## Review the safety data sheets for each of your molding and casting materials,then make and compare test casts with each of them

# Author : seunghwan-ji

We tried as many material as possible to make mold and cast something like silicon, urethane resin, gypsum plaster and colorants for urethane Rubber. <br>

And also vacuum degassing. <br>

Every materials are from Smooth-on except gypsum plaster.<br>

# Silicone rubber

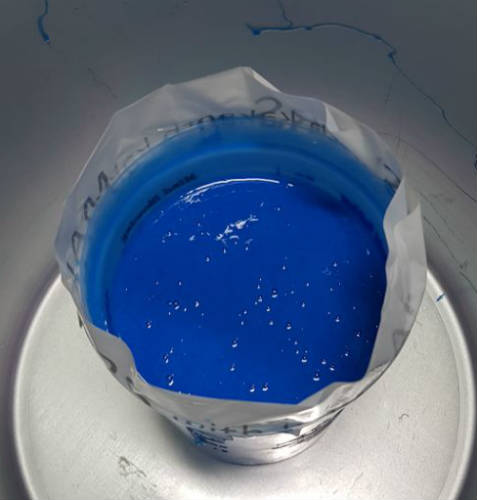

** MOLD STAR 30 **

https://www.smooth-on.com/products/mold-star-30/ <br>

Mold star 30 is blue silicone. It’s mix ratio is 1A:1B by volume. <br>

And it’s pot life and cure time is 45minutes and 6hours each. <br>

Output was flexible and high resolution.

<br>

** MOLD STAR 20T **

https://www.smooth-on.com/products/mold-star-20t/ <br>

Mold star 20T is translucent silicone. It’s mix ratio is 1A:1B by weight and volume. <br>

And it’s pot life and cure time is 6minutes and 3-minutes each. <br>

Output was more flexible than Mold star 30. And it has high resolution too. <br>

Here’s the Safety data sheet for these two materials. <br>

https://www.smooth-on.com/msds/files/BD_DS_Eco_Equ_EZB_EZS_Psy_MS_OOMOO_Reb_ST_SS_Soma_Sol_Sorta.pdf <br>

Safety - Use in a properly ventilated area (“room size” ventilation). <br>

Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. <br>

Wear vinyl gloves only. Latex gloves will inhibit the cure of the rubber. <br>

Store and use material at room temperature (73°F/23°C). <br>

Warmer temperatures will drastically reduce working time and cure time.

Storing material at warmer temperatures will also reduce the usable shelf life of unused material. <br>

These products have a limited shelf life and should be used as soon as possible. <br>

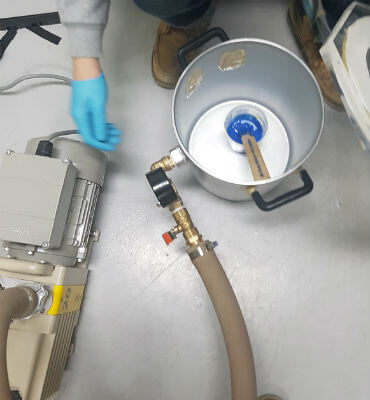

# Vacuum degassing

Degassing is advantageous for high quality of casting material removing bubble inside the material. <br>

But it can’t be done if material’s pot time is short. <br>

So we tried vacuum degassing on Mold star 30 that has 45minutes pot life. <br>

After mixing 2 parts and mix with wood stick thoroughly, put mixed material cup inside the degassing machine. <br>

Then, turn the lever to make vacuum.<br>

Material will be bulge up removing bubbles.<br>

Degassing until material shrink, then we can get degassed material.<br>

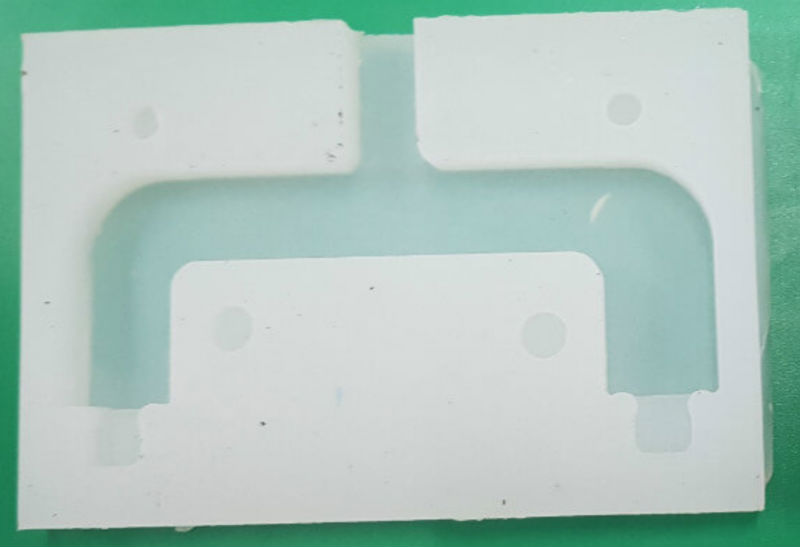

# Flexible urethane foam

** FLEX-FOAM IT-X **

https://www.smooth-on.com/products/flexfoam-it-x/<br>

FLEX-FOAM IT-X is white flexible urethane foam that expand 6times after mixing.<br>

It’s mix ratio is 1A:1B by volume and 105A:100B by weight.<br>

And it’s pot life and cure time is 50seconds and 2hours each.<br>

It is porous material because it expand to make more hard surface we should give pressure to mold.<br>

It expands 6 times by volume but it was difficult to calculate the adequate amount of mixture.<br>

First trial was almost half of the mold. But it expands little bit.<br>

Here’s the Safety data sheet.<br>

https://www.smooth-on.com/msds/files/Flex_Foam-It_Series.pdf<br>

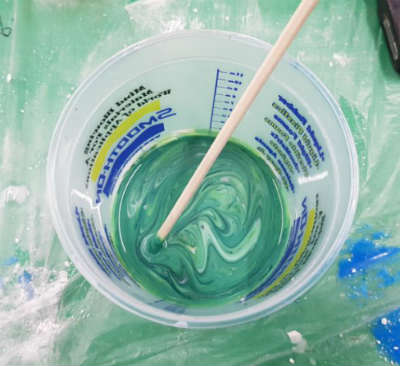

** FLEX-FOAM IT-X with So-STRONG **

https://www.smooth-on.com/products/so-strong/<br>

So-STRONG is liquid urethane colorants. We can put this ratio of between 0.01% - 3% of the total weight (Parts A + B mixed) of the material being cast.<br>

Seunghwan tried yellow and green tint to make light green.<br>

In this case, Seunghwan put generous amount of material and it expanded well.<br>

It has little flexible and sticky surface.<br>

Here’s the Safety data sheet.<br>

https://www.smooth-on.com/msds/files/SO-Strong.pdf<br>

# Urethane

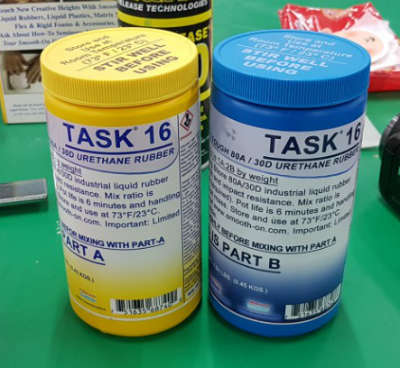

** TASK-16 **

https://www.smooth-on.com/products/task-16/<br>

This material is light yellow color urethane that has little elasticity.<br>

It’s mix ratio is 1A:2B by weight. And it’s pot life and cure time is 6minutes and 24hours each.<br>

On the data sheet, it says the color of material is light yellow.<br>

But the material Seunghwan used was almost brown.<br>

But it cured well. It has hard surface and high resolution.<br>

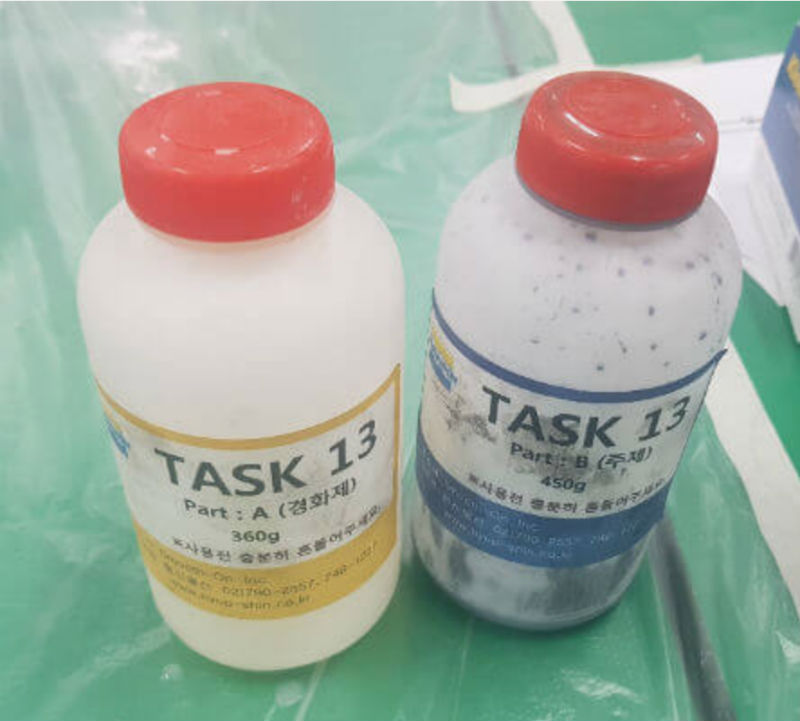

** TASK-13 **

https://www.smooth-on.com/products/task-13/<br>

This material is black color porous urethane that has little elasticity also.<br>

It’s mix ratio is 100A:120B by weight.<br>

And it’s pot life and cure time is 3minutes and 20minutes each.<br>

Output was fine at the surface that contacts with the mold.<br>

But side and top part have porous surface. And it has slight flexibility.<br>

Here’s the Safety data sheet for these two materials.<br>

https://www.smooth-on.com/msds/files/TASK_13_14.pdf<br>

Materials should be stored and used in a warm environment (73°F/23°C).<br>

These products have a limited shelf life and should be used as soon as possible.<br>

All liquid urethanes are moisture sensitive and will absorb atmospheric moisture.<br>

Mixing tools and containers should be clean and made of metal, glass or plastic.<br>

Mixing should be done in a well-ventilated area. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.<br>

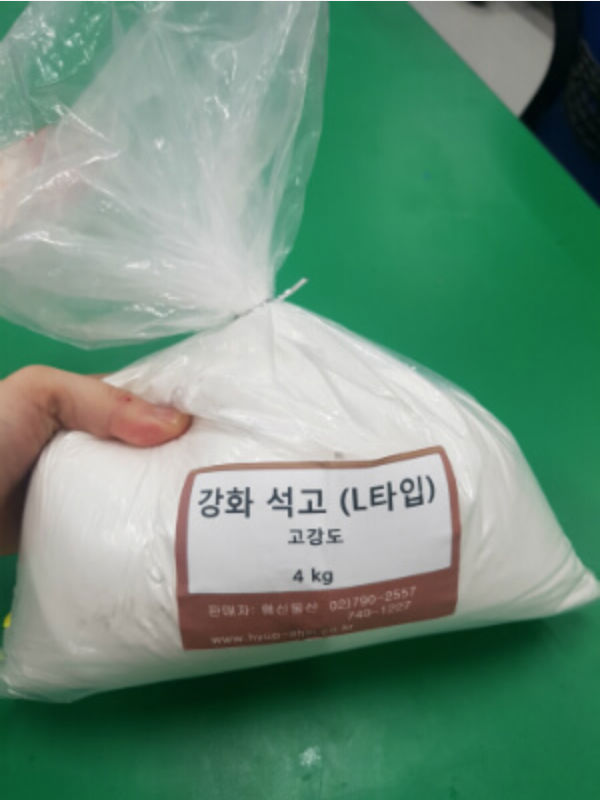

# Gypsum plaster

** Reinforced plaster L type **

Here’s the Safety data sheet<br>

https://images.homedepot-static.com/catalog/pdfImages/99/998d8cb0-b7f8-4d16-a73f-39bfc89b8744.pdf<br>

In the case of this gypsum, the ratio of gypsum to water is 100: 35.<br>

Sunghyun tried coloring with acrylic paint. It cured well and it has really hard surface.

<br>