WEEK 17 - WILDCARD WEEK

Assignment

group assignment:

-produce test coupons for your composite fabrication process(es)

Here is the link to Group assignment.

individual assignment:

-read the safety data sheet (SDS) and technical data sheet (TDS)

for the resins that you're using

-design and fabricate a 3D mold (~ft2)

and produce a fiber composite part in it,

with resin infusion and compaction

COMPOSITE

I tried composite.

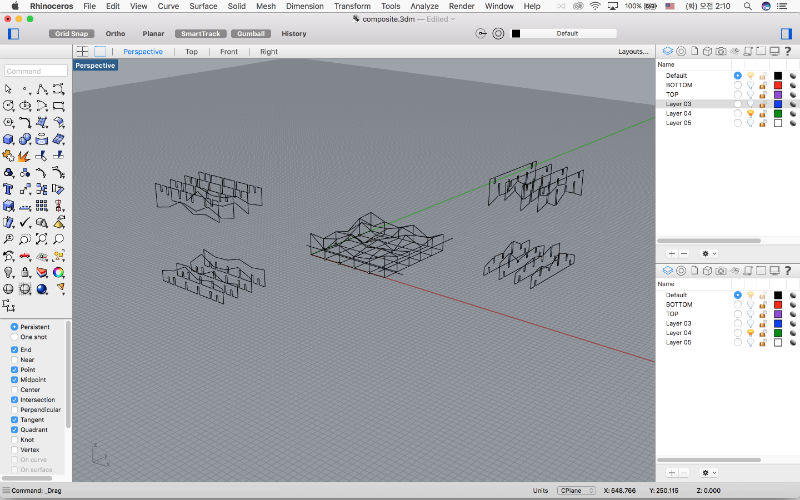

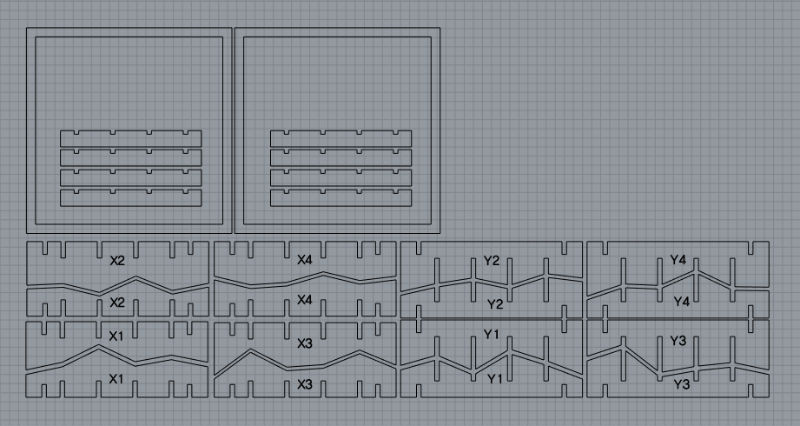

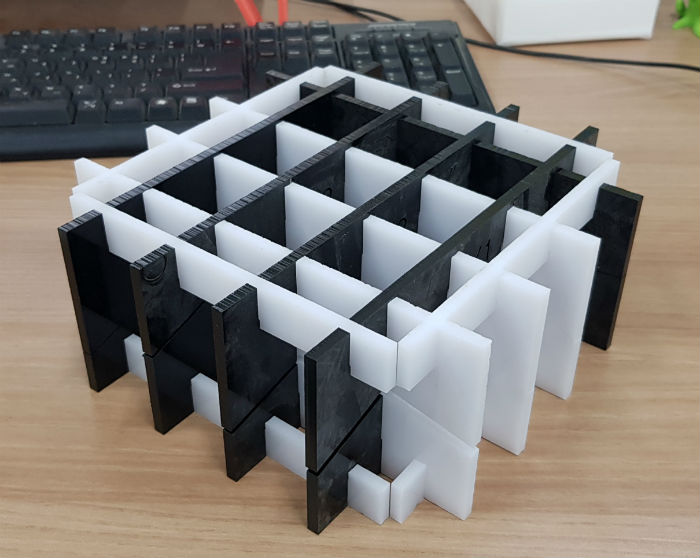

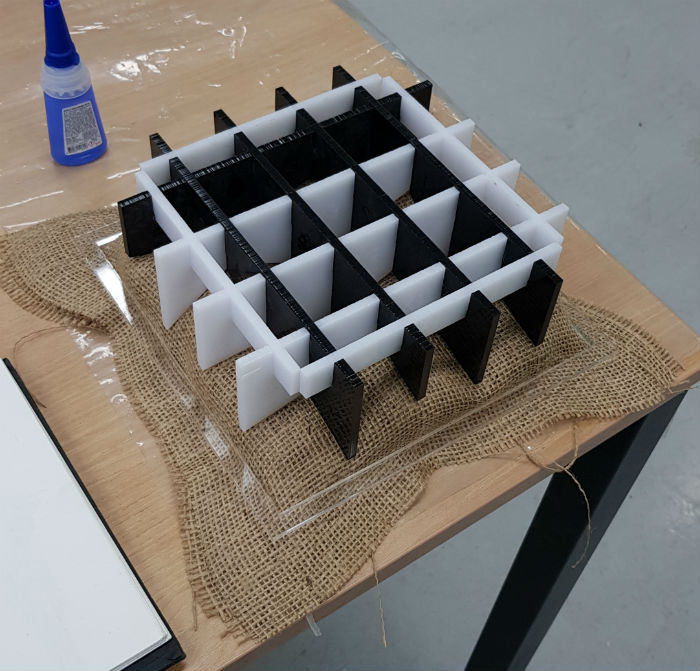

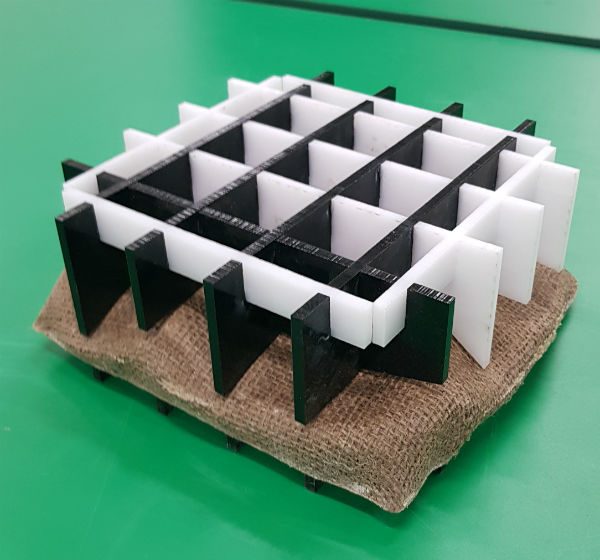

I made template with laser cut acrylic 5t. I made kerf and press-fit that has different height at each intersection and size 200*200.

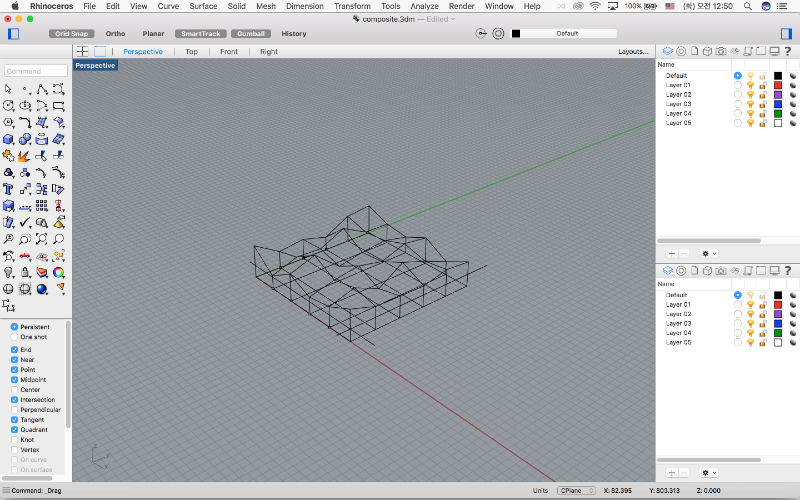

And I made bottom and top with the same surfaces to give pressure to composite.

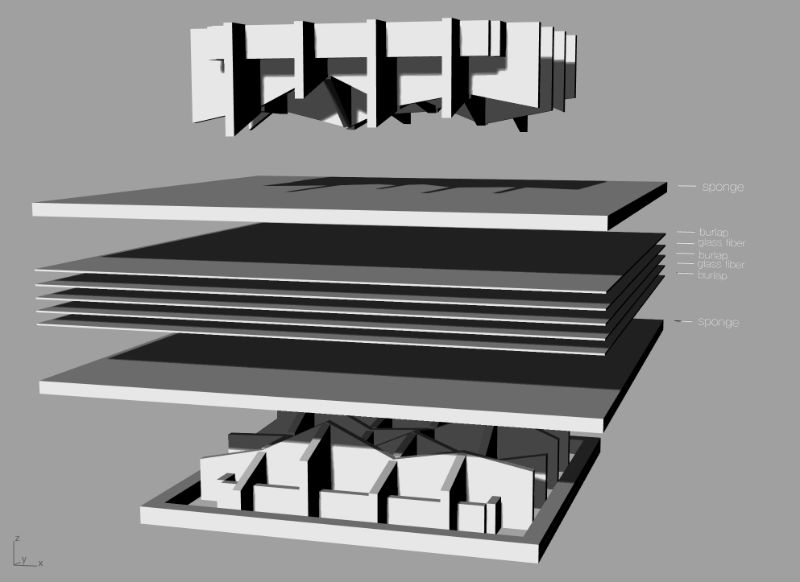

When I give pressure to them, pressure will be on only at the template. It’s too tiny so I used noise absorbing sponge at the both side to give pressure on every surface.

I drew bottom part like this and the top part. And I made square rim to hold extra part of composite.

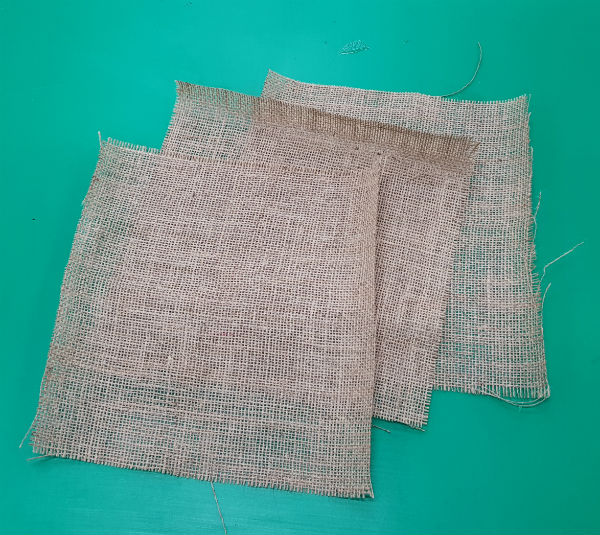

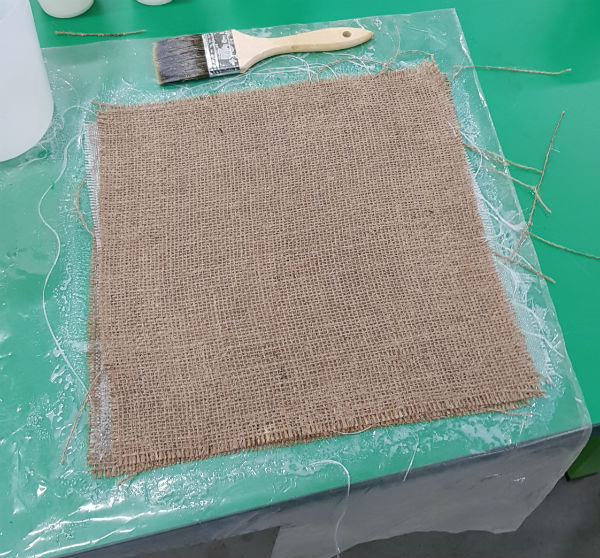

Materials are resin and 2 glass fiber, 3 burlap. And layers like this.

LASER CUT

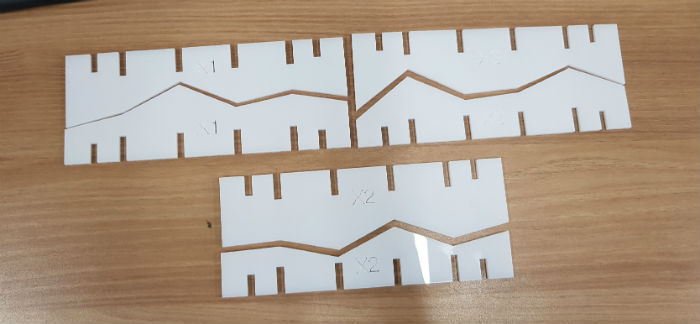

Laser cutting paths

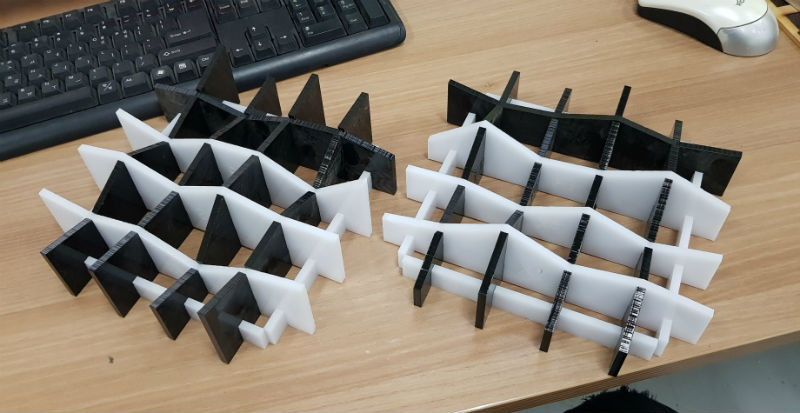

Cutting was fine and I assembled them.

two part were fit well.

And I put some instant adhesive to hold tight.

COMPOSITE

We used this epoxy. and here is the site we bought.

And, here is the data sheet.

I rehearsed like this without sponge.

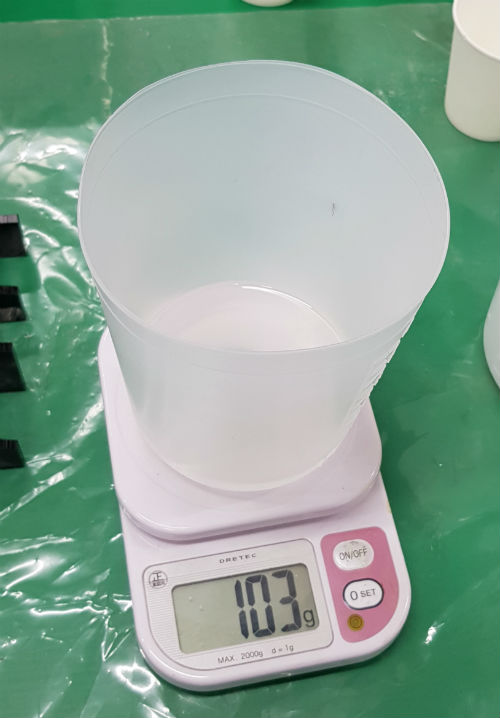

I used this resin and its mix ratio was 100:13 by weight. First I made 113g but it was incomplete enough to apply 5 layers. So I should make 113g one more time.

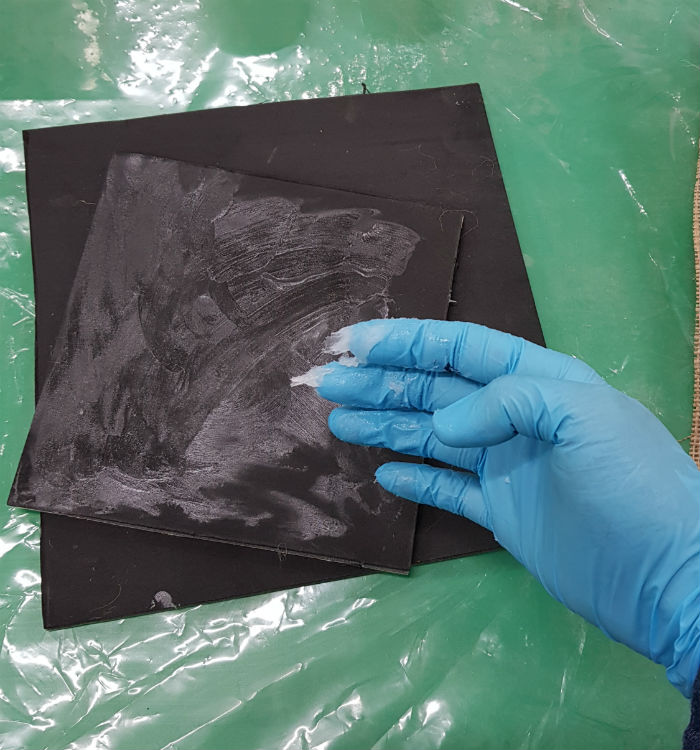

Its pot time was 30minutes and cure time is 12hours. Before mixing, I put baseline on sponge and release spray to acrylic.

Mixing resin for about 5minutes and applied resin with brush on the first burlap. And repeat for glassfiber and another burlap. after 5layers done.

I put sponge on bottom template and place composite on it.

Then I put square rim and another sponge and acrylic top part.

Then I put two wood and clamped them.

demolding

Epoxy resin sticked to MDF. so i cut it with the Dremel.

I bought these stuff to out side and get safty shield, gloves and suit.

i put cutting tool. and start cutting.

After cutting done it looks fine and sponge was demolded well.

and also output fits well to templetes.

Here are my works.

Download