|

|

|---|

Assignment |

Final Project |

About Me |

|---|

Week 17

0.Assignment

Design and produce something with a digital fabrication process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it. Possibilities include (but are not limited to) composites, textiles,

biotechnology, robotics, and cooking.

1.practice

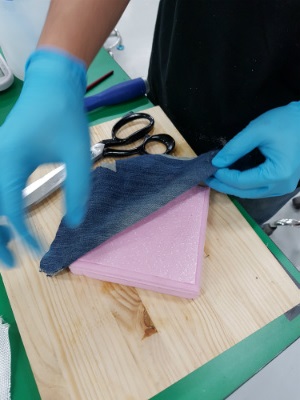

What we did was a composite, so we did not know about fiberglass lamination,

so we decided to try and learn about composites with instructors.

After making a basic frame, we made a composite by putting the gesso on the floor,

and edge so that the frame and composite did not adhere.

The materials used are jeans and glass fiber,

My stacking order is glass fiber - jeans - fiberglass - jeans.

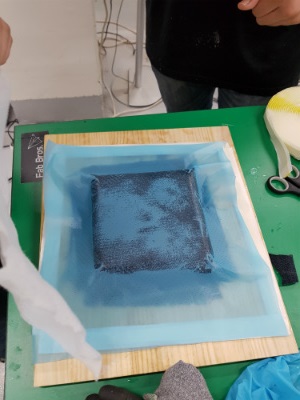

Then we made another to use the vacuum pack, the order of which is jeans - fiberglass - jeans - fiberglass - jeans.

When making the vacuum, use a vacuum cleaner instead of using other equipment.

I finished the composite and checked the result, and according to the instructor, it was very hard without bending if it was well done.

But what I have made is somewhat curved in the middle, according to the instructor,

I did not see the process properly, but when I put the epoxy on it,

I did not have a proper amount of it, so it was not hard but bent.

Also, I checked the result of using the vacuum pack, and it was very hard and unbent.

2.Make something

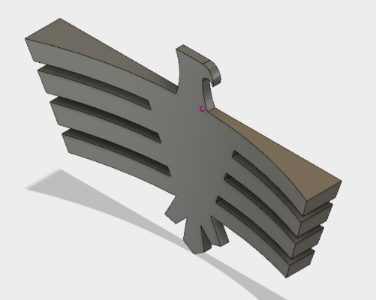

At first I decided to go ahead with the composite by thinking about the shape of an eagle.

I used Fusion 360 to take shape and then cut the mdf with a laser cutter,

I had a mixed problem so I surely failed.

My problem was that I had misunderstood the composite from the start, so I sought advice from the instructor,

and I looked at how the other Fabs people did it.

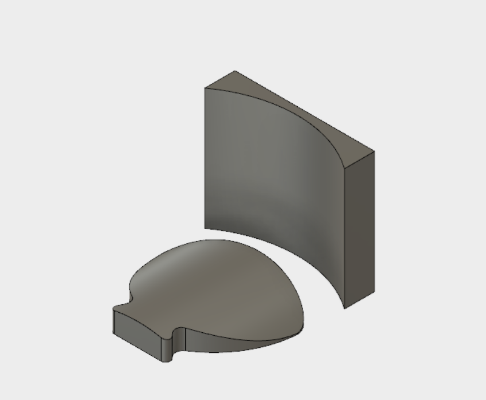

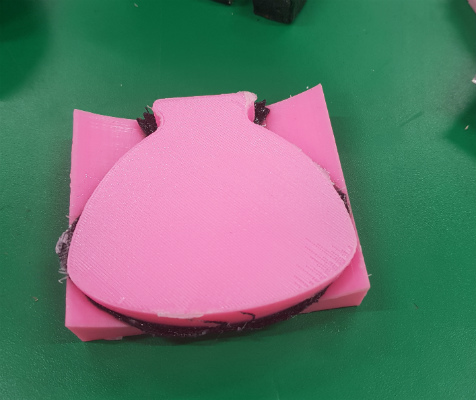

After that, I decided to make a shell shape to make it as easy as possible.

I used a 3d printer to make both sides. The left side was PLA and the right side was ABS.

The ABS was shrinkage and cracked, so I made only PLA.

I used the clamps to apply the pressure so that the desired shape could be obtained,

but it was difficult to detach the epoxy by using it more than necessary.

This was done using Instructor's 3D printer and when I proceeded to do it,

I cut the shape of the material as closely as possible.

After that, I used Hammer and Hera to separate it!

You can download my work here

zip file download