3D Printing and Scanning

At our Fab lab we have several 3D printers, some are brand new and some are 5 years old printers. This week group assignment would help us to conduct and get familiar with the capabilities of each printer. We have Ultimaker 2, Ultimaker 3 , Form 2, Lulzbot taz 6, Witbox, Zortrax and delta WASP 3mt. For this test we will use the Ultimaker2, Ultimaker 3, Zortrax m300 and Form.

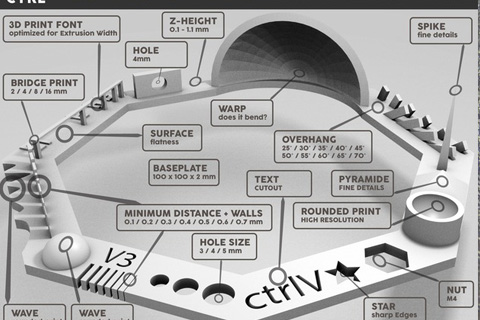

The test includes:

- Nut, Size M4 Nut should fit perfectly

- Wave, rounded print

- Star, Sharp Edges

- Name, Complex Shapes

- Holes, Size 3, 4, 5 mm

- minimal Distance: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

- Z height: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1 mm

- Wall Thickness: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

- Bridge Print: 2, 4, 8, 16 mm

- Sphere, Rounded Print 4.8mm height

- Sphere Mix, 7 mm height

- Pyramide, 7 mm height

- Overhang: 25, 30, 35, 40, 45, 50, 55, 60, 65, 70°

- Warp, does it bend?

- 3D Print Font, optimized for 3D printing

- Surface, Flatness

- Size, 100 x 100mm x 23.83 (10mm width)

- Spike, minimum Layer Time, 21 mm height from Bottom (include Baseplate)

- Hole in Wall, 4 mm diameter, check for proper print

- Raft Test, raft should be just under the model

- Retract Travel, check retract settings for longer travel

Printing Problems:

- One of the ultimaker 2 extruding wasnt moving out material as the filament was blocking it.

- Ultimaker 2, I decreased the speed to 60% for a better print as due to speed the spaces between print wasnt showing (ADD PIC HERE)

- Ultimaker 2, Decreased the infill density to 85%

- Ultimaker 2, Some dust was on the build plate, thus the print wasn’t sticking.

- Form 2, Support use a lot of resin and increase the print time. ( Sibu was confident enough to try printing the same model without support, We challenged him that the print would fail) fortunately, the print was a success.

- Dr.Musa has noticed that 3d test object printed by form is smaller that the actual object. Form software do easily allow the user to adjust the height by just trying to move the object

- The caliper we used wasn’t not precise at all

Results and parameter:

Ultimaker 2:

- we decreased the speed to 50% of the actual speed

- Min Z height is 0.33mm

- min gap thickness 0.3mm

- over hang angle= 55

- 5mm hole = 4.7 mm, 4mm hole = 3.85mm 3mm hole= 2.77mm

- Bridge print up to 1 mm

- Text cut out was ok

- star sharp edges were bad

- It bended a bit

- okay for rounded print

- spike details were below average

Ultimaker 3:

- Min Z height is 0.16mm

- min gap thickness 0.7mm

- over hang angle= 60

- 5mm hole = 4.24 mm, 4mm hole = 3.67mm 3mm hole= 2.52mm

- Bridge print up to 8mm

- Text cut out was perfect

- star sharp edges were perfect

- It did not bend

- High resolution for rounded print

- spike details were okay

Form 2: (** not yet completed**)

- Min Z height is 0.24 mm

- min gap thickness =

- over hang angle= 70

- 5mm hole = mm, 4mm hole = mm 3mm hole= mm

- Bridge print up to 8mm

- Text cut was filled with resin

- star sharp edges were perfect

- It did not bend

- High resolution for rounded print

- spike details were perfect

Zortrax m300:

-Zortrax has a 0.5mm nozzle

- Min Z height is 0.7mm

- min gap thickness 0.3mm

- over hang angle= 60

- 5mm hole = 4.95 mm, 4mm hole = 3.82mm 3mm hole= 2.85mm

- Bridge print up to 6 mm

- Text cut out was filled with support

- star sharp edges were perfect

- It did not bend

- High resolution for rounded print

- spike details were average