3D Printing and scanning

Group Assignment

3D printing technology is fascinating, it progresses everyday. In our fablab, we have 3DCOE for 3D printing where we have different printing technologies (Delta WASP 3MT, Zortrax, lulzbot, Da vinci FUll colot printer, Envision tech 3SP, form 1 &2, and ultimakers)

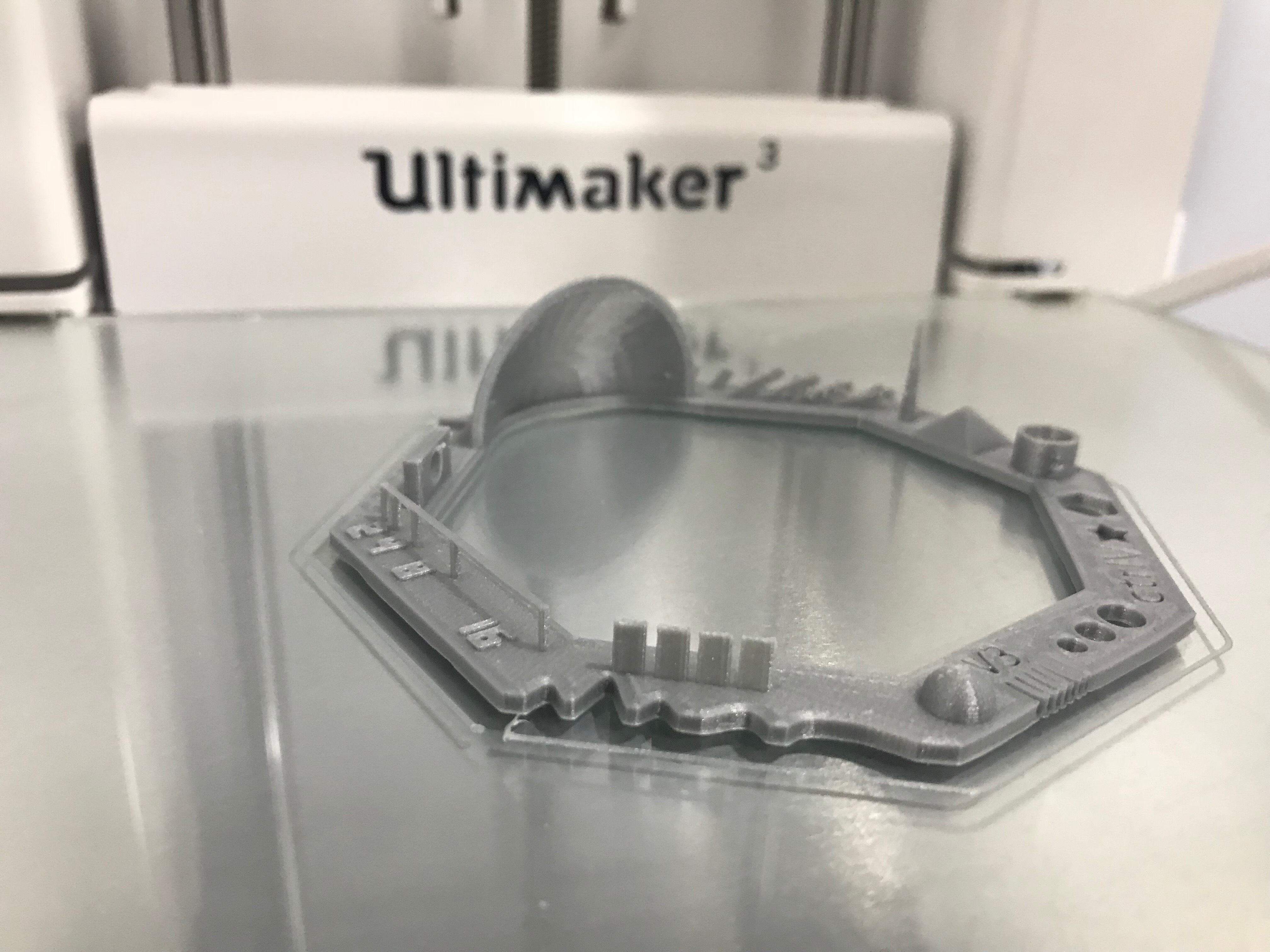

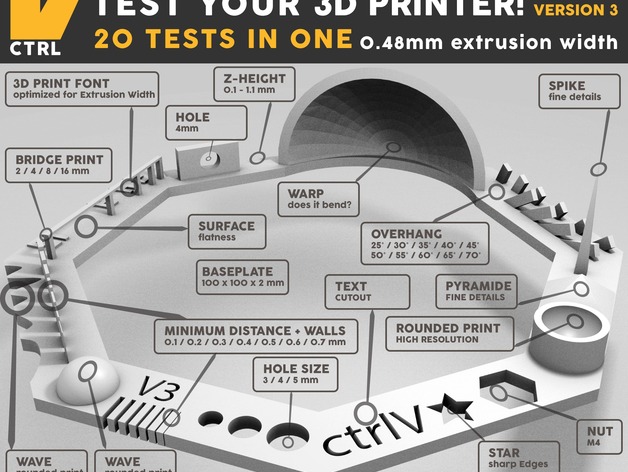

For the group assignment, we printed a test model on ultimaker 3 and Form 2. by comparing the 3D model to the printed part we can identify the parameters. for the ultimaker 3 we found out the paramaters for the printing and overhang angels, wall and gap thickness. For UM3 (minimum z-height=0.16, minimum gap thickness=0.3, overhang angle=50) as for the Form 2 (Minimum gap thickness= 0.7 , mimum z-height=0.1, overhang angle=70)

This test has gave me an idea about the limiation of the 3D printers.

.jpeg)

3D design and Printing

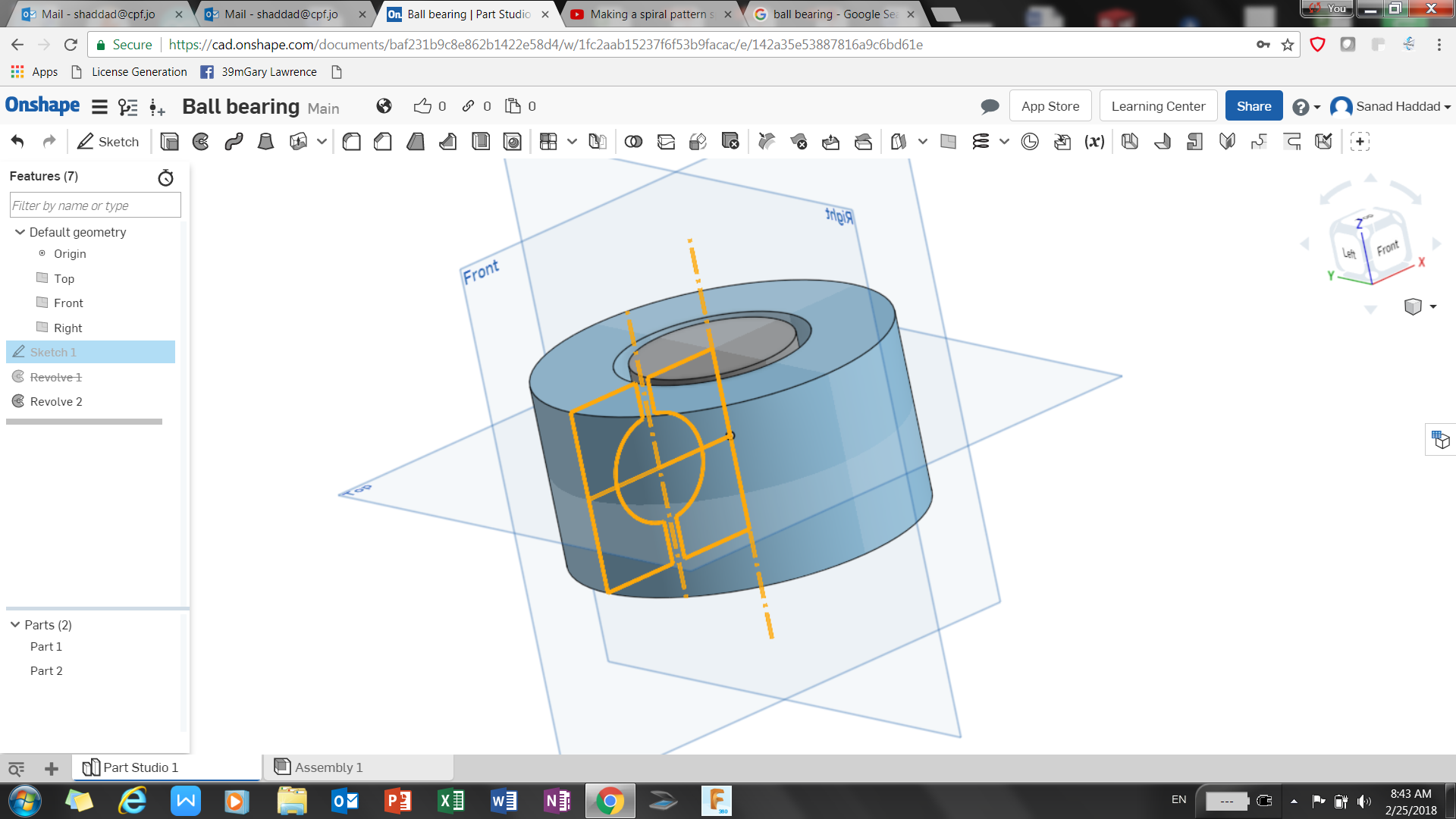

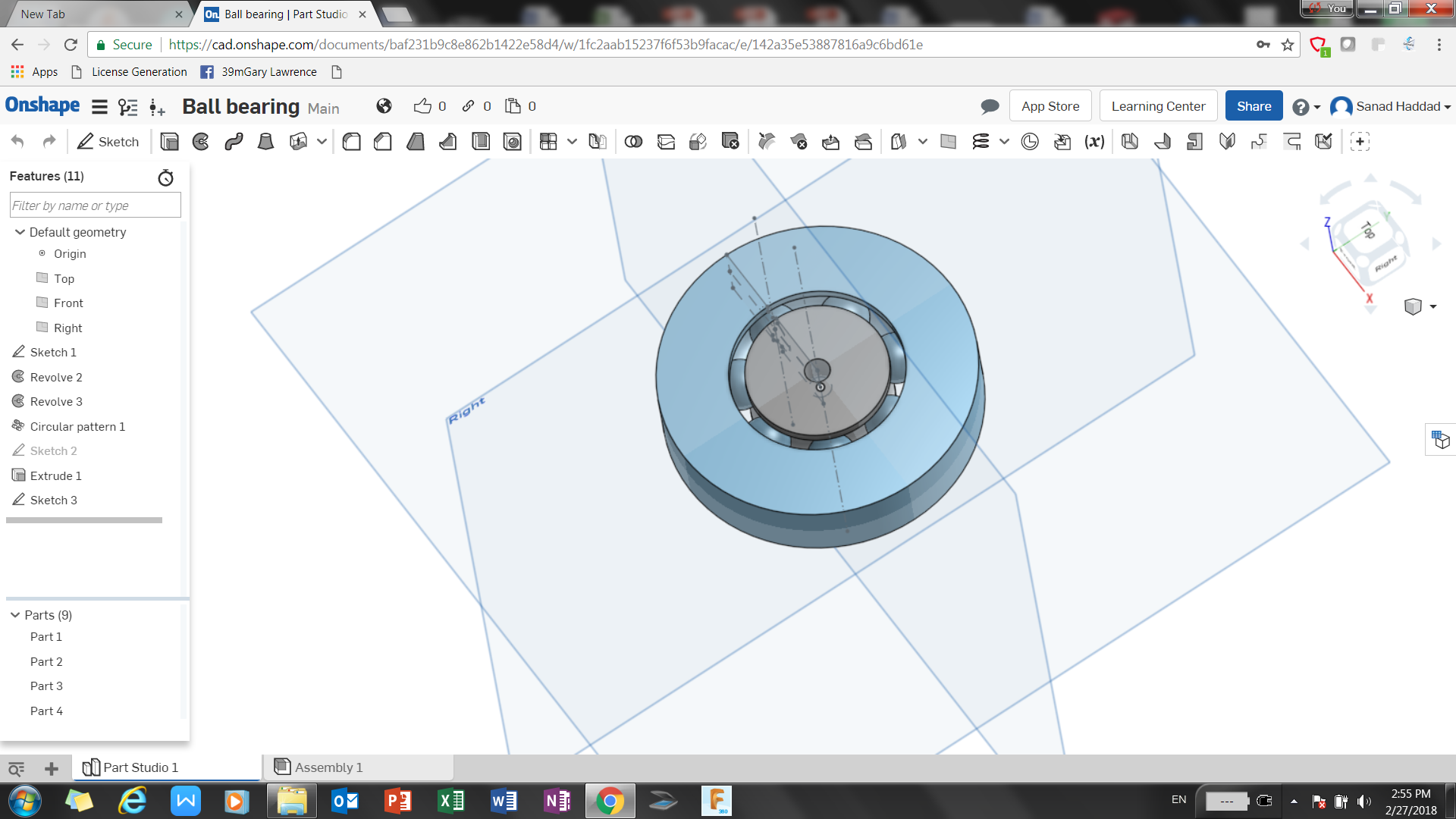

I have designed a ball bearing that could not be made subtractively, I used onshape to design two iterations of ball bearing, one with 4 balls and one with 7 balls. The idea is to print the ball bearing with the ball in place. I printed the ball bearing using the lulzbot and the instructor used form 2, I was able to have a working ball bearing as the gap thickness I used is 0.3 mm for the FDM, but that wont work for the form 2 where the balls got stick to the walls.

.jpeg)

.jpeg)

Ballbearing by sanadhaddad on Sketchfab

3D Scanning

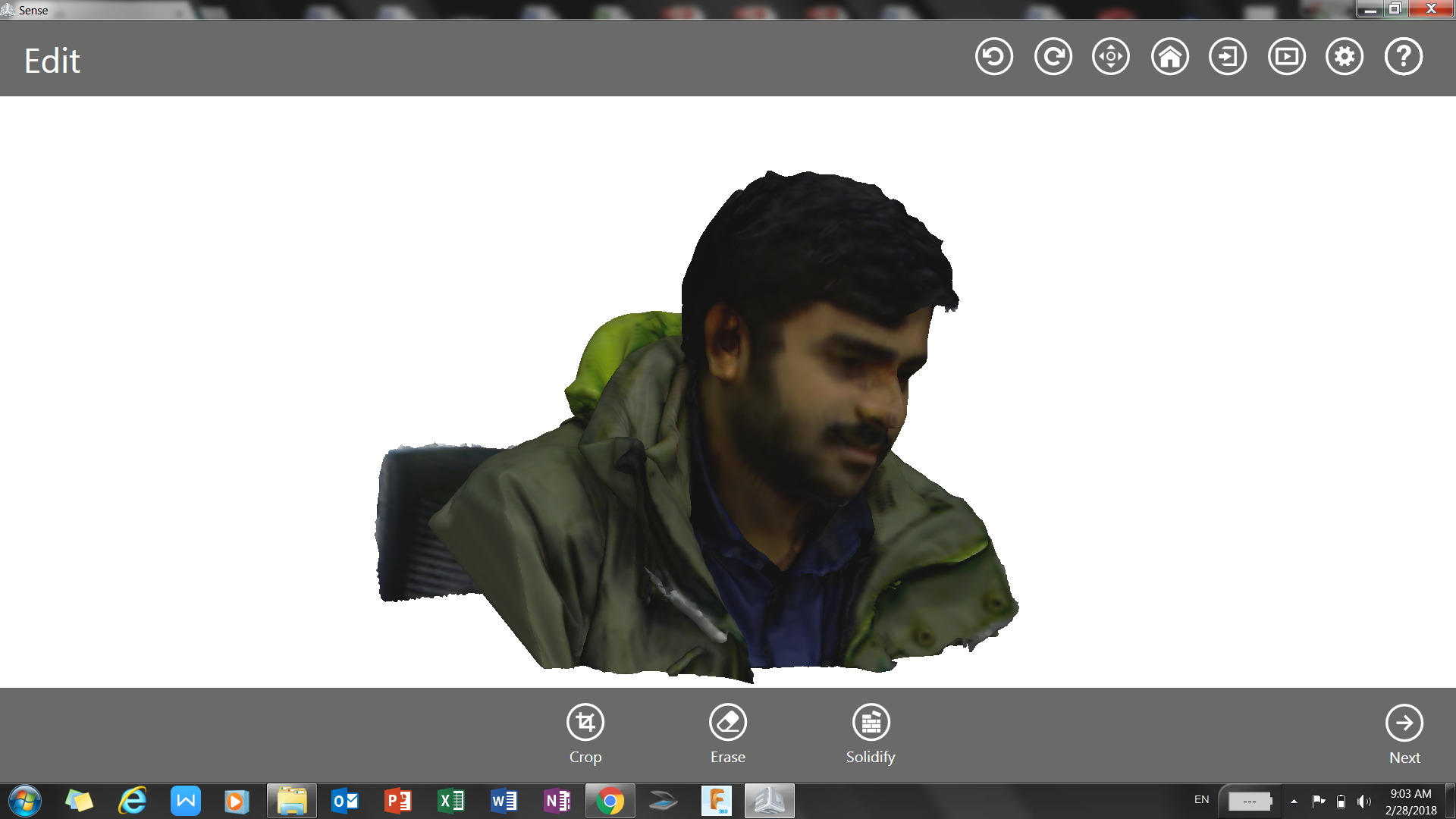

I used sense first generation to scan the head of our instructor, I downloaded the software from (cubify.com/sense). in the software you will be asked about the scaned item (object/human) and you will have to scan the item very carefully either by rotating the scanner or the item itself.