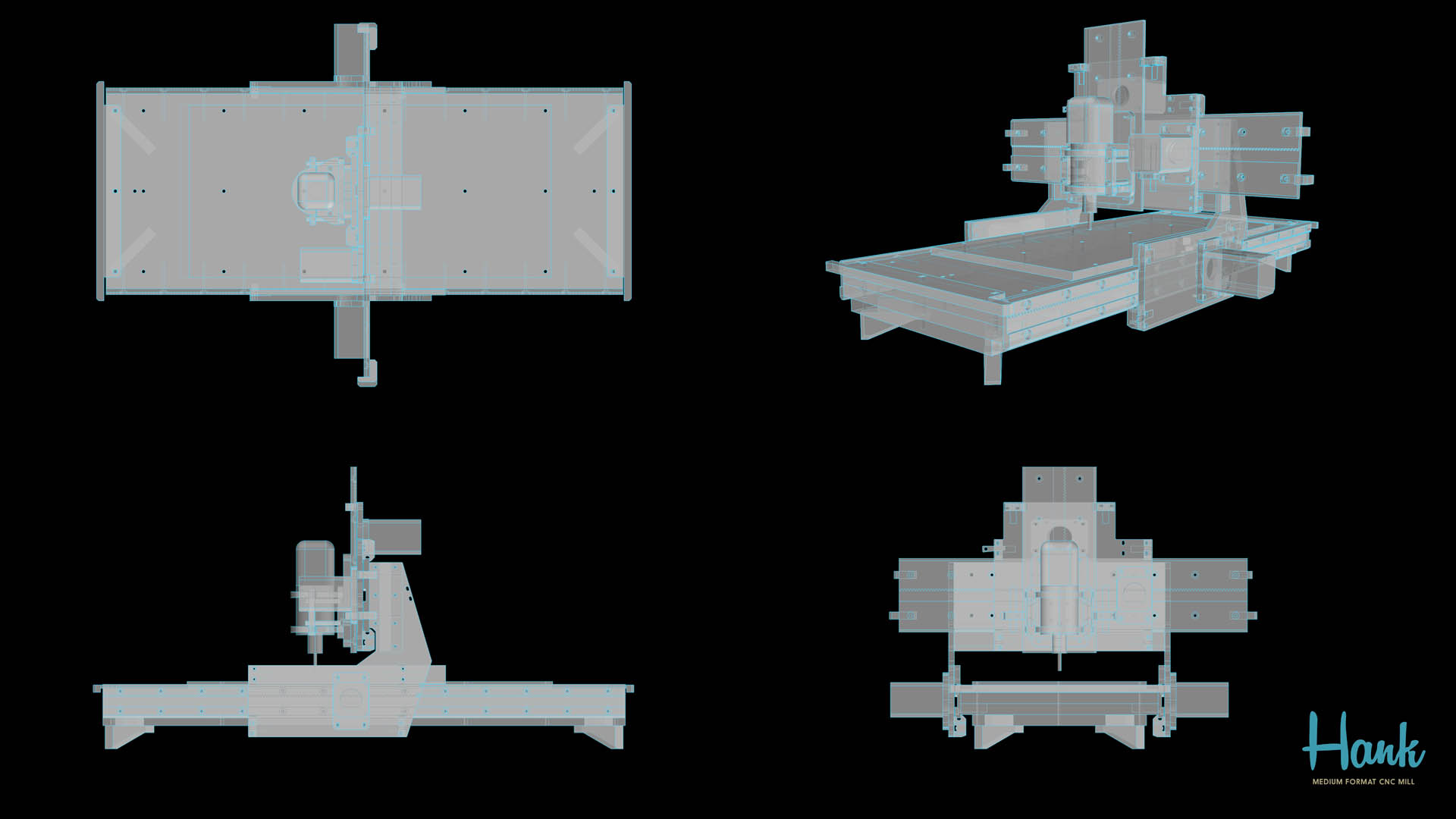

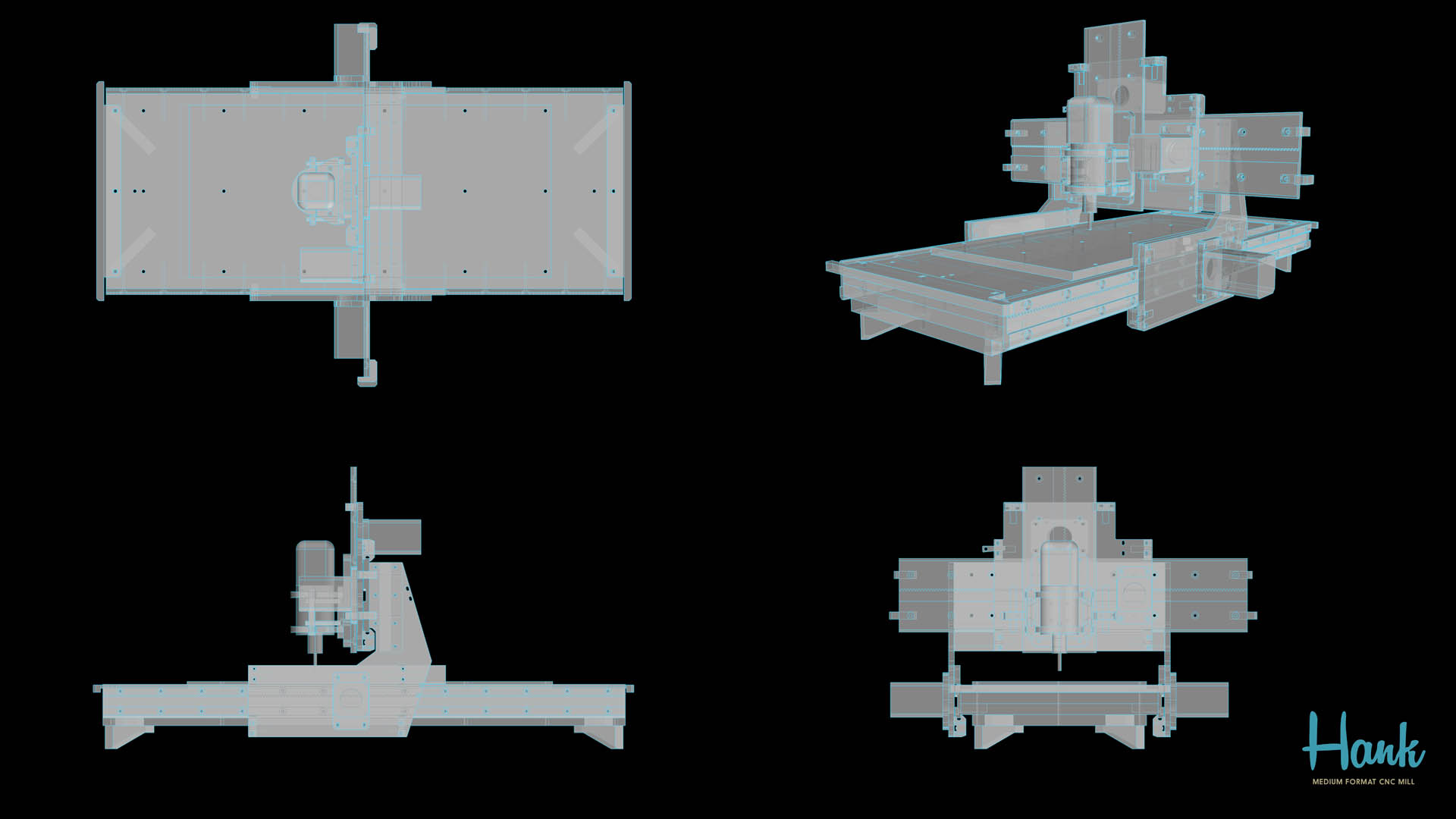

The original machine design file is consided to be a medium CNC, so for us we changed the size of the machine to make it smaller(mini).

The assignment was to design a machine that includes mechanism, actuation, and automation.

For this assignment we choosed to create a mini CNC machine, we used the design made by Jens Dyvik more info.

The original machine design file is consided to be a medium CNC, so for us we changed the size of the machine to make it smaller(mini).

Since file of the machine are available for free online, we downloaded them and generated the DXF files.

We imported the DXF files generated, in VCarve software for milling them.

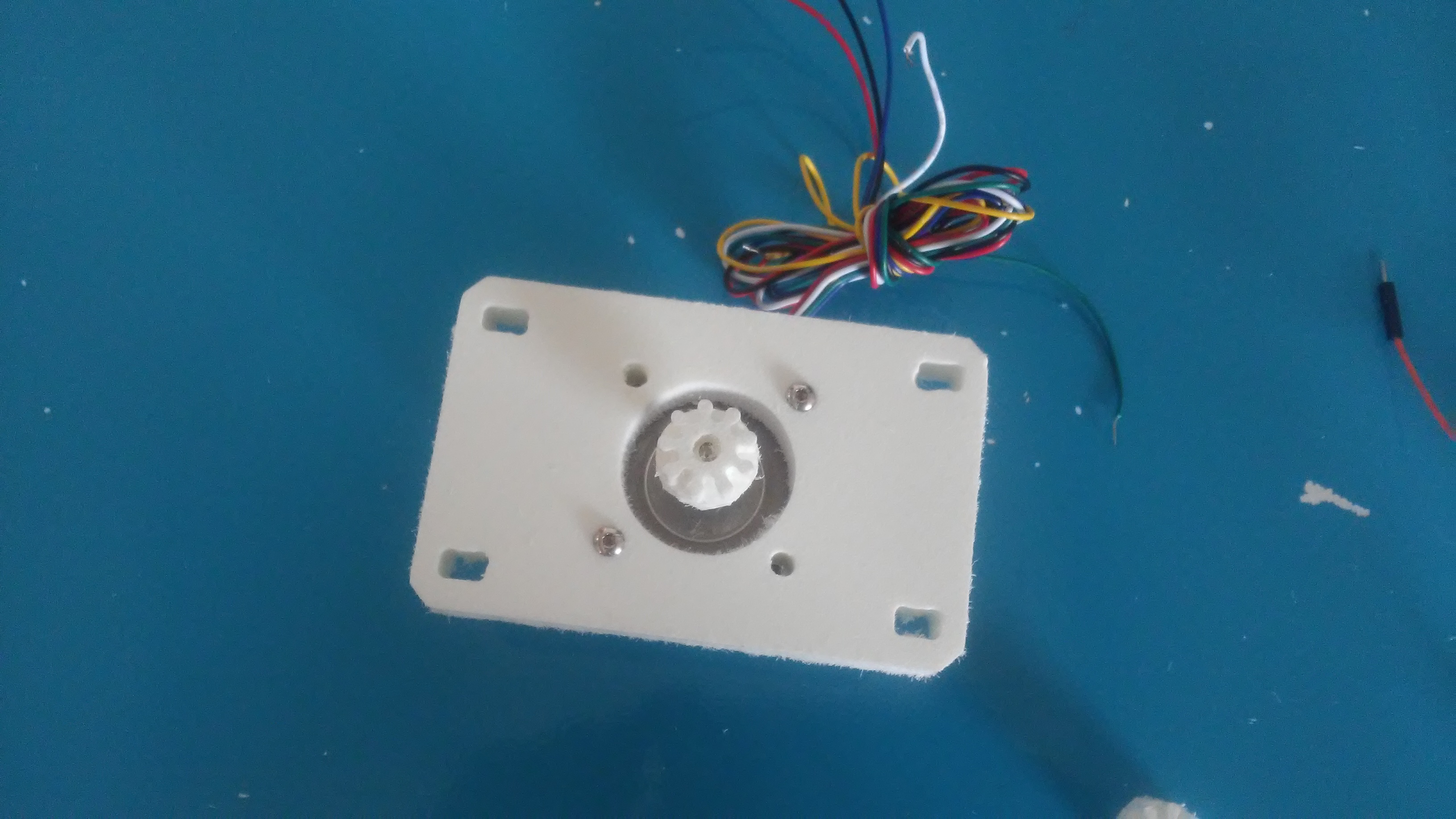

Here we first milled the body part made of plastics.

This are parts we milled in plastic.

After we milled the base part which is made of wood.

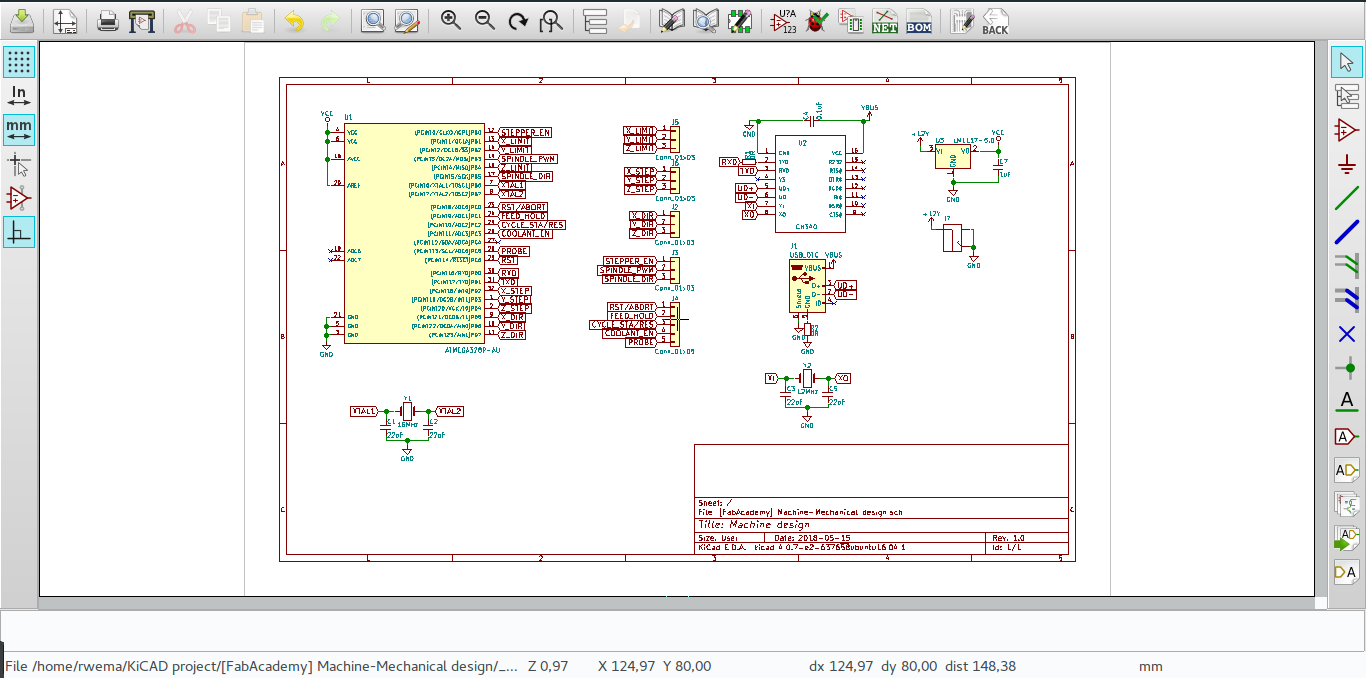

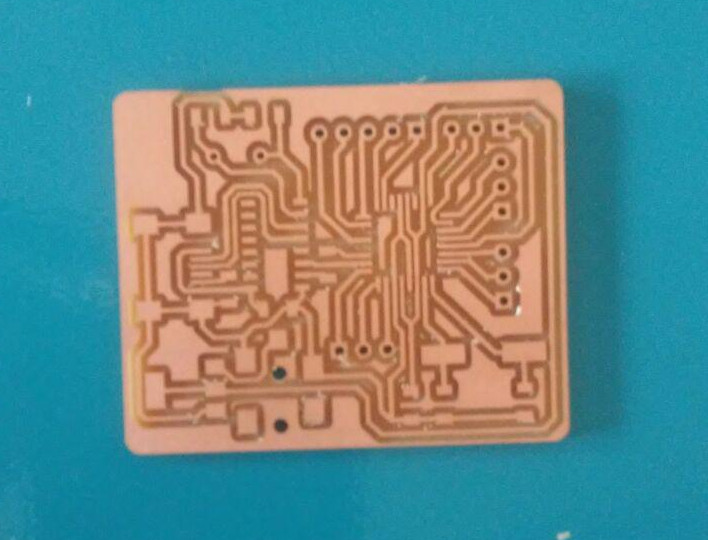

For electronic part we designed the schematic using KiCAD software.

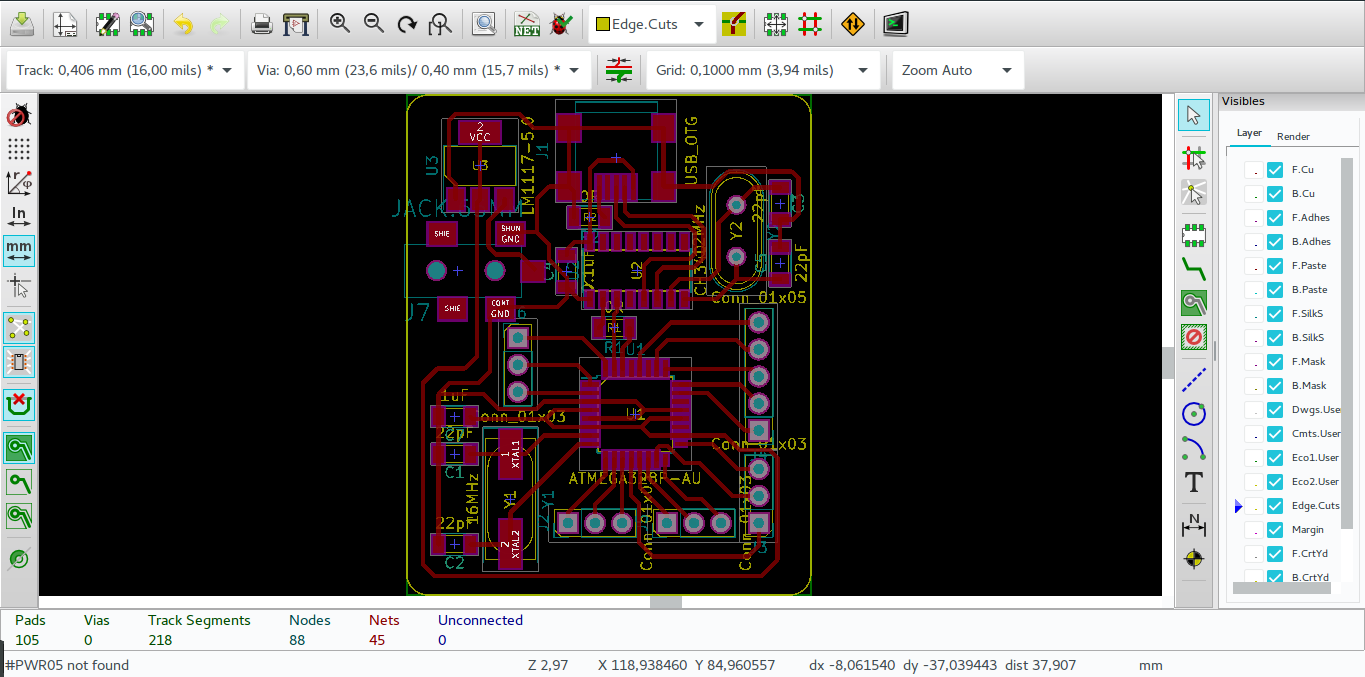

And from the schematic we designed the board.

We did generate RML files to mill the Board. After we milled the board as show below.

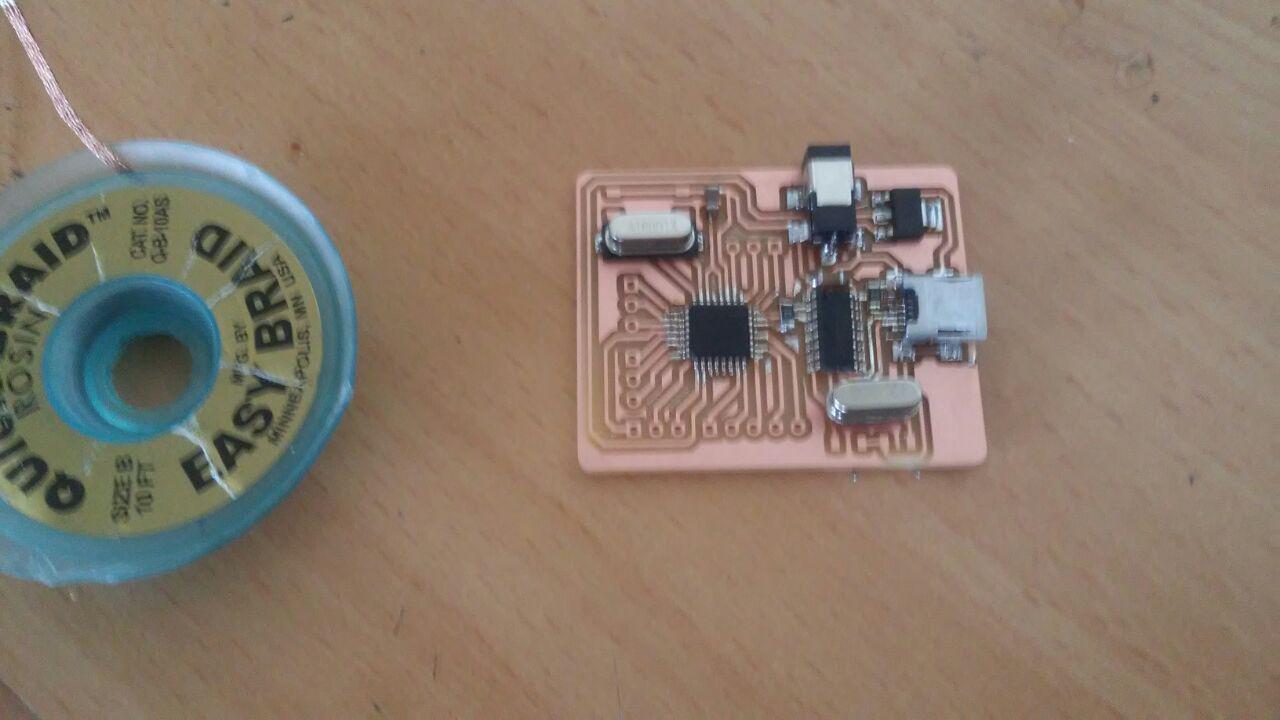

we soldered all the components, the left hole pads are to wires to connect to the motor driver.

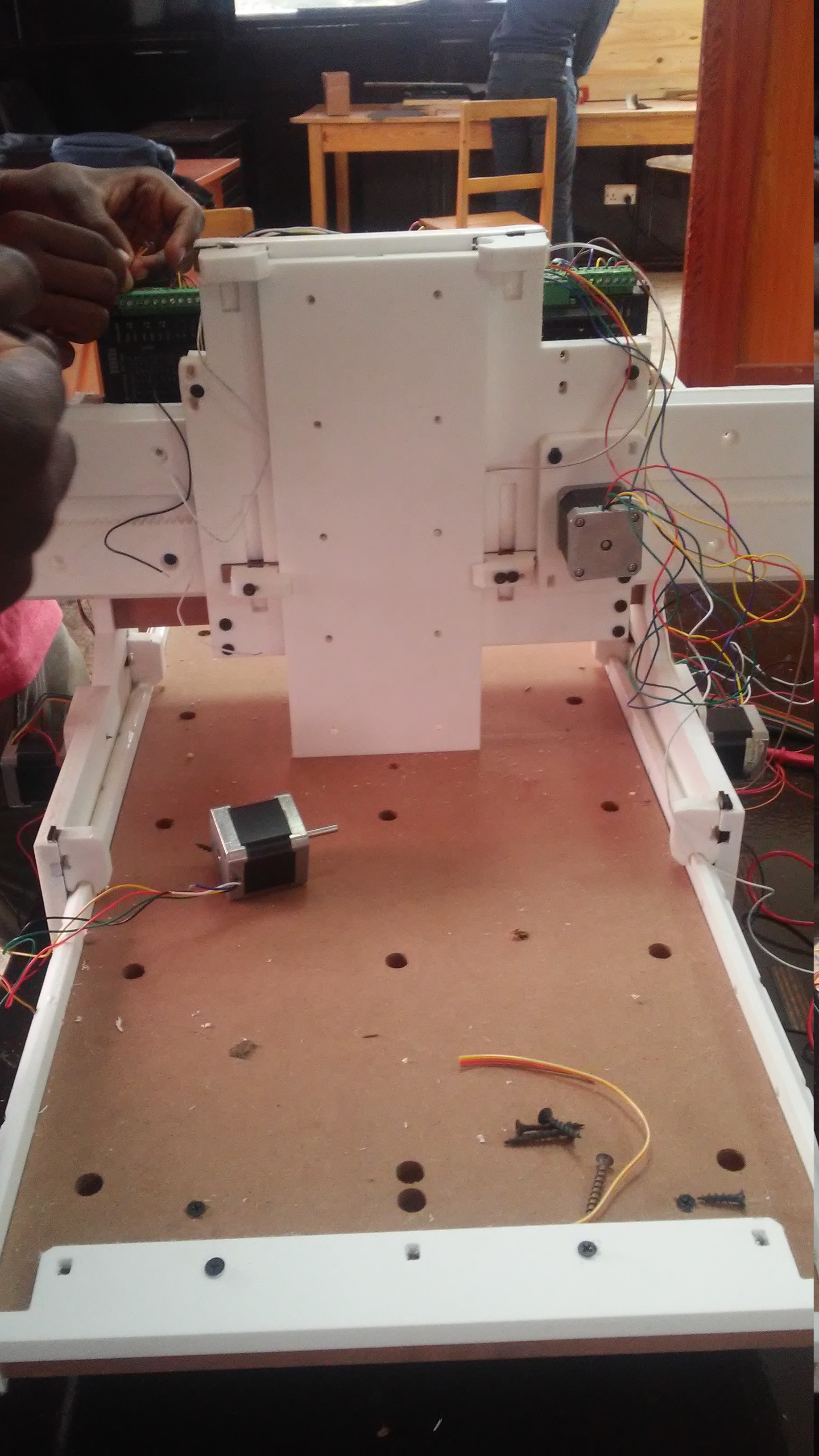

Here we started to assemble different parts.

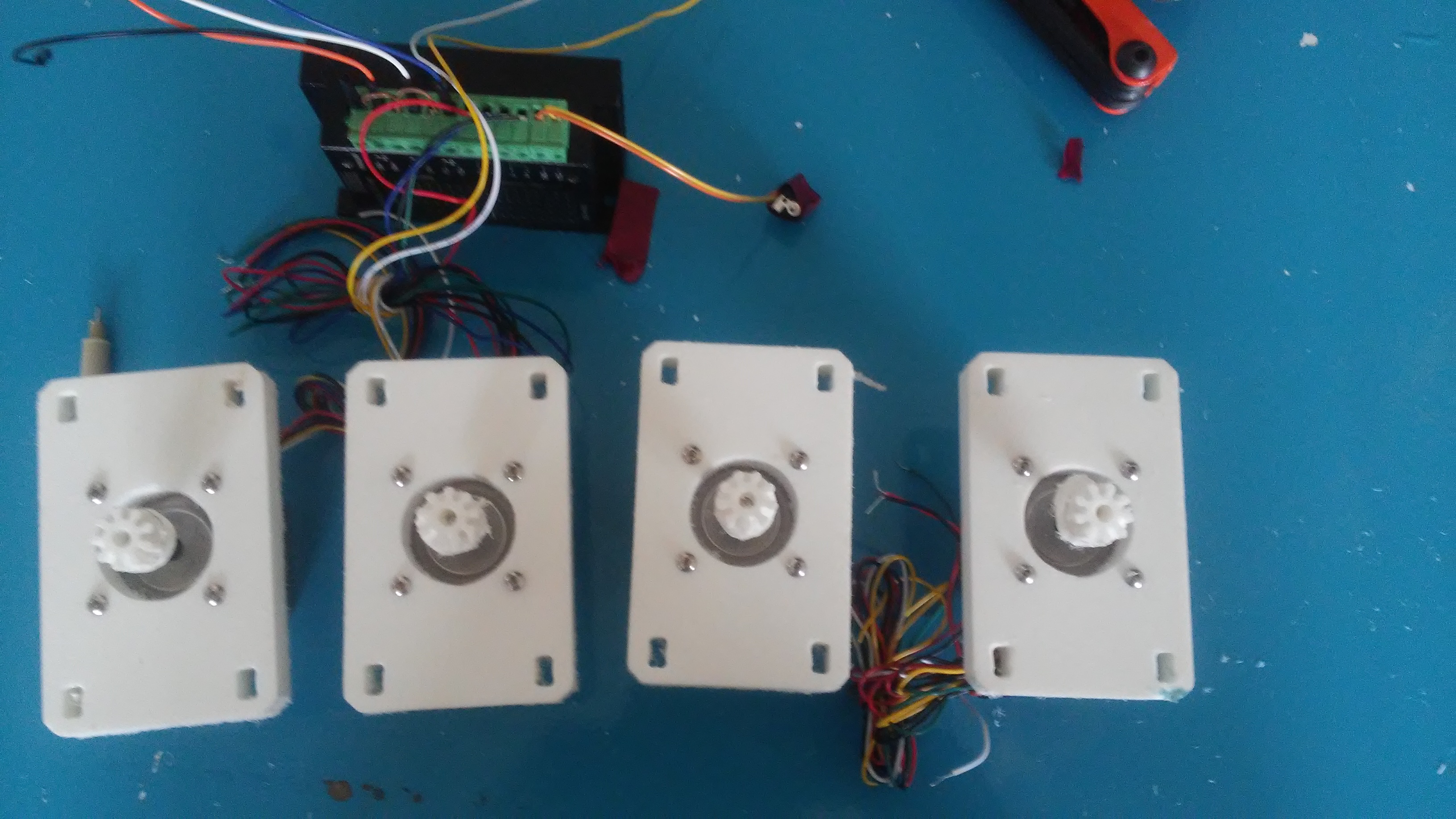

We started on motors assembling them.

Here we first fixed the bottom part of our mini CNC machine.

After we fixed the top part which supports the motor.

Here we are assembling in group.

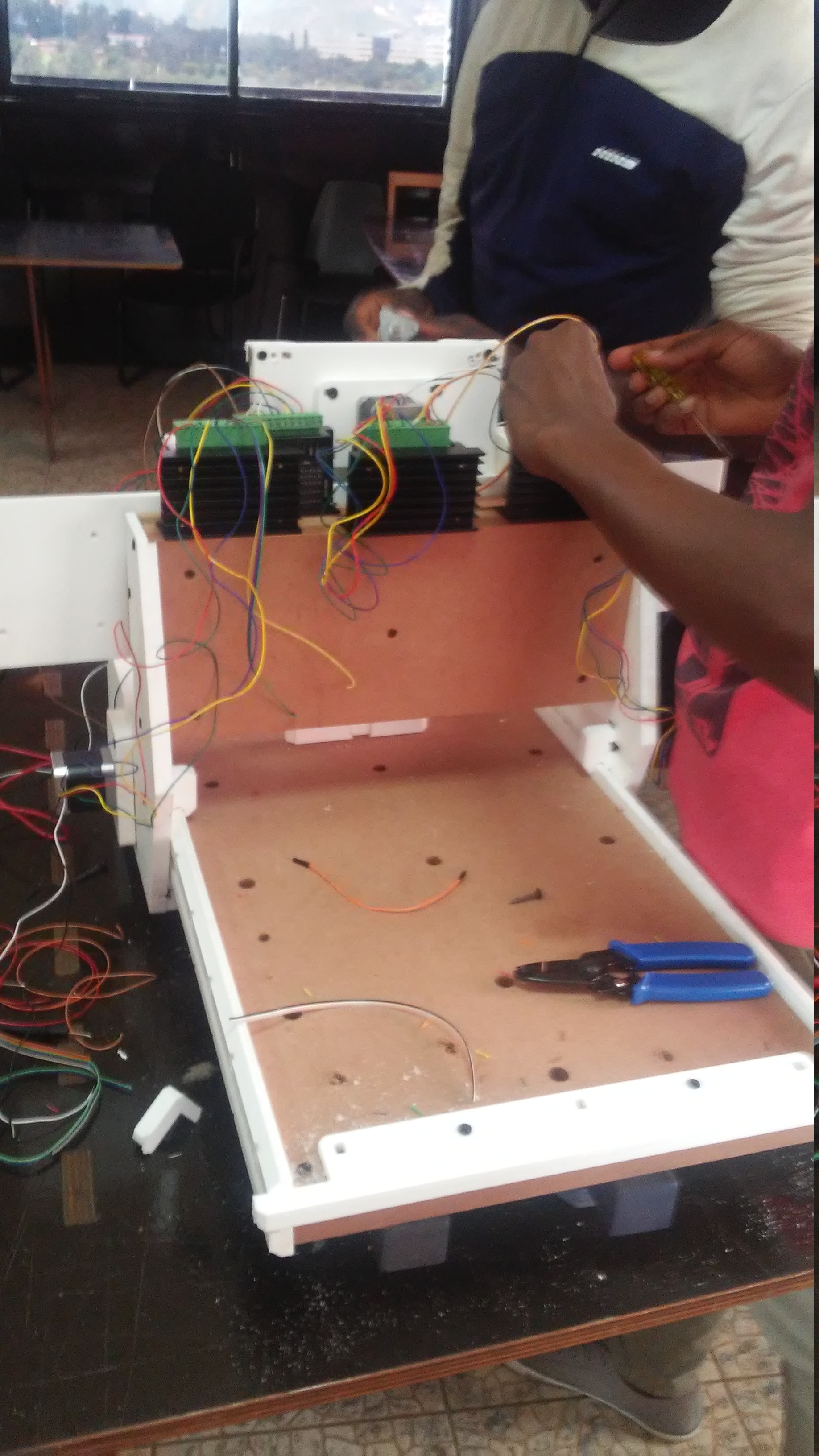

After assembling all parts, we mounted the motor driver on the part top part to enable easy wiring.

Then we mounted motors in their place.

This the image of the fully assembled machine.

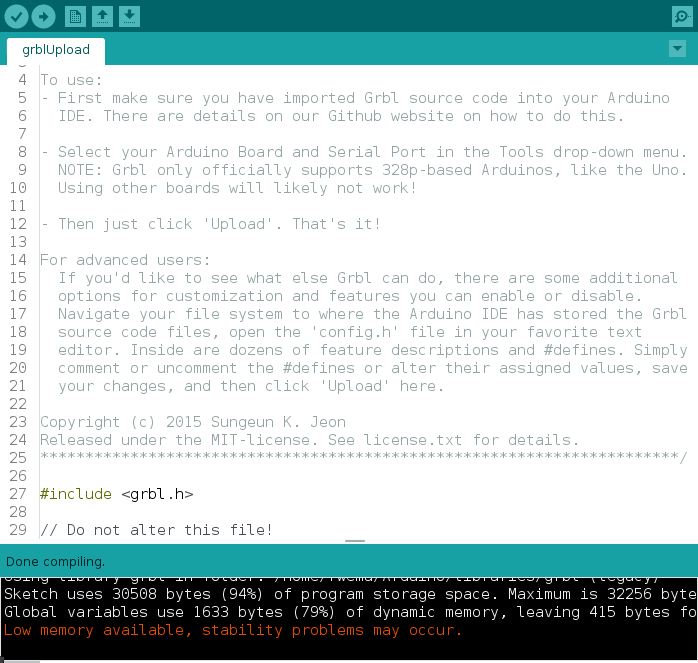

For programming the microcontroller we used an open source software to parse G code and control CNC milling machine, which can be found on github Here.

We opened the file in arduino IDE and there is only one line of code written in, which calls the library used to handle the CNC machine.

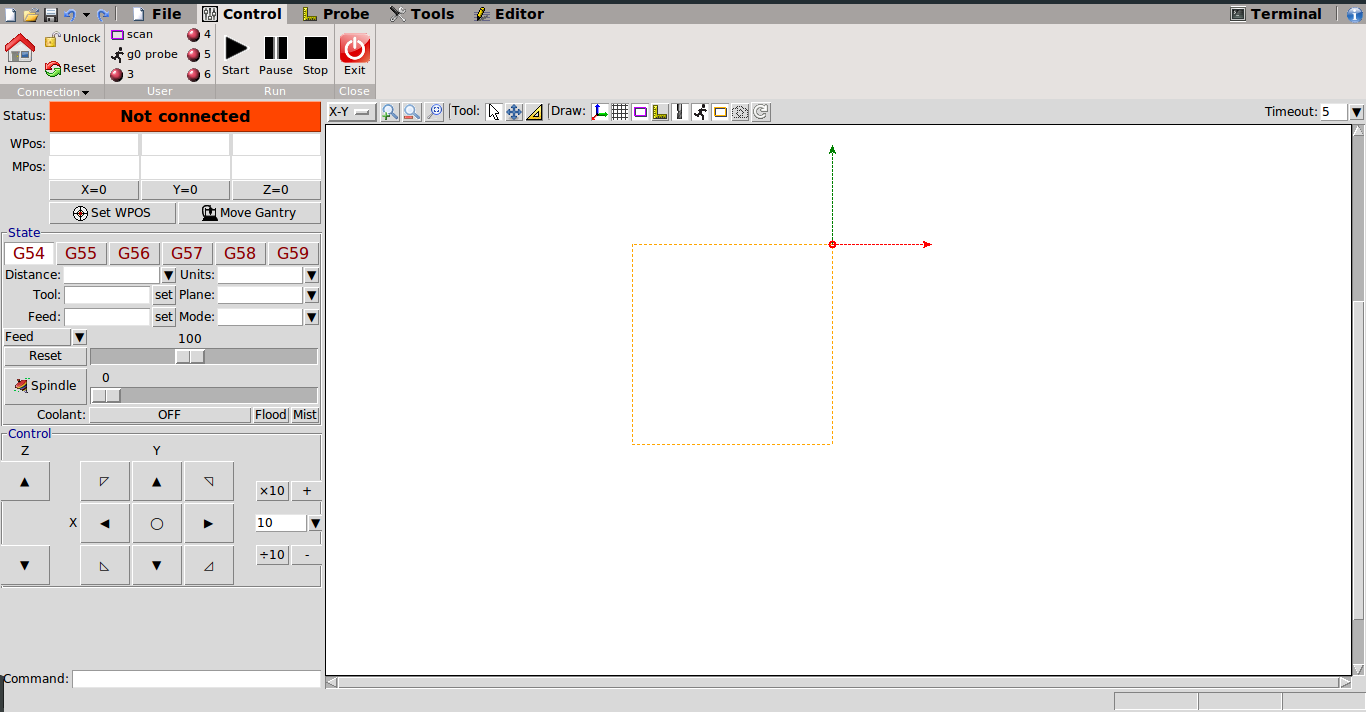

We also used another open source software for CNC command sending, autoleveling and G-code editor, it is called bCNC. This software acts like a G-code sender for GRBL.

| Electronic | Machine cutting | Assembling parts | Programming |

|---|---|---|---|

| Fred | Ziadi and Reine | Ziadi, Samatha, and Jean Claude | Jean Claude |

List of file used.