Making zero Z axis on the machine

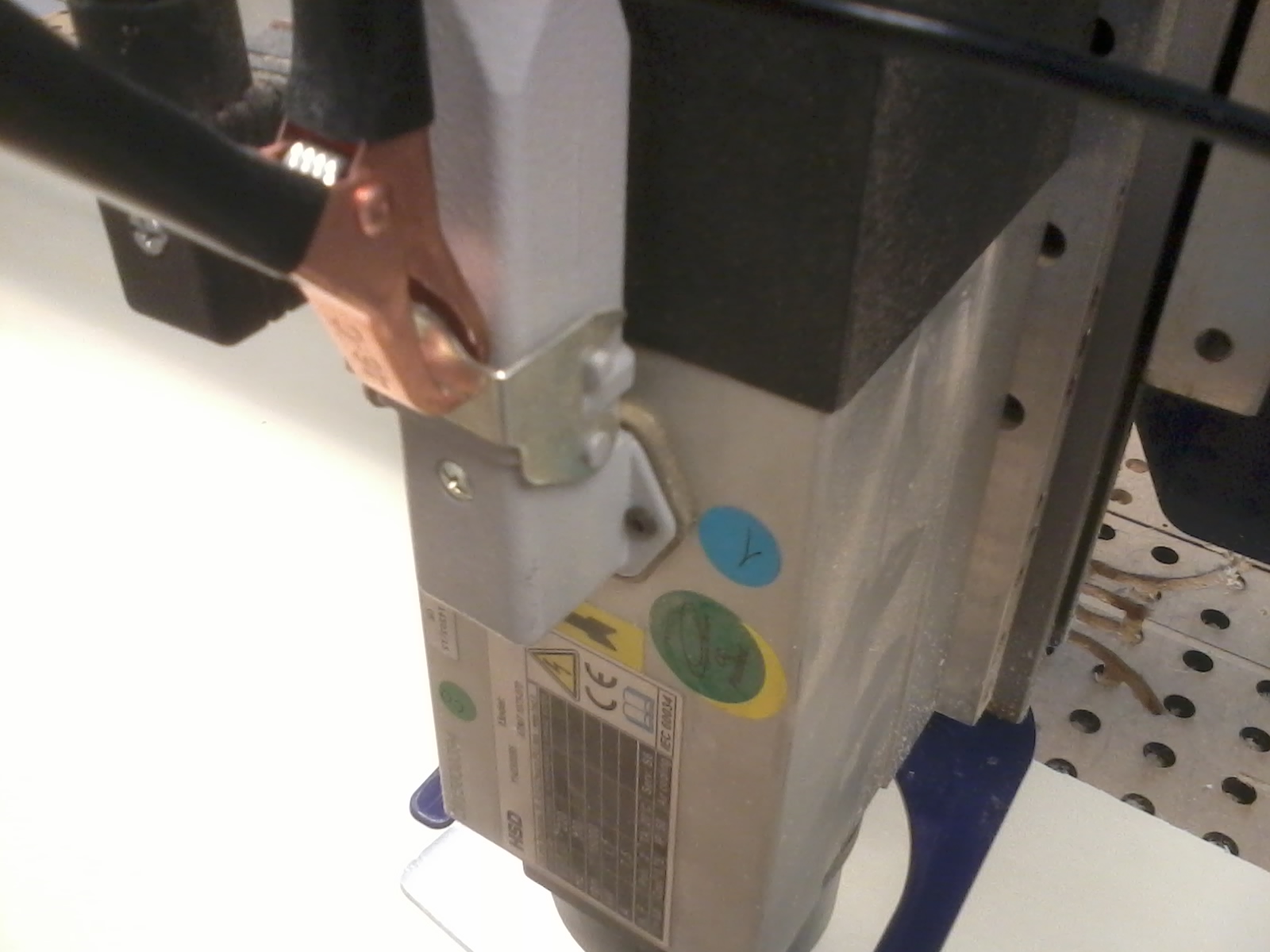

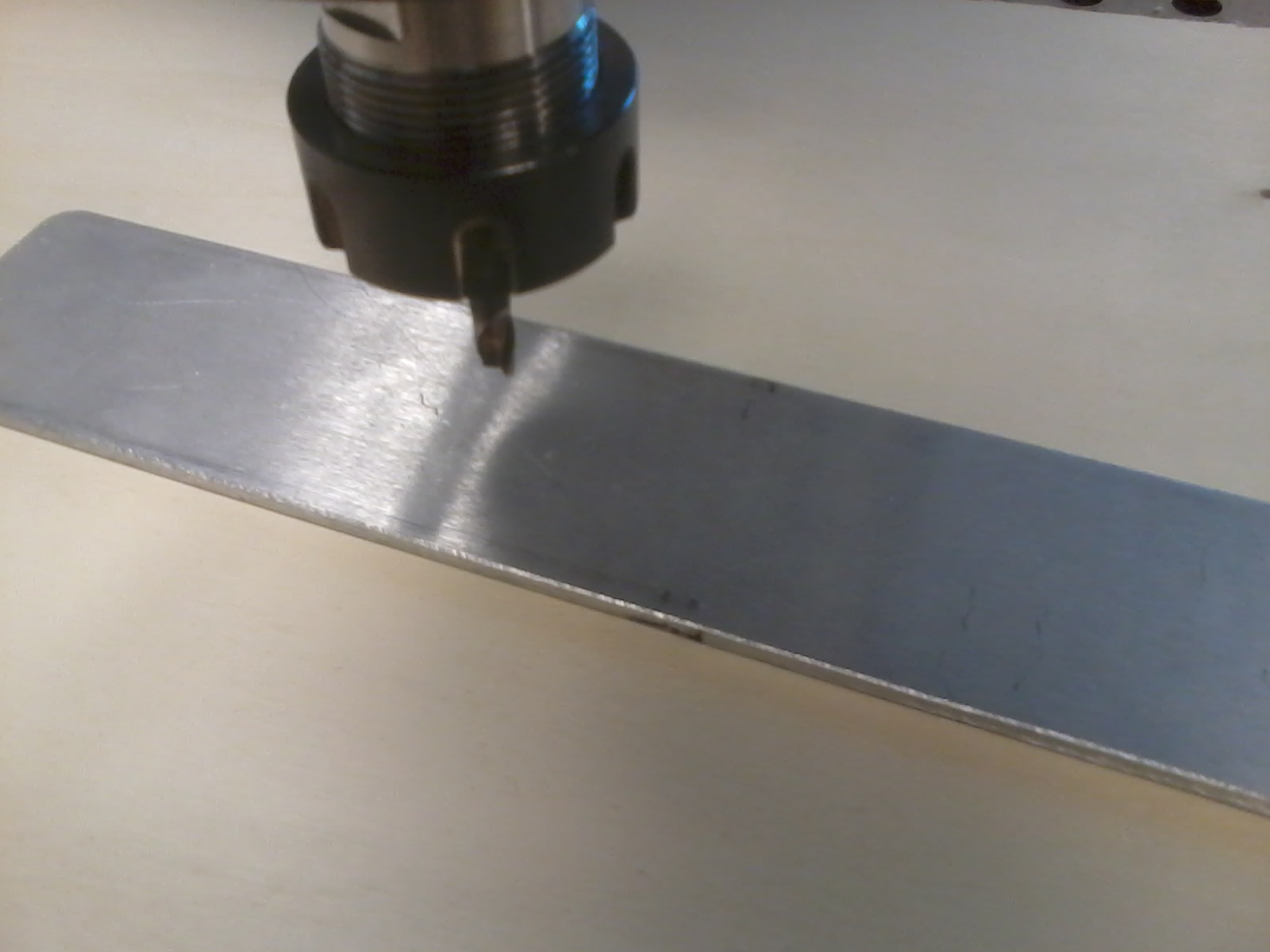

To make the zero Z axis on the machine, we put the connector on the motor and the plate on the piece of wood.Then on Shopbot 3 software, we clicked on Z-zero height using Z-zero plate. Then machine move down until touch the plate twice and the software automatically substract plate thickness.

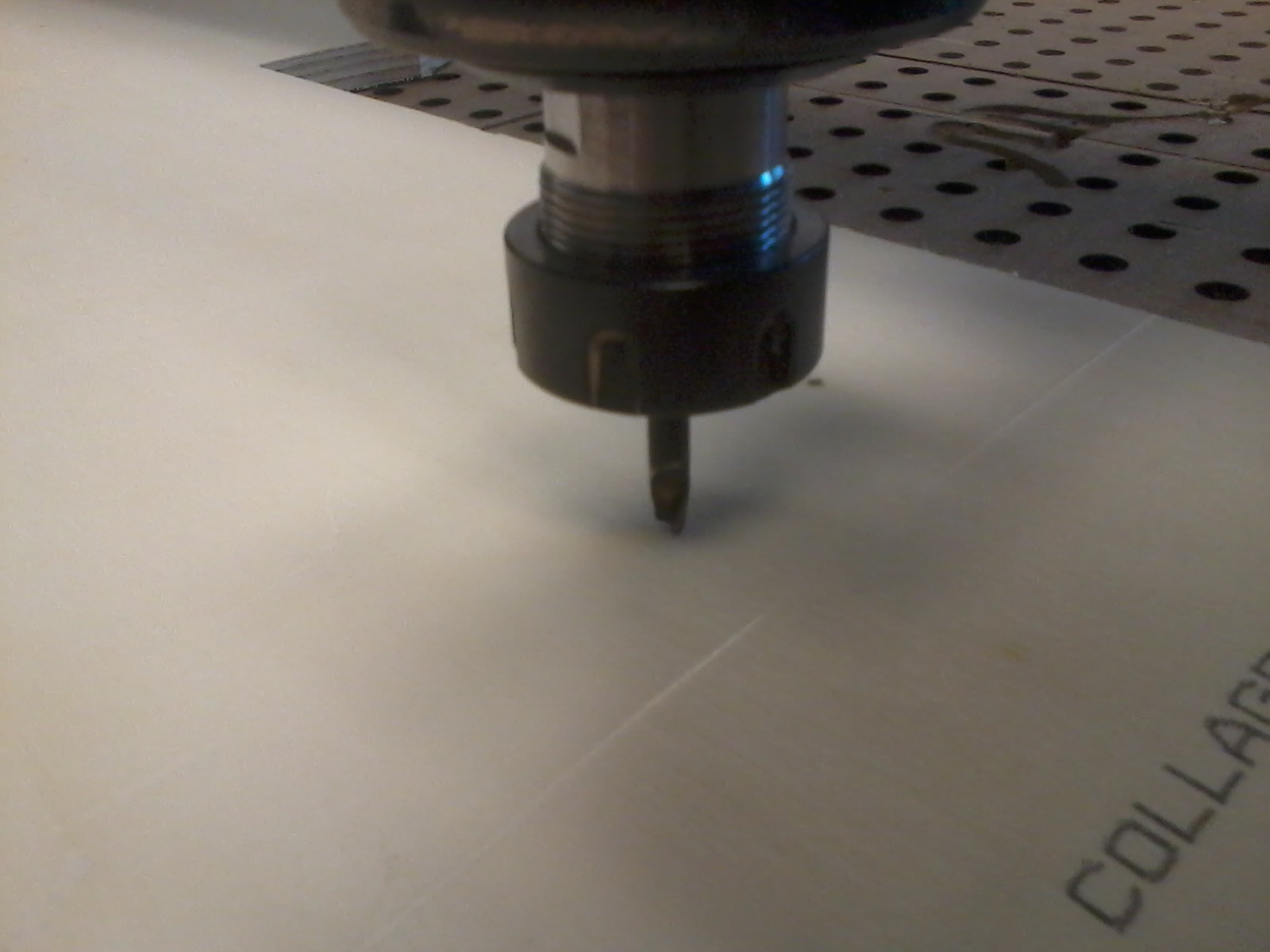

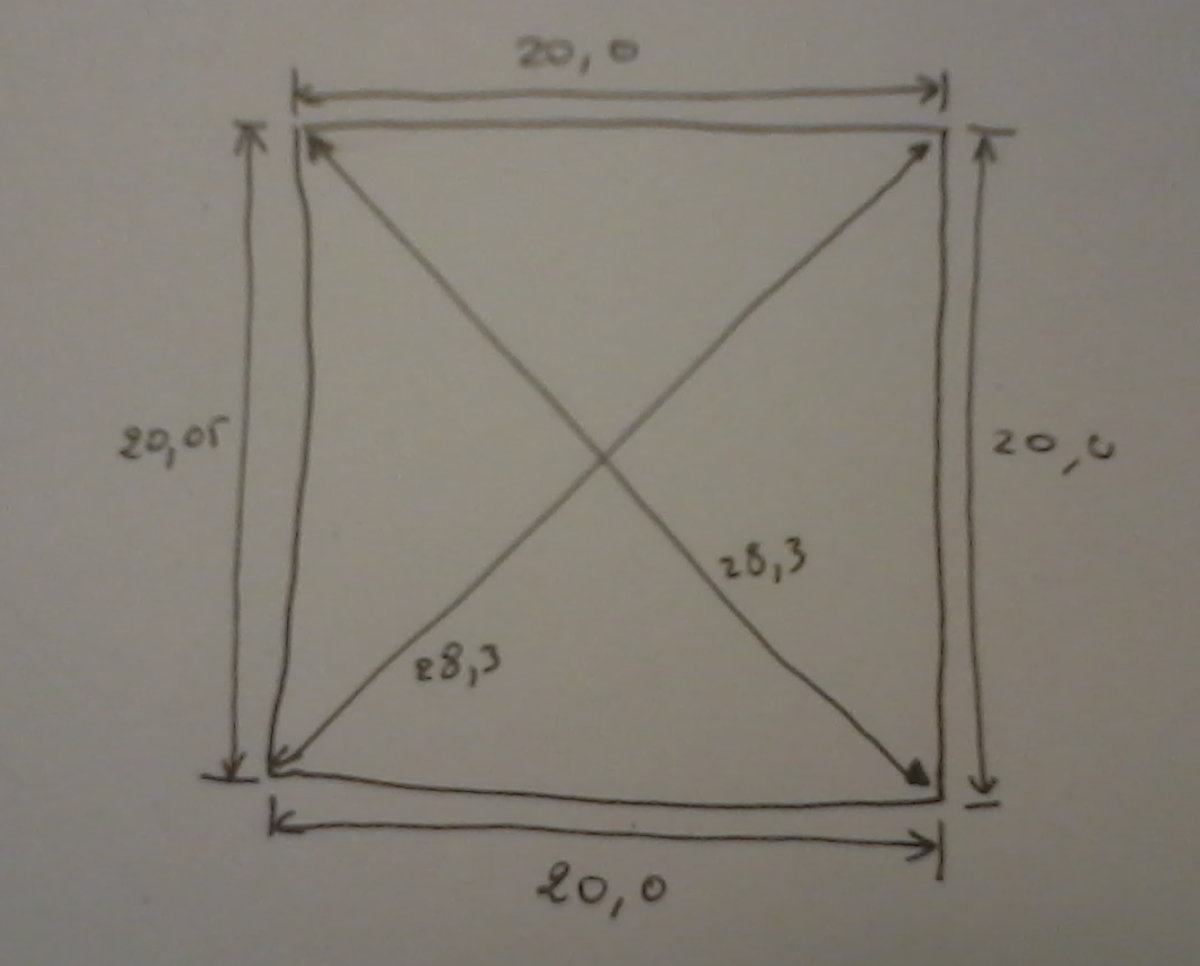

After making Z-zero, we moved on different place on the woodsheet and verified zero stays good.

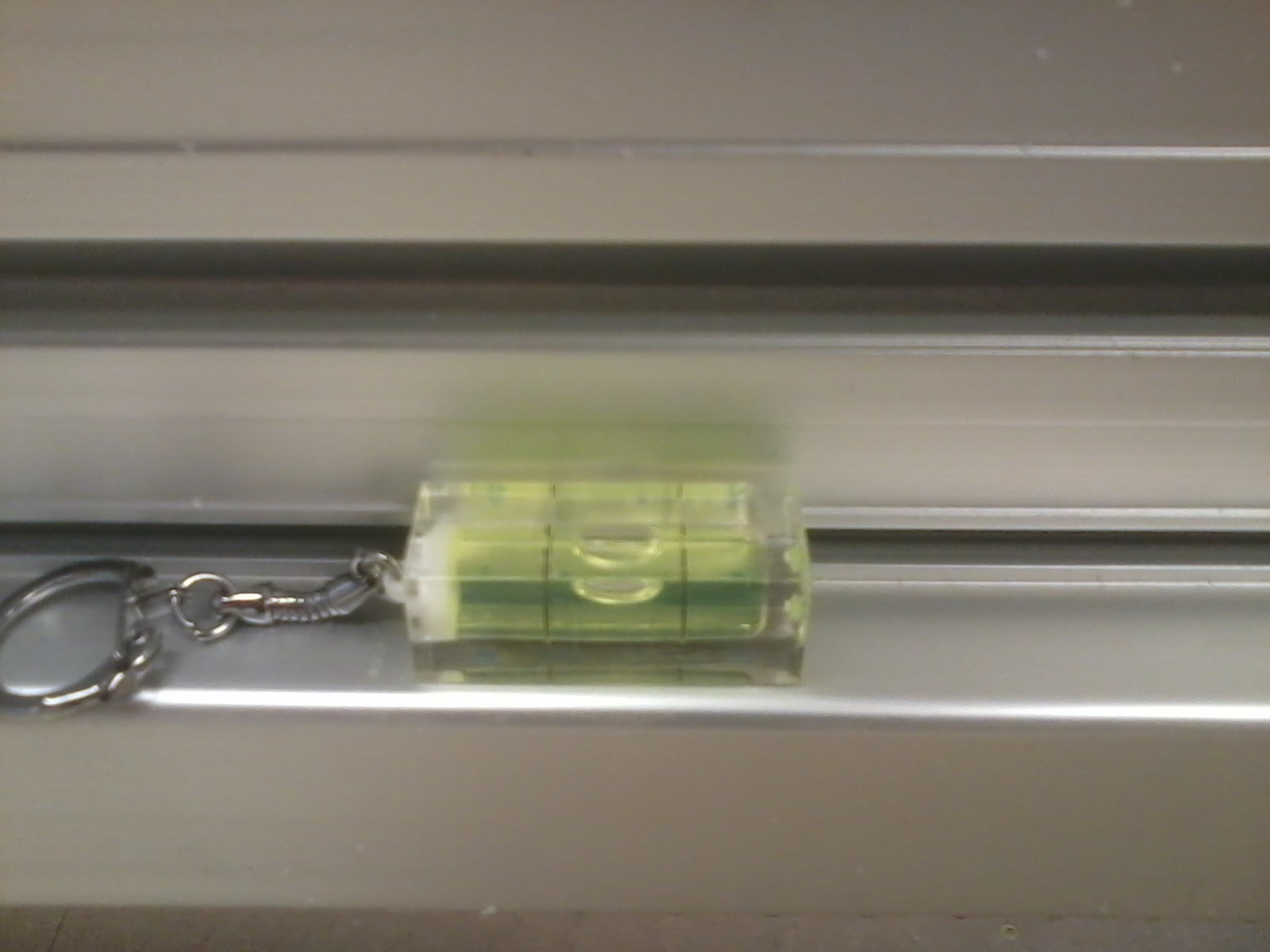

We also verified machine horizontality with a spirit level.