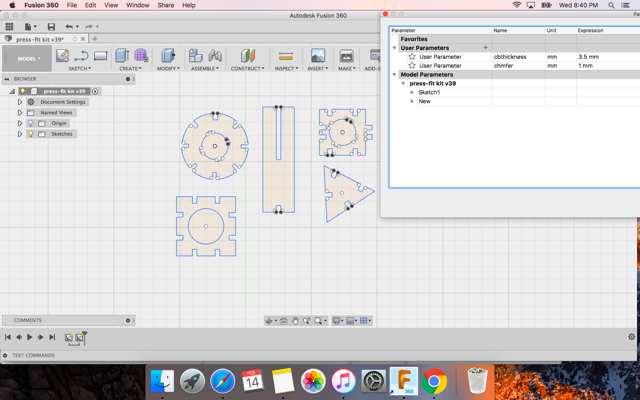

The cardboard that we had was around 3.7mm thick. Hence in my design, I added the parameter 'cardboardthickness=3.5mm' for optimal fit, accounting for the laser kerf.

The width of all the notches is kept equal to 3.5mm and the fillet radius (to substitute for chamfer) at 1mm, with the help of parametric designing in Fusion 360.

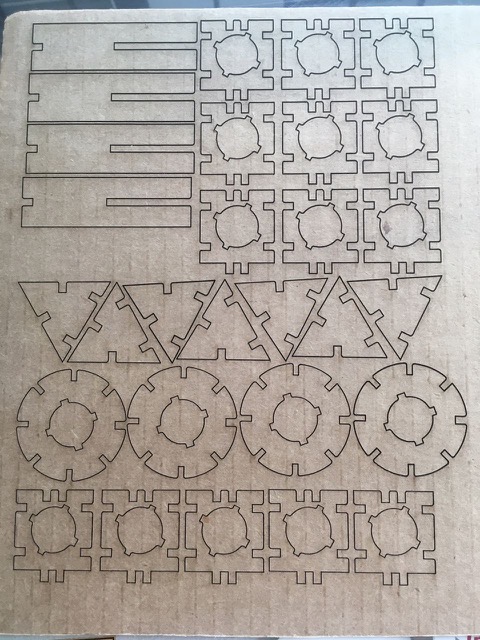

My kit. More pieces, more fun!

These are the 6 main pieces in my kit. (The inspiration for this kit came from this previous fab academy student's webpage. I landed upon it when googling for 'how to make wheels in cardboard press-fit').

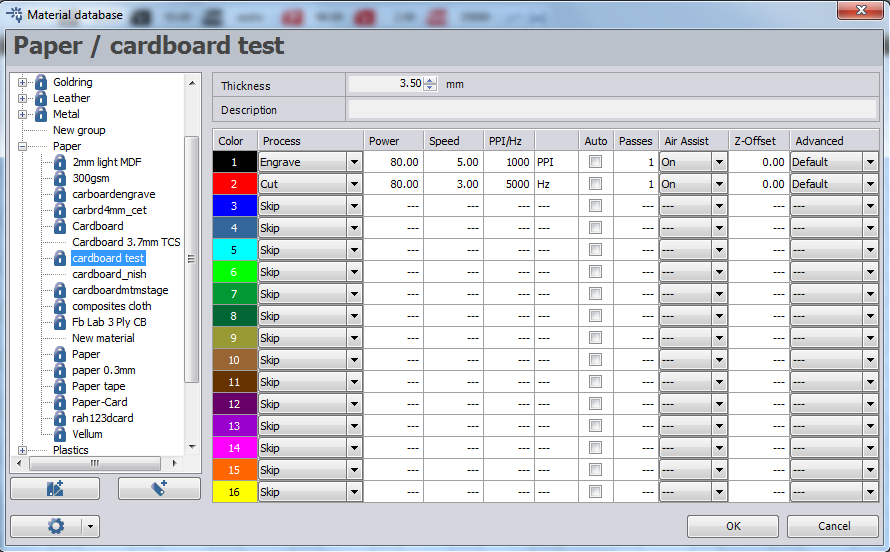

I followed the steps listed in the previous page to operate the laser-cutter. I used the following parameters: Power=80W; Speed=3% and frequency=5000Hz

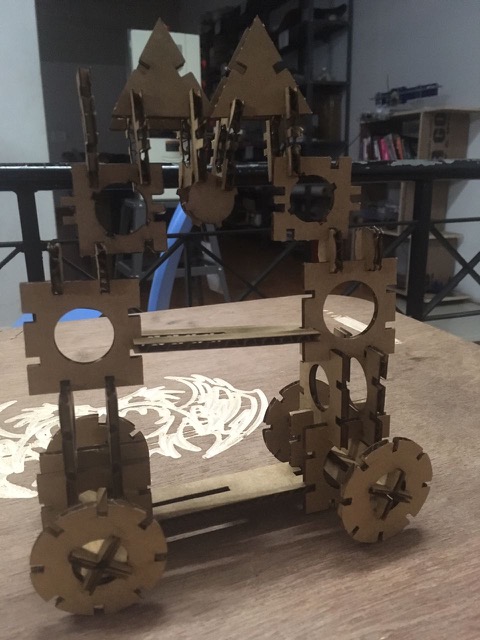

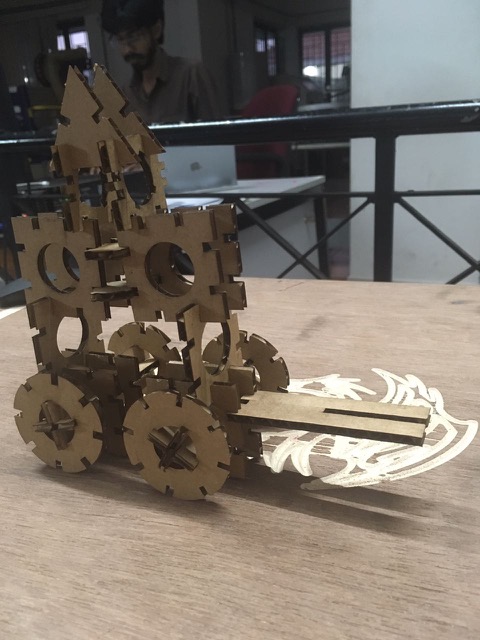

These are a few designs I assembled with my kit. The wheels do rotate! Check the video at the top of this page.

A flimsy Onam float

A flimsy Onam float A temple car from Madurai

A temple car from Madurai

A windmill along NH44, Tirunelveli district

A windmill along NH44, Tirunelveli district

Getting cranky at around midnight

Getting cranky at around midnight

Here are the design files:(.dxf)and (.f3d).