|

|

|---|

Assignment |

Final Project |

About Me |

|---|

Week 8

0.Assignment

*group assignment

test runout, alignment, speeds, feeds, and toolpaths for your machine

*individual assignment

make something big

1.Tutorial

The CNC used in the seoul innovation fablab is shopbot and the material used is plywood 12t.

Unlike pcb milled or lasercutter, the CNC to be used at this time was used under supervision of the instructor

because the machine was large and strong, and was trained with classmate Seunghwan Ji before use.

It was safe to be emphasized in the education, but some of the people working elsewhere worked as carefully as possible

to hear that their hand was injured by a mistake and that their daily life was hindered.

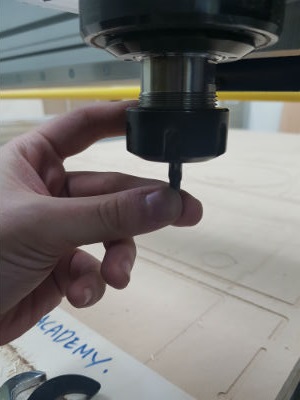

Like other CNCs, we use a collet and an endmill. The endmill we used this week is a 6mm endmill.

One of the educated memories is that the use of endmill and drill is very different.

If the drill is just a hole drill, the endmill can be drilled like a drill, but it can be moved to the XY axis.

After training, I went with the instructor to learn how to use it.

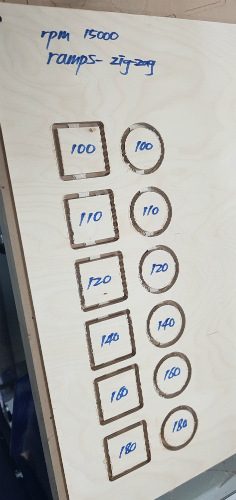

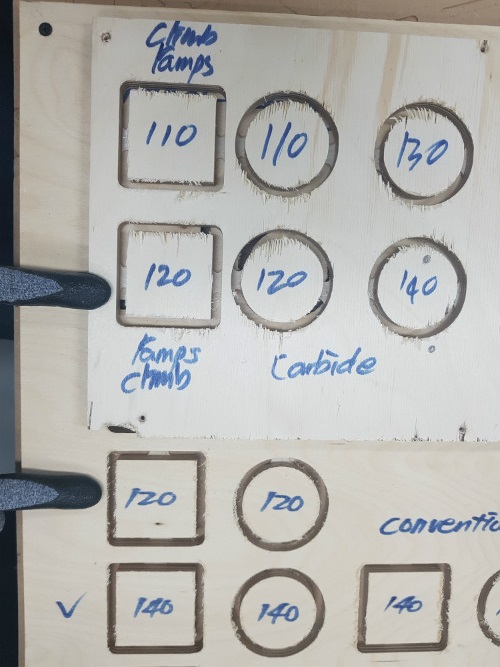

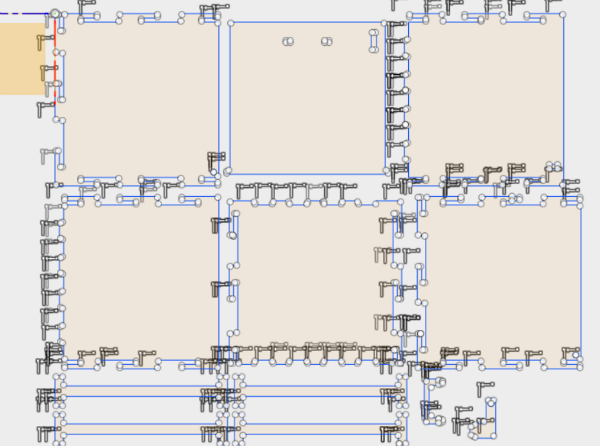

We tested it with basic squares and circles, and the RPM has been fixed and the feedrate has changed.

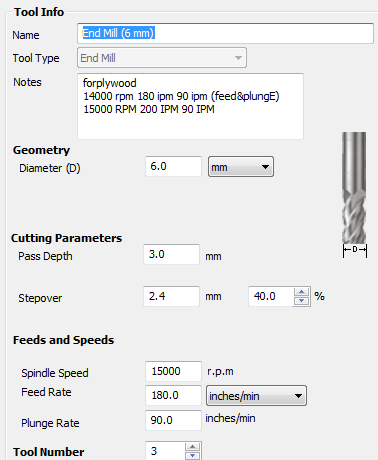

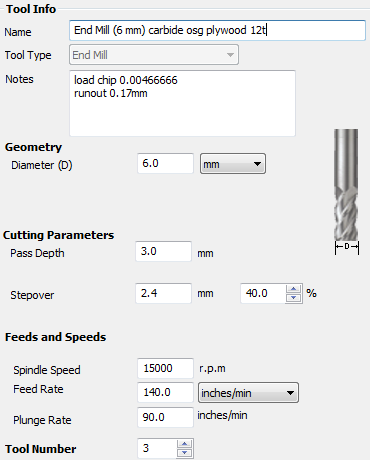

The set values of the program set by the instructor are as follows.

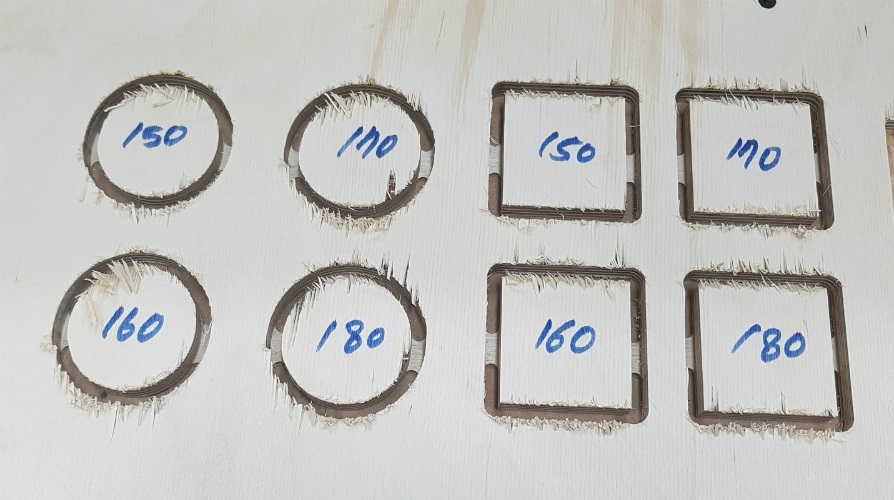

However, this plywood was much more difficult than thought, and the grain came out more than other trees.

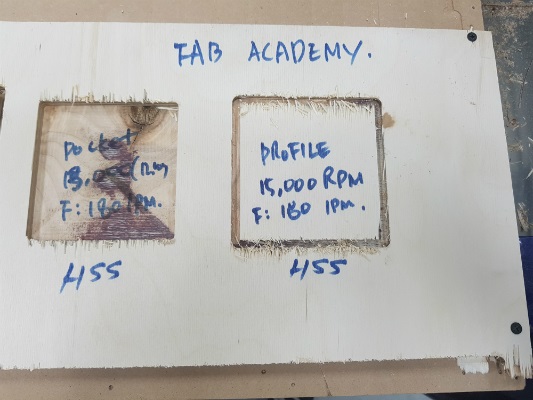

It is a comparative picture of pocket and shaved profile.

pocket went down the RPM to see the difference in grain.

I can see that the grain is less than the profile and the section is smoother because I lowered the RPM.

I then measured the runout and originally had to be 10mm or more.

However, the value of runout could not be obtained because it was measured to be less than 10mm.

Because I could hear a little bit of plywood, when I saw it with the naked eye, I thought that it was attached to the sacrifice board,

and proceeded as it was, so endmill had difficulty in measuring it by digging the plyweed diagonally.

I changed the plywood to see the difference with the other plywood and then fixed it firmly and proceeded.

This is a picture of the result, but the grain was sharply reduced compared to the plywood before cutting,

particularly compared with the feedrate of 140 inches / min, it was very neat and I had to trim a little.

2.Making something big

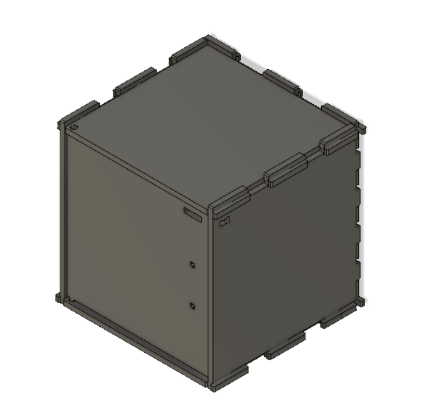

The locker I made this week was made with a locker because I did not have a personal locker in the lab.

|  |

|---|

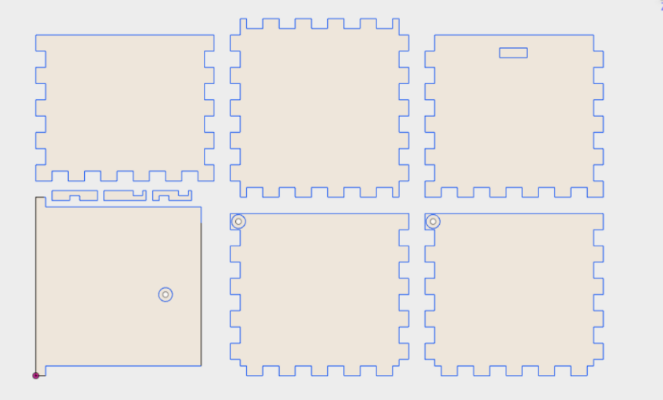

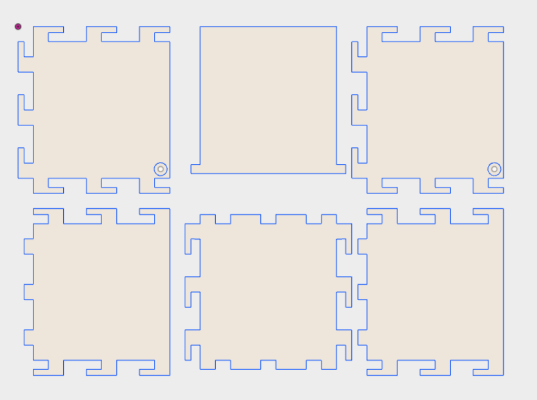

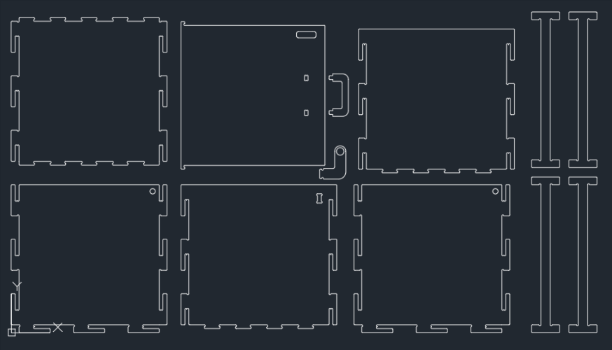

Two prototypes were made with a laser cutter, one of which is a simple joint and the other is a slide joint.

|  |

|---|

After choosing the model, I chose the second choice because it would be a little stronger if I used various joints.

I tried assembly at Fusion 360.

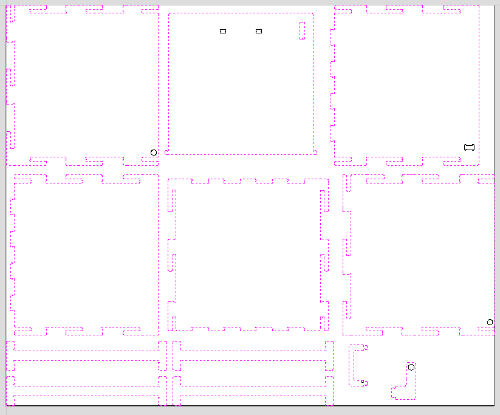

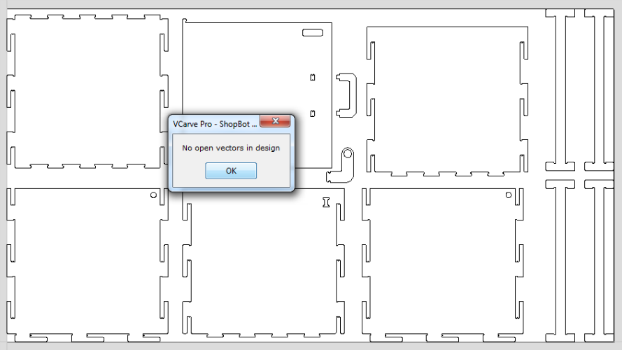

I then tried to run the program to use the CNC, but there was a problem.

I used the function to show an open vector in the program, all the parts are openvector.

So, after using 'join', autoCAD tried to check if the parts are connected without disconnecting them, but it is not connected.

I tried some solutions on the internet and tried to save it as dxf using another 2D program.

So I saved in dxf using inkscape and opened it again with autoCAD, but the same problem happened

Another method was to use the 'plane' function in fusion, which eventually failed.

As a result, I solved the openvector problem and solved the problem by redrawing the parts.

If you painted the parts, you could use 'join' function of autoCAD and make a final check in the CNC program.

|  |

|---|

The file that resolves the problem.

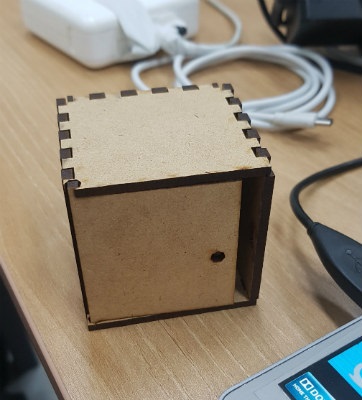

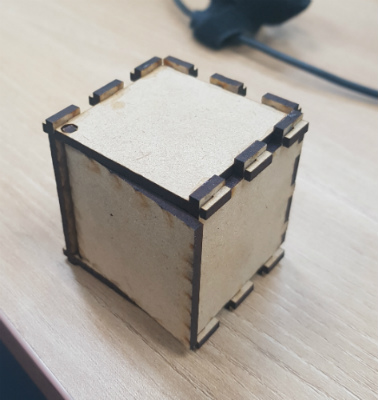

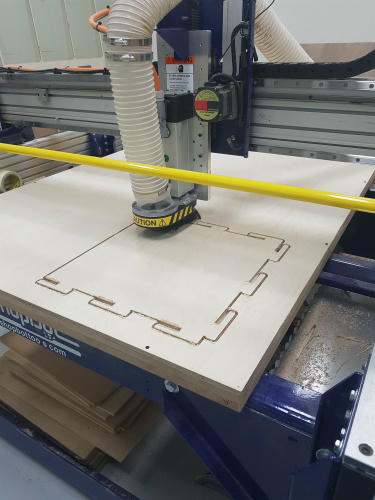

I finished the file and I cut it with cnc and decided to assemble it.

It was nice to use cnc, but it was a big problem.

When fixing the wood, the center was not fixed, so a step occurred, which made the joints too narrow and the assembly became difficult.

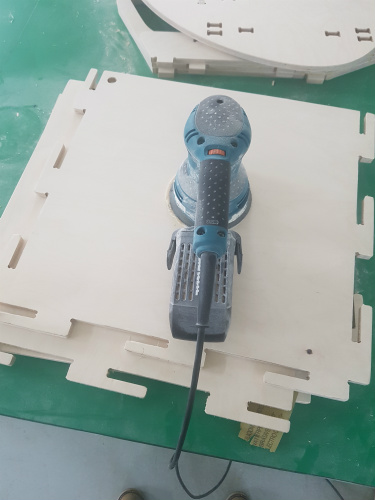

I got advice from an instructor and classmate and found a solution.

It is a way to shave off enough to get into the seams when sanding.

It was very hard to do, but it was very nice to be finished.

It has since become a warehouse.(It looks very dirty..)

You can download my work here

zip file download