Computer-Controlled Machining

Assignment

Make something big!

…can I build a wooden house? maybe ... of 3 floors? jokes aside ... I had no idea to design something non-trivial ... then ..think…think…think…..

I lit a light bulb ...IDEA!

FAB Cabinet!

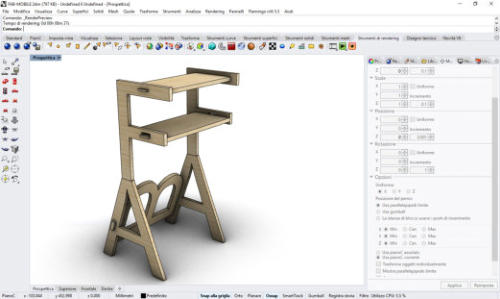

immediately start working to design the fab-cabinet through a 3d program, I chose to work with Rhino 3D because I like it a lot and I think it's a very powerful software.

Let’s Start to modeling!

using the tool for the text, insert the letters F A B giving an extrusion of 18 mm like the wooden board that I will use to cut the pieces. I place the letters F and A and unite them with a Boolean operation ... then I rotate the letter B and place it on the back side. The linear shelves are easy to make, with the instrument for rectangular solids I create the shelves of the same thickness. To give a more realistic appearance, I look for a wooden texture on the net and the load in the rhino program as texture of the material.

It’s nice …but…

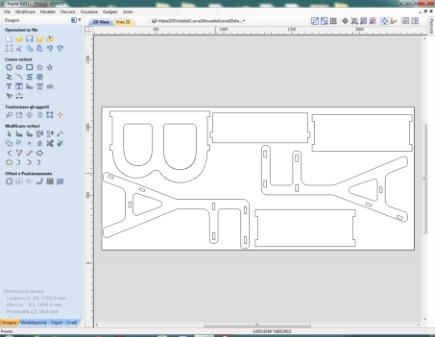

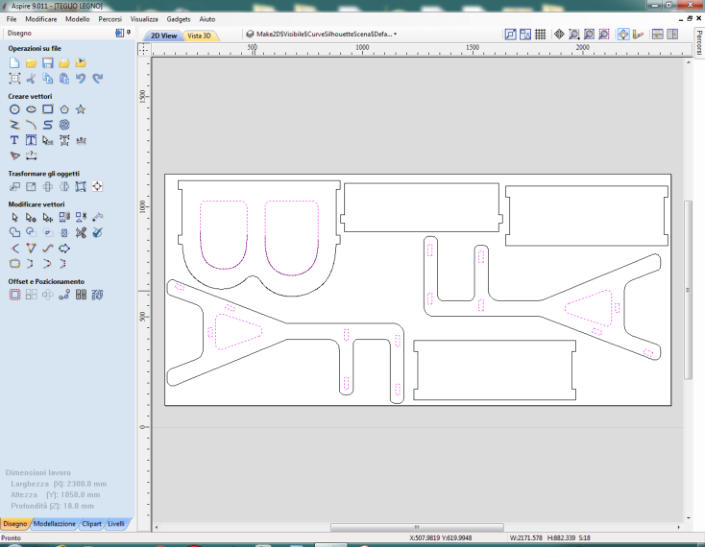

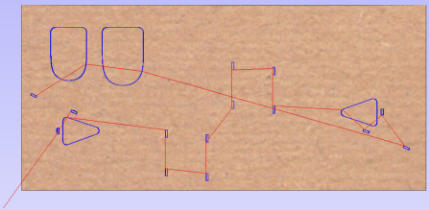

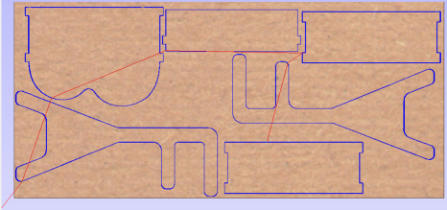

for the machining with the numeric control machine, I would prefer to have a softer, more rounded shape, the work is better with rounded profiles. Anyway, I am going to make a restyling of the furniture cabinet. I plan to connect all the corners to 90 degrees and also the internal parts to be excavated, such as B and A, all rounded up.The result satisfies me a lot, so I move on to prepare the files for the processing. First of all I need the pieces to be cut to be on the same two-dimensional plane, so I redraw the parts with the measurements I have determined.When the work is finished, the file to be exported looks like this:

The

file

is

saved

in

the

DXF

format

and

must

be

transferred

to

a

pen-drive

because

the

shopbot

that

cuts

the

wood

is

in

the

carpentry,

I

transfer

the

file

and

after

making arrangements with the staff I go to the carpentry for processing.

TEXTURE

Woodworking, wood, milling program.

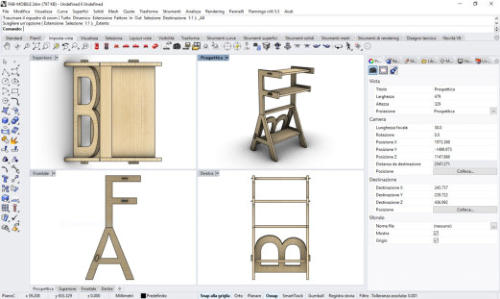

The machine is the Shopbot Alpha, very large and extremely powerful but also dangerous, the safety rules must be scrupulously respected, then wear the protections and I go to measure the wooden panel (250x125 cm and my .dxf file working on 230x105 cm) that I will have to fix on the top of plane of machine.

to

prepare

the

dxf

file

and

make

it

suitable

for

processing,

you

must

use

the

program

Vectric

Aspire.

Once

the

program

has

started,

load

my

file

and

verify

that

there

are

no

breakpoints

in

the

drawing

profile.

There

are

open

vectors

and

so

you

have

to

close

those

paths,

I

do

it

using

the

appropriate

function of the program.

I Selected the open vectors and combine them with the specific tool.

The same operation must be repeated for the external profile, if there are open vectors.

create a path

To perform the machining of both the external part and the internal holes and openings, it is necessary to create work paths and save them.

The internal and external paths are two separate

operations to be performed in two stages

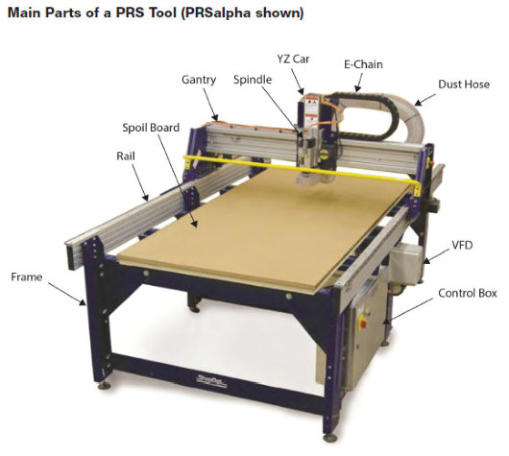

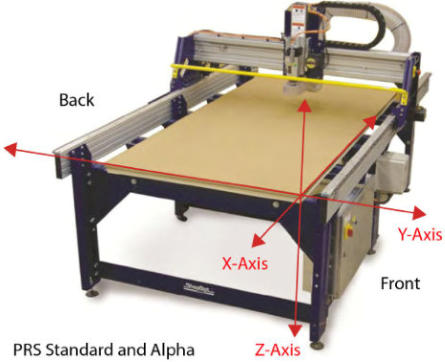

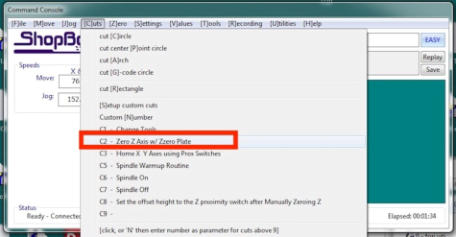

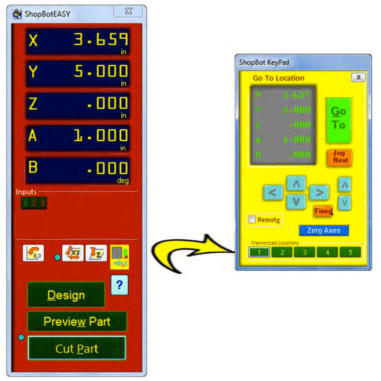

Shopbot settings of x,y,z axis (from the official manual)

Like the small roland milling machine that we at the fablab use for electronic boards, even the bulky shopbot needs to reset the axes. The x and y axis are simple to set, while the z axis needs a dedicated procedure.And now you can cut it!

My 3D model

My Real object

Don't you find it

a good job?

Original Files and Useful Links

My mistake...

Taken from the enthusiasm .. I started to immediately model my object in 3d creating the assembly to see how it would be the final result.Then I realized that for processing I needed a 2d file, in .dxf format to process the work paths useful for the wood milling machine. After several attempts to break down my 3d model that I had extruded and combined with Boolean math operations, I realized that it took a long time and it would be much faster to do it all over again. The lesson I learned is that : you have to start from the 2d file for processing, save the two-dimensional file and then extrude the polygons to create and compose the 3d object.

Ground Clip

Z zero Plate

Shopbot is cutting the panel

The

cutted

panel,to

hold

up

it

it's

a

good

idea

to

place

the

pieces

of

wood under bottom.

to

remove

the

scraps,

I

use

a

chisel

and

a

hammer.

Small

strokes,

but

strong.

it

is

useful

to

wear

protective

glasses,

because

some

wooden

scabbards could fly away.

Front View

Side View

Back View

the wood pressed panels

My safety kit

Splash screen of Vectric

My imported .dxf file

The FabLab’s Shopbot

The tool to Fix Open Vectors

The selected open vectors

The External Path

The Internal Path

Save the Paths to folder

Two separated files

The internal and external paths of the process that the cutter will follow

Software to use: Vectric Aspire

Launch Software

Double-click the ShopBot 3 icon to open the machine’s control program.

The

first

time

the

program

is

opened,

there

will

not

be

a

settings

file

for

the

machine.

Click

“OK”

and

a

prompt

will

appear

to

load

a

settings

file

for

the machine

Tool Movement

This

panel

provides

essential

machine

information

and

controls.

The

following

steps

will

walk

through

some

of

the

most

frequently

used

controls,

including

installing

a

bit,

zeroing

the

machine’s

three

axes,

and

cutting

a

couple

of

sample

projects.Click

on

the

yellow

button

to

bring

up

the

“KeyPad”

panel.

The “Easy” Control Panel

The Keypad

This window allows the user to manually move the X-, Y,- and Z- axes of the machine. Click on the blue arrows to move the spindle/router and gantry.X- and Y-axes can also be moved with the cursor buttons on the computer keyboard. Use the “Page Up” and “Page Down” buttons on the keyboard to move the Z-axis up and down.Move the spindle/router to a safe Z position below the Z proximity switch and near the middle of the deck.Click on the X in the upper right corner to close yellow KeyPad

Test each axis with the keypad

Turn ON the control box. Click on the yellow keypad window icon within the red position window. If the icon is not visible, click “move/cut” under “Mode” on the red position window.

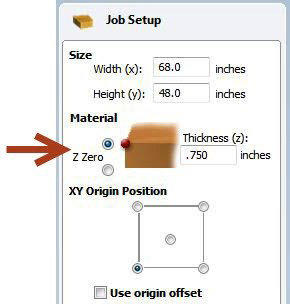

Zeroing the Z-axis

The Z-axis must be zeroed each time that the machine is turned on or bits are changed. Zeroing can be done to either the top of the material or to the table surface. Zeroing to the top of the material is a better choice when a precise cut depth is needed (when cutting an inlay pocket, for example). Zeroing to the table surface is a better choice when through-cutting parts in wood. Because wood products naturally vary in thickness, the top surface of any given area may be higher or lower than other areas. Zeroing to the table surface will provide the most consistent through-cutting results. Whichever location is chosen, the location must be identified in the CAD/CAM program (as shown here for VCarve Pro). Failure to match what is specified in the software with what is done at the table can result in ruined material and/or broken bits!Z-axis zeroing process

Ensure that the software is set to Move/Cut mode. Place the grounding clip on the bit, if possible. Otherwise, place it on the collet nut or shaft of the spindle. Set the plate down directly beneath the bit. NOTE: To test the circuit before running the zeroing routine, touch the plate to the bottom of the bit. Check that input 1 lights up on the screen and goes off as soon as contact is broken. Click on the Z zero button, or type a C2 command. The Z-axis will touch the plate twice and then move up to a safe height. The Z-axis is now calibrated and the machine is ready to cut. Place the Z zero plate back in its holster. Remove the grounding clip from the bit and secure it safely.

close

path cards

add cards

delete all cards

add cards automatically