Computer aided cutting

Vinyl Cutter

This is not the first time that I used a Viynl cutter, I had previously used it during the pre-fab academy. The vinyl cutter is basically a machine that has a sharp blade used to cut the vinyl into a computer designed model.

When you work with the vinyl cutter. you must be aware of the type of vinyl you are usuing, the roll and grip positions when placing the vinyl. Important set up step is to make sure that the origin is set correctly and the grip is placed correctly.

I used Inkscape software for the 2D design of my model where I edited the settings of cutting which included converting the model into a vector, resize of the printing area, and choosing the dpi. Afterthat, we added the printer on Fabmodules to initiate the interface between the software and the vinyl cutter.

The vinyl cutter that I used is the roland CAMM-1, I did a test to ensure that the knife is cutting properly and not cutting through the whole vinyl.

Below is the 2D model that I downloaded from the internt for test.

Laser Cutter:

This week, we focused on the laser cutter task. the assignment is to design a parametric kit that can be assembled in multiple ways.

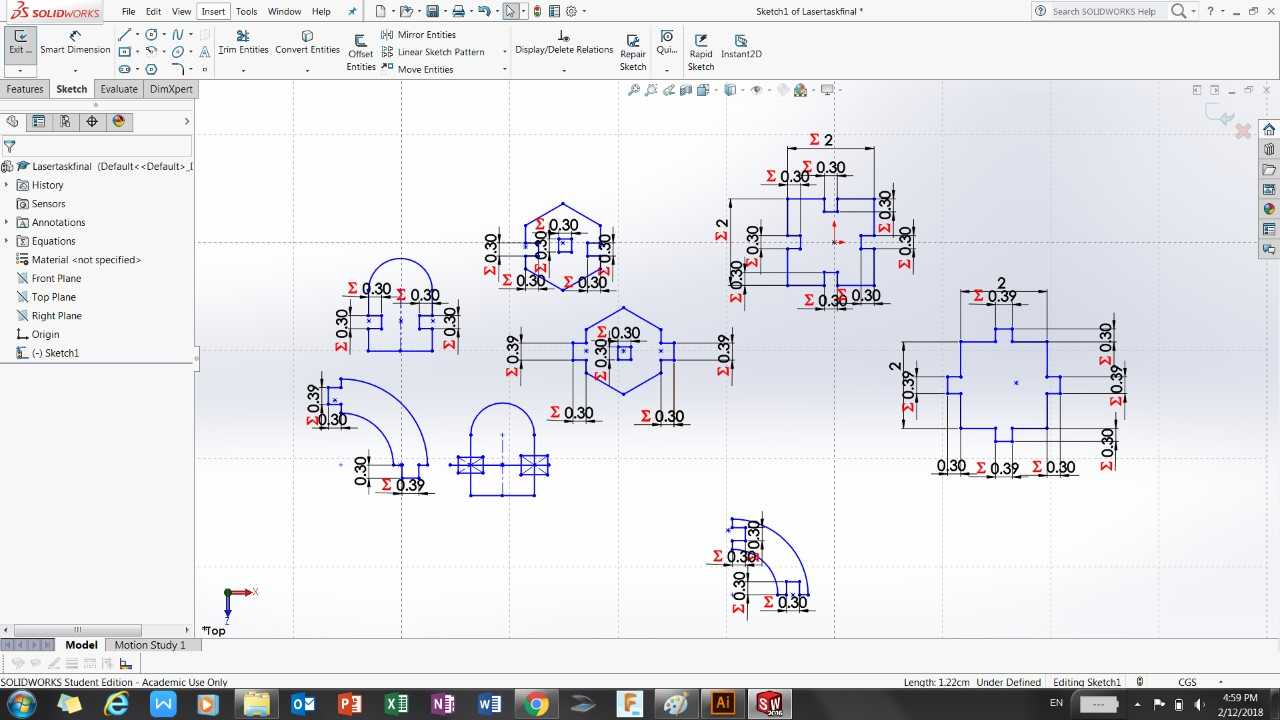

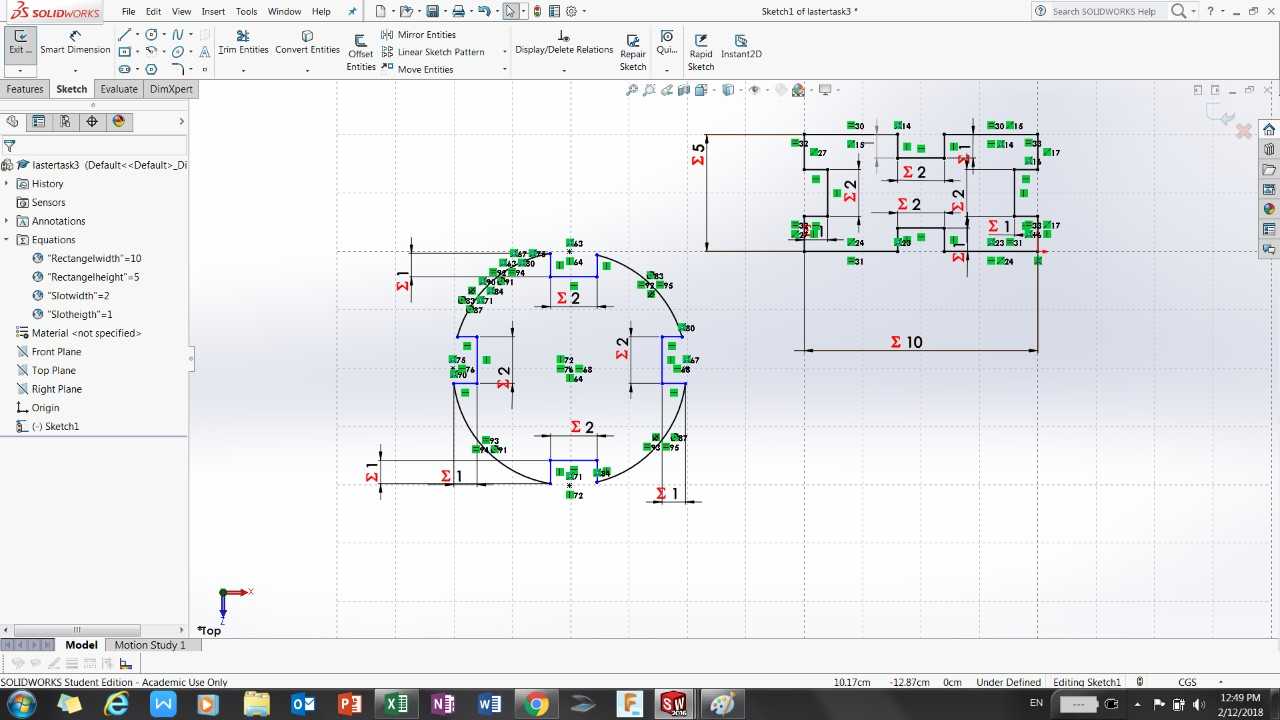

I started this task by designing the 2D parametric models that will be used later as a construction kit. I used solidworks to do that as I have faced a few problems with onshape to design a parametric shapes.

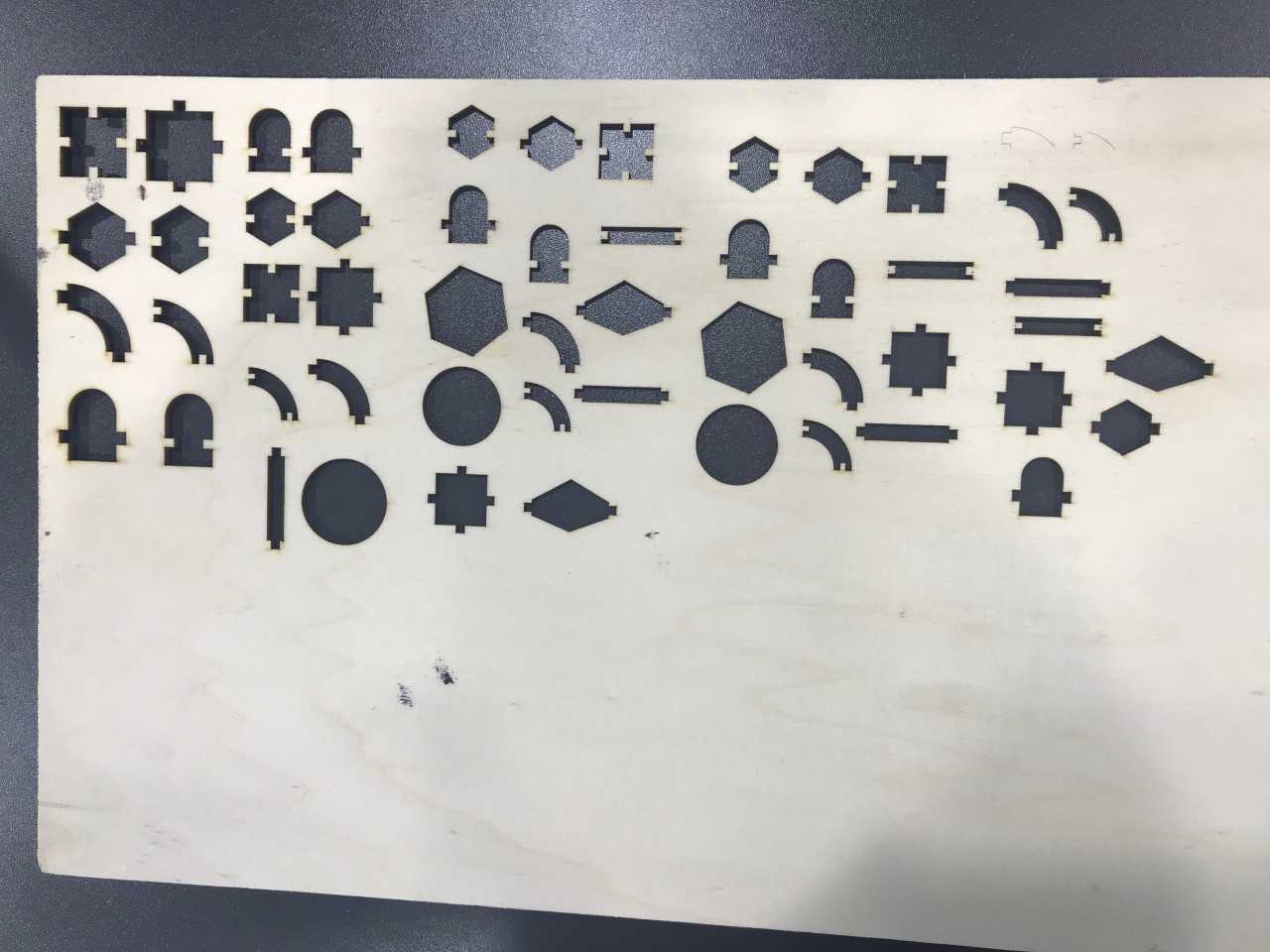

To test the laser cutter parameters, We cut several pieces of card boards with different slot sizes for the tolerance that we need to consider in the parametric model

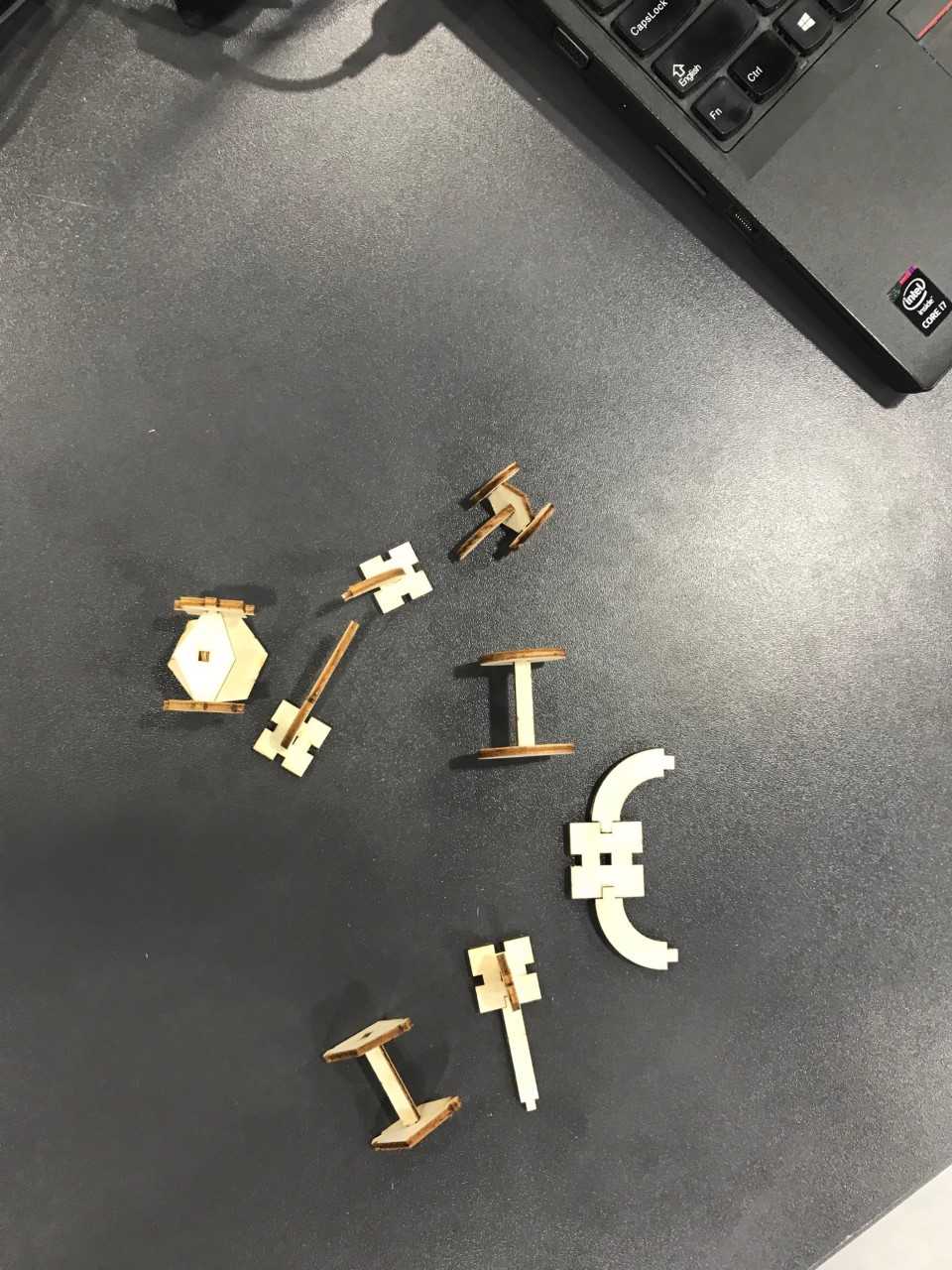

in the test, we realised that changing the slots by 0.01 mm would give the best result for the joints. I had spent a lot of time working on my “module”. But when I actually cut it out I realised it was fundamentally wrong. And so a long process of improvements began. I produced about 5 versions before the final one, and during that process I learnt a lot about both the material and the laser. afterthat I started working on the parametric model with the desired tolerance. you can also change any dimension in my parametric model and the rest will adapt

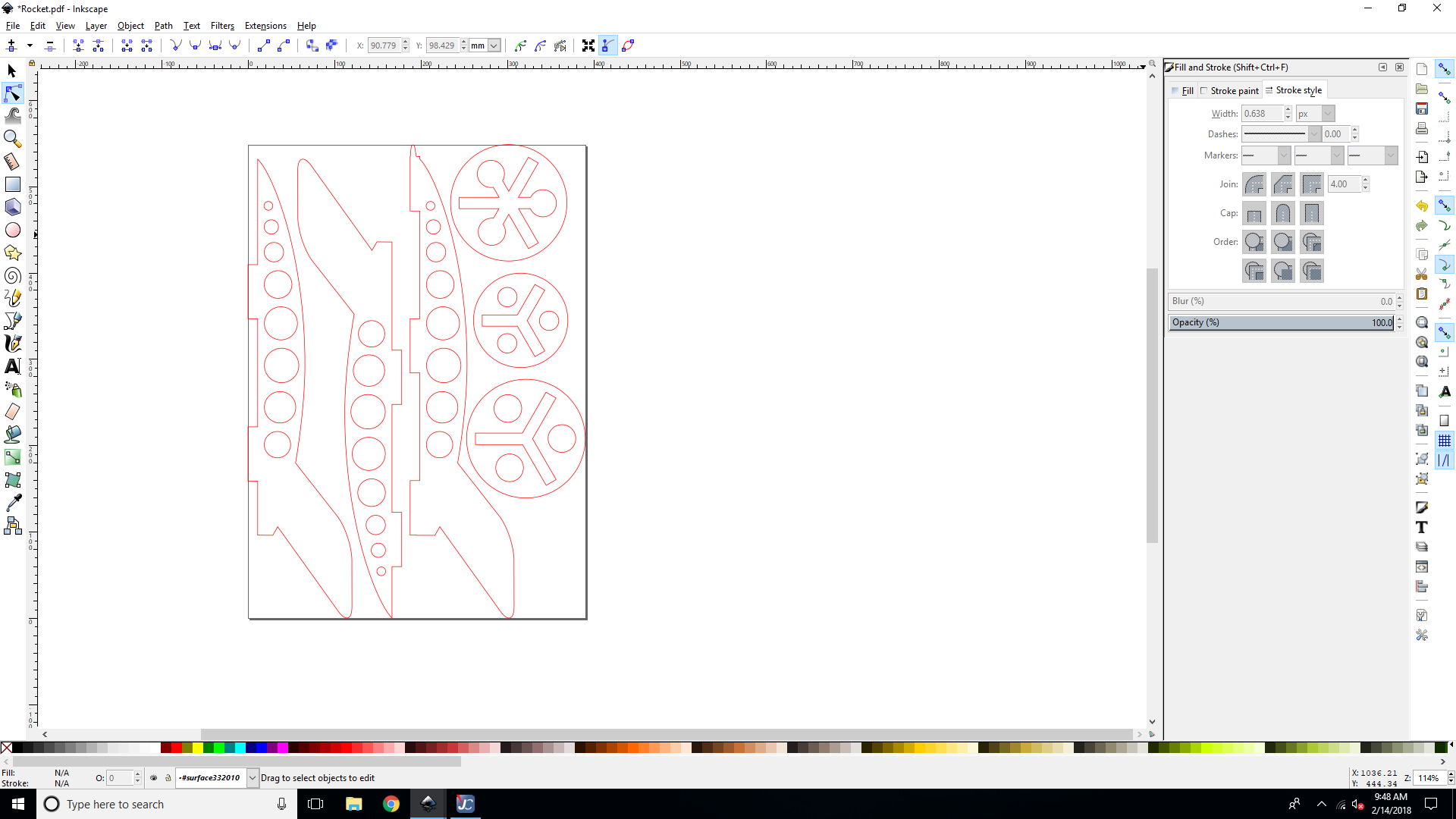

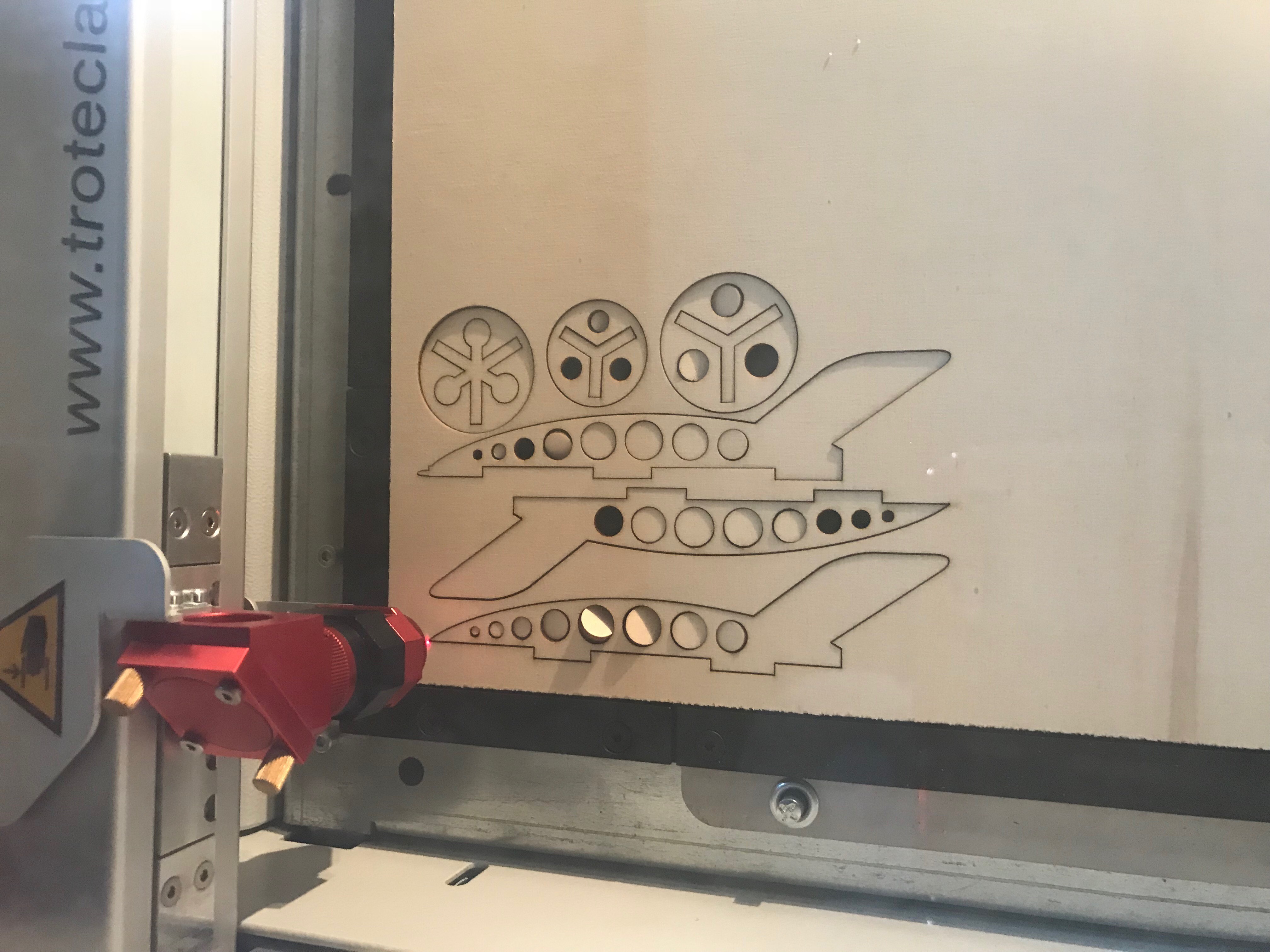

I tested the parametric parameters on a rocket kit first:

.jpeg)

below you will find my model in solidworks:

i wanted to have a few simple pieces as possible to make multiple shapes in three dimensions. After I tested my model on a cardbaord I used plywood to cut my final kit. what had to change was not the overall design, but rather small details, such as tolerances and dimensions of parts. It took me more than one effort to arrive to the final design because this was an exploratory process of trial and error,