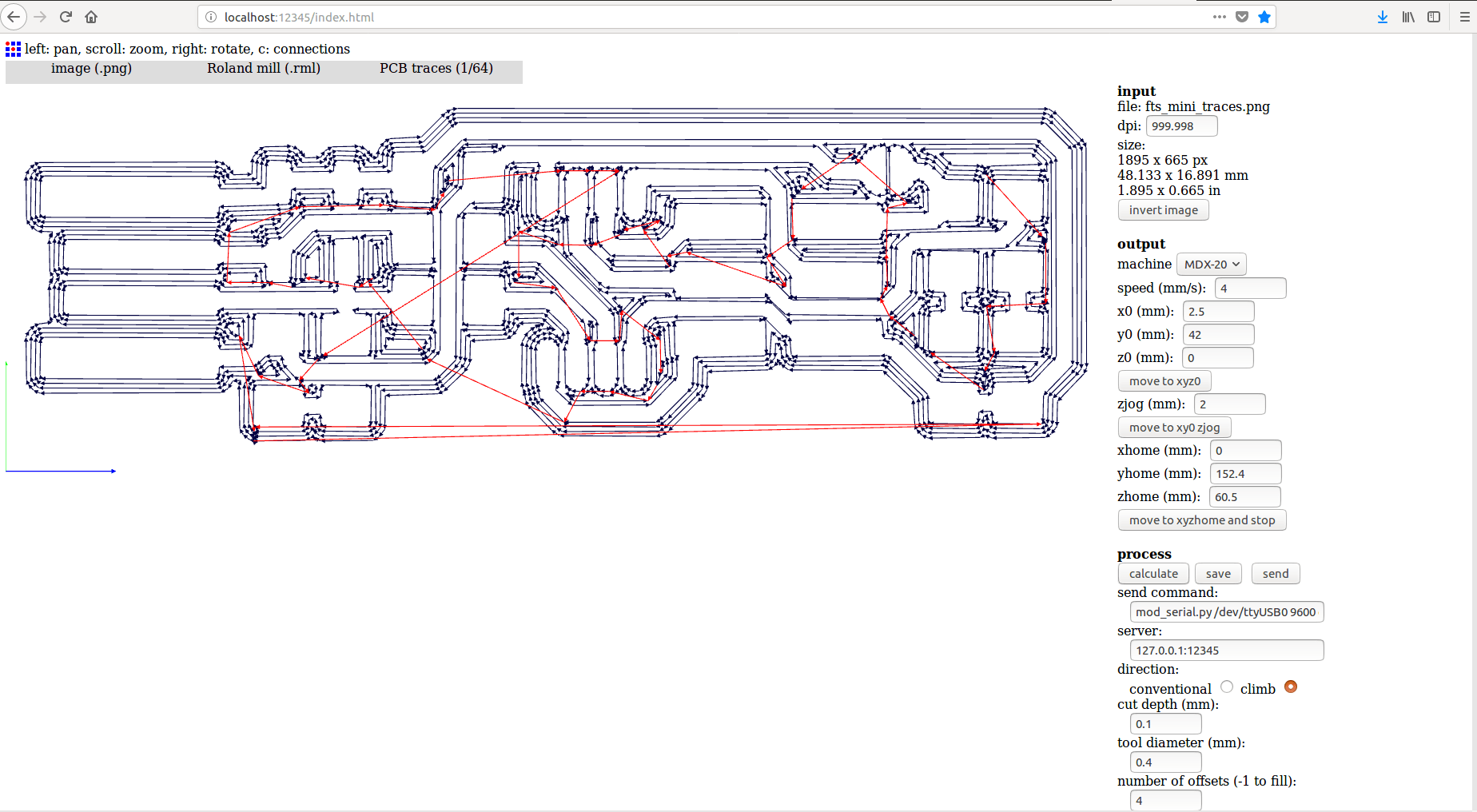

Design for Milling and Cutting

Software : Offline FabModules

Input Format : Image(.png)

Output Pocess : Roland mill(.rml)

Select Tool : PCB(1/64) - for Milling

Set Axis : Set X, Y & Z

Select Machine : MDX-20

Calculate

Sending : Send

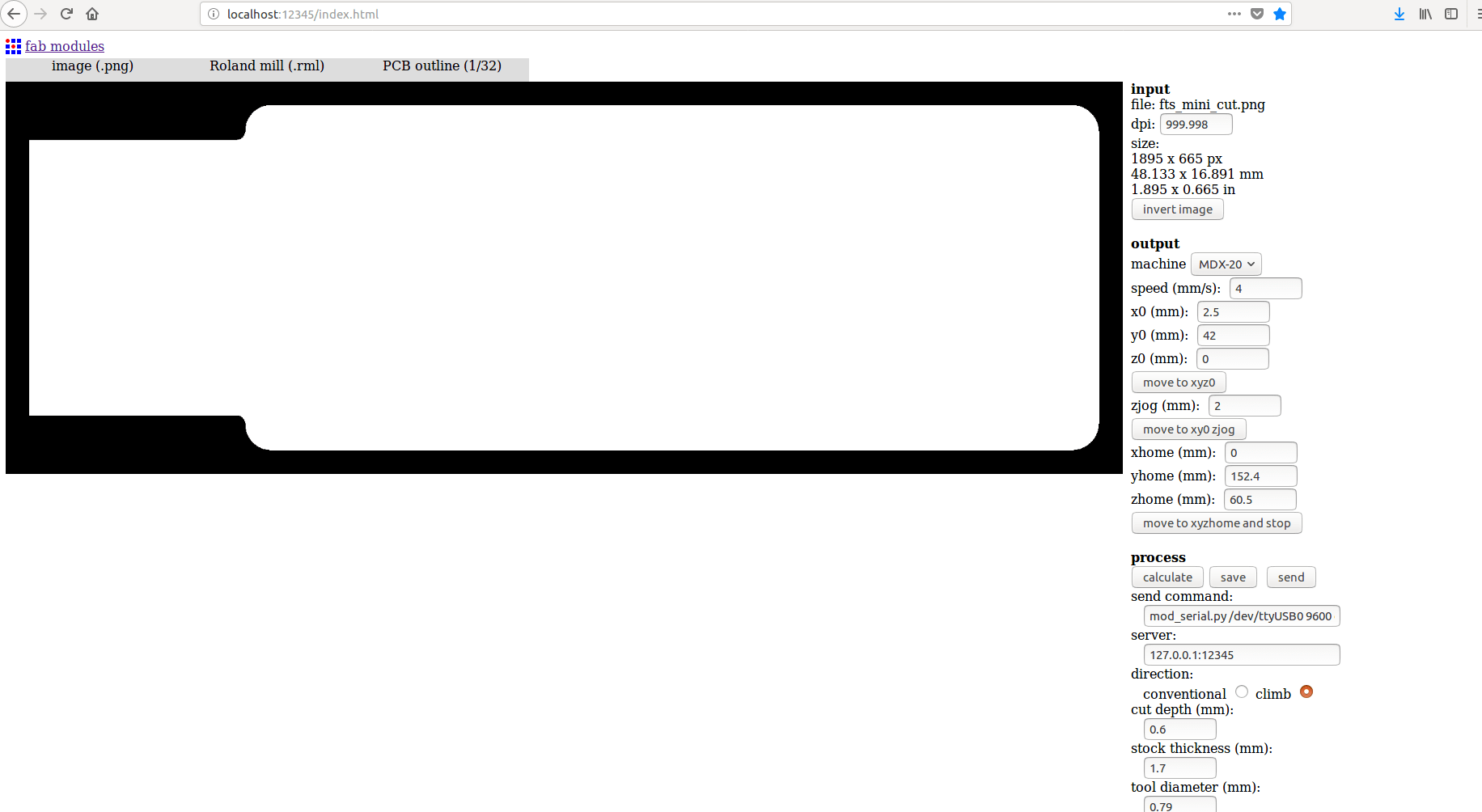

Software : Offline FabModules

Input Format : Image(.png)

Output Pocess : Roland mill(.rml)

Select Tool : PCB(1/32) - for Cutting

Set Axis : Set X, Y & Z

Select Machine : MDX-20

Calculate

Sending : Send

Settings on Milling Machine

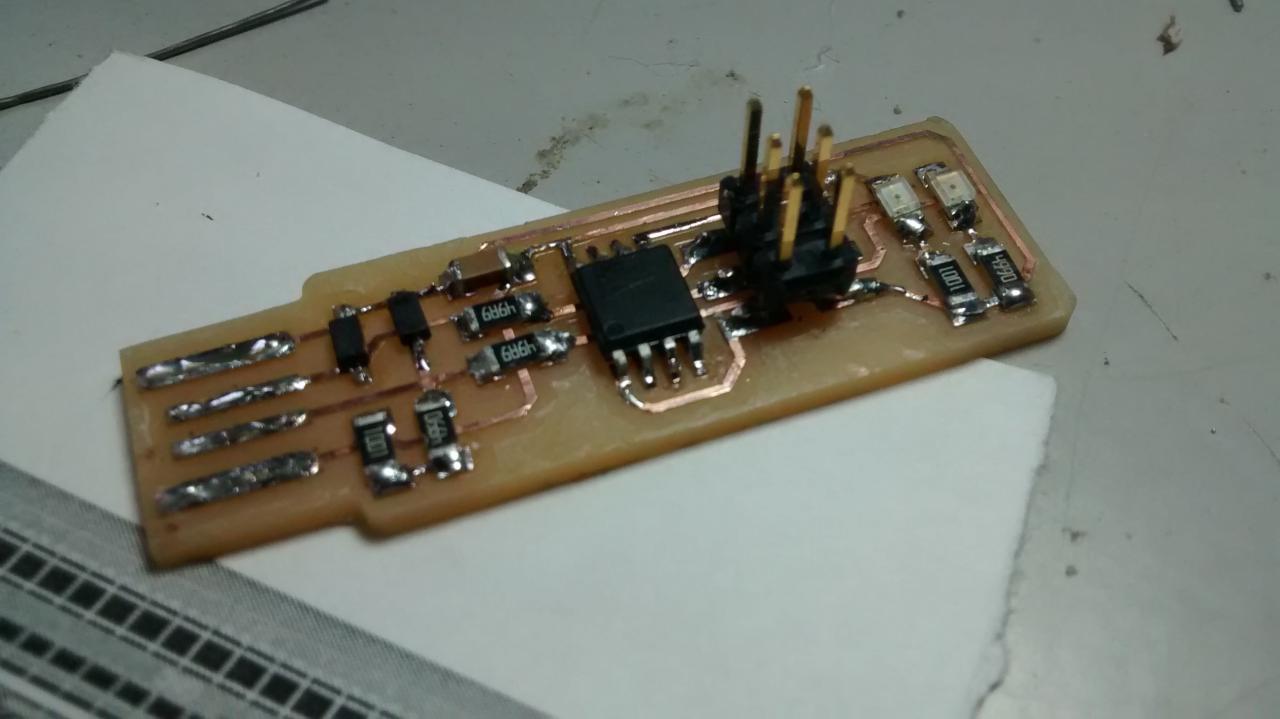

My USBtiny - ISP

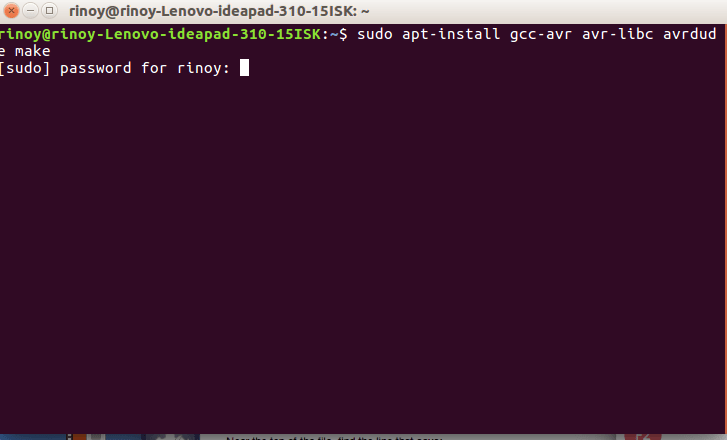

Steps include in Flashing process

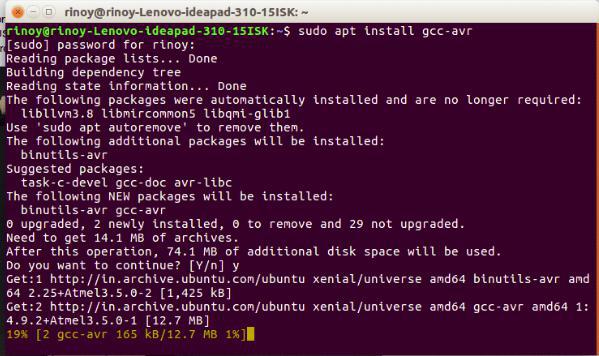

1. Install Compiler for Debugging

sudo apt install gcc-avr

2. Install Library for Compiler

sudo apt install avr-libc

3. Install flash to convert hex file to chip

sudo apt install avrdude

4. Install all functions to store in file

sudo apt install make

OR we can run on single command as shown below

sudo apt install gcc-avr avr-libc avrdude make

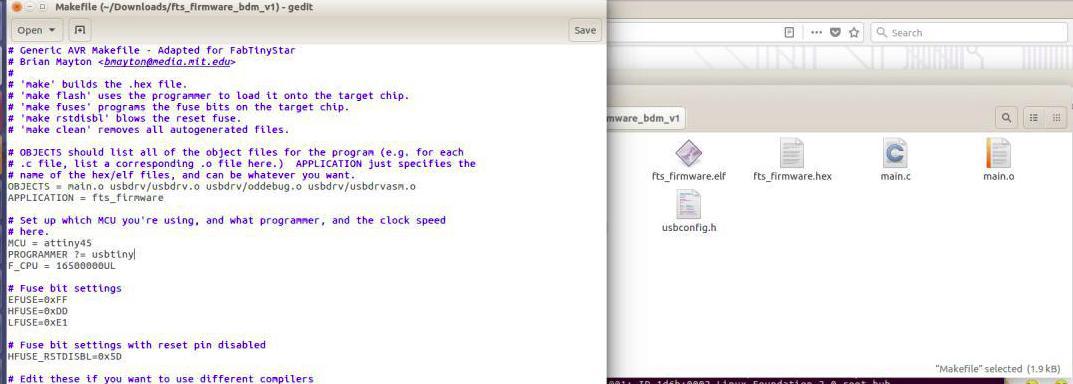

EDIT PROGRAMMER ?= "usbtiny"

Dowload Firmware and Open Terminal from inside firmware folder

1. Converts elf to .hex file

make flash

2. Fuse certain functions

make fuses

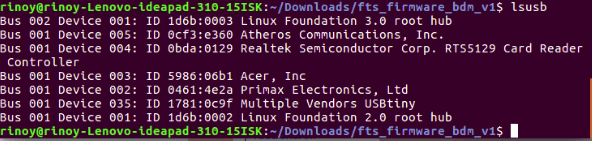

3. Search whether USB has listed

lsusb

4. Disable the RESET function

make rstdisbl

5. Confirm the USB listing

lsusb