- Create your artwork.

- Aside from simple fonts already in the Windows or Mac operating system, you can purchase additional fonts, or you can purchase artwork that is Vinyl Cutter Ready Vector Art such as the Mega Vector Art Collection.

- Bring your artwork into a vinyl cutter cutting program.

- Connect up your vinyl cutter.

- Load your material.

- Select and set up setup your blade.

- Create a small line of text that you can send to the cutter.

- Weed all the text you have cut.

- Cut your artwork.

- Remove your cut vinyl.

- Weed your vinyl.

- Apply transfer tape.

- Prepare your target surface.

- Apply your graphics. s

Computer-Controlled Cutting

lasercutter

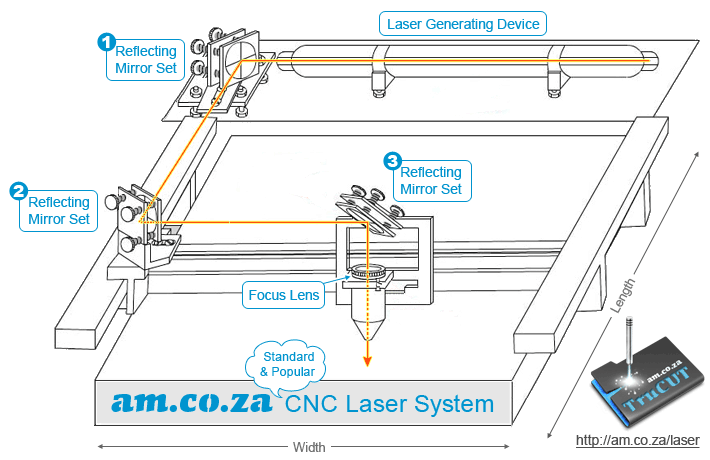

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas,[1] leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Our Laser Parameters

Our Low Power TruCUT CO2 Laser is suitable for fine surface engraving. Design for hobbyists, crafters to cut thin materials (greater than 3mm) and engrave fine quality pictures on smooth surface.

Raster Images

Raster (or bitmap) images are generally what you think about when thinking of images. These are the types of images that are produced when scanning or photographing an object. Raster images are compiled using pixels, or tiny dots containing unique color and tonal information that come together to create the image.

Since raster images are pixel based, they are resolution dependent. The number of pixels that make up an image as well as how many of those pixels are displayed per inch, both determine the quality of an image. As you may have guessed, the more pixels in the image and the higher the resolution is, the higher quality the image will be - but with a large file size.

For example, if we scale a raster image to enlarge it, without changing resolution, it will lose quality and look blurry or pixilated. This is because we are stretching the pixels over a larger area, thus making them look less sharp. This is a common problem, but can be remedied by using raster image editing programs such as Photoshop to change resolution and properly scale images.

Common Raster Image Types: JPG, TIFF, GIF, PNG, BMP

Vector Images

Instead of trying to keep track of the millions of tiny pixels in a raster image, vector images, or line art, keep track of points and the equations for the lines that connect them. Generally speaking, vector images are made up of paths or line art that can infinitely scalable because they work based on algorithms rather than pixels.

More info about vector on Adobe illustratorAdobe Illustrator is a vector graphics editor developed and marketed by Adobe Systems.

Engraving

Engraving is the practice of incising a design onto a hard, usually flat surface by cutting grooves into it. The result may be a decorated object in itself, as when silver, gold, steel, wood, or glass are engraved.

Engraving my design

Laser cutting

Before i cut on laser first i was design Parametric design in solidWorks.After i save it in dxf file in order to be visible in coreldraw.

After saving in dxf i open it in corelDRAW in order to calibulate the power and speed of vector. and then i cut it.

After cutting on laser cutter i assemble my design in the difference shapes like stand of picture and soon.

Vinlycutter

A vinyl cutter is a type of computer-controlled machine. Small vinyl cutters look like computer printers. The computer controls the movement of a sharp blade like a knife. This blade is used to cut out shapes and letters from sheets of thin self-adhesive plastic (vinyl).

A symbol / label can be produced using a Vinyl Cutter such as a ‘Sticker Machine’ or a ‘Craftrobo’. These machines are controlled by a computer and operate similar to a printer. Essentially they cut out shapes in adhesive vinyl. The vinyl can then be stuck onto almost any surface.

A vinyl cutter (or vinyl plotter) is a computer-controlled plotting device with a blade instead of a pen. A vector based design is created in a software program (usually Adobe Illustrator or Corel Draw) and then sent to the cutter where it cuts along the vector paths laid out in the design. The cutter is capable of moving the blade on an X and Y axis over the material, cutting it into any shape imaginable. Since the vinyl material comes in long rolls, projects with significant length like banners or billboards can be easily cut as well. The one major limitation with vinyl cutters is that they can only cut shapes from solid colours of vinyl. A design with multiple colours must have each colour cut separately and then layered on top of each other as it is applied to the substrate. Also, since the shapes are cut out of solid colours, photographs and gradients cannot be reproduced with a stand alone cutter.

Vinly cutting

vinly cutter parameters

On i vinyl Parameters i try to add link which container all parameters which needed in to cutter best quality of sticker.

More infoCutstudio

Roland’s powerful CutStudio software provides the necessary tools to design and create professional custom cut graphics for a wide range of applications. The Roland part RASD-CSWIN-01 is bundled with purchases of new CAMM-1 GR and Stika SV vinyl cutters. The software is compatible with all older Roland cutters.

Here you can download all file on this week Download the files here