## Characterize the specifications of your PCB production process

# Author : seunghwan-ji

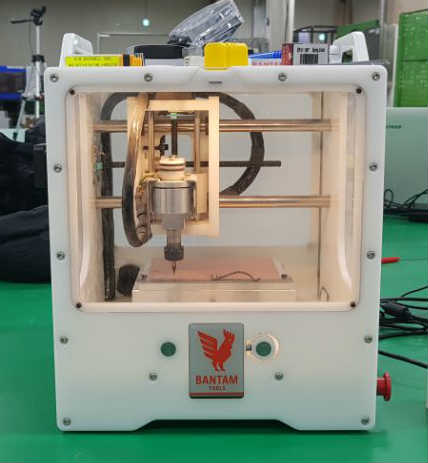

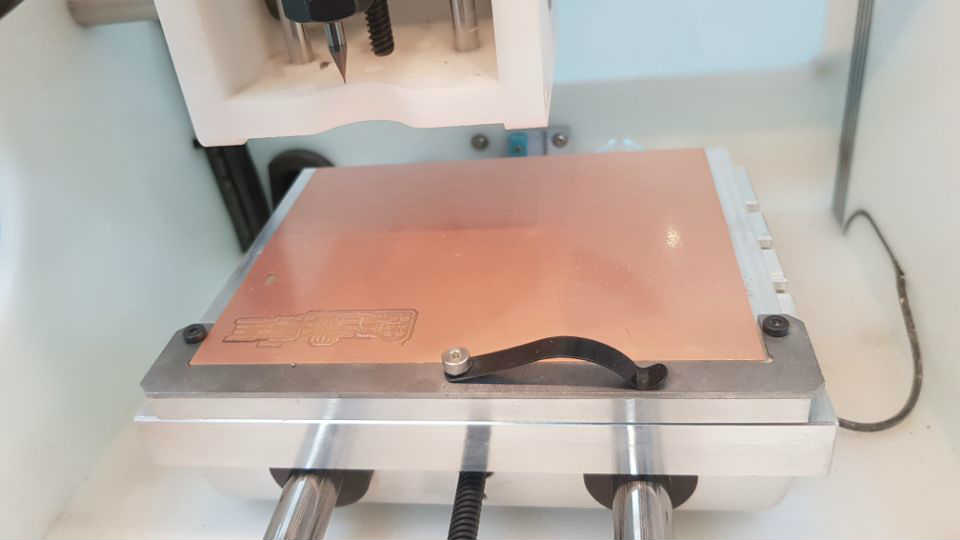

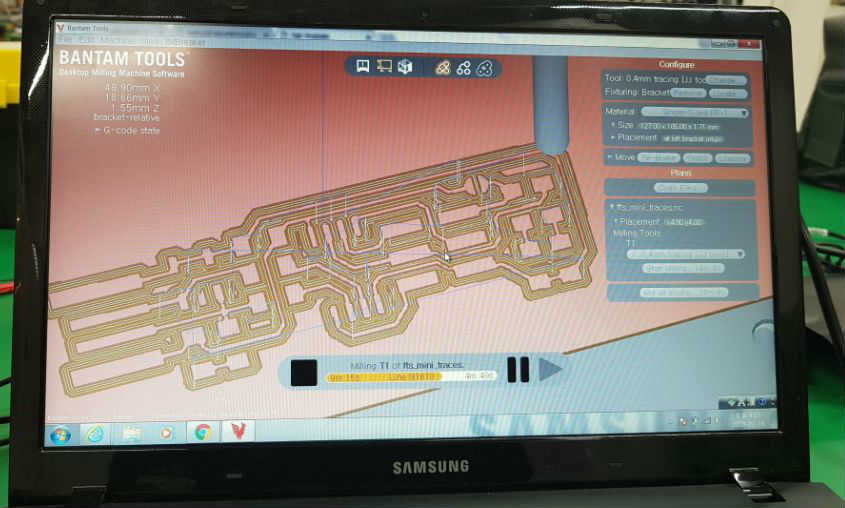

This is pcb milling machine we use. It’s name is BANTAM now, which is other mill before.<br>

Extensions supported by BANTAM are EAGLE (.brd), Gerbers, SVG (.svg), G-code (.nc, .tap, .gcode).<br>

different to other milling machine like Roland, it has electronic tool length measuring function.<br>

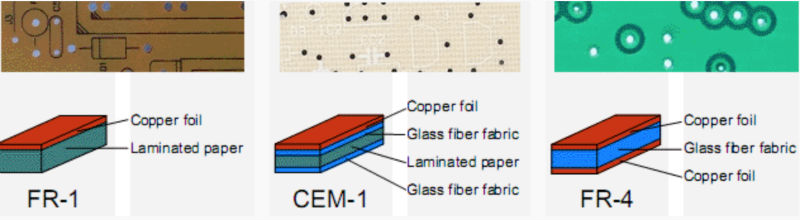

This is the material we use it called FR1.<br>

It has thin copper on the top to flow electricity.<br>

And phenolic paper under copper foil.<br>

We used double sided tape to secure copper board to sacrificial bed.<br>

FR4 is double-sided copper board and it has glass fiber fabric between copper foils.<br>

It’s stronger to heat than FR1 but you should be careful to not inhale glass fiber dust.<br>

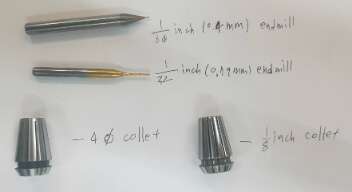

These are tools we use for milling PCB board.<br>

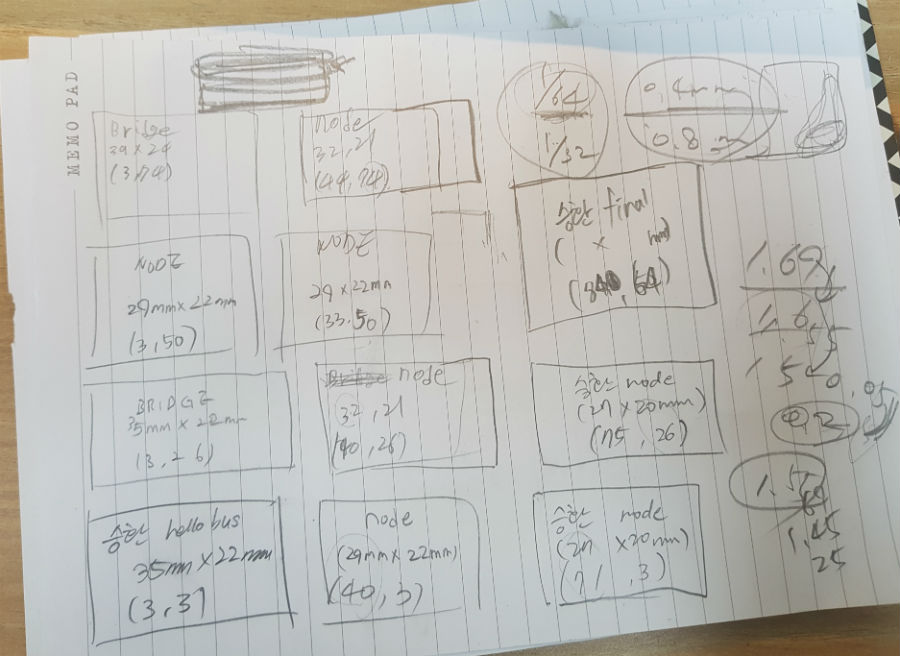

We use 1/64inch end mill to cut trace and 1/32 inch to cut outline.<br>

And these endmill have different shank diameter.<br>

we should use proper collet to each shank diameter to hold the tool tight.<br>

And cut length is related to cut depth. We should use longer tool than cut depth.<br>

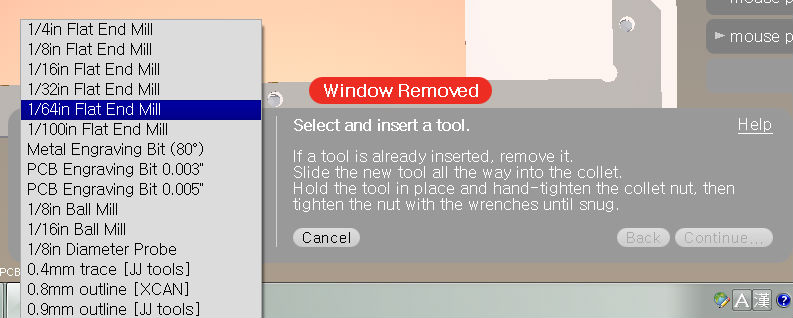

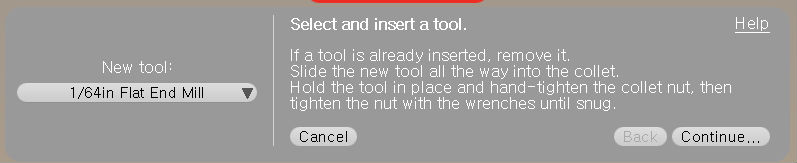

When we set tool on the machine we should measure the tool length.<br>

And this process is essential every time you change the tool.<br>

When we change the tool and set tool on program, it automatically start tool measuring.<br>

It moves to right part of sacrificial board and slowly goes down.<br>

When the tool touches the board and electricity goes though and stop.<br>

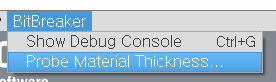

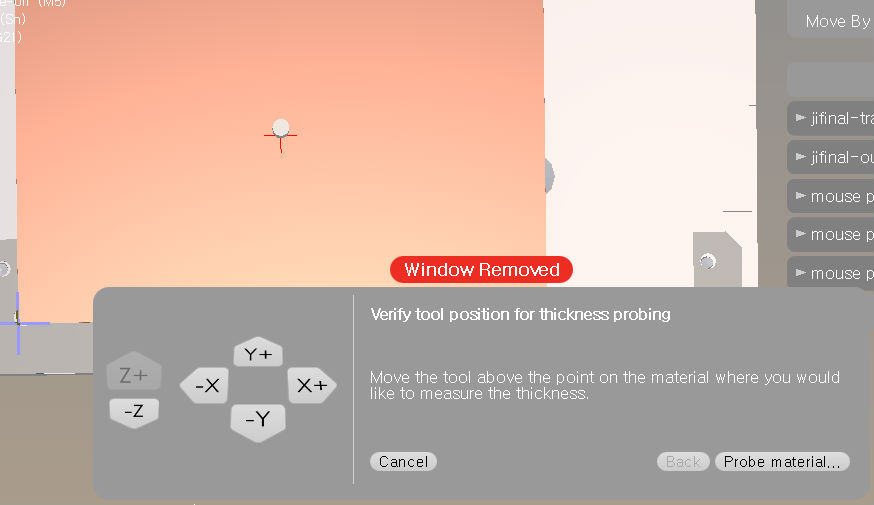

Each material has slightly different thickness.<br>

So we should measure material thickness using Bitbreaker tool.<br>

When we push Bitbreaker, we can set the location.<br>

Measuring the part you will cut is better because FR1 board has slightly different thickness on each part.<br>

There is black metal clip. When measuring material thickness clip should be on the material to flow electricity though the copper surface.<br>

When we open .nc extension file created by fabmodule program show simulate image.<br>

And we can set placement avoiding used part. So we left this paper beside to machine.<br>

So that everyone using machine can set the unused placement.<br>