Assignments

- design a machine that includes mechanism+actuation+automation

- build the mechanical parts and operate it manually

- document the group project and your individual contribution

This week was something very special to our fablab members ,we just tried to

apply all the week sense to make our machine .We just decided to go with our plan by step by step

In first there is different openion from all the members with different types of machine

so we just started a table discussion the Each one write different suggestions on a sheet of paper

1. Tactograph - Tactile image printer by extruding fevicol

2. Object tracking camera mount with roll, tilt and pan

3. Braille Printer/Embosser

4. Object Shooter

5. Wall printer

6. Automated drink mixer

7. Dosa Maker

These are the top 7 machines that from our group suggestions ,From that we all

selected Braille Printer/Embosser It was suggested by me all are happy to

go with that decision

Braille Printer

Braille Printer is a braille language maker that is using by the blind people

for recording the knowledge for them.I put forward the idea for the machine week I just selected it is because this machine that can make through a CNC

arraignment is very suits for this week and also There is no printed notes for blind people

thats limits there knowledge ,mainly the btaille printers in the market having very high cost

throught this our aim is to make this machine in limit cost and more effectively.

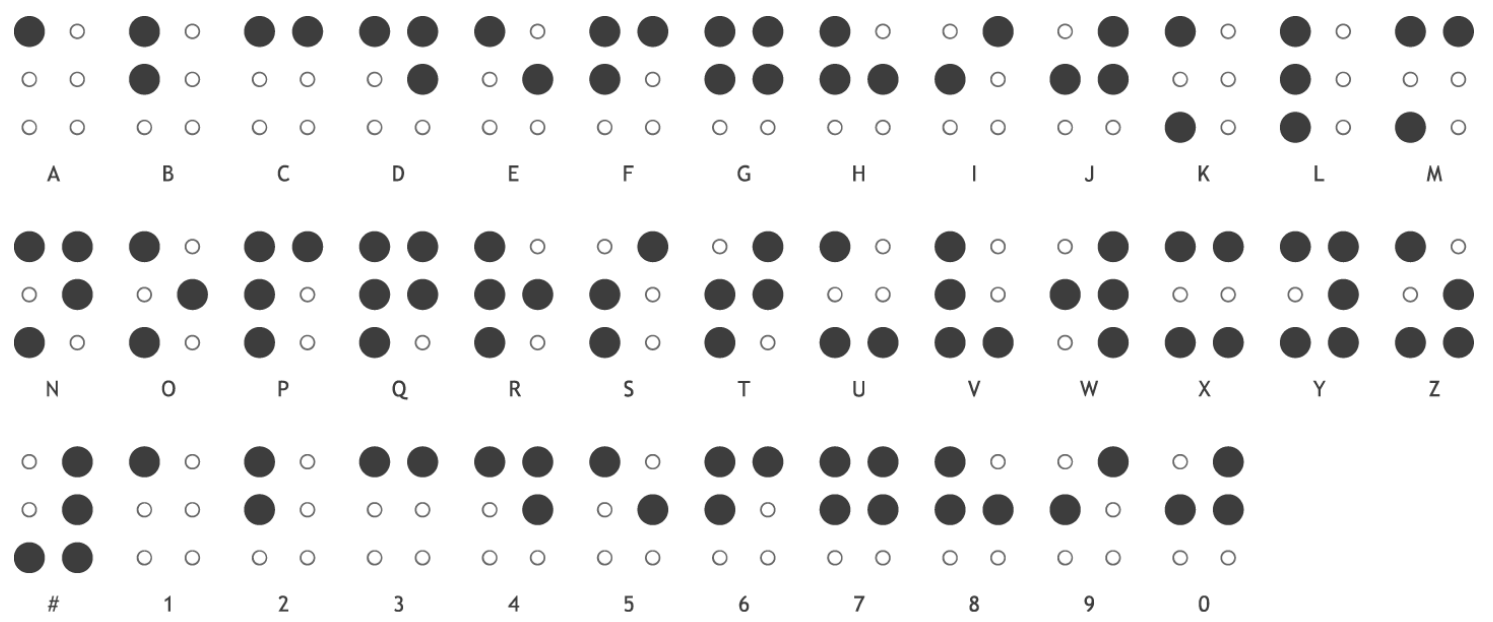

Braille language is mainly with some "Dot matrix" ,Braille alphabets into tactile Braille cells by either embossing or making projections. This projections hellps the blind people

to improve there reading skills.Here each dots aligned in a perticular manner here the vertical and horizontal array of dots having equal distatnce and after each alphabets there is an equal distance

for each alphabet there is a perfect arraignment of dots

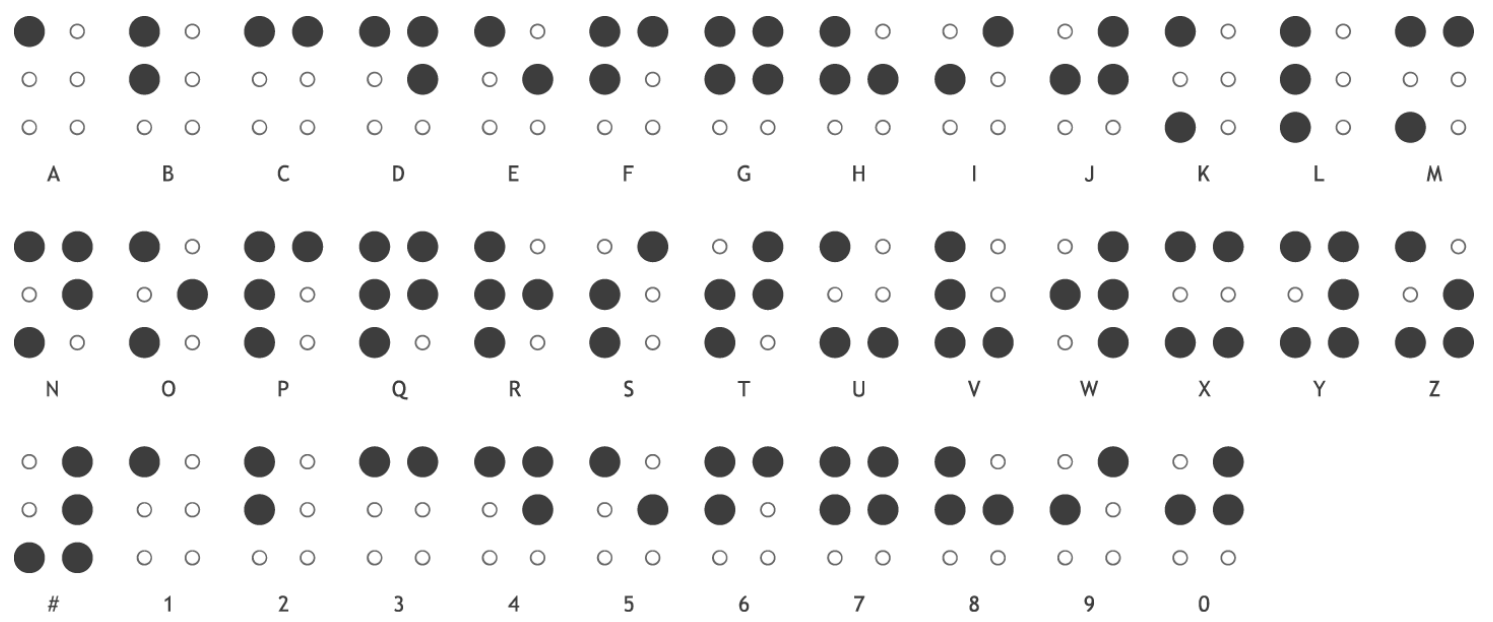

Our Idea for making the braille printer was not so unique ,we just decide to mave the head of hte printer and the paper which is on the base in the xy direction using stepper motor,Using this in mind we draw a design on paper as a rough skecth using this skecth we begin our work

PURCHASING OF ITEMS

Amith and Akhil was doing the inventory they made a list that what we need for this machine,

solenoid

coupler for connecting roller with stepper motor

bearings and small screws

Stepper Motor - 2 (one for printer head movement and one for rolling the paper)-available in our lab

8mm smooth Rod for moving the head

GT2 betl(1.4mm tooth)

Driven pulley and driver pulley

we used most of the items from the labs but ,we want a solinoid and linear ball bearing for that we aproched a shope

here we got the items that we want execpt solinoid that we orderd online because we decide the punjuation into the paper

using a solinoid

I,Renoy,Vishnu , and Aby did the purchasing of the items,

Trail arraignment of parts

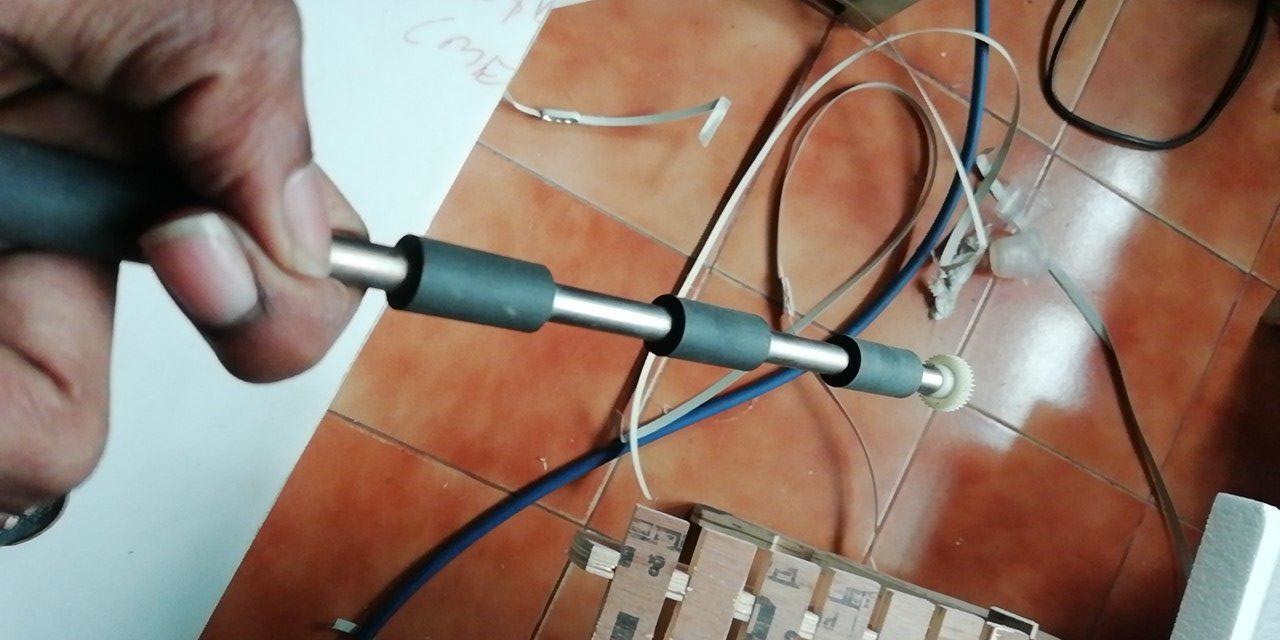

In firts we made a side wall for the the rod that is the moving medium of the the solinoid head and attaching the motors and also a small base In laser cut Base is done by vishnu in the dimension of dimension 42mmx42mmx42mm then we arranged it it was our first arraignment,Then Now we began to divide each tasks.We choosed a peculiar way in designing the components each guyz are making there parts and all by measurements this will reduced the no .of errors

First arraignment of parts

First arraignment of parts" Here You can see our group works and tasks

My Tasks was,

1.Available filecollection/Idea collection

2.coupler Design

3.Assembly of Base / Rod holder

4.Final Testing

Available filecollection/Idea collection

I just mentioned The Idea and details in above ,Just a word as braille language we doesn't have too much knowledge about

braille printer so we choosed Wiki here we got moere Idea then we start how we are going to do

our work in right

Our instructors Yadu sharon & Lancy Felix gave more Idea for impliment our projects in success.

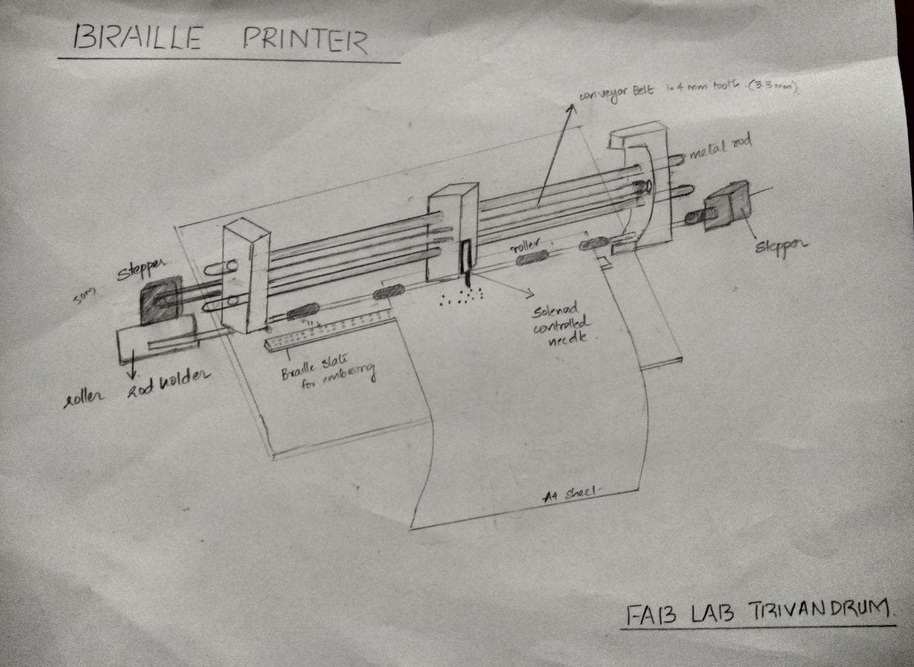

Hunt for paper Roller

For making the printer their is a necessasry "ROLER" for making the movement of paper that was a big task to me to find the roller ,then Vishnu brings an old printer from his home thats help me to find a roller with out any damage ,i chosed it because it has the rubber bushes also it makes the paper tight ,I spend my time for making sure that I got the roller with out any damage and I got help from the other group members Aby and Akhil

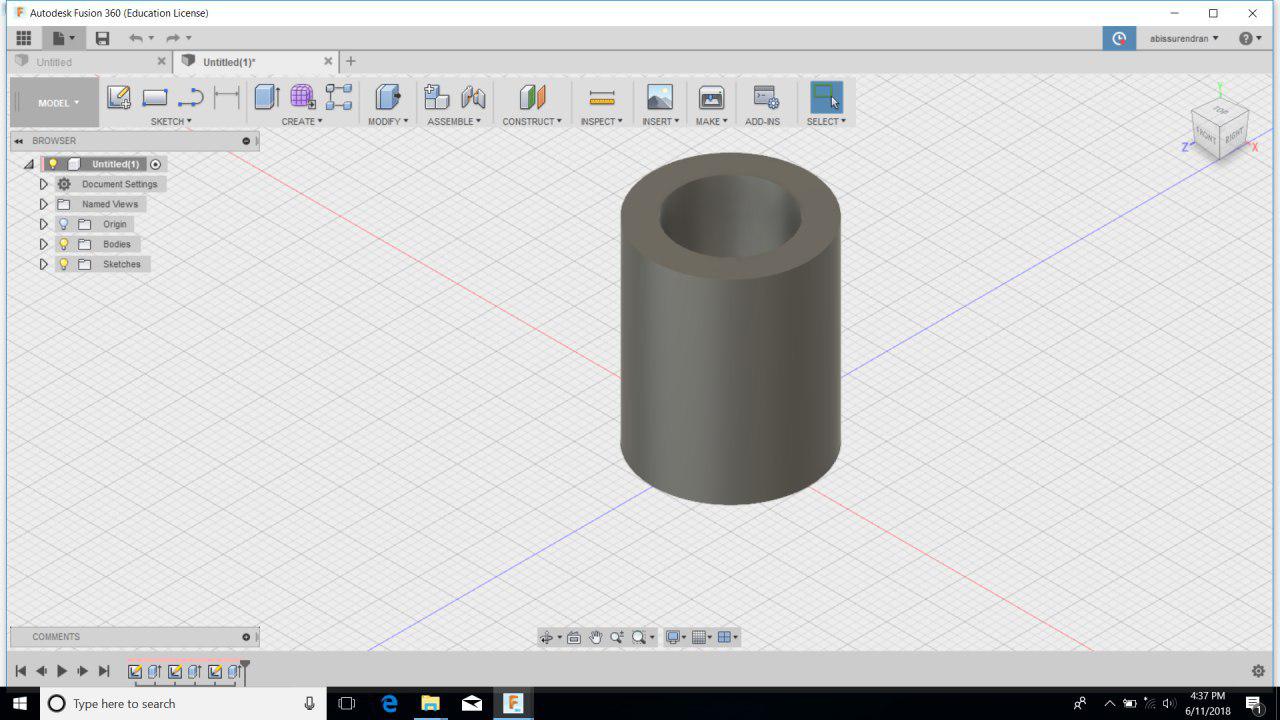

coupler Design

Here when the Arrainging of Rod to the motor coupler It wasn't tight enough we can use the screws in the couplers for tightning but it will affect the allaingment off the Rotation Because this Rod's rotation is causing the Y axisis movement of paper.Then I decide to print a coupler holder in fusion 360.I measured the Inner DIA of the motor coupler and the outer dia of the Roller rod then I draw by differencing these two diamensions ,

After Drawing on fusion I export it as .stl file and opened it in "cura" for 3D printing in Ultimaker

Here you can download the fusion file

Here you can download the .stl file

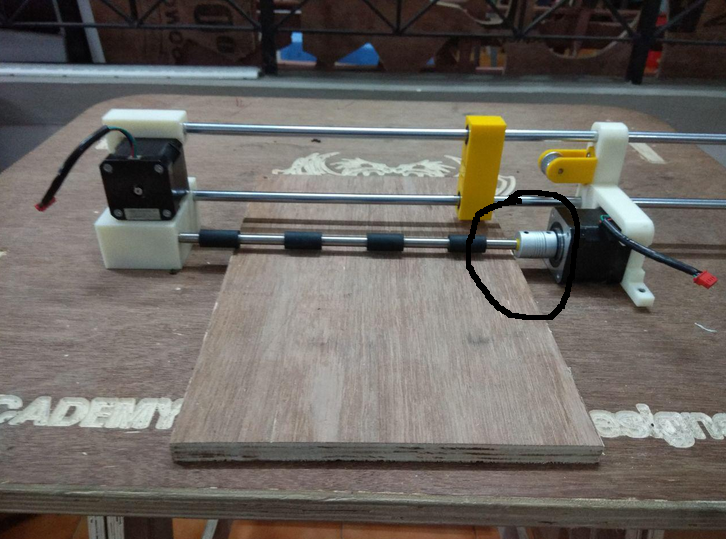

Here you can see the coupler I designed is attached inside the motor with the rod that makes the rollers for perfect allignment for rotating the paper in y direction

Now the roller is tighten inside motor coupler

Now the roller is tighten inside motor coupler Machanical arraignment

After different designs from the group member assembled the parts It seems very tight and fit accuratly the division of the task help to make all the parts that the printer needs so I and other with the same task joins to arrainge the parts