Many materials are composites; when a material is combined with another kind of material, it would receive a new charasteristic from its partners and create a kind of new material that has most of the characteristics of the materials combined. For example, if you combine a crispy but hard material with a very strong fiber net, you will get a kind of composite that has both the hardness and tenacity. For this week's assignment, I am going to combine the guaze with the epoxy to create such a composite.

PREPARING THE MATERIAL

READ THE MATERIAL DATASHEET

I am using guaze to be as the fiber net, which could provide tenacity, while epoxy resin adheisive is hard and crispy after solidification, which provide hardness (harder than acrylic).

For the epoxy, I read the datasheet (in fact, it is printed on the bottle). There are two kind of epoxy: A and B. I have to mix them with a weight proportion of 2 : 1; however, because of difference in density, the actual volume proportion of 1.8 : 1, or any inacuracy in the mixture proportion would cause the result to be soft and sticky, since one of two epoxy would not be reacted completely.

Another important thing is that when epoxy is reacting(solidifying), it will produce a lot of heat and will generate some toxic gass called benzene, which would cause illness. So do not do this reaction in your own room. Always have an air purifier or move it outdoor in five minutes after the expoxy A and B are mixed (that is the time before the drastic reaction begins).

DESIGNING THE MOULD

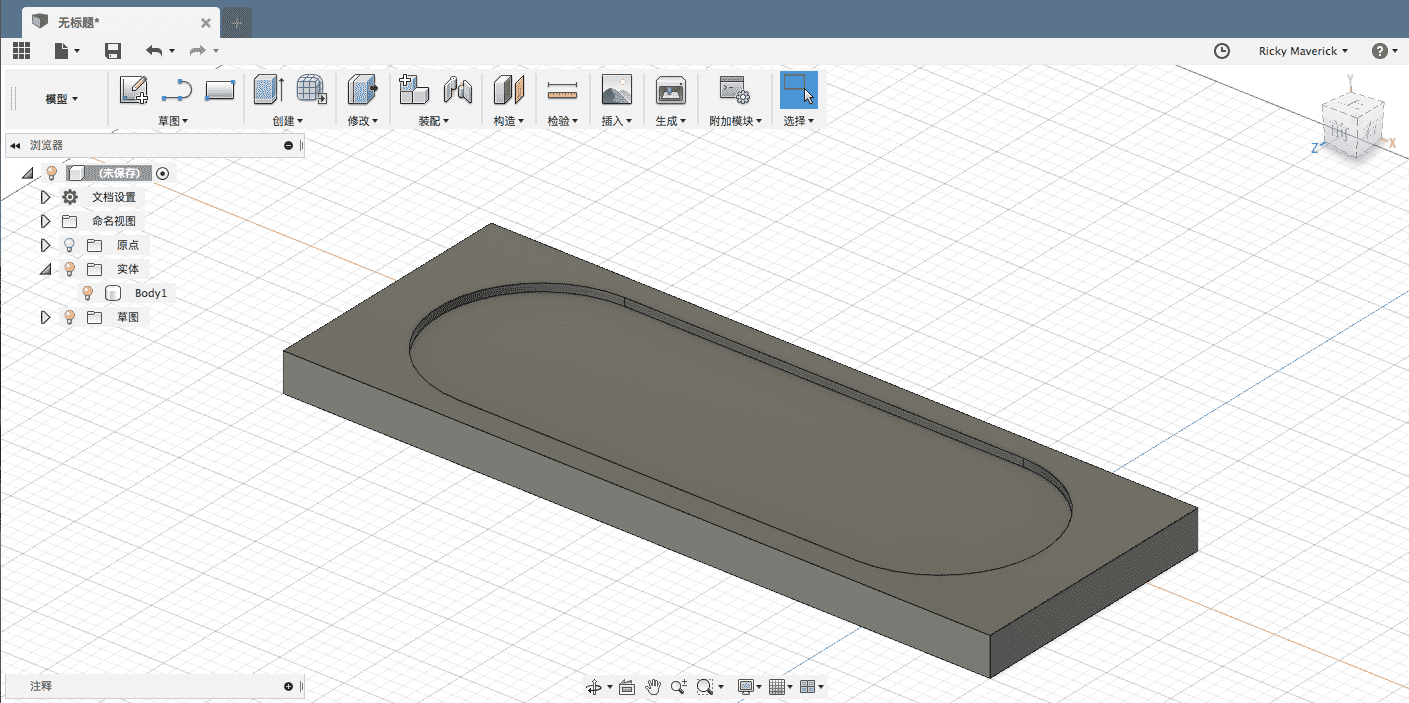

I designed a very shallow plate as a mould. Here is the design files. And before we pour materials into the mould, remenber to use plastic wrap to cover the mould so that the solid can be easily separated from the mould.

This video shows how to use Fusion 360 to create CAM jobs.

Then generate NC code that could be read by milling machines.

Then put the code on a USB drive(FAT-32) and load it on a CNC machine controlling system. Mill it out.

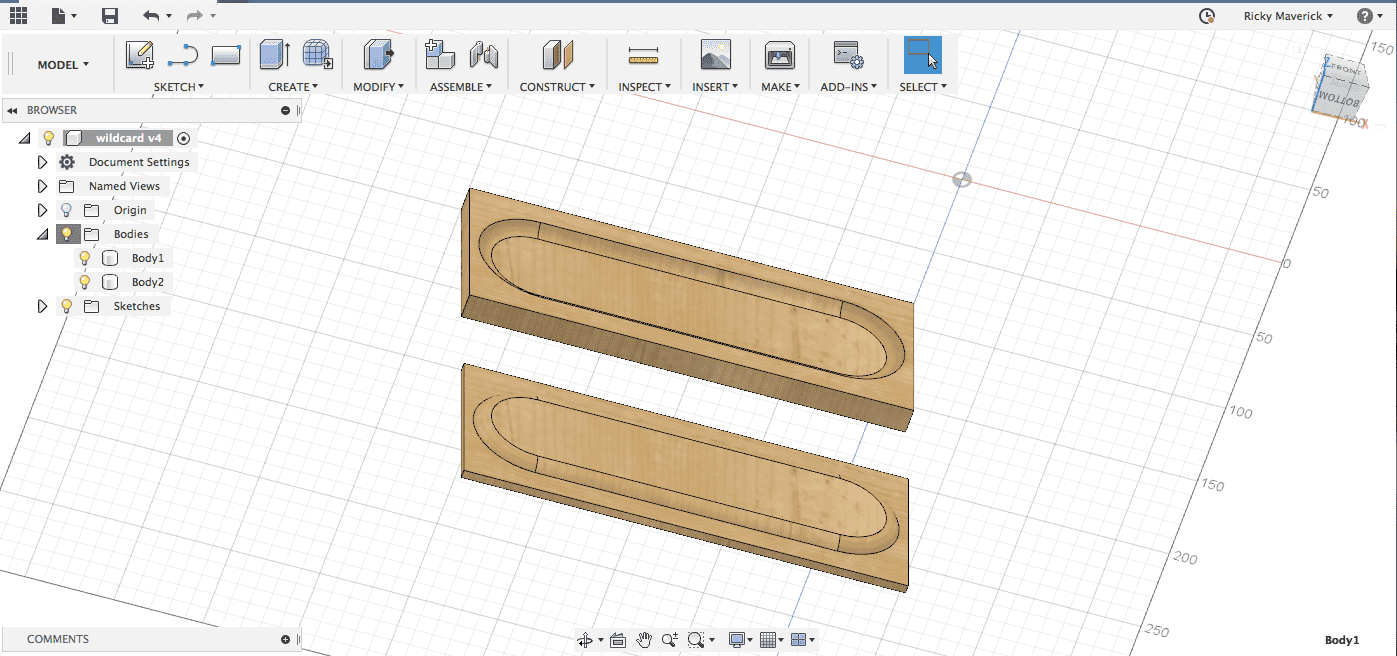

Then I designed the upper part of the mould so that I could add pressure to further compress the material.

This is the video of simulation of the milling process.

MAKING THE COMPOSITE

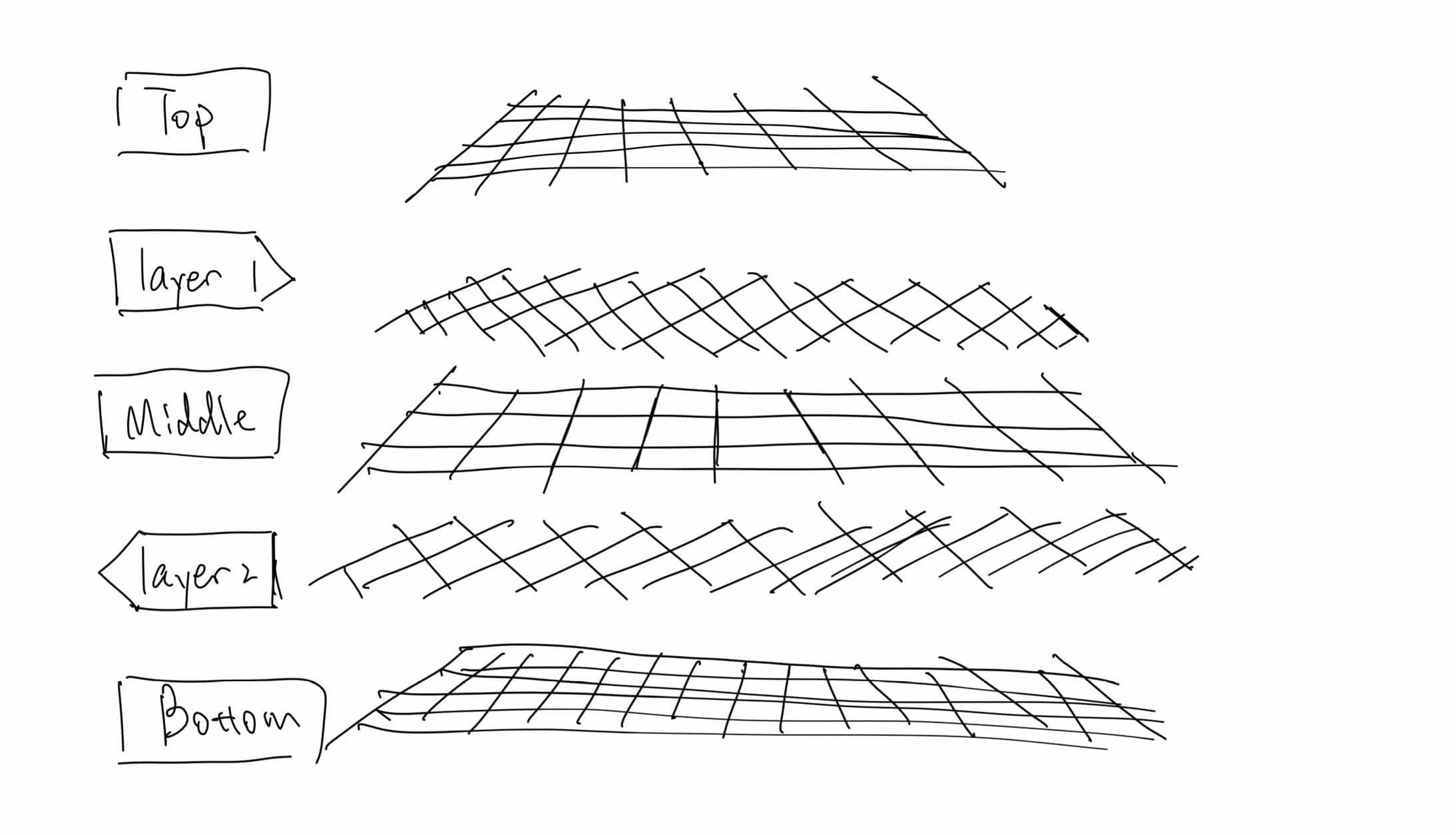

To make the internal structure of the composite more regular, I designed five layers of guaze. Every time I put a layer of guaze, I pour some epoxy on the layer.

The sketch of different layers. The layer 1 and layer 2 are in different dirrection to the top, bottom, and middle layer.

Solidifying.

This is the result.

PROBLEMS AND FIXES

In fact, for the first trial I failed because I did not cover the mould with plastic wrap, and when I tried to separate the mould and composite, I destroyed the composite to get it out.

For the second trial, I did not get a ideal composite because the proportion of epoxy A and B was not accurately controlled. To fix it, I used new injectors and cups, and then used a heater to make the reaction faster and more compete.