Home

Week Fifteen : Mechanical Design

Assignment

In this week, we had to

Design a machine that includes mechanism, actuation & automation

Build the mechanical parts and operate it manually

Document the group project and your individual contribution

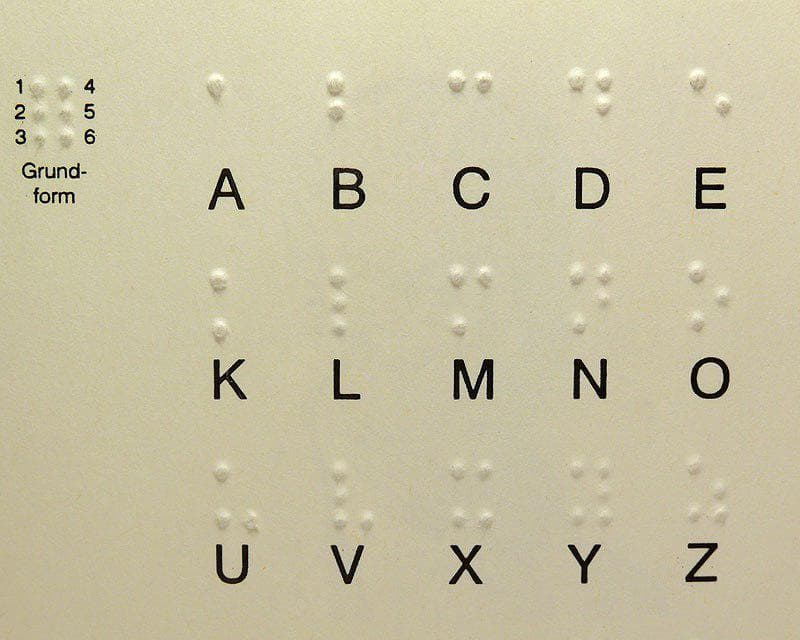

Braille is a system of raised dots that can be read with the fingers by people who are blind or who have low vision. Teachers, parents, and others who are not visually impaired ordinarily read braille with their eyes. Braille is not a language. Rather, it is a code by which many languages—such as English, Spanish, Arabic, Chinese, and dozens of others—may be written and read. Braille is used by thousands of people all over the world in their native languages, and provides a means of literacy for all

Alphabets corresponding to the Brailles code is shown below

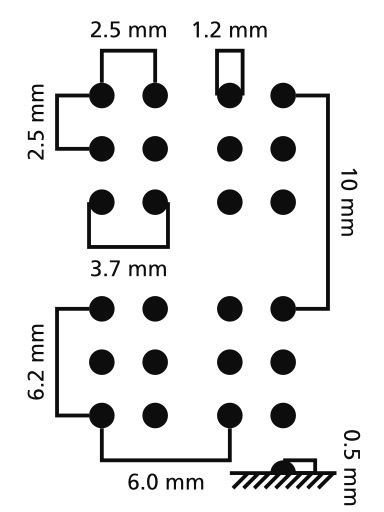

Standard Spacing and Dimensions of Brailles code is given below

Components used for Brailles Printer

I did helped in preparing Inventory and to list out the components needed for this project

SOLENOID

NEMA STEPPER MOTORS

ROD with rubber support to roll the paper

THERMOCOL PIECE

PVC FOAM BOARD

LINEAR BEARING

DRIVER PULLEY

DRIVEN PULLEY

PLYWOOD

EPS - EXPANDED POLYSTRENE

SMOOTH RODS

LIMIT SWITCH

SCREWS

Machines used for Brailles Printer

ULTIMAKER - 3D PRINTER

DIMENSION - 3D PRINTER

TROTEC - LASER

SHOPBOT

BAND SAW

I played a major role in using these machines as our group is preparing designs, i got involved in using testing the design works 3D printing, laser cutting, shopbot machining and band saw.

Tools used for Brailles Printer

VERNIER CALIPER

HAND DRILL

DUAL POWER SUPPLY

CUTTER BLADE

SCALE

For testing paper quality to get the impression right first we tested BUTTER PAPER

I also done all the assembly works, cutting the proper dimension of EPS - EXPANDED POLYSTRENE to fit in the gap betwwen BED

For making an impression on paper we needed a push-pull solenoid, which we bought online

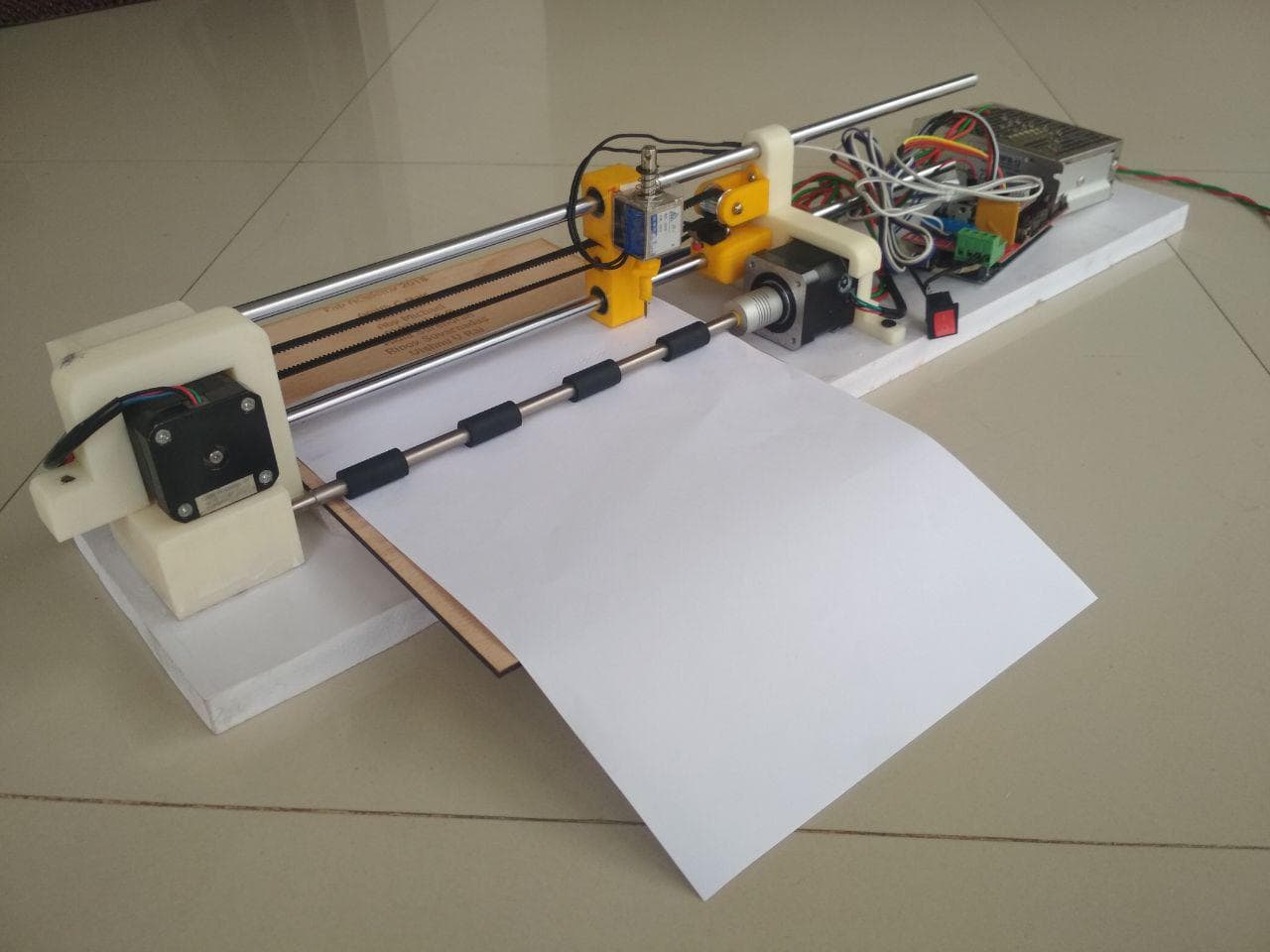

For understanding the working of a printer, we dismounted a normal printer and took its rod with rubber so it can be re-used in our printer

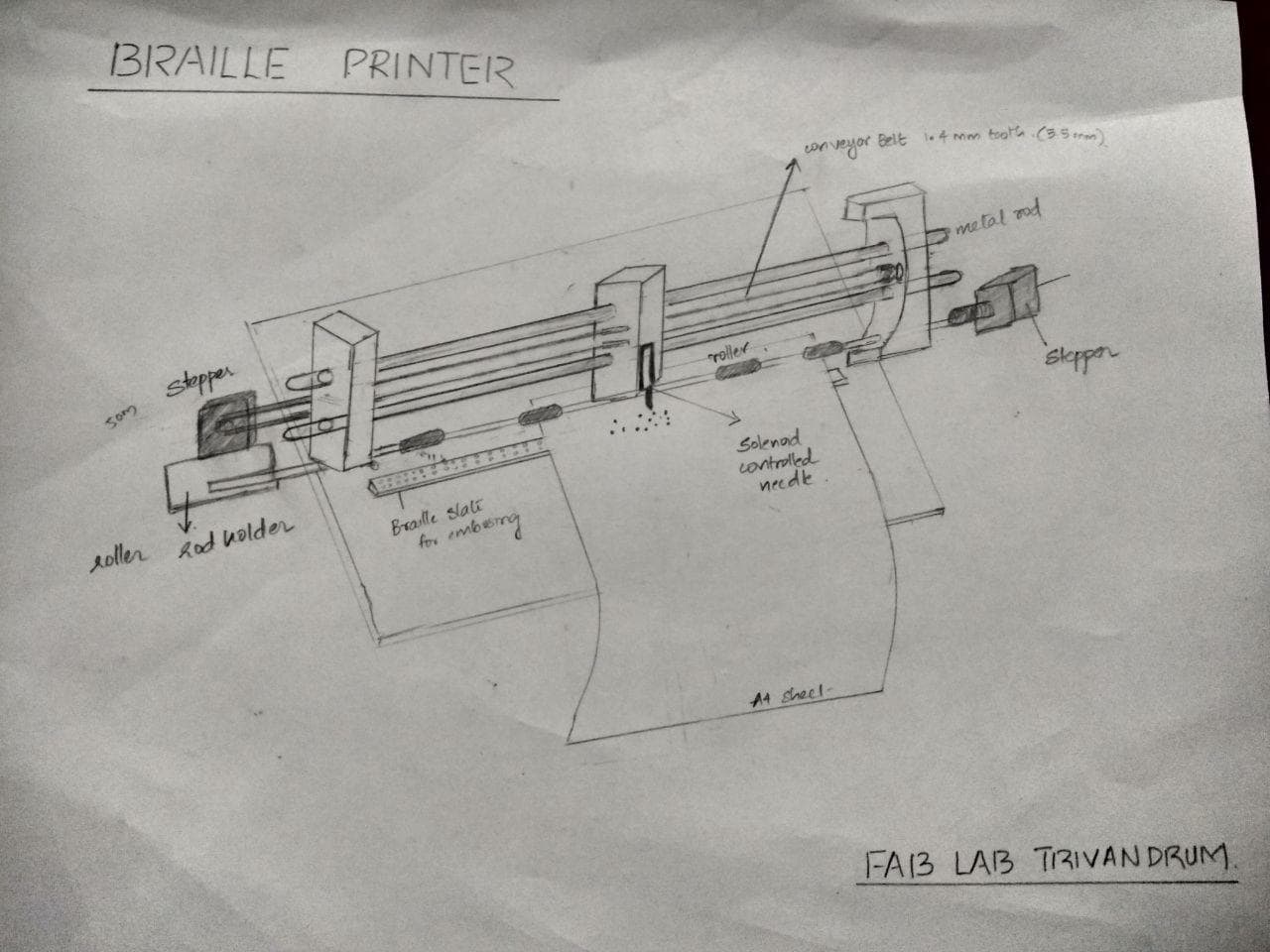

We have made many design ideas how the whole assemby should be,and each of us had different ideas and after a great session with our group we finalised a design

Arduino Mega

The Arduino MEGA ADK is a microcontroller board based on the ATmega2560. It has a USB host interface to connect with computers.It has 54 digital input/output pins (of which 15 can be used as PWM outputs), 16 analog inputs, 4 UARTs (hardware serial ports), a 16 MHz crystal oscillator, a USB connection, a power jack, an ICSP header, and a reset button

Ramps14

Ramps is short for reprap Arduino mega pololu shield, it is mainly designed for the purpose of using pololu stepper driven board (similar to 4988 driven board). Ramps can only work when connected to its mother board Mega 2560 and 4988/DRV8825

Designs

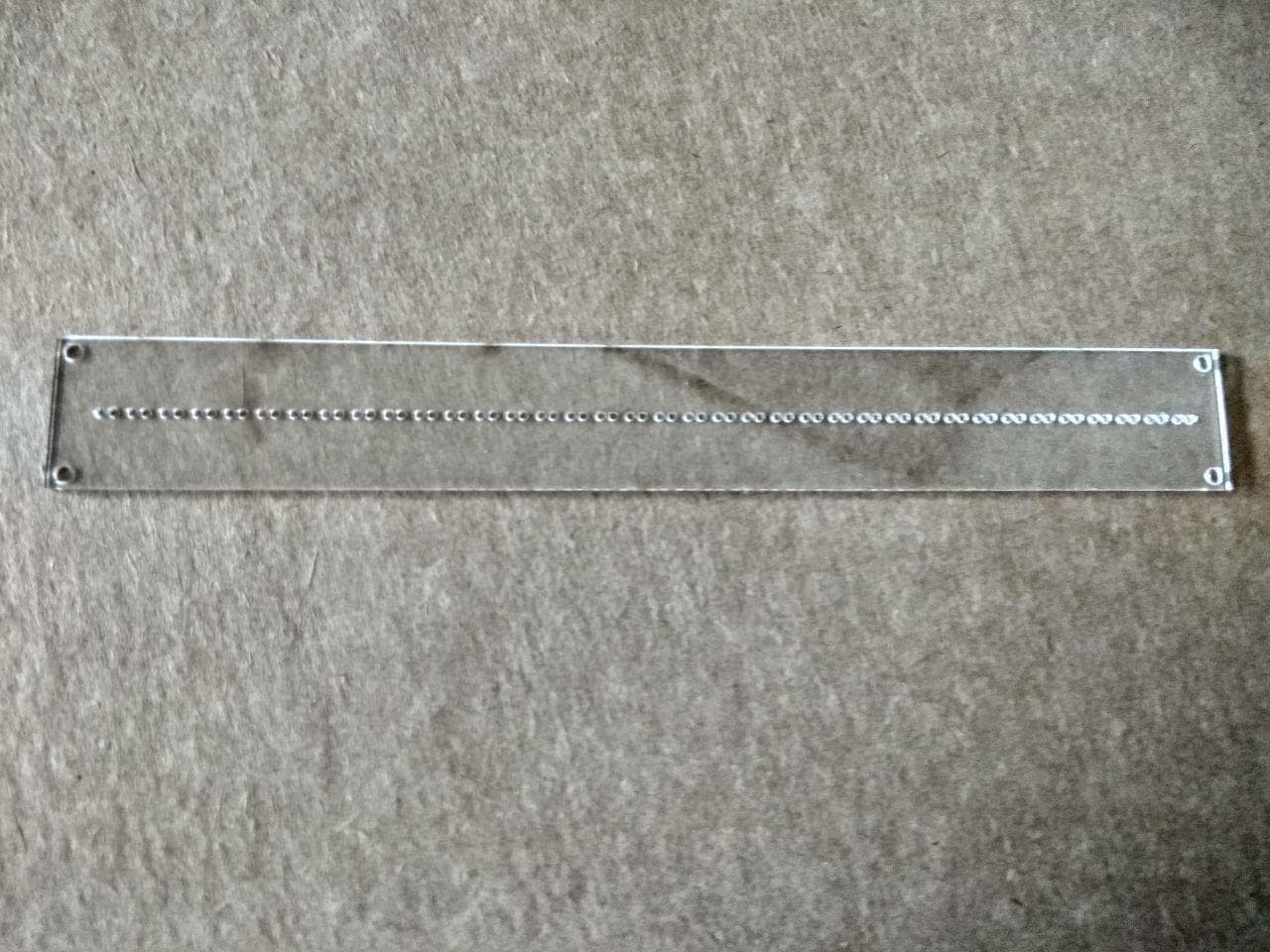

I was assigned with making a braille slate having holes at the standard distance of the braille script. This was done to facilitate the smooth piercing of the holes and to act as a support for the paper around the holes to avoid damaging the paper during the piercing of holes

I have used Fusion360 to design the pad so that the impression would clearly made with the standard distances of the braille script

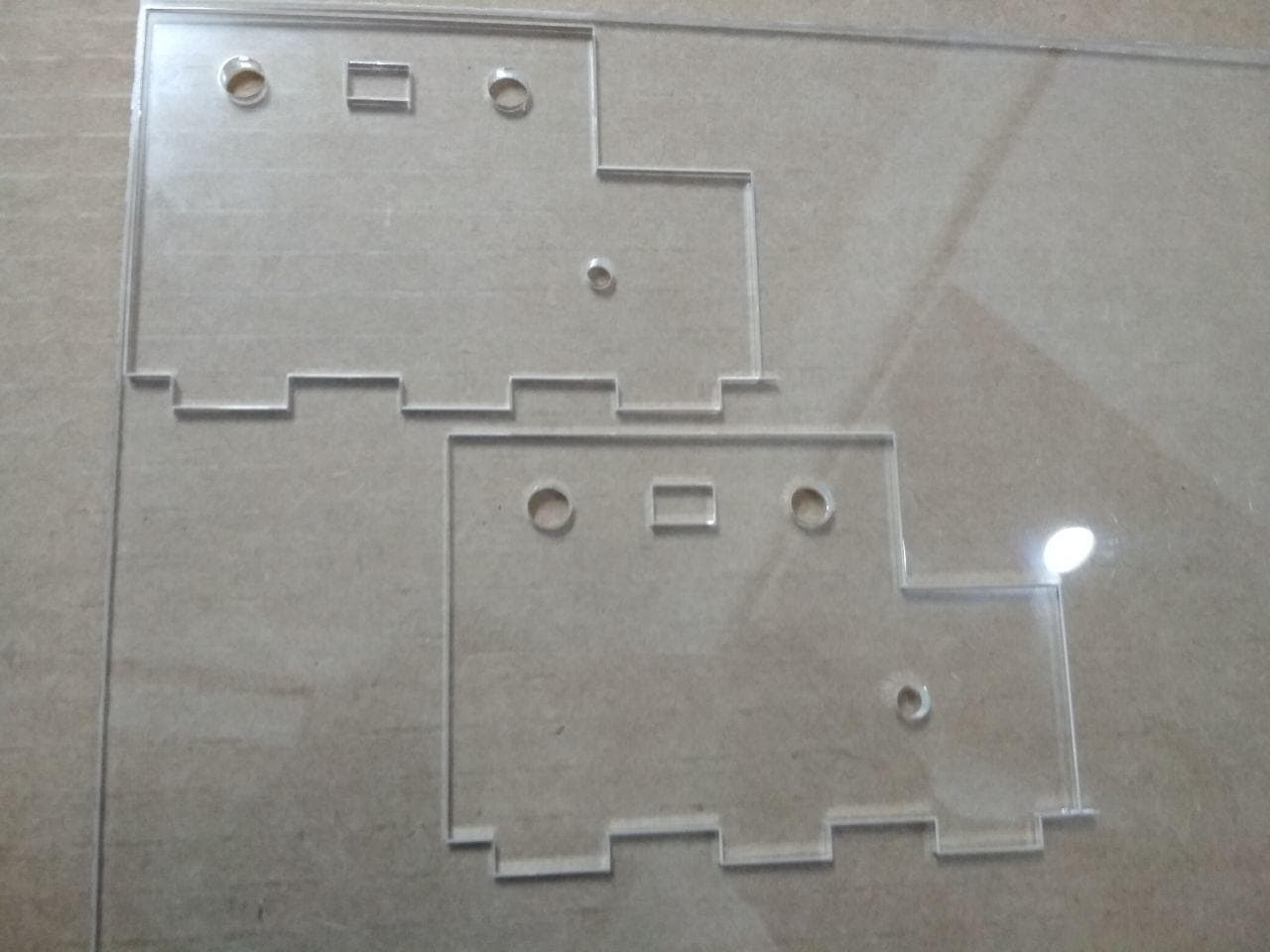

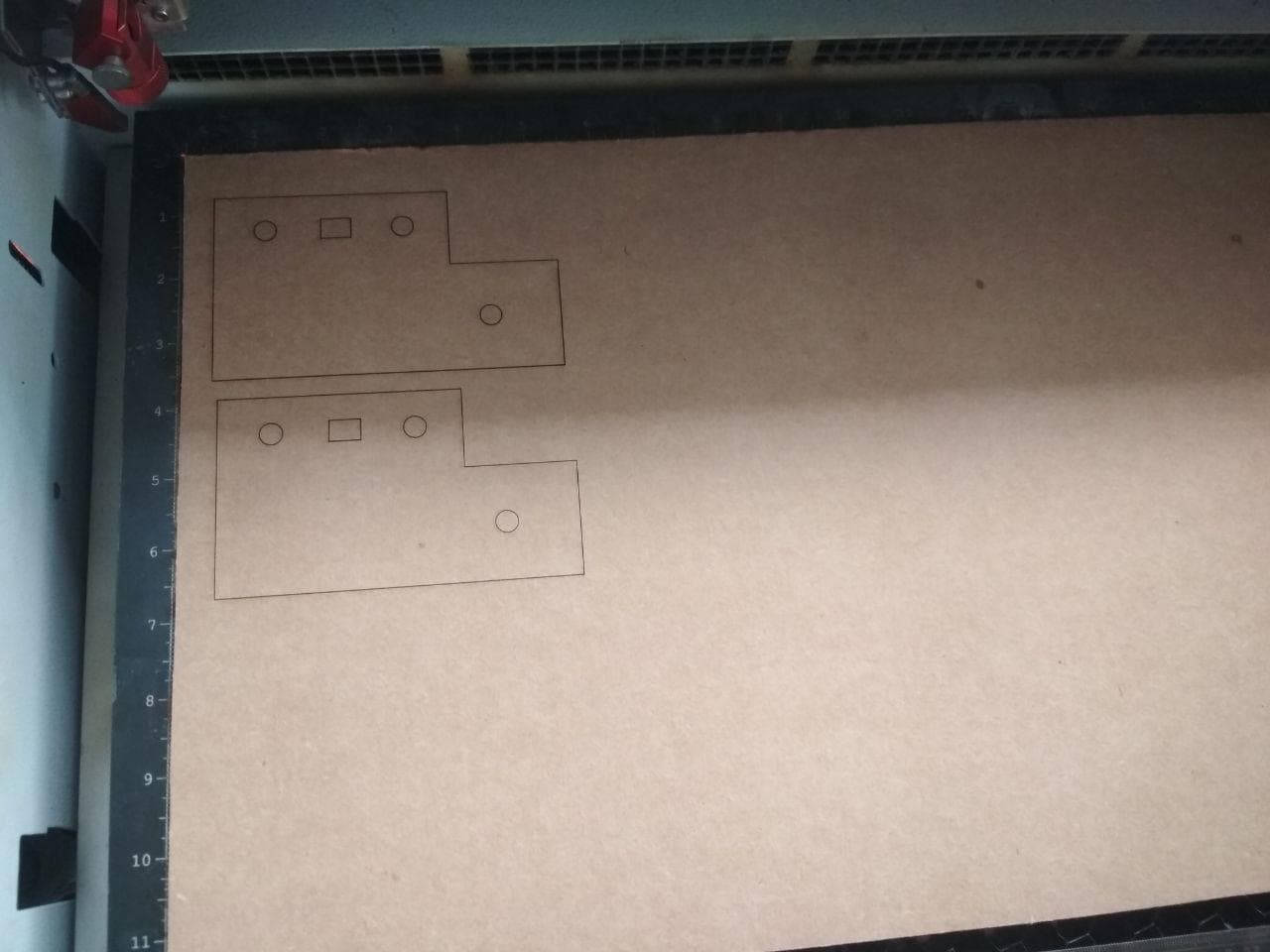

I have laser cut the design file to know how it look like

I have also 3D printed a design which I downloaded from this link

I have been using the mahines, when others give me the design I have operated the machines and checked the design and tested

I have also laser cut a side design in both cardboard and acrylic which was just for holding the rods to test the movement of head

I Joined with Akila to give feedback from the existing design and also gave the input measurements for the design

Me Helping in assembly - Testing the movement of head

Video of Solenoid Testing

I checked the availability of solenoid at the local markets

I have joined with Abhilash in improving the solenoid by testing it with varying current and voltage

I was involved in small hardware purchase

I have procured a damaged printer along with ABY and ABHILASH and opened up to get the roller with rubber bushes for the paper feed mechanisms

How it look like

For more Details Visit the below link

ClickHere