# author : sunghyun-an, seunghwan-ji

## Documentation

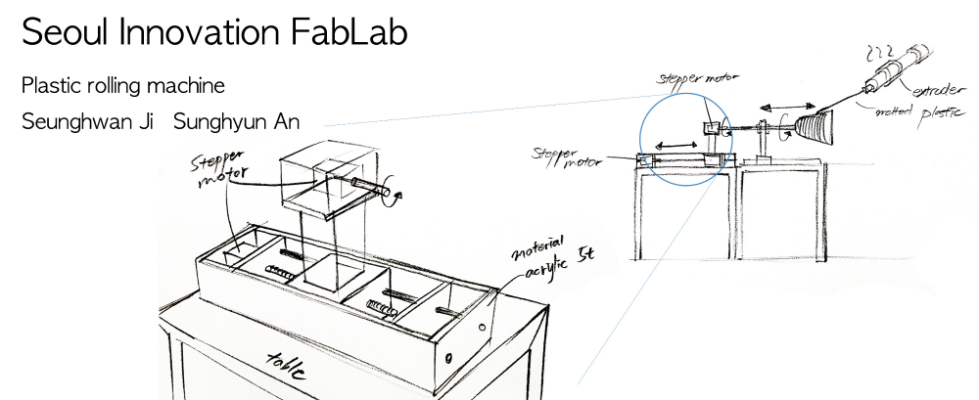

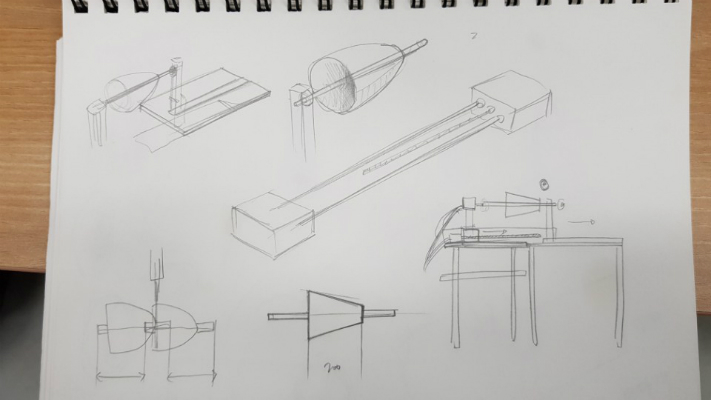

It is a draft idea written by seunghwan.

Described roughly how it works.

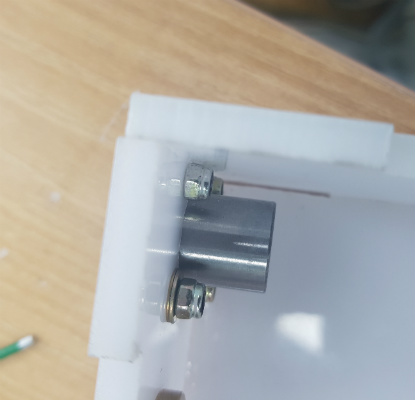

Parts entering both sides of the body did not collide with the washer.

I had to remove the washer and assemble it.

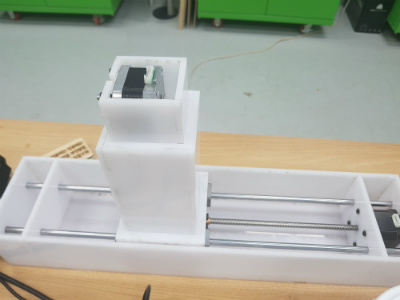

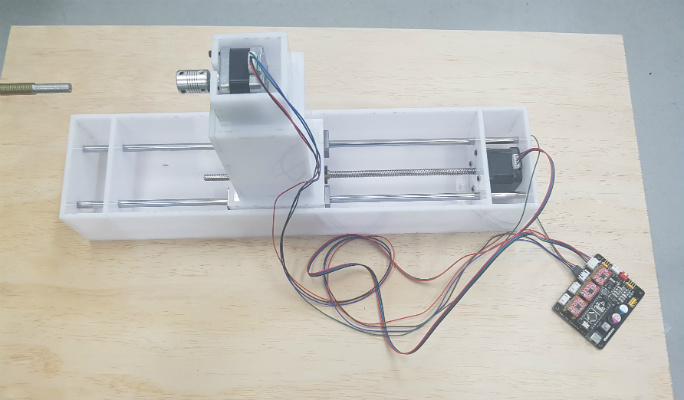

It is the appearance after the first assembly is completed.

We turned the motor by hand and confirmed that it worked well.

After the upper structure is assembled, it is bonded.

After bonding the upper structure, it was turned by hand.

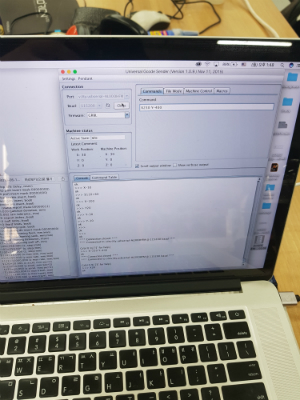

We connected the cables to the stepper motors to use the GRBL.

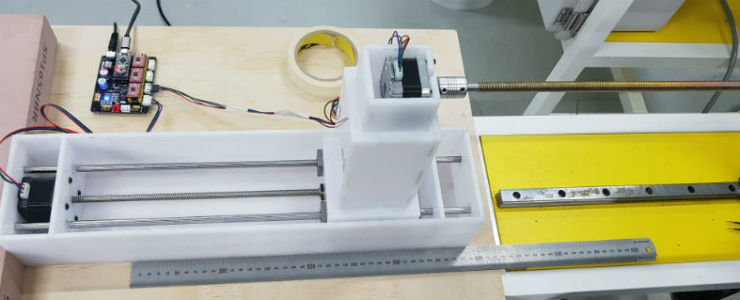

The extruder is placed parallel to the X-axis and what is visible behind the machine is the wood left to prevent it from being pushed back.

The polishing rod could not be fixed and was adhered using glue gun.

The material used will be pellets and will crush the recycled plastic.

We're preheating the extruder to melt the plastics, and we have been learning about the GRBL command.

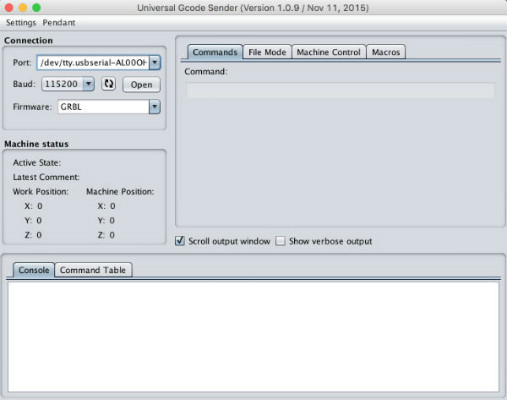

It is GRBL window and can command by typing command in Cammand slot.

It is in operation.

Many plastics are used to find the optimum value.

Not a joke.

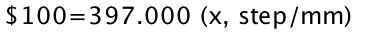

Meanwhile, I found an optimal value for the X value and applied it.

<br>

We tried to shoot it after applying it.

Finished!

We connected the lamp with the project name and it had enough shape to attract admiration!

<br>

# Watch the video

<iframe src="https://player.vimeo.com/video/270080437" width="640" height="360" frameborder="0" webkitallowfullscreen mozallowfullscreen allowfullscreen></iframe>

<p><a href="https://vimeo.com/270080437">sifb_mtm</a> from <a href="https://vimeo.com/yongwoosong">Seoul Innovation Fab Lab</a> on <a href="https://vimeo.com">Vimeo</a>.</p>