Molding and Casting

Goals

- Design a 3D mould around the stock and tooling that you'll be using, machine it, and use it to cast parts.

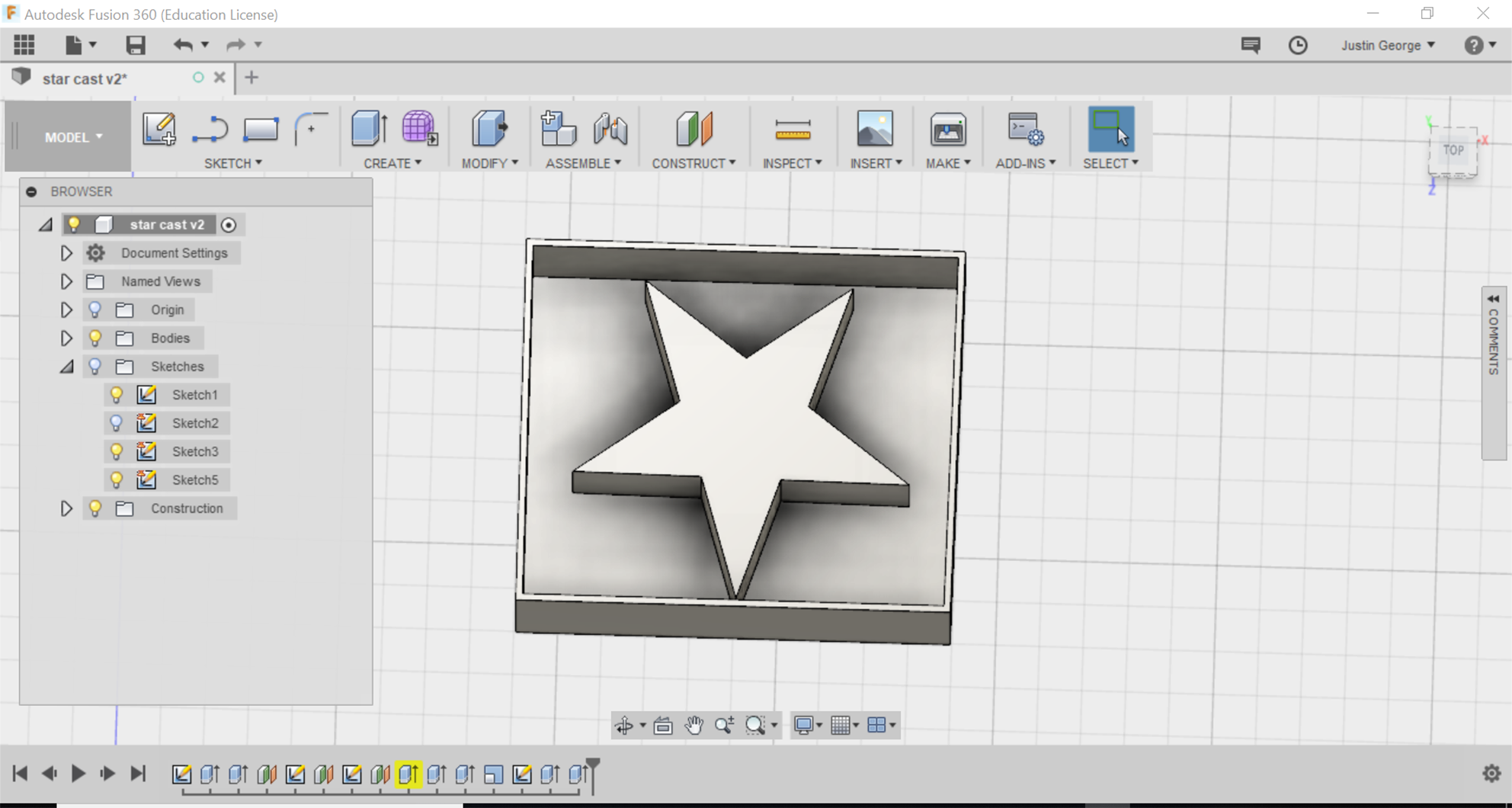

3D CAD

I decided to build a star shaped mold for the molding week. I designed a simple mold using fusion 360

After the model was milled using Roland modela machine and Wax.

Initially we used i/8 end mill to do initital milling and 1/8 flat mill to do finish cut.

I used silicon resin to create my mold. Silicon resin has two parts.

Next step is to mix the Part A and Part B of the solution to create the mold resin. They are mixed in 1:1 propotion.

Resulting solution is mixed well and poured it slowly to the mold and let it to form mold.

I

Casting

Next is the Casting Part. I used liquid plastic to cast my mold. It is similiar to silion resin as mixing ratio of part A and Part B is 1:1.

After a few minutes, i checked the mold to get my product.It was difficult to take it out and was imperfect because i over poured the mold.

Problems faced

- After milling of the mold was finished i found out that since the flat bit was smaller than space between the wall and the body it was merged with the machine.

- it was problematic to brake away the mold because of the overflowing of the casting material.