Assigment:

Group assignment:

- Test the design rules for your 3D printer(s)

-Individual assignment:

- design and 3D print an object (small, few cm)

that could not be made subtractively

- 3D scan an object (and optionally print it)

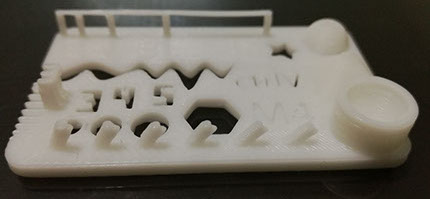

This was the first attemp printing a test on this 3D printer, I used this model that I downloaded from thingverse:

3D printing test file

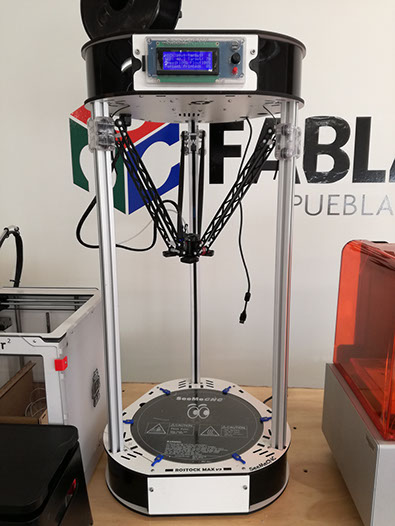

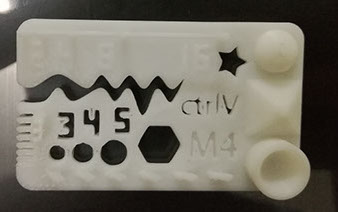

As you can see, it was not the efficient material and the 3D printer too, the material that I used on this 3D printer was PET. I tryed another 3D printer and other material too (PLA) and this was the result.

The result was much better so I decided to Print my objects on it.

I designed this object on Solidworks

-Create a circle and extruded

-Create another circles on the top of the base you extruded

-make a curves on each circle and begin on the center of your circle

-Use the tool sweep for each curve and its respectively circle.

-Use the tool shell on the top of each tentacle for make it emptied.

The object I made cannot be made it subtractively because the following aspects

-The curves direction

-The way the curves flow.

3D scanning

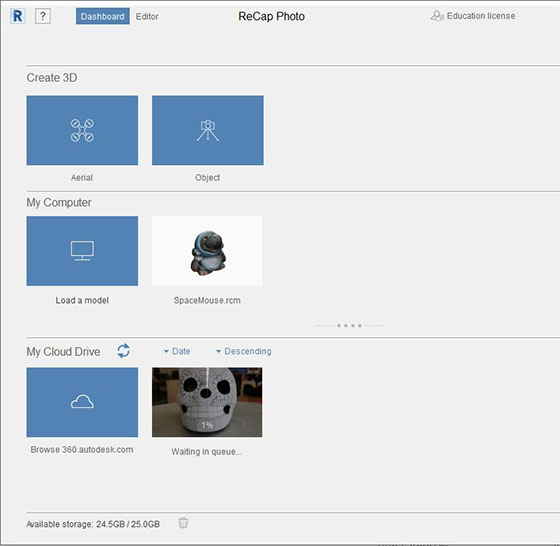

First I tryed to scan an object using photogrammetry, I used ReCap Photo from Autodesk to do this. You will need to take various pictures from the object you want to scan I use my smartphone and a rotating table.

Open the ReCap Photo software, click on object and upload all your photos, your photos will it send it to a cloud form autodesk to make the 3D object.

I waited 12 hours to download the file that autodesk will give it to me but this never happened, always was waiting for queue and never advanced of 1% load.

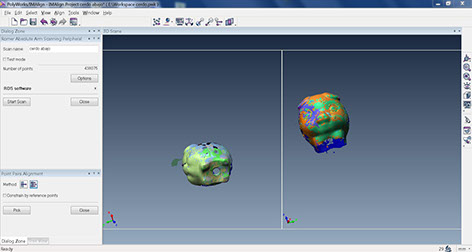

I also used a Romer Arm to make a 3D Scanning, it has a great definition because it generates a point cloud of your object which detect a small details with great accuracy, your object need to be black or white for more accuracy making the 3D scanning but I used a shiny blue object and it work too, not like I wanted but it worked.