Week 4

Computer Controlled Cutting

Equipment

Laser Cutter

- Hardware: X Cut 1390, X Cut 1390 M

- Software: Fusion

- Material: 3mm MDF

Vinyl Cutter

- Hardware: Roland?

- Software: Illustrator, Vinyl

- Material: Vinyl sticker sheet

Laser Cutting

Video Tutorial on how to operate the laser cutter in the FabLab Seoul.Finding Kerf

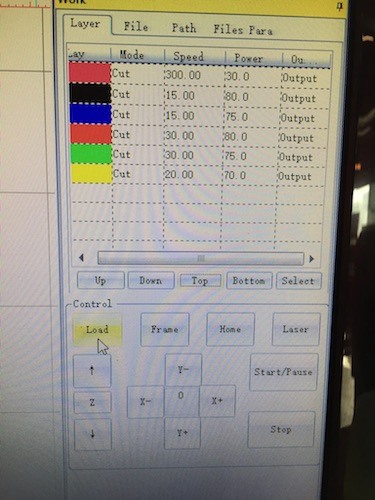

Test Speed & Power Settings

Aim to use minimum power when making a cut.

Optimal settings for cutting 3 mm MDF: Speed: 15 Power: 75

Select vectors and choose the appropriate settings for each one based on whether you want to cut through or do engravings. Group similar cuts by color coordinating them. Sequence the cuts so that inner cuts are at the top of the list ie. Cut from the inside and make your way out.

Try out different speeds & power for your material to determine the best combination. Once finished with your design, upload file to send to the cutter.Measure 9.5 mm from laser

Load the material being cut into the lasercutter. Put the z distance of the laser from the material 9.5 mm as is this is the optimal focal distance of the lens.

Measure frame

Move the laser to the top right corner of your desired frame. This is the origin point. Set Origin point and select frame. If the frame fits within the parameters of the material without overlapping another cut, then proceed with the cut.Estimating Kerf

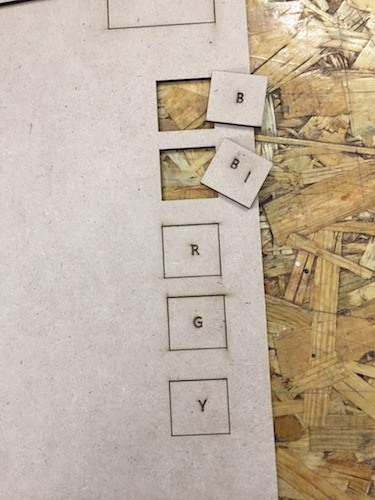

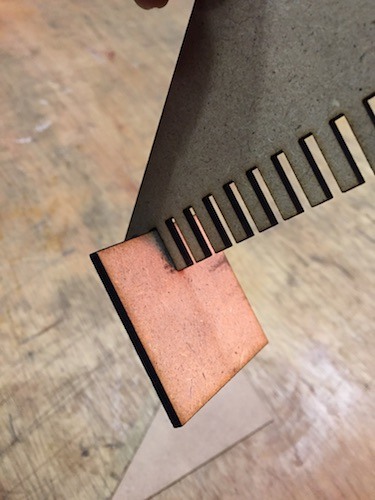

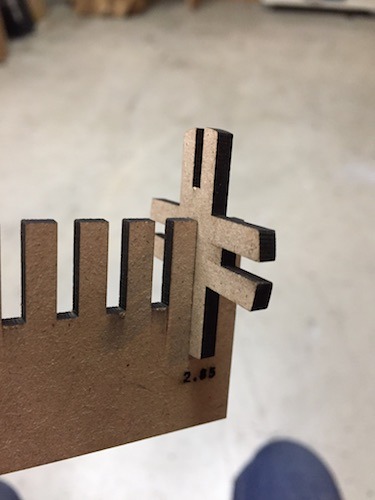

First cut a hole out of the material to take an estimate of the kerf. Outer Dimension of wood piece was 50 mm and Inner dimension of box was 49.75. Estimated kerf at .125 (.25/2).

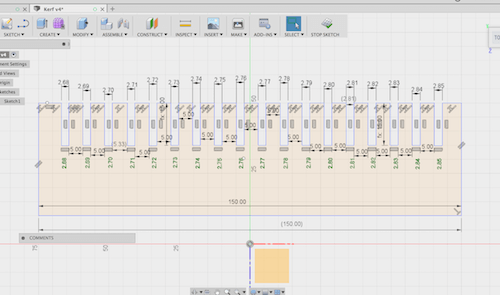

When making test cuts will -.25 as starting point (double kerf) since we will be trimming from both sides. 2.75 and going up/ down in increments of .01 mm.

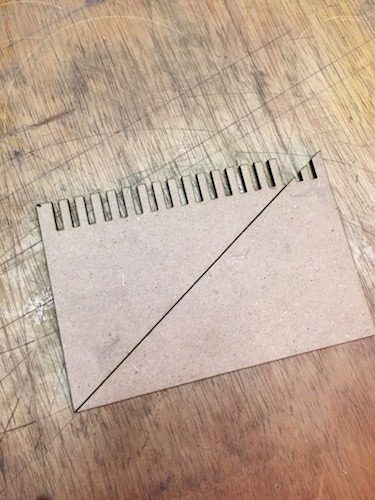

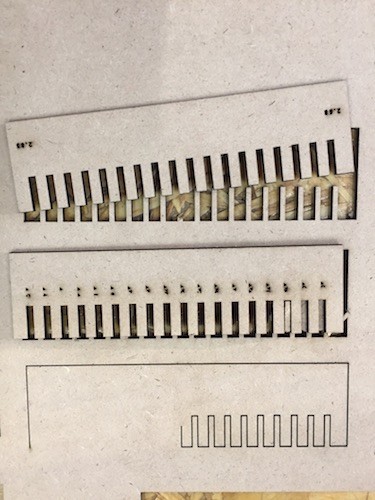

Didn't realize that construction lines from Fusion 360 transferred over to the Laser Works program. Forgot to remove a construction line in the lasercutting program so it made a diagonal slice through the comb.

Fit in around 2.82

I was working with another labmate at the time and we later realized that he hadn't measure the material away from the laser at 9.5 mm. Also I had not been tracking the speed/ power of my cuts when trying to determine the kerf. It was getting late at the lab, so I decided to try the whole process again the next day.

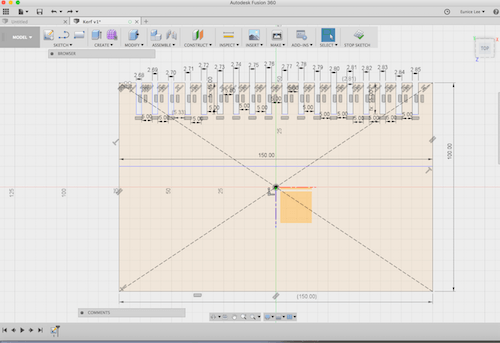

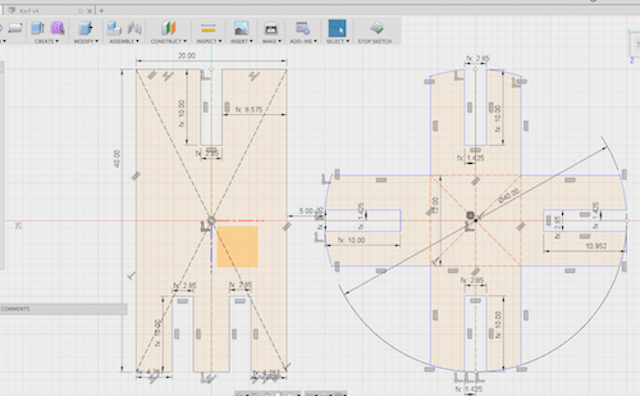

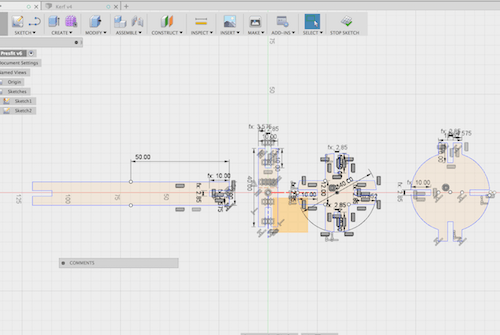

New measuring comb sketch with labels. Note: In order for texts to be read in Lasercutting software from Fusion 360 -> Explode text: Click text, Right click, Explode text

Bottom comb- Forgot to put the engraving settings at top

Middle comb- Laser didn't make clean cut through so had to increase power. Also the text was too small in Fusion 360 (2 mm) to translate well in the laser cutting sofware and didn't quite show up

Top Comb- Speed: 15 Power: 80

Fits well at 2.77

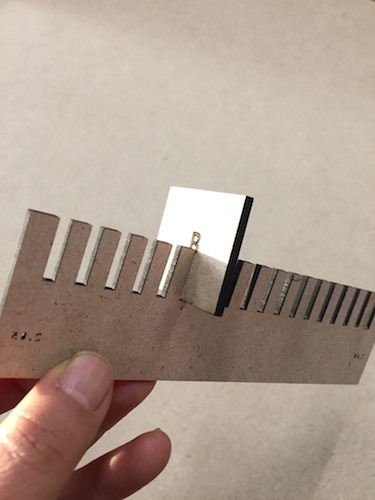

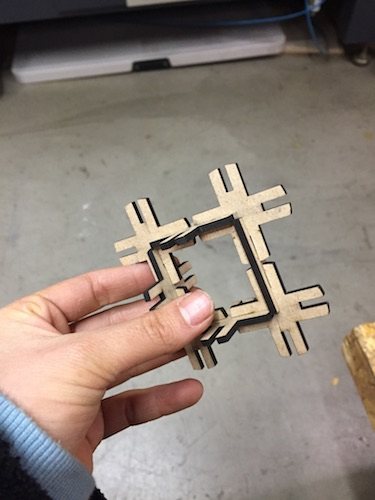

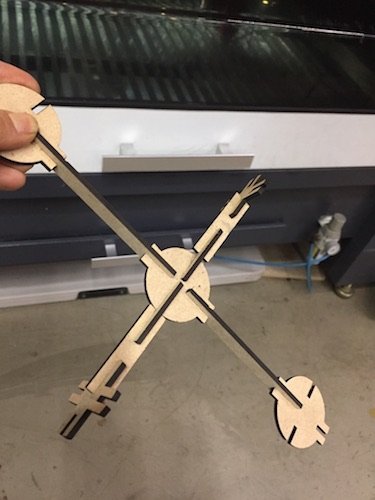

Press Fit Construction

Parametric Design

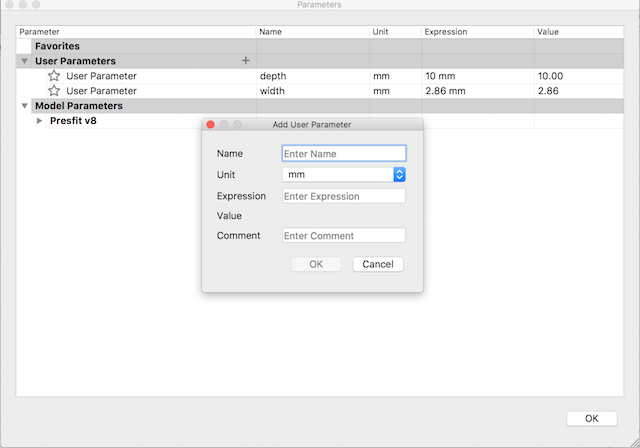

In Fusion, you can assign values parametrically. Select Modify from the toolbar and choose Change parameters.

Fit seemed better suited now at 2.85. Modified parameter settings.

A few pieces weren't holding together, so I took up a notch to 2.86. Seems to be the sweet spot for the 3.0 mm MDF.

Vinyl Cutter

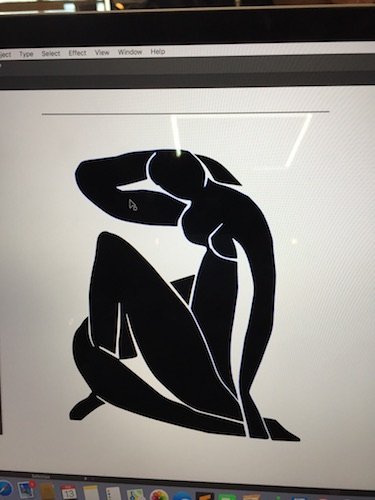

Found Blue Nude painting by Matisse on the internet.Create DXF file using Illustrator

Image trace -> Trace & select Default -> Expand -> Ungroup -> Outline -> Save as DXF

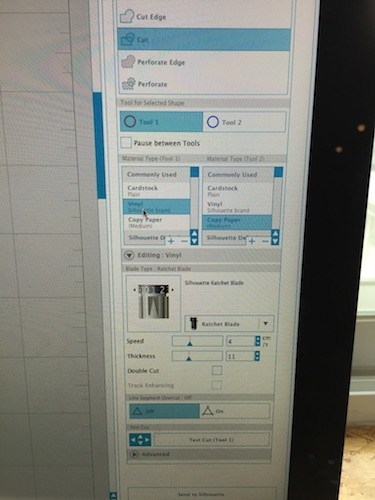

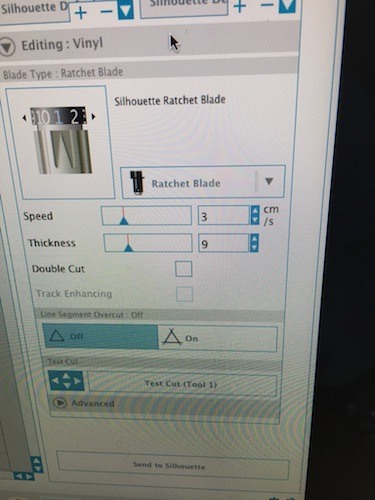

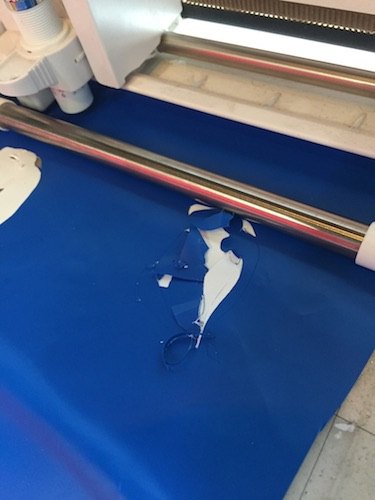

Import DXF file into vinyl cutting software. First test cut with settings & results.

The sticker was all kinds of messed up so I lowered the speed as well as thickness.

Second round of test cut

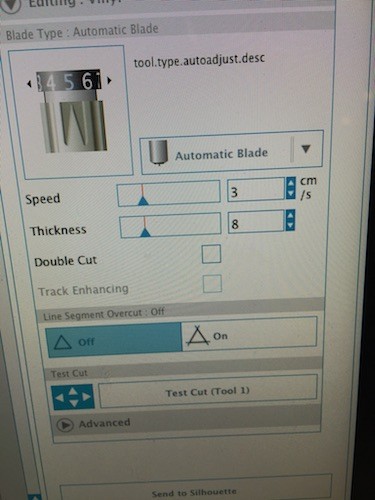

Same results. One of the lab workers walked by and noted that my blade settings were set to ratchet. Should be on auto blade.

Third try

Done

Phone snapped a partial selfie while putting the vinyl sticker on the back of it.