Week9: Molding and casting

Group assignment:review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

-> link

Individual assignment: design a 3D mold around the stock and tooling that you'll be using, machine it, and use it to cast parts

-> link

Individual assignment: design a 3D mold around the stock and tooling that you'll be using, machine it, and use it to cast parts

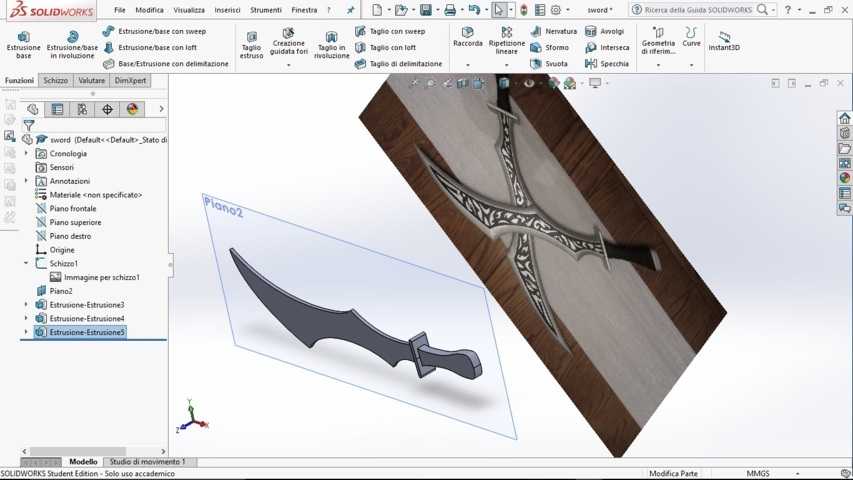

The model

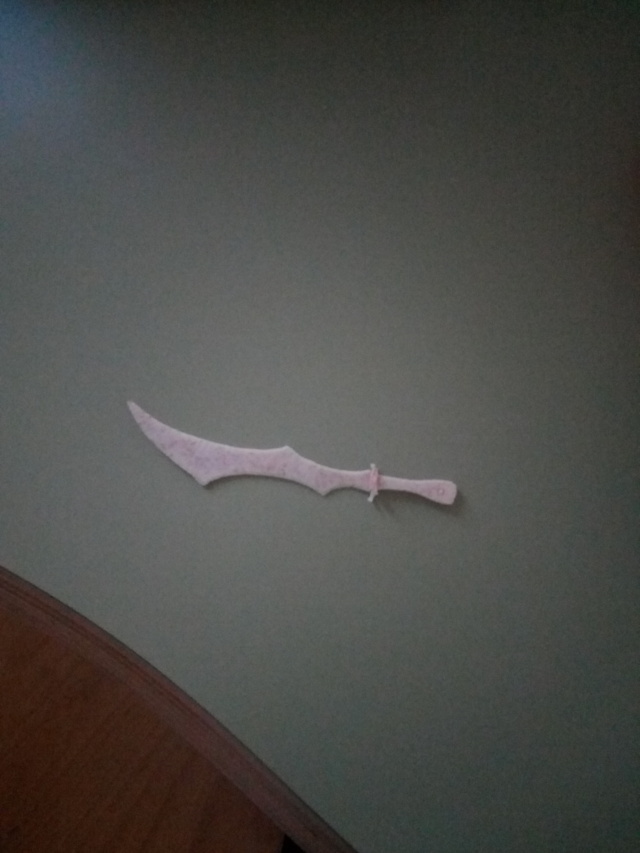

This week was very interesting for me because I could make a an object that I always wanted to make, a sword-shaped keychain. This sword is used by

one of my favorite champions in a game, so I found an image on the internet and used it to make the 3D model

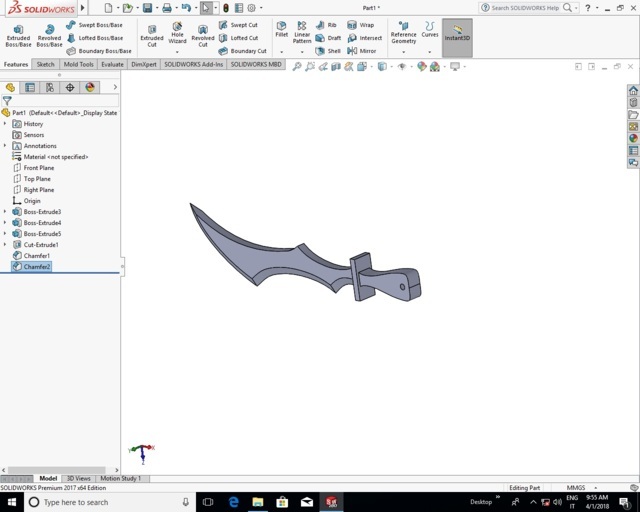

Since the design is quite complex I followed a tutorial of a sword that was really useful -> here the link. Once I inserted the image I traced the outline dividing it into 3 parts, each with a different extrusion to obtain different volumes

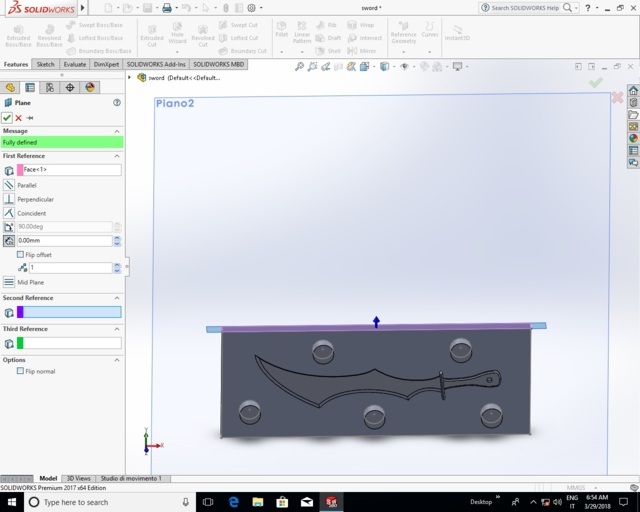

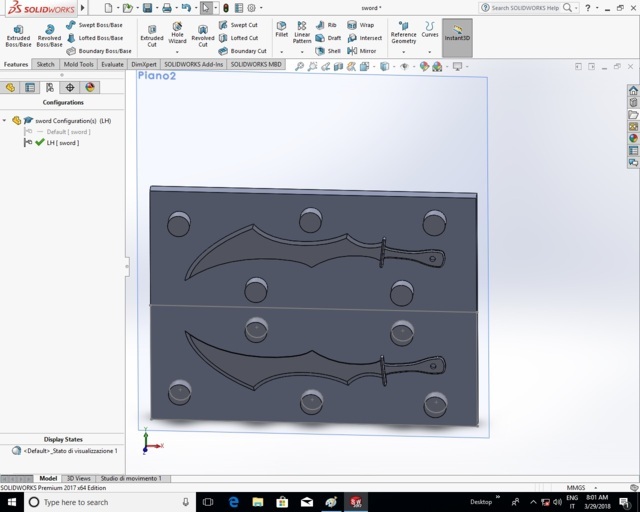

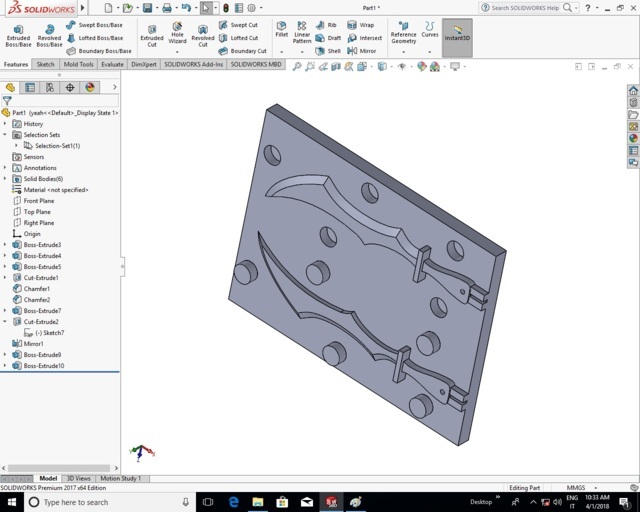

After making the registration keys and the breather (which I didn't because I wanted to do them by hand) I duplicated the model, in this way the faces will coincide

Since the design is quite complex I followed a tutorial of a sword that was really useful -> here the link. Once I inserted the image I traced the outline dividing it into 3 parts, each with a different extrusion to obtain different volumes

After making the registration keys and the breather (which I didn't because I wanted to do them by hand) I duplicated the model, in this way the faces will coincide

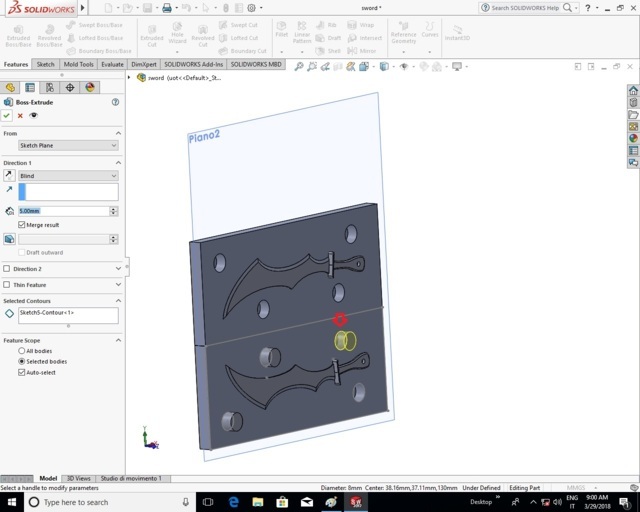

After the mirroring it was hard creating the holes for the keys because the one I took from one side took it away from the other,

so I first made the holes and then the extrusion of the keys, in this way it worked. So I exported the model in STL.

Milling

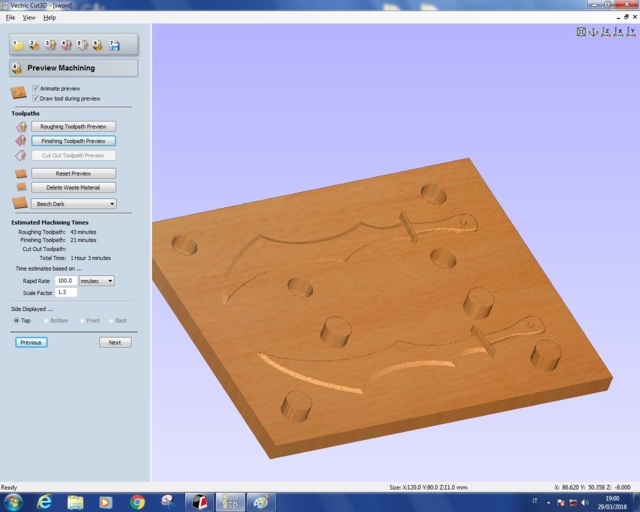

For this work we will use the Roland

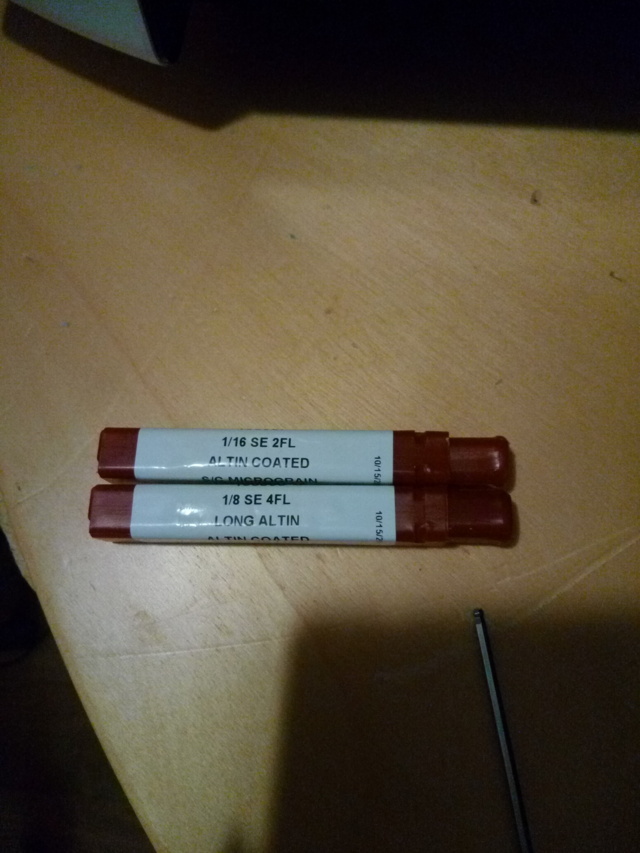

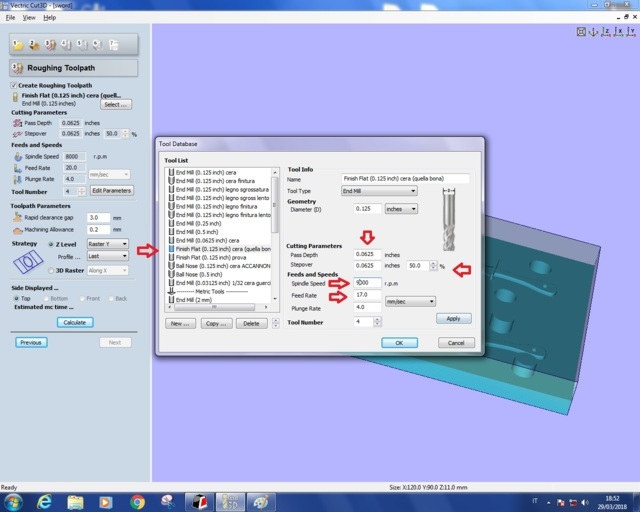

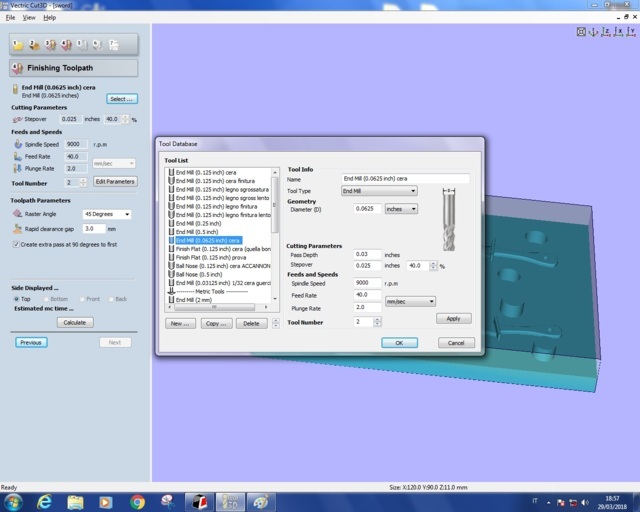

Some info on Vectric Cut 3D: there are several parameters to insert and two different files to save. In fact the first part of the work will be roughing (and in our case the 1/8 tip will be used) while the second part is finishing (smaller tip, 1/16).

Pass depth = indicates how much the tip drops in every pass

Stepover = it is expressed in percentage because it represents the distance between the previous cut and the next one (high percentage means you need more time to mill)

Spindle speed = it is measured in r.p.m (revolution per minute), consequently it express the speed related to the spins in 60 seconds

Feed rate = indicates the speed of the progress done on the workpiece

Plunge rate = indicates the speed at which the tip goes downward (through the material)

Below you can see what parameters I used for the Roughing and the finish toolpath

Some info on Vectric Cut 3D: there are several parameters to insert and two different files to save. In fact the first part of the work will be roughing (and in our case the 1/8 tip will be used) while the second part is finishing (smaller tip, 1/16).

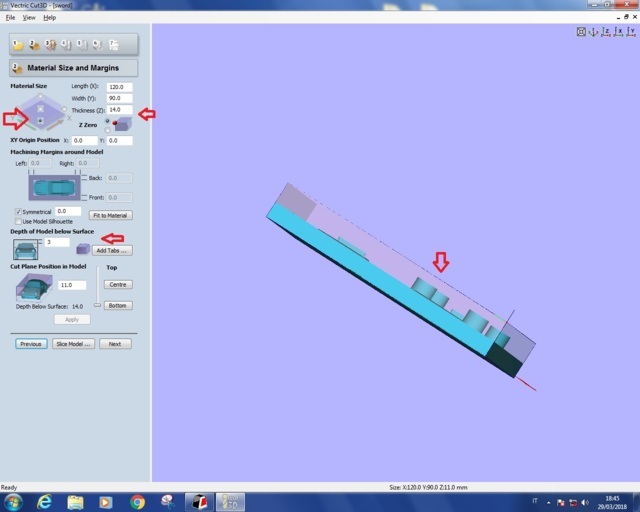

In this part is important to set the position of the origin and the depth to start creating the model. Greater is this measure, thicker the mold will come.

Some notes about parameters:

Pass depth = indicates how much the tip drops in every pass

Stepover = it is expressed in percentage because it represents the distance between the previous cut and the next one (high percentage means you need more time to mill)

Spindle speed = it is measured in r.p.m (revolution per minute), consequently it express the speed related to the spins in 60 seconds

Feed rate = indicates the speed of the progress done on the workpiece

Plunge rate = indicates the speed at which the tip goes downward (through the material)

Below you can see what parameters I used for the Roughing and the finish toolpath

As you can see there is an option that shows you the toolpath preview

After saving the file I launched it on the Roland and waited for the result, cleaning the excess wax little by little

After saving the file I launched it on the Roland and waited for the result, cleaning the excess wax little by little

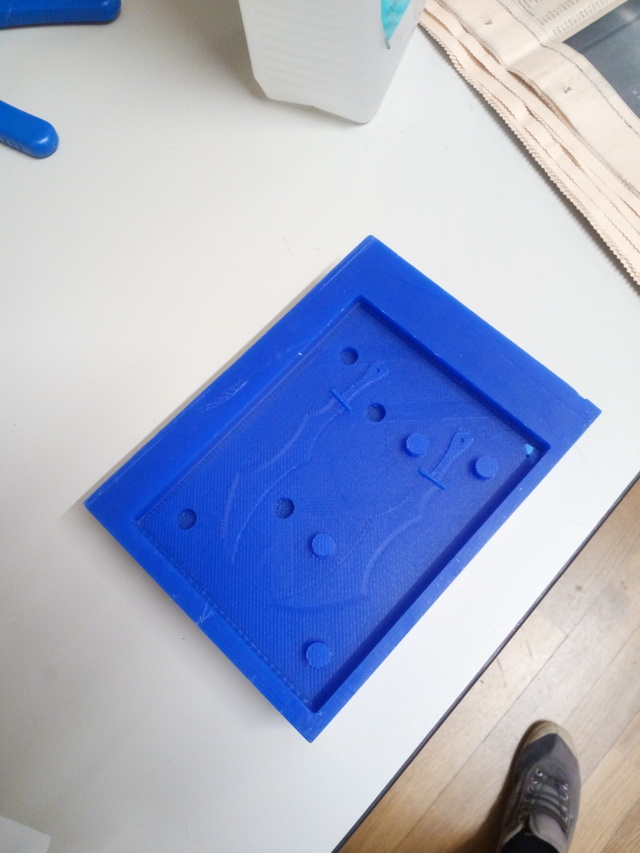

The negative mold

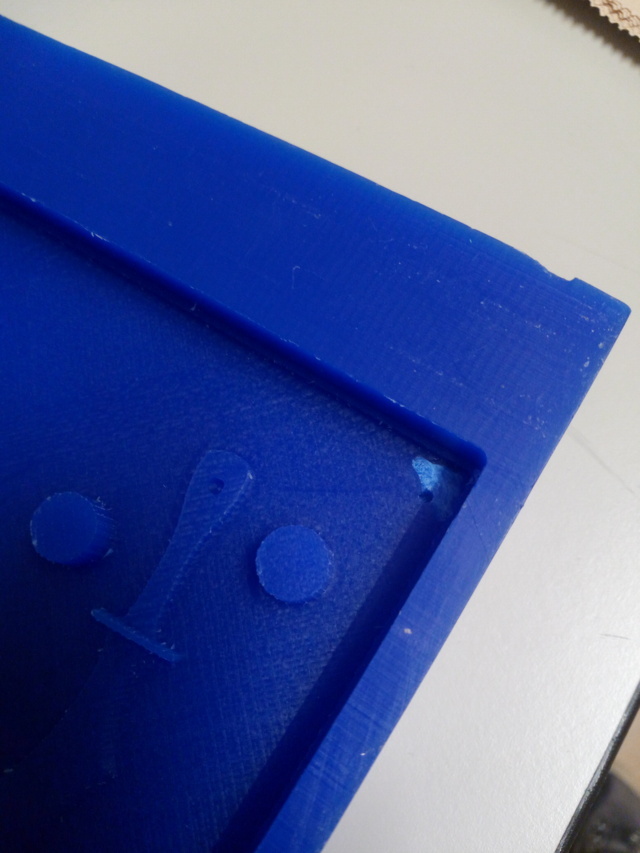

After several time, this is the result

Advice! It's important to set the Z origin of the tips: this happened because I didn't that at first time.

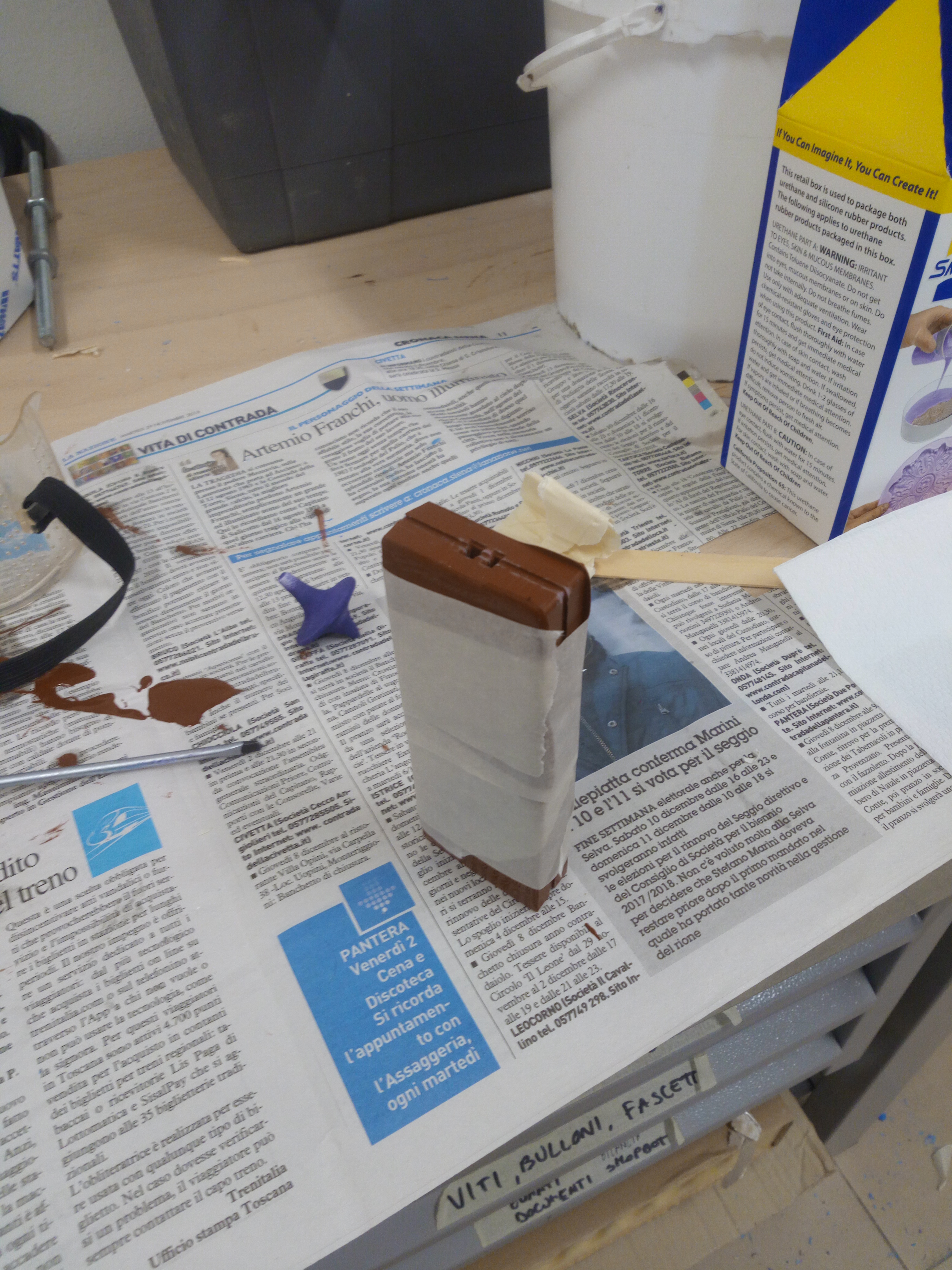

For the negative mold I used this silicone rubber Antichita' Belsito and the relative catalyst in proportion to 5%

After 24 hours the mold were finally ready

From this moment on I have to say that I encountered several problems: doing various casting tests the result was not satisfactory, in fact the sword came too thin. So I decided to do all the process over again.

I modified the model making it thicker

AndI also added the channels.

Another problem: when I redid the mold I probably didn't mix the silicone rubber enough and it didn't catalyze, so I had to clean the positive mold (it was a very long and boring job)

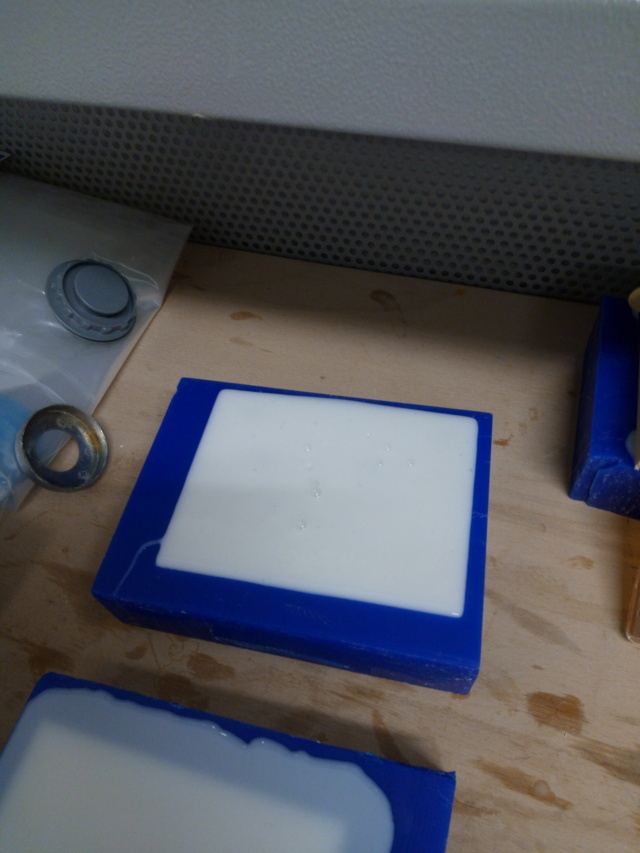

This time for the negative mold I used Smooth-On Mold Max 60 and the result came very good

Then I prepared the mold

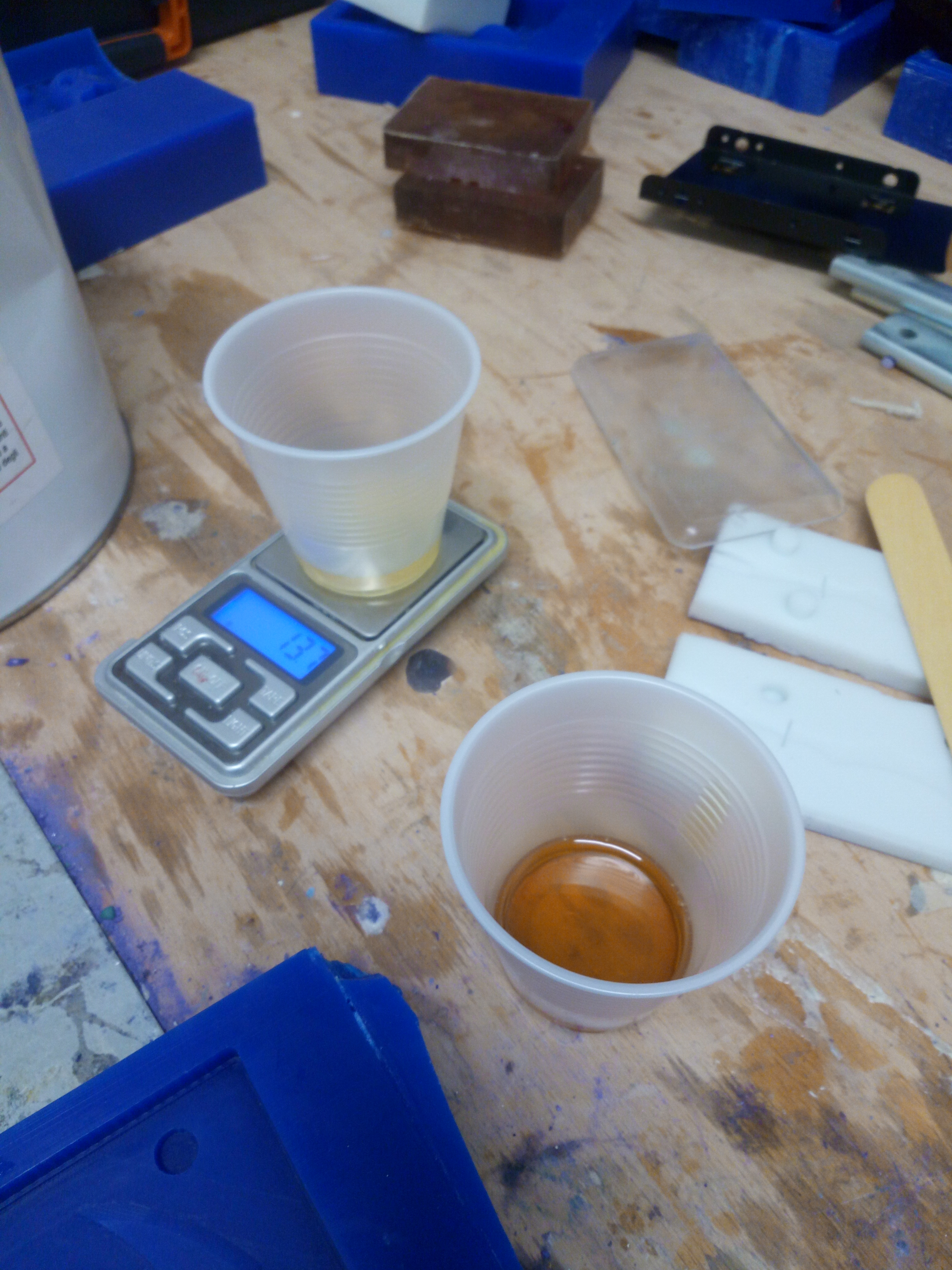

Well, it's time to talk about the Sintafoam, a polyurethane resin. Here the manufaturer's webpage with the datasheet. These are the general instructions for using this resin:

The Pot Life is 120/130 secs

The Cure Time is 250/310 secs

The ratio between A and B parts is 1:1

And above all it is very important to use gloves since the resin is a corrosive material

To give a touch of class to the sword I used the green dye and the glitter, so it is less threatening.

I am very satisfied with the result. The most delicate part is definitely mixing the silicone to make it catalyze well, but also pouring the resin before it starts to harden is quite complex. In fact you have to let the air out gradually from the mold to avoid the formation of air bubbles, but in a very short time.

Advice! It's important to set the Z origin of the tips: this happened because I didn't that at first time.

For the negative mold I used this silicone rubber Antichita' Belsito and the relative catalyst in proportion to 5%

After 24 hours the mold were finally ready

Casting

From this moment on I have to say that I encountered several problems: doing various casting tests the result was not satisfactory, in fact the sword came too thin. So I decided to do all the process over again.

I modified the model making it thicker

AndI also added the channels.

Another problem: when I redid the mold I probably didn't mix the silicone rubber enough and it didn't catalyze, so I had to clean the positive mold (it was a very long and boring job)

This time for the negative mold I used Smooth-On Mold Max 60 and the result came very good

Then I prepared the mold

Well, it's time to talk about the Sintafoam, a polyurethane resin. Here the manufaturer's webpage with the datasheet. These are the general instructions for using this resin:

The Pot Life is 120/130 secs

The Cure Time is 250/310 secs

The ratio between A and B parts is 1:1

And above all it is very important to use gloves since the resin is a corrosive material

The final result

I am very satisfied with the result. The most delicate part is definitely mixing the silicone to make it catalyze well, but also pouring the resin before it starts to harden is quite complex. In fact you have to let the air out gradually from the mold to avoid the formation of air bubbles, but in a very short time.