Mechanical and Machine Design: Producing the Fruit Peeler

WHAT TO DESIGN?

Our local instructor this week, Eino Antikainen. As we are 8 people in FabAcademy at FablabOulu, we thought splitting in two groups was a good idea, so every one would have the chance to participate. Eino had a good idea for a group work, which was started to be planned by one group. Then, Tapio (from the technical staff of our Fablab) suggested Megumi about a Lather machine. Megumi and Marta started to think about that, and thought it would be too complex machine for this assignment. But while they were thinking of this, they started to envision a fun machine: a fruit peeler!

So this is our page, the page of the team Apple Peeler. Our goal is to create an automatic apple peeling device.

BackToTop

FIRST WEEK: MECHANICAL DESIGN

DISASSEMBLING AND DISCOVERING THE PIECES

When starting to think about the design, we agreed our aim would be to try to recycle as much as possible. Last year's projects (one and two) were laying around. So we decided to disassemble those and try to reuse as much as possible for our project.

Both projects were done with the cut files for the SCIENCE cardboard designed by Nadya Peek (Machines that make: cardboard stages that Eino modified ).

The files to cut the different parts we use are at the end of the page. We believe it is better to reuse what we have, but if anybody needs to build from scratch, it is possible to do that with the attached files.

BackToTop

IDEATING

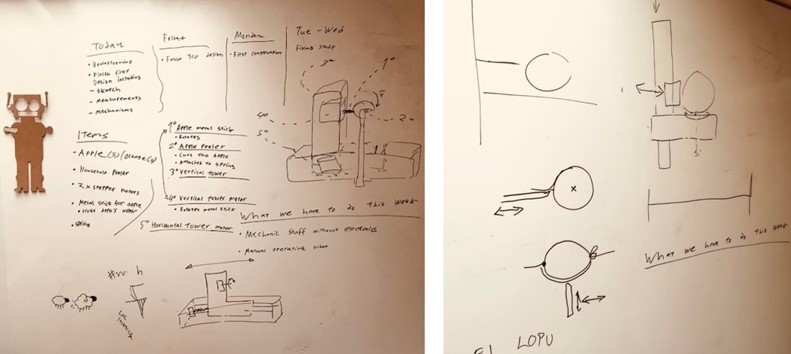

We began by brainstorming our idea. First, we summarized what we had to do this week:

- Finish machine´s mechanical functionalities

- Operate the machine manually and document it

With these sketches, we identified main movements needed for our Apple Peeler (picture on the right, above):

- Apple rotation

- Apple horizontal movement

- Blade movement towards and away from apple

Finally, we decided that for our Apple Peeler we needed:

- Automatic rotation of the Apple

- Achieved by rotating pitchfork with a stepper motor

- Automatic horizontal back-and-forth movement of the Apple

- Achieved by using modular machines that make (LINK)

- Automatic apple-peeling procedure

- Achieved by using custom spring and custom peeler design

BackToTop

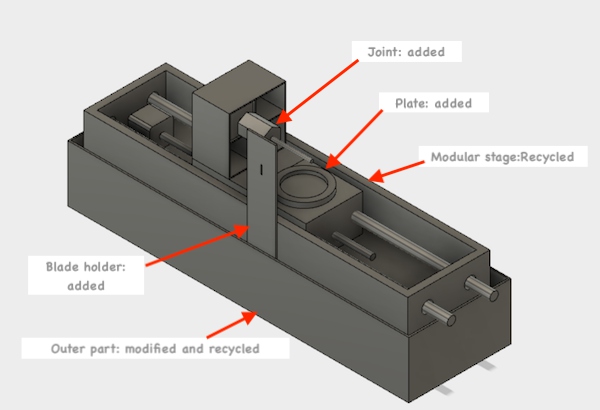

DESIGNING AND MAKING THE PIECES

According to the sketches we had, we started to define what parts did we need. We identified the following

- One stage for the Horizontal motion

- One motor for the horizontal motion

- Some (3) smaller boxes to configure an L shape structure that will move horizontally

- the vertical piece should also hold the rotating motor at an adequate height

- One motor for rotating the fruit

- Some piece to hold the apple for rotation

- This one should have at least two tines, so it won't rotate freely inside the fruit

- Some piece to hold the previous piece to the motor

- A blade

- A support for the blade

- A box to support it all

- A bowl to hold the peel of the fruit

- Some support for the bowl

The following 3D model shows how our Peeling Machine would look like:

BackToTop

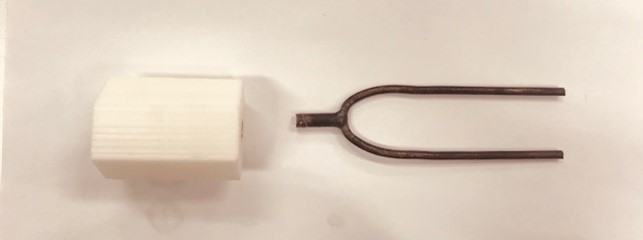

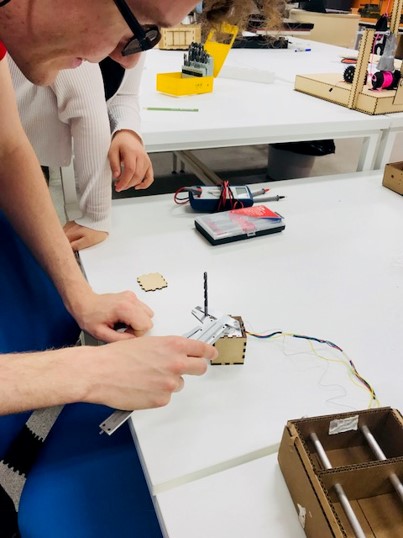

Rotating structure

As mentioned before, we were interested in recycling as much as possible. When deciding the piece to hold the apple, we first thought of creating it. With the help of Eino, we started to think how we could use spare pieces for that. But then, the idea of using a "makkaratikku" (that is a metallic stick to cook sausages in the fire). There were several of them in the common coffee room close to the Fablab. It just needed a bit of love to transform it to an "omennatikku" (stick for apple).

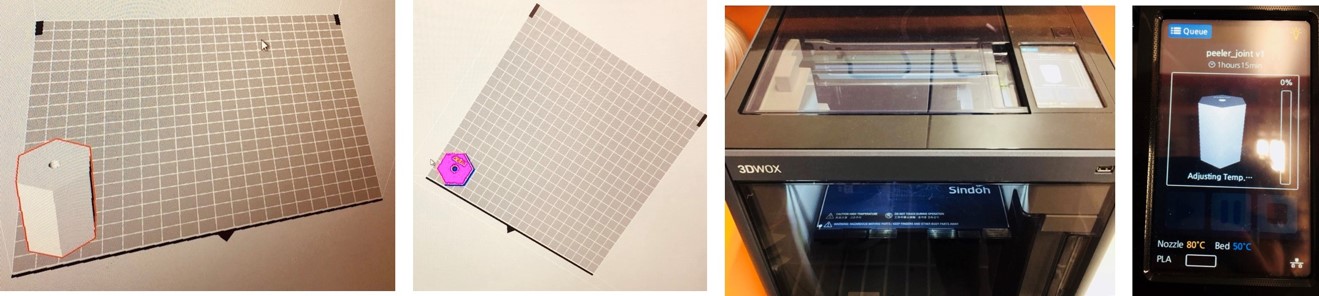

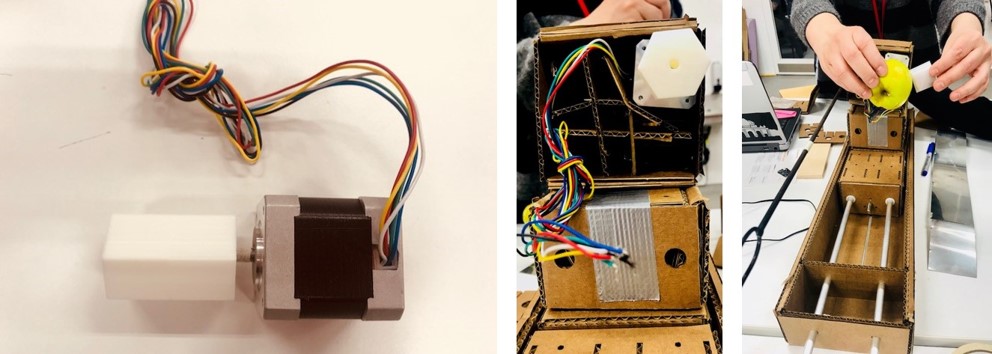

Then, we needed a small piece to attach the apple holder to the motor. We got inspired by a 3D printed piece we found in the lab, which was almost perfect for us. So we measured both axis (motor and stick) and designed the piece. We decided to make it pentagonal to easily grab it if needed.

Then, we 3D printed it.

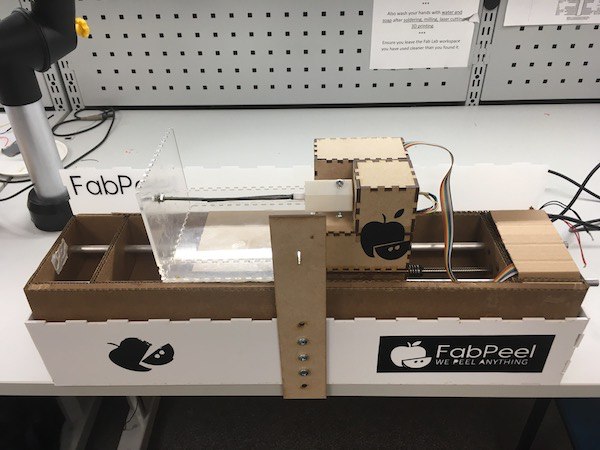

And attached it to the motor. We again roughly assembled our machine. Looking good!

We did not cut the "omenatikku" yet. We preferred to wait a bit to be sure how much we needed to cut.

BackToTop

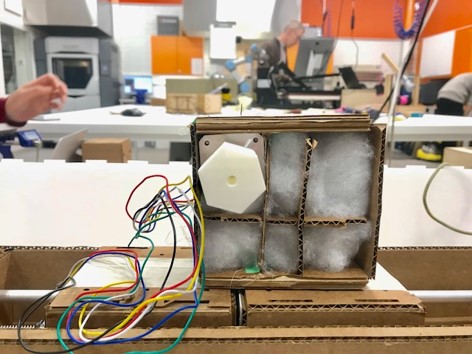

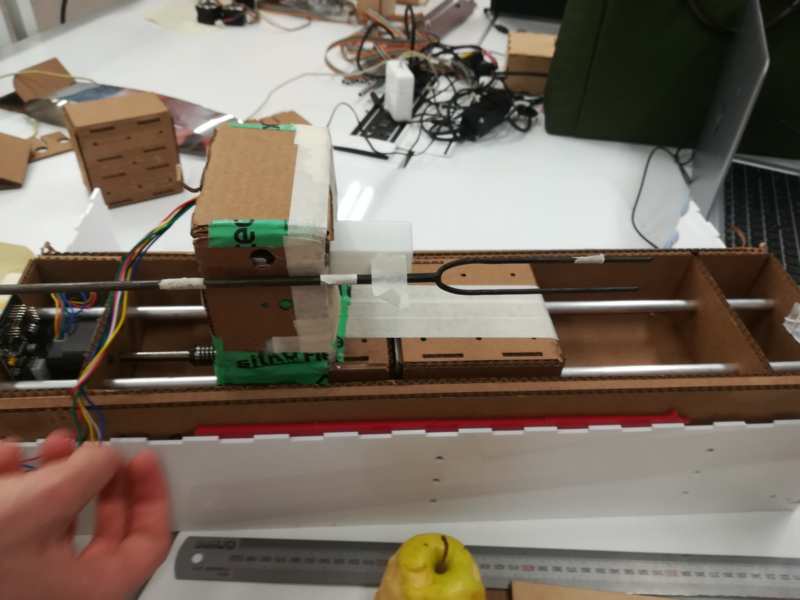

Moving (L) Structure

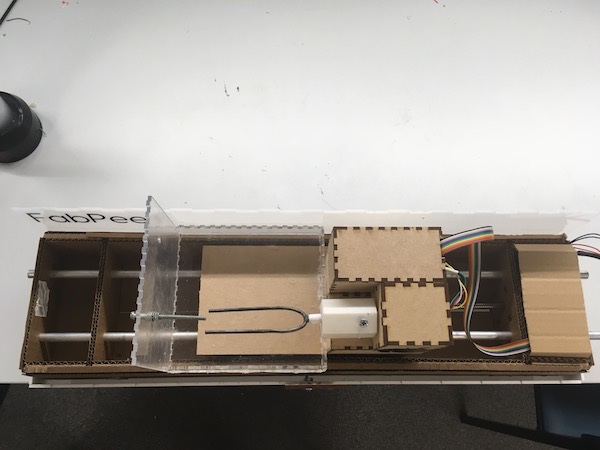

We attached the lower two boxes together, so they will move as one piece horizontally. Then, we inserted the motor in the correct place of the other box.

Then, we added all together with two sided strong tape. We would need to see if the motor would get too hot for this structure.

We measure how long we needed the apple holder, and then cut it

Finally, we assembled the apple holder to the piece that will attach it to the motor.

BackToTop

Peeler

We did try several ideas for the peeler. The peeler is the result of several tests, some thinking and some research for ideas in the Internet.

We first thought to use a spring to hold a commercial peeler that would stay close to the apple, while it rotated. We discarded the commercial peeler, as the usual peelers have a long blade which would make it difficult to peel the apple without rotating the blade too.

We then discarded the spring also, and decided to use a plate and attach to it a blade. And we then decided to use a U shape piece of metal as the blade.

We tried several materials for the plate. We wanted something a bit flexible. So we started attaching plastic pieces together. But the result was a too flexible plate.

We then tried with a piece of MDF. This was finally the perfect solution. We then studied how to attach the blade to the plate. This also depended on where and how the blade would actuate on the apple. After some testing, we decided to attach the blade perpendicularly to the plate. To better attach them, we measure at what height we needed the blade, and we laser cut a piece with a hole for the blade.

Bowl

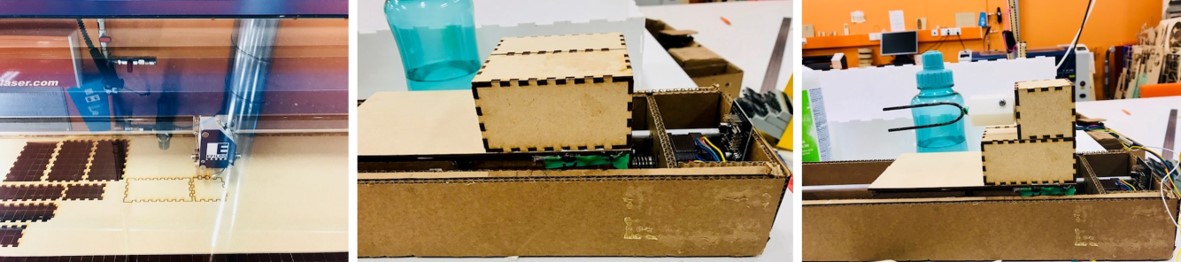

We decided we needed some recipient to gather the peelings. Peetu decided some structure, laser cut and give it an epoxy bath. He documented it in his page.

The bowl turned up to be a bit small. We will decide on this the next week, when everything is properly assembled.

BackToTop

Stickers

We decided we would decorate the future box

BackToTop

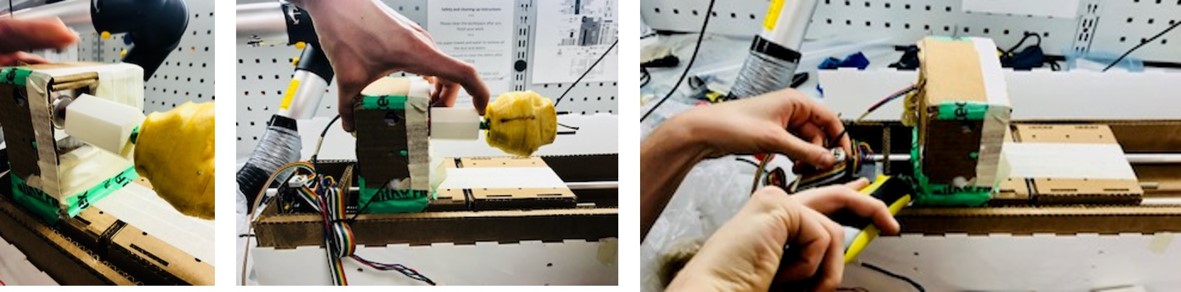

PUTTING IT ALL TOGETHER AND TESTING

Finally we designed and built:

- Design the whole structure

- Design the L structure and build it including support for the rotating motor

- Design the rotating structure and build it

- Design the Blade holder and build it

- Design the bowl and build it

- Design the stickers

Video of the result of this week.

We cannot wait to make it work! Up to now, it looks it will peel the apple, although at this point it looks it wants to eat it also...

BackToTop

SECOND WEEK: MACHINE DESIGN

At the beginning of the week we already knew that we would need to do some adjustments; for example, we needed a bigger bowl. So the plan is

- Make a new bowl

- Adjust the container box

- Program the gestaltnodes

- Try and adjust...

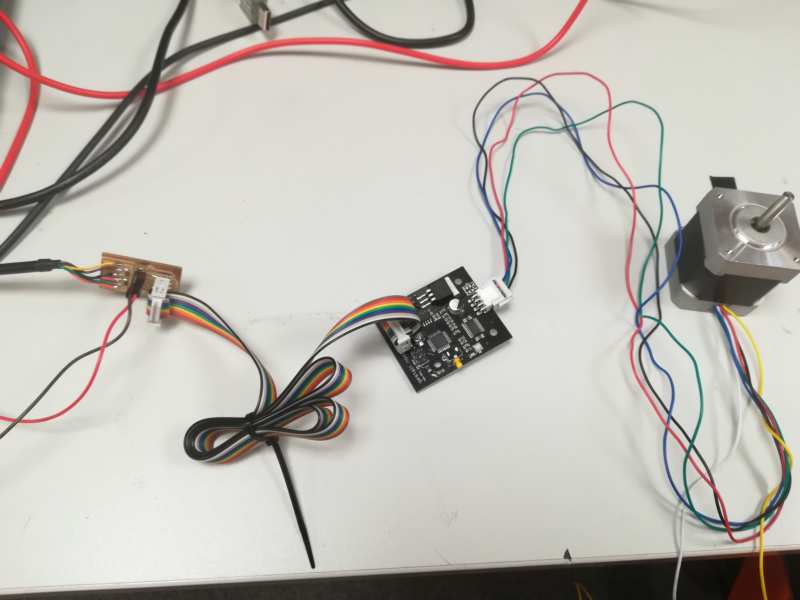

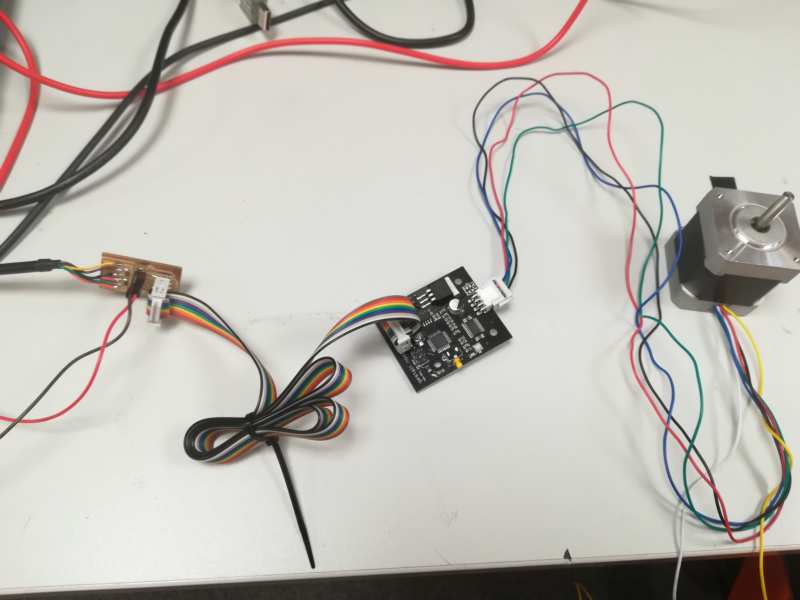

PROGRAMMING

More detailed information can be found at Marta's page.

We prepared the programming environment by

- Installing python 2.7

- Installing pyserial

- Cloning Gestalt from github and installing it

single_node.py example from Gestalt. The connections needed for the motor and the power source values (12 V , Ilimit of 0,600mA) can be checked from below:

xy_plotter.py example, that handles two nodes

- Slow Horizontal movement and rotation up to some point in the horizontal axis

- Stop and go back to the starting point

BackToTop

TESTING AND ADJUSTING PIECES (ITERATIVE)

New bowl

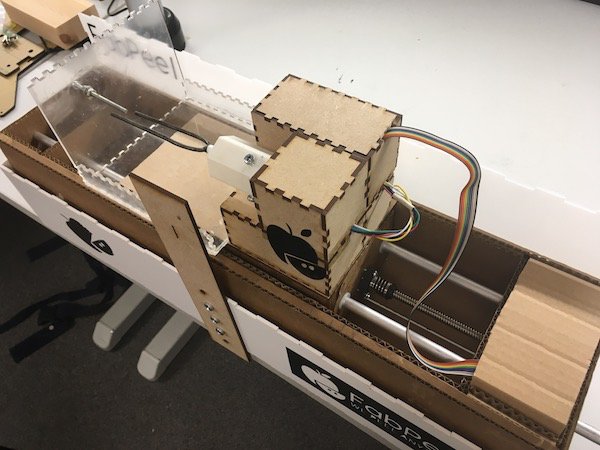

Since our current bowl is a bit small, and the apple peel could easily make the machine wet, we decided to design a bigger one that fits there and cover all the surface. So using acrylic 3 mm and designing the bowl in Inkscape and laser cutting it resulted in a bowl that satisfies our need.

BackToTop

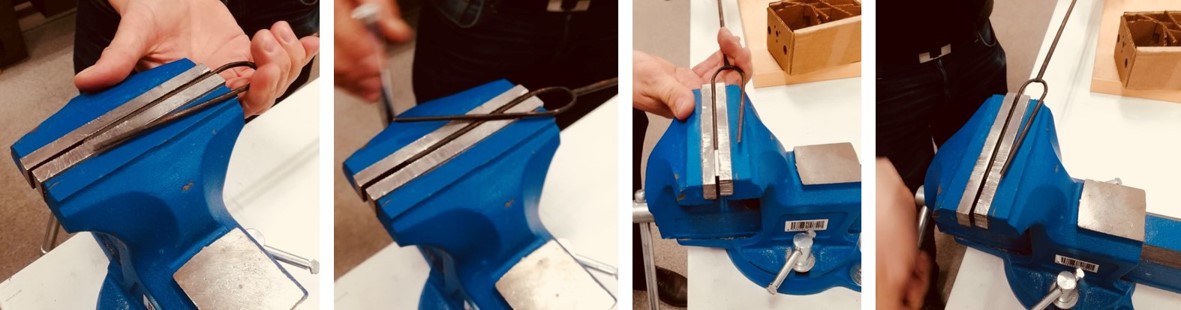

Sharpening the blade

In order to enjoy having a sharper blade that peels better, we sharpened our blade with use of file and paper. And we wrapped some tape around it and attached it to the spring. We would fix it later on more tight using bolt and nut.

BackToTop

Adjustments in the fruit holder

After programming of the motor was done, we tested the machine with different motor speeds. We noticed that the apple holder is a little bit loose and moves downwards. So first we closely had a look and discussed together what could be done to fix the issue. And eventually we decided to disassemble the part that holds the motor and try to find another way to get the motor fixed!

BackToTop

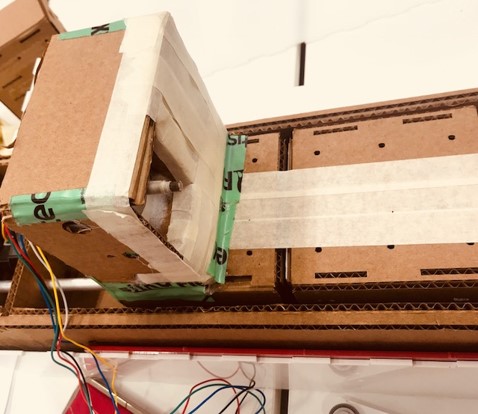

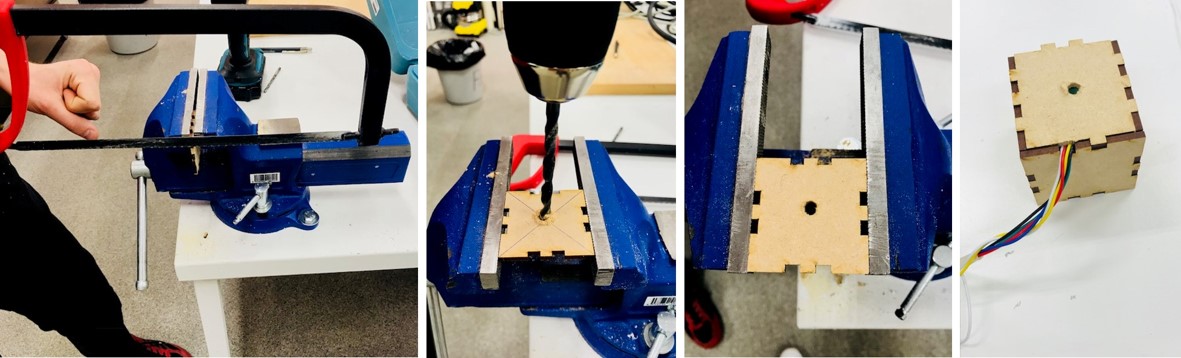

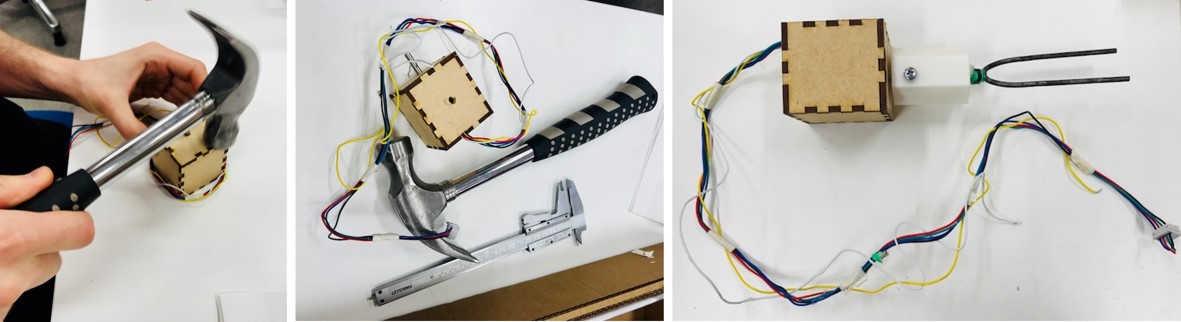

New structure for holding the motor

We decided to keep the motor still by placing it inside a box. So we designed the box and laser cut it. Then we needed to make some minor modifications manually to the box. So we measured the bar that passes through the apple holder.

We cut one of the legs of the box. And we made a hole using drill machine.

We cut one of the legs of the box. And we made a hole using drill machine.

When the parts were cut, the fit was really tight, so we used a hammer to help fit them into place. We also screwed the bar to the 3d printed part of the apple holder to keep it more stable.

When the parts were cut, the fit was really tight, so we used a hammer to help fit them into place. We also screwed the bar to the 3d printed part of the apple holder to keep it more stable.

We made another box to adjust the height and to place the motor on top of it.

We made another box to adjust the height and to place the motor on top of it.

BackToTop

Modifying the Bowl

we decided to hold the fruit from both sides to keep it more steady and thus help the blade to cut better. For that, we removed one of the walls of the bowl and made a new one with a hole, which is higher and we screwed a long enough screw to it. And the purpose was to pass the end of the fruit through it.

Modifying the peeler plate

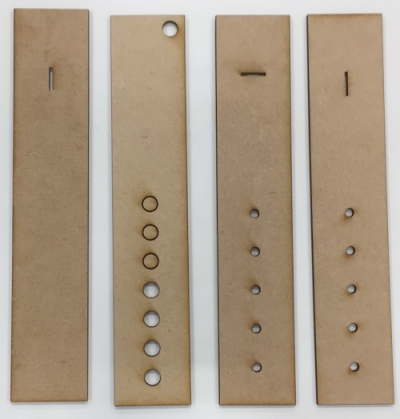

To finally attach the blade structure (blade and plate) to the main structure, we would use some holes that were originally in the box structure. We designed the new peeler plate by using Fusion 360 and Inkscape. He measured distances between the holes in plastic, the hole sizes and the hole for the blade in the original plate. After few failures, correct measurements were found and fitting peeler stick was cutted (right-most). The peeler stick was screwed to plastic with bolts and screw. It worked fine:

Finishing touches

We finished our machine with few stickers we had made before:

Reflection & Final Images

Reflection

These two weeks have been good learning experience about machine design. Through mistakes, we have learned lot about machine designing:- Motors should be attached precisely to prevent unexpected movements

- Motor do not have enough torque to push the fruit so the blade can do its work. We tested different materials as blades, as well as different shapes for the blade, and nothing helped much.

- Connecting two pieces well together with a 3d printed clutch is very precise work

- Bending of the materials for building the blade has to be investigated

- Tearing rolling, un-symmetric fruits is difficult

Final Images

In the following videos, the two different movements of the motors can be appreciated: rotation and back and forward. Also, the final structures to hold the electronics are visible and the green tape has been removed. Finally, it can also be seen the different parts fit properly together.

BackToTop

Files

- F3d File for 3D model of the machine

- Stl File for 3D model of the machine

- F3d File for Joint for rotating structure

- Stl File for Joint for rotating structure

- Svg File for Blade holder

- Dxf File for Blade holder

- Svg File for Peeler stick (first try)

- Svg File for Peeler stick (second try)

- Svg File for Peeler stick (third try)

- Svg File for Peeler stick (final version)

- Svg file for MotorBox 1

- Svg file for MotorBox 2 & 3

- python code for the machine adapted from example xy_plotter.py

- Logo svg file

- Presentation slide png file