## characterize your laser cutter, making test

# Author : seunghwan-ji

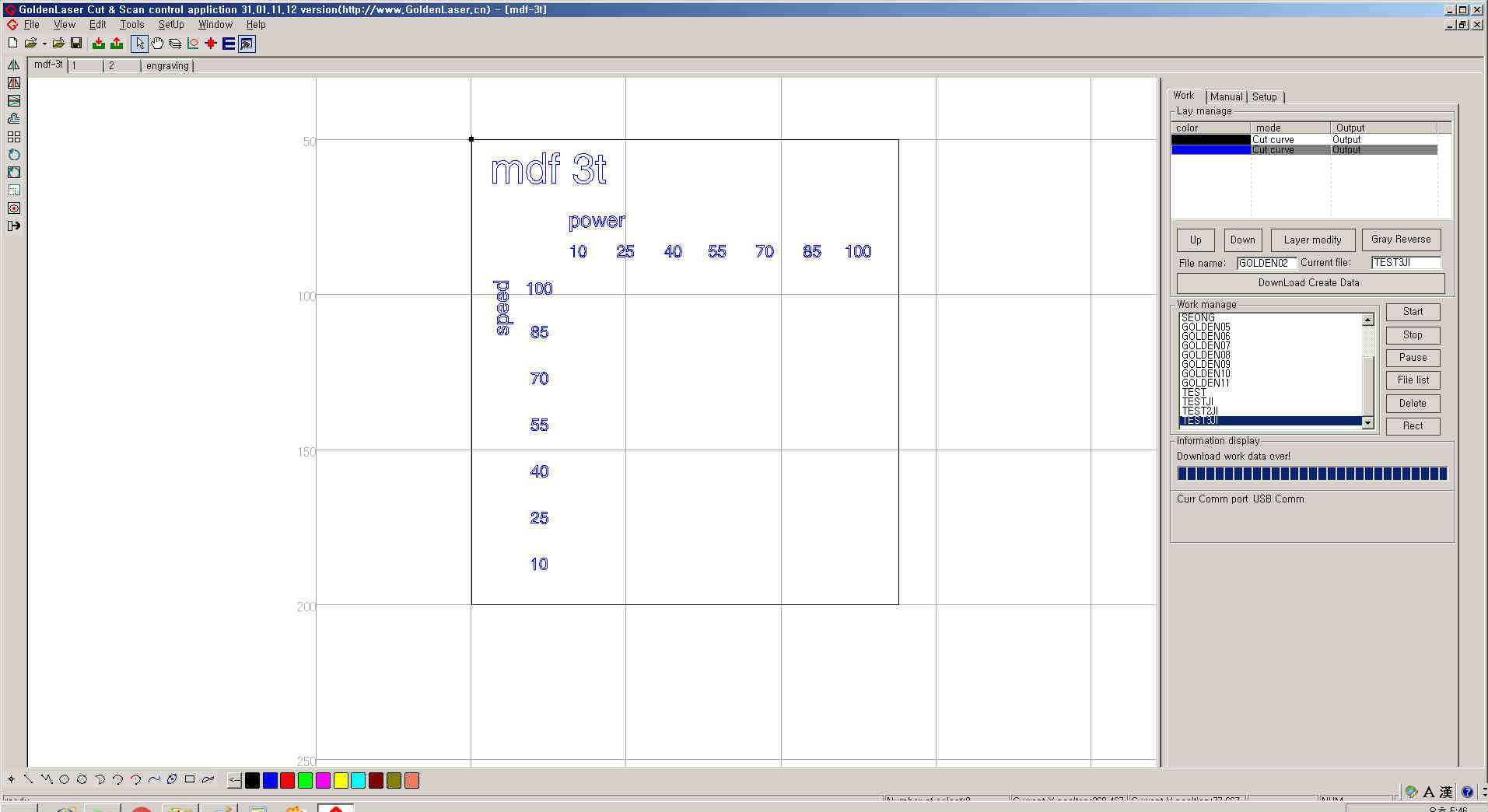

This is our laser cutting machine that we use. K2C-X which is local brand. It's software is golden laser cut&scan control application

It shows how we set the laser height.

Put acrylic cylinder on top of the material and release bolt to move the laser machine head gently. <br>

You should remember to fasten to fasten the bolt.

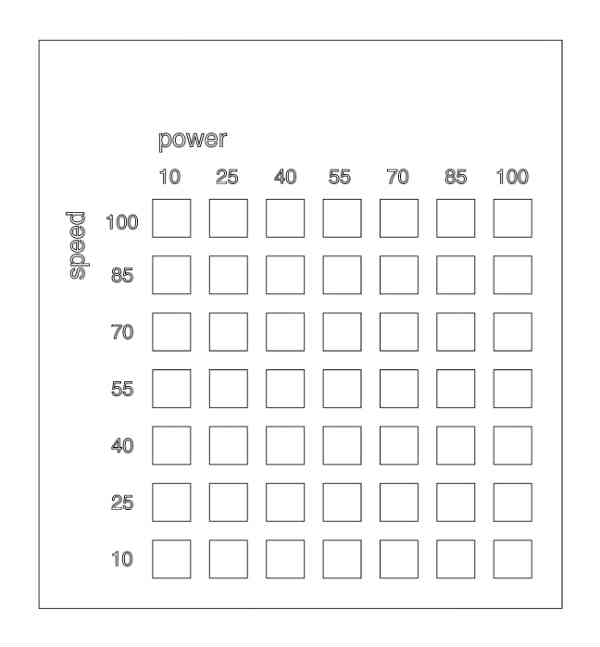

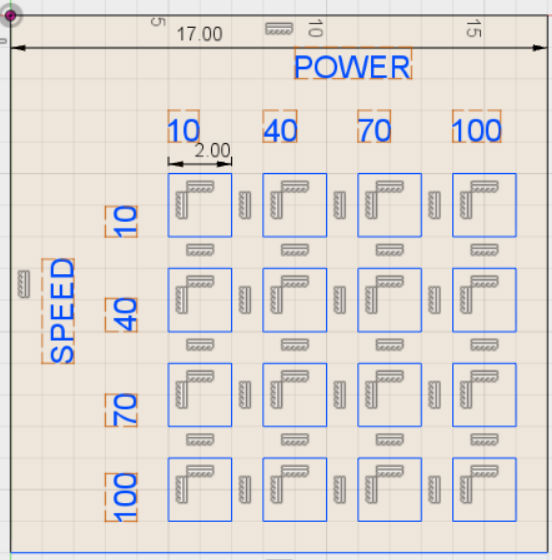

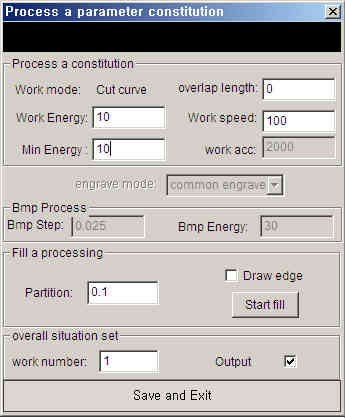

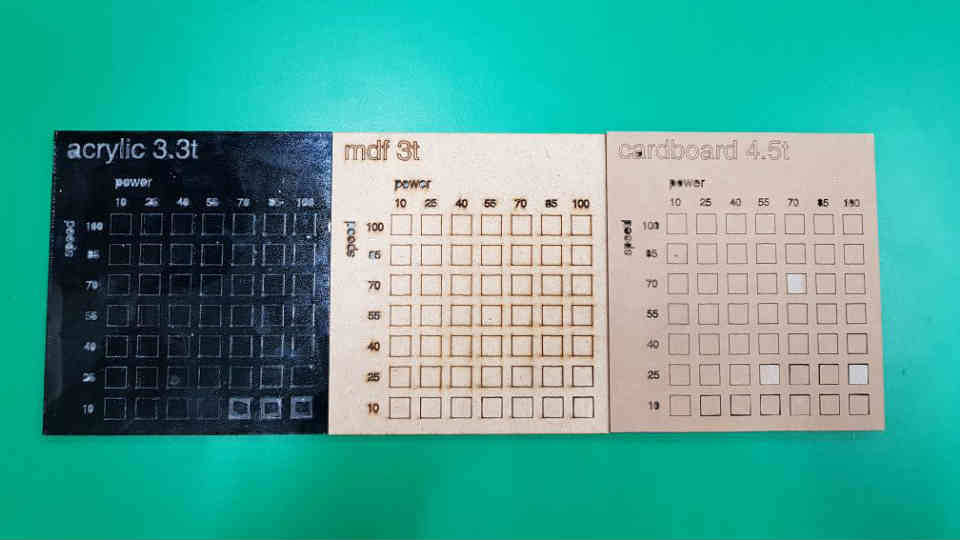

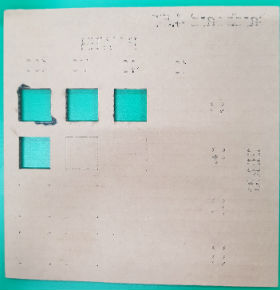

We draw testing template using Rhino and Fusion 360 like above to measure the kerf value and to determine how power and speed values affect the outcome.

Out test materials : <br>

acrylic 3.3T, MDF 3T and corrugated cardboard 4.5T <br>

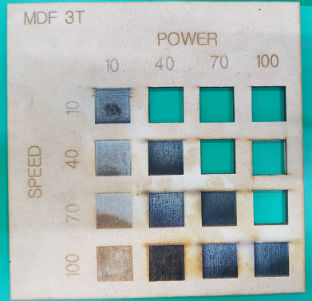

Seunghwan tried different cutting values and Sunghyun tried cutting and both engraving values. <br>

These are our results.<br>

Ideal values for cutting acrylic 3.3T is 10/50<br>

Ideal values for cutting corrugated cardboard 4.5T is 30/60<br>

Ideal values for cutting MDF 3T is 25/80<br>

Even at the same power, they didn't get cut off at faster speeds. <br>

we found out as the power gets higher , the 'KERF' value increases

Our corrugated cardboard got burnt at the back with value 10/100.

And engraving depth is getting deeper. <br>

Now we understand why it is (almost) impossible to make right depthness with laser