3D Printing

Test 1

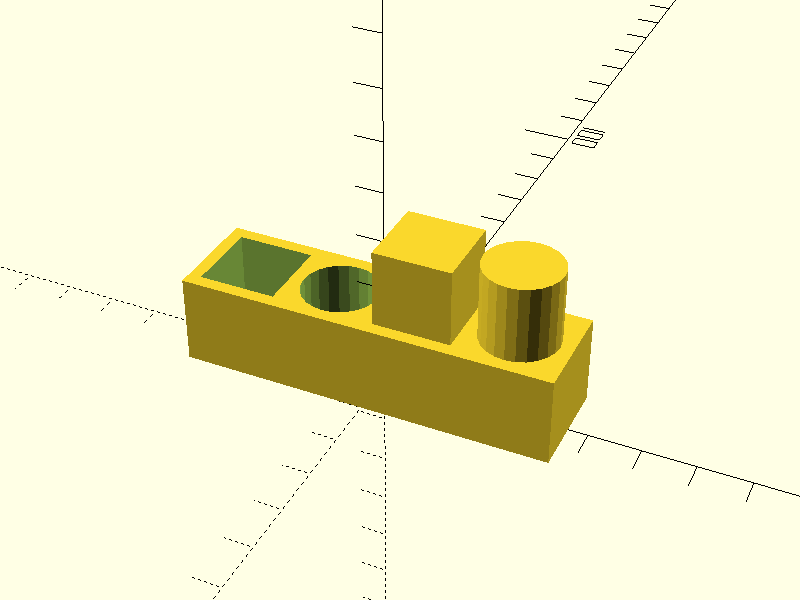

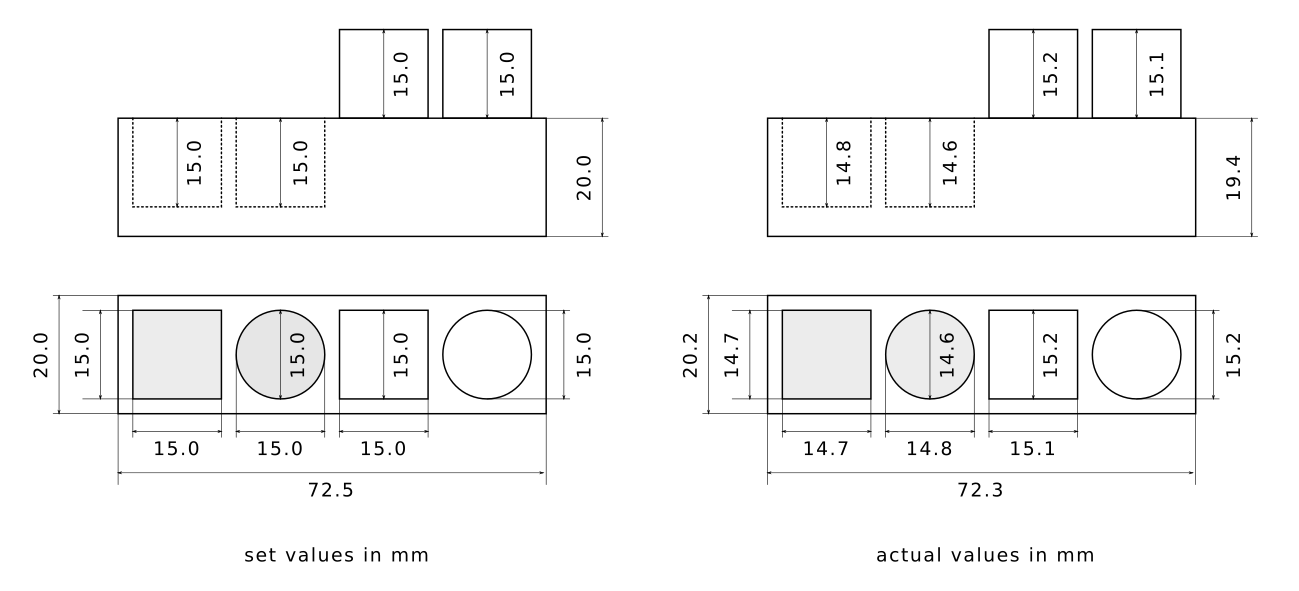

We created a test file to analyse the size characteristics of the 3D printer. We chose OpenSCAD to create cubic and cylindrical pockets and extrusions on one piece of material.

size = 15;

margin = 2.5;

difference() {

translate([0,0,(size+margin)/2]) cube([4*size+5*margin,size+2*margin,size+margin],center = true);

translate([-1.5*size-1.5*margin,0,size/2+1+margin]) cube([size,size,size+1],center = true);

translate([-0.5*size-0.5*margin,0,margin]) cylinder(r = size/2, h = size+1);

}

translate([0.5*size+0.5*margin,0,1.5*size+margin]) cube([size,size,size],center = true);

translate([1.5*size+1.5*margin,0,size+margin]) cylinder(r = size/2, h = size);

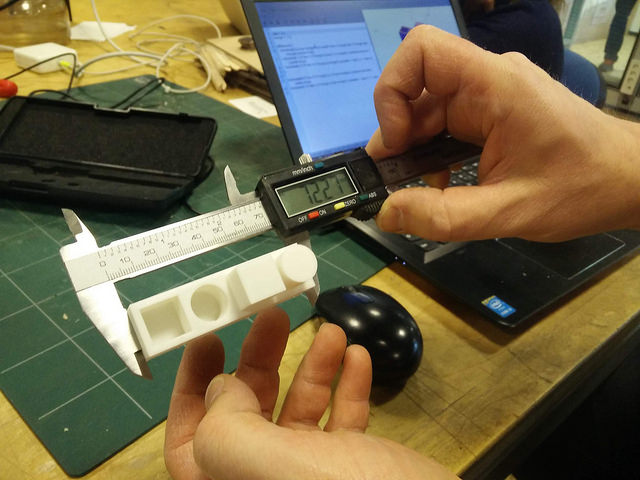

For the first test, we used the caliper to measure the internal and external distances on the object.

- We found that the exterior measurments are slightly larger than the original file, while the interior measurements are slightly smaller.

- The max difference of the extrusion of the extrusion was 0.2, while the pocket was 0.3

Test 2

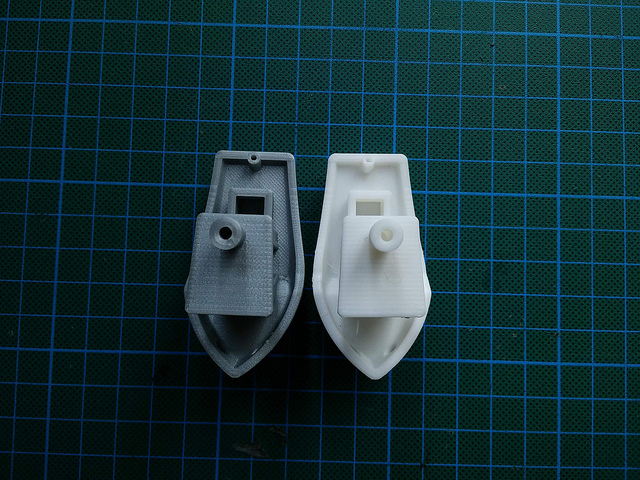

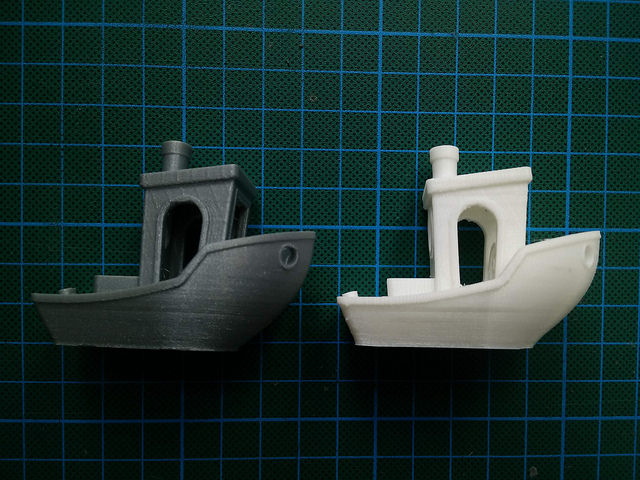

In order to reference different material, I printed an additional test, the 3D Benchy boat in ABS and polycarbonate (PC). Each part of the boat has dimensions which serve to test the printers ability to print complex angles and thicknesses. We created the following table of comparable features,

| # | Parameter | ABS | PC |

|---|---|---|---|

| 1 | Bridge Roof Length | 23.1 | 23.2 |

| 2 | Chimney Roundness (Outer) | 7 | 7.1 |

| 3 | Vertical Overall Roundess (chimney to floor) | 47.8 | 47.8 |

| 4 | Vertical Overall Height (cupboard to floor) | 15.4 | 15.3 |

| 4 | Bridge Front Window (Width) | 10.4 | 10.3 |

| 4 | Bridge Front Window (Height) | 9.3 | 9.5 |

To summarise, we found the Boaty an effective tool in comparing different material. The Ultimaker 3 is a reliable 3D printer but there are slight variations when creating the same object in different materials.