WEEK 18

Applications & Implications

Slow Glass

What will it do?

Slow glass will help people focus on slow, thoughtful breathing to reduce stress and anxiety. For exhalations, the lower portion of the hour glass will get increasingly brighter as it seemingly pours out of the top. During inhalation, the light will dim in the lower portion and appearing to move upward as the top portion gets brighter until it is fully lit. The light simulates both sand moving through the glass and the rising and falling of the breath in the body. The breathing glass is switched on and off by flipping it to the other side.Who has done what beforehand?

There have been a few models of hour glass shaped lamp designs. I found one that has a similar concept of the light moving from top to bottom. This one is nice because you can change the time intervals. Hour Glass Lamp The main difference between the one I will make is 1. the ability to reverse the light 2. the continuous movement of light throughout the glass 3. the dissassociation with time itself. Number 3 is the main one. I want this breathing lamp to have the opposite effect on our relationship with time. THe hourglass is a very literal confrontation with the idea that time is running out. This in itself is usually a source of stress for many of us. The breathing glass is meant to have reverse affect as it is not based on a standardized or traditional sense of time. It is meant to have us slow down and be in the present and continuous moment.I also found that there was a Canadian group that made a Breath lamp. It is a sphere that increases & decreases in brightness to cue breathing. Breath lamp . The have quite a nice design- simple yet effective.

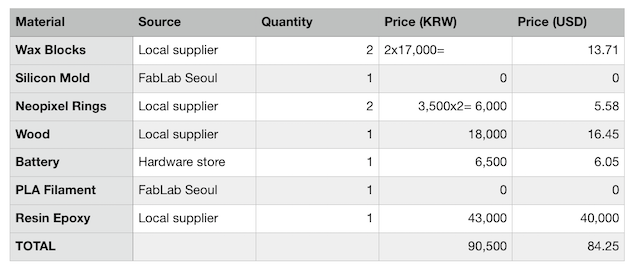

What materials and components will be required?

Where will they come from?

How much will it cost?

What parts and systems will be made?

The lamp portion will be cast in clear epoxy resin, which will have wood composite for bases that house the PCBs & battery. I planned to make a FabKit to be used with the Neopixel rings and the sensor. We found out later that we are not allowed to use FabKits and that we had to design our own boards from scratch.What processes will be used?

3d modeling: Fusion for design 2d: Presentation slide Molding & Casting: Hourglass 3d printing: Hourglass & middle section to house the electronics Electronics Design: PCB Board for input & Output Input: Capacitive Sensor & Tilt switch Output: Neopixel rings Lasercutting: box for holding mold & rings connectors and holding down neopixelsWhat tasks need to be completed?

I changed my idea for the final project pretty late in the course, so I had limited time to get all of the things together for my new design.I'm interested in lighting designs so I had it in my mind to make a nice lamp design. I wasn't sure what the input would be, but since I knew that I would be working with neopixels, I started to familiarize myself with the libraries & codes. I started looking at unique lamps for inspiration and gathered some ideas about design & materiality.

Once I had created a concept for my lamp, I started designing in fusion. The fabrication processes individually will take a long time, so this is something that needs to be done early on. I will first need to 3d print the final hour glass shape to make a mold that I will eventually cast in resin. I will lasercut acrylic so that the lamp can fit inside and I can make a mold with a solid piece. Once the mold is finished, I can cast with epoxy resin.

On electronics side, I need to program the capacitive sensor to have the correct output for the neopixels. At first I was trying to learn to use the accelerometer but I later realized that it was unnecessary for what I wanted to achieve. I just wanted the hourglass to be able to switch on and off by flipping it over like an ordinary hourglass. However, my instructor said that a switch input like that may be considered too simple and to try something else instead. I was really racking my brain about another input sensor that I could use with my glass without it being too distracting to the main concept of the lamp. I thought that it would be nice to be able to control the color in accordance with your mood, so I decided to make a capacitive sensor to change colors. After getting at least the neopixels and capactive touching that I could then try out the tilt switch for the whole design.

After my first cast, I wasn't happy with the results. There were a lot of bubbles and scars and it looked pretty terrible. When I was 3d printing the lamp, I was surprised because I generally don't like the look of 3d printed objects, but I thought that it looked quite good. I tried printing with the clear PLA and I was happy with the way that it looked. I will keep things as an alternative if my other casts don't come out well, or if the resin does not have the results that I am hoping for.

What questions need to be answered?

What is the best way to fit all of the electronics in a small space? Should the units be wireless?What is the schedule?

I will first try to get the programming started as I know this will be the most challenging part for me. I would like to have at least the individual sketches working for each of my devices by the 13th, so that I could spend the next few days just fixing up and combining the codes so that they can work together.While I am programming, I can also get started on the fabrication. As most of these processes include a long waiting time, I will be able to work on coding the neopixels to get the effect that I want. I would like to have my first test cast done at least a week before my presentation. This will give me a chance to make any changes if needed to the hourglass design.

It would be ideal to have the project complete at least a few days before the presentation so that I could use this time for any debugging and to work out any design mishaps.