Week 9 - Molding and Casting

Assignment

- CNC Wax blocks using Roland or Shopbot

- Create a mold out of the design

- Cast out of the mold created

Tools and software used

- FUSION360 modeling and CAM

- Roland MDX-40

- 6mm flat mill-1/8 Flat mill-1/8 Ball mill

- Smooth-On (PMC, SortaClear and Oommo 25

Designing object in fusion

I use Fusion 360 to design the object for molding using 3 sketches in various heights and LOFT between them

I created doublicate tabs to place the object correctly. and then i split it in half

-----------------------------------------------

I used Fusion Cam to create the toolpaths for the Roland MDX-40

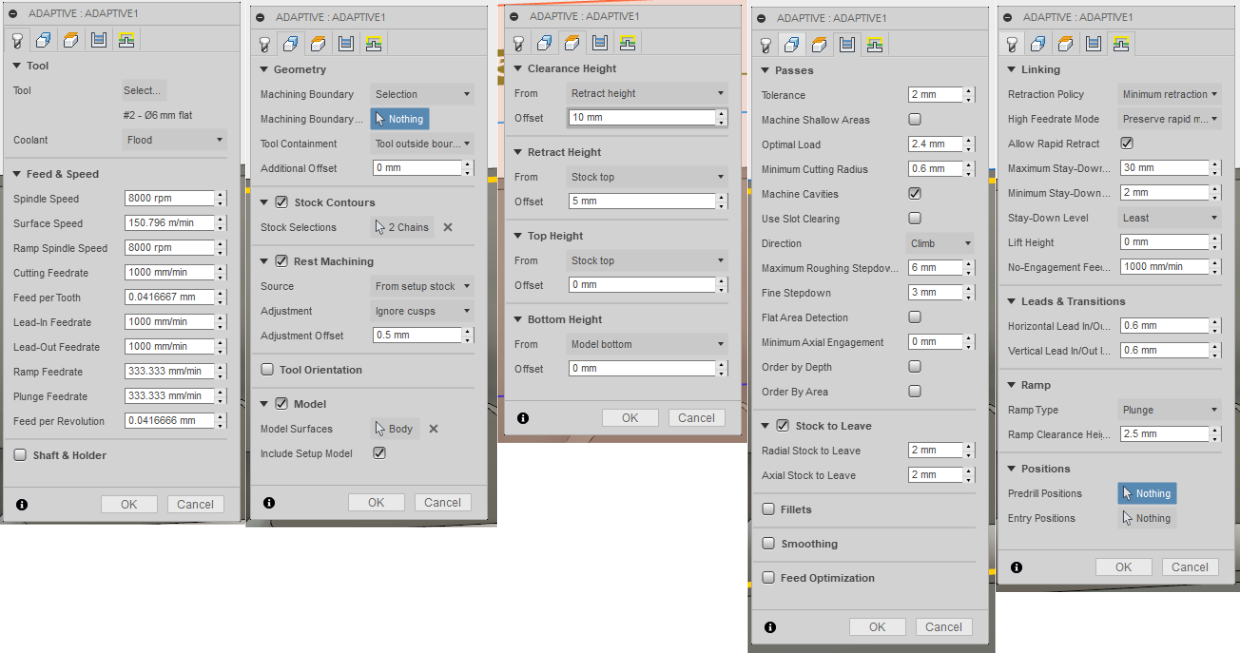

3D Adaptive clearing to remove material. 6mm Flat mill

-----------------------------------------------

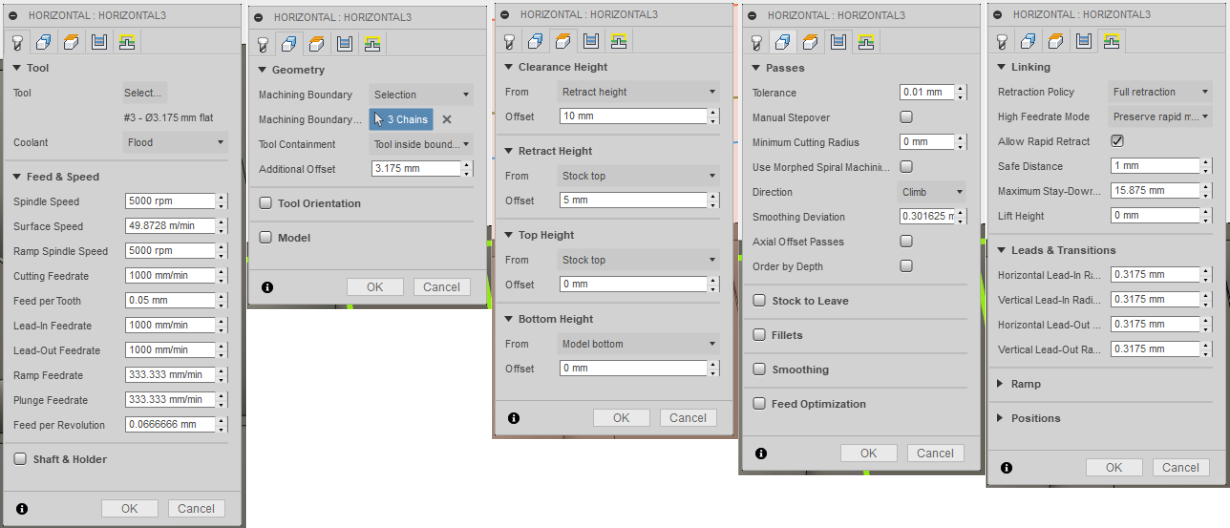

3D Horizontal finishing for flat surfaces. 1/8 flat mill

-----------------------------------------------

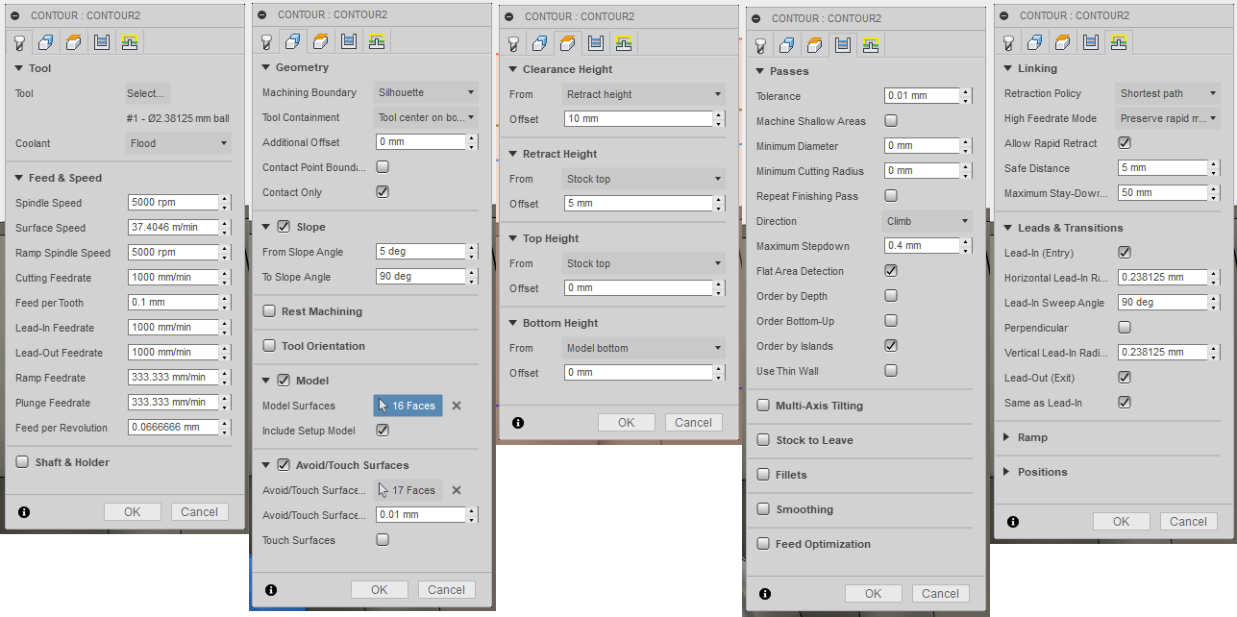

3D Contour for finishing. 1/8 Ball mill

-----------------------------------------------

Finished Wax with the first Sorta Clear mold. The object was too close the the wall for the 1/8 ball mill. However I did mold test which would not work for casting.

-----------------------------------------------

I changed the placement of the pieces and on tab so the 1/8 mill bits would fit between the problomatic areas

-----------------------------------------------

Closeup of the new mold with good finish

Casting test with the PMC.

-----------------------------------------------

Came out alright however there were a little wet areas which indicate either the material is old or the mixture was not correct.