Electronic Production

This week is dedicated towards learning about Electronic production.

Prof. Neil talked us through PCB milling, soldering components and techniques

He suggeested we build an ISP board and program it. This was completely

new to me since I'm new to electronics.

The design was already available in the fabacademy site.

Fab ISP

In-system programming (ISP), also called In-Circuit Serial Programming (ICSP),

is the ability of some programmable logic devices, microcontrollers,

and other embedded devices to be programmed while installed

in a complete system,

rather than requiring the chip to be programmed prior

to installing it into the system. --wikipedia--

Fab-ISP is an in-system programmer for AVR microcontrollers,

which can be developed with in a fablab. This allows us to program

microcontrollers on other boards using a 6 pin IDC cable.

Programming is done through

avrdude.

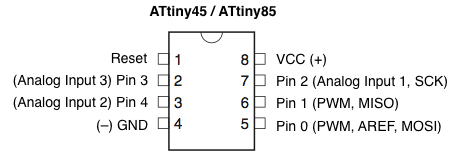

We are using ATtiny45 chip in this ISP.

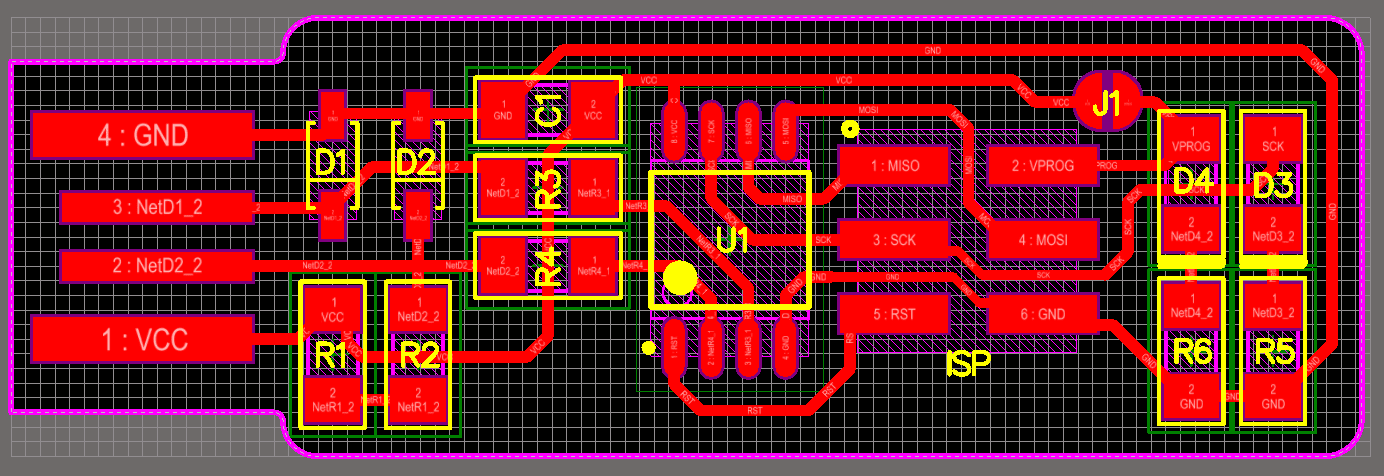

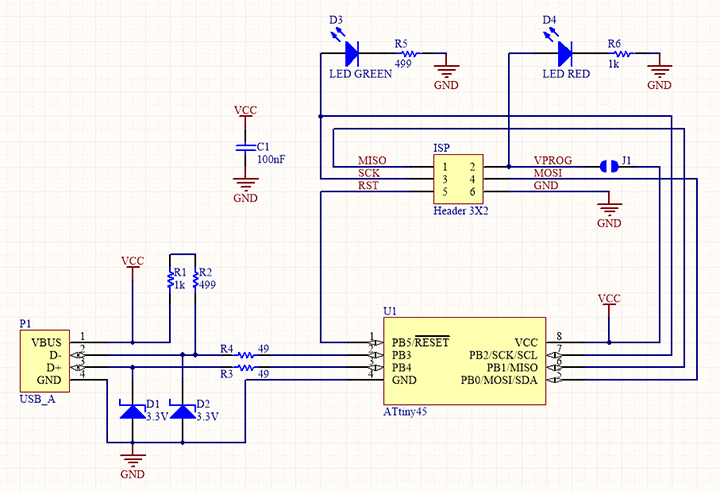

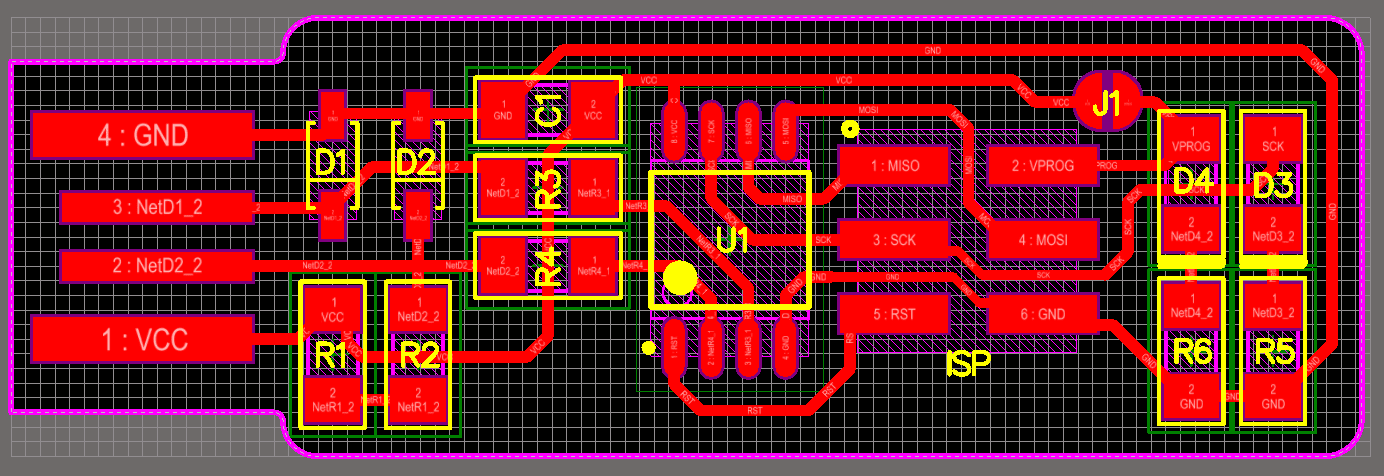

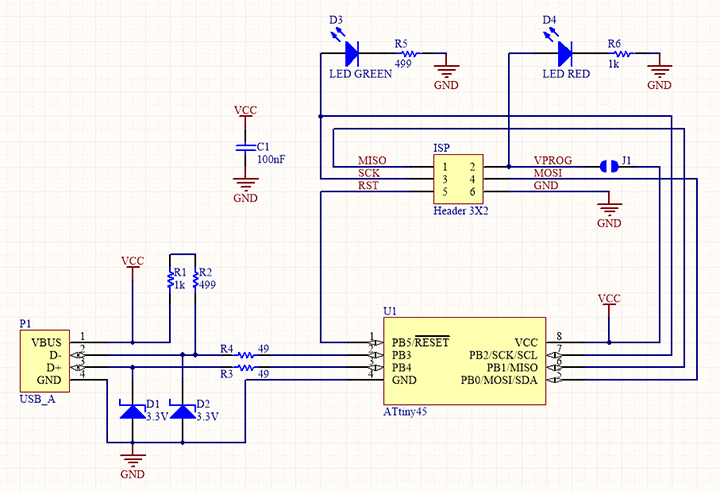

Below is the desing provided

ISP Schematic

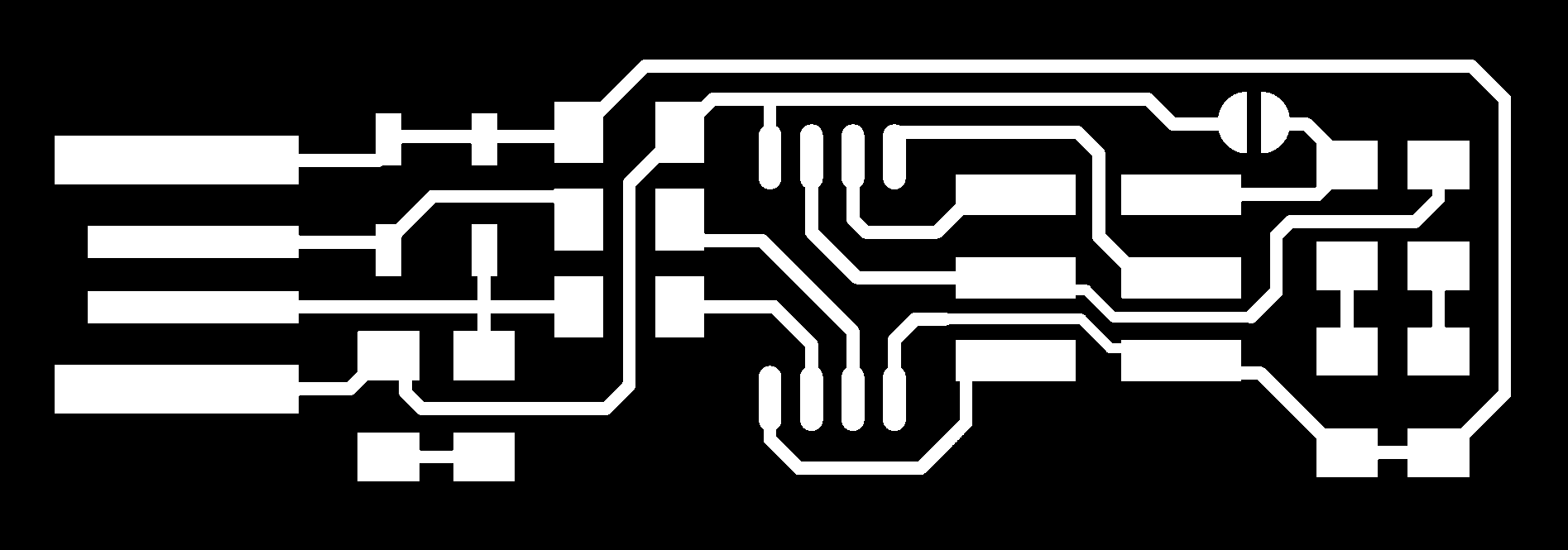

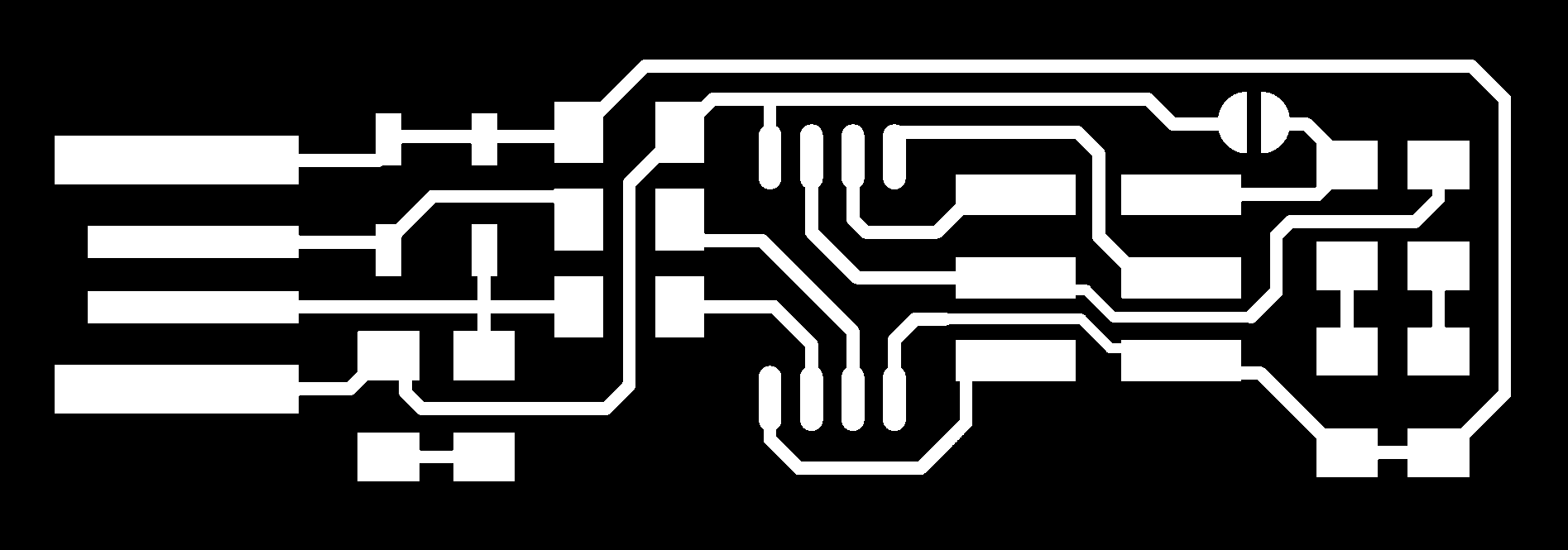

Trace Images

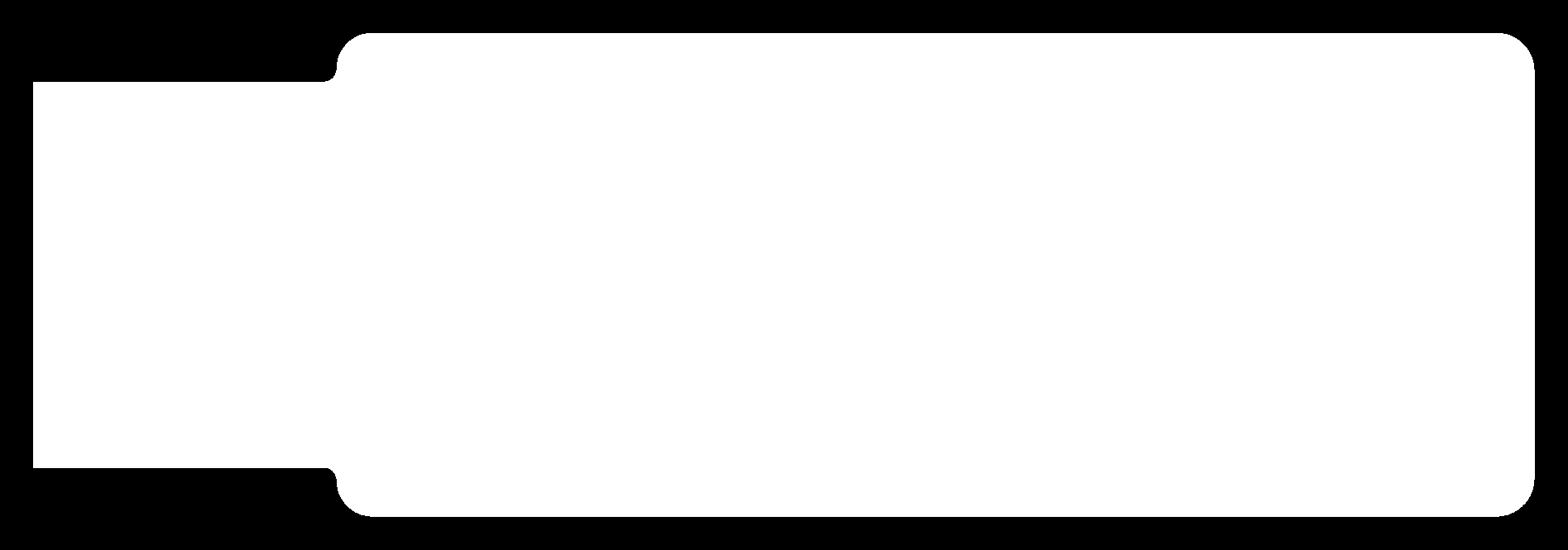

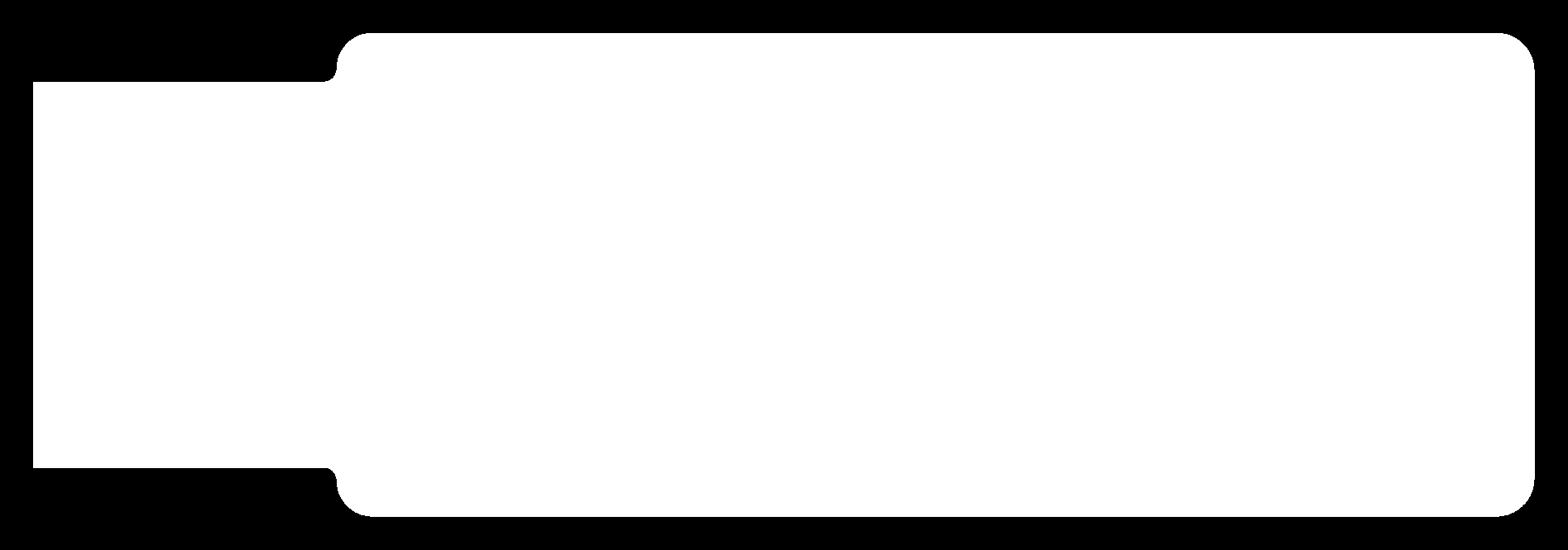

Cutout Images

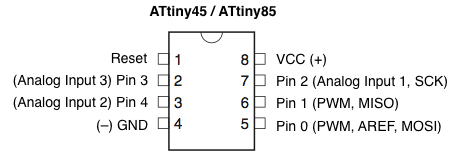

ATtiny45

For the production of the programmer we use ATtiny45 microcontroller.

ATtiny 45 is a small and cheap microcontroller that can be used for

for running simple programs. It has eight legs with 6 general purpose I/O

lines and 4KB of flash memory.

Pin Out Diagram

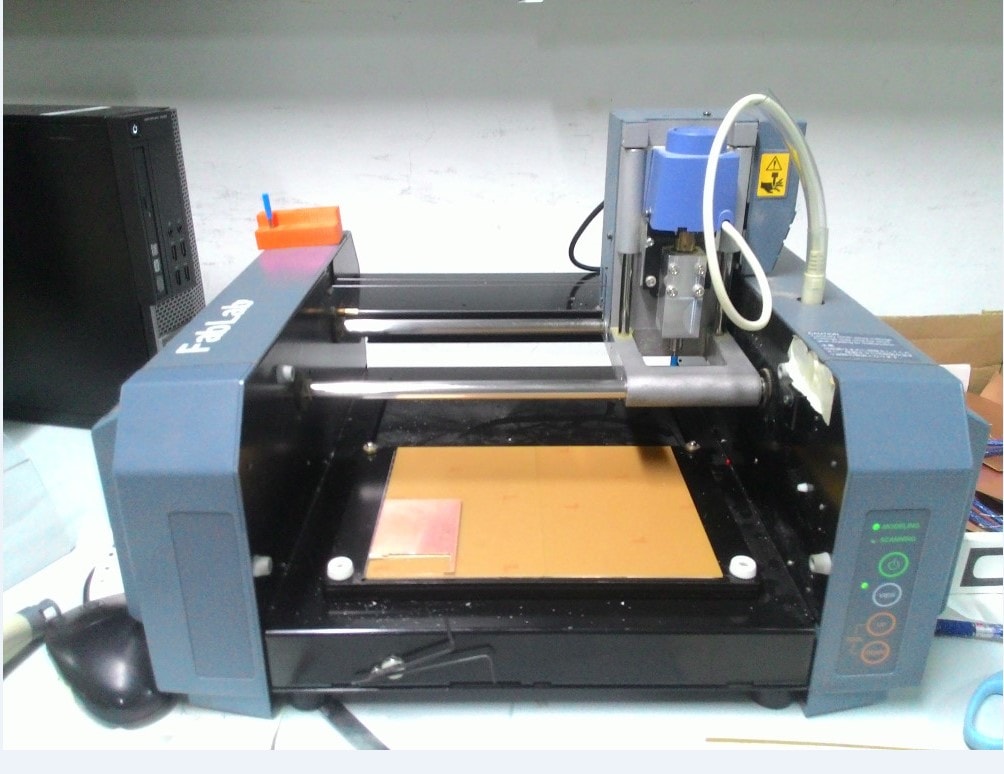

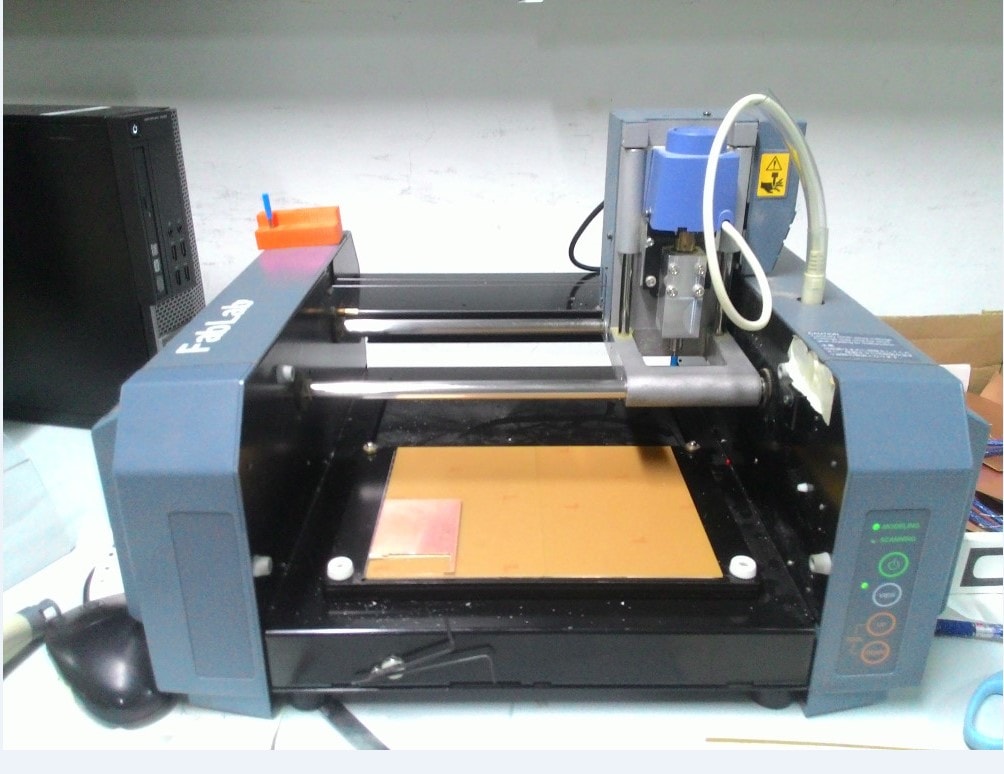

Roland Modella 3D plotter

Roland Modella MDX-20 is a desktop CNC machine used

for making PCBs, carving moulds with soft materials like wax and

can also be used for scanning 3D models of objects.

The detachable

base plate moves along Y axis, the header where the driller is mounted moves along X axis and

the carriage where the motor is attached moves along the Z axis.

Setting up the machine

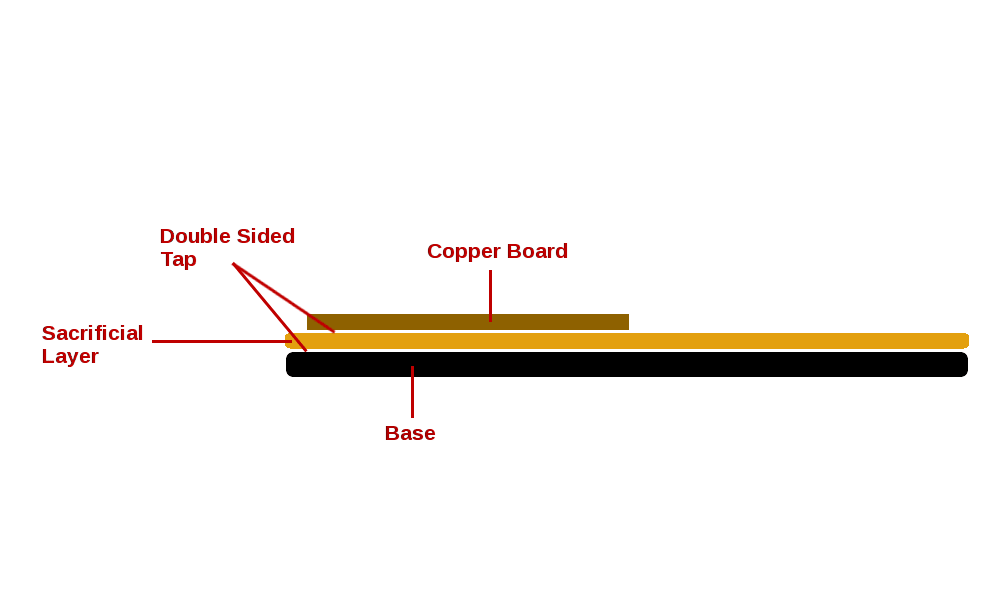

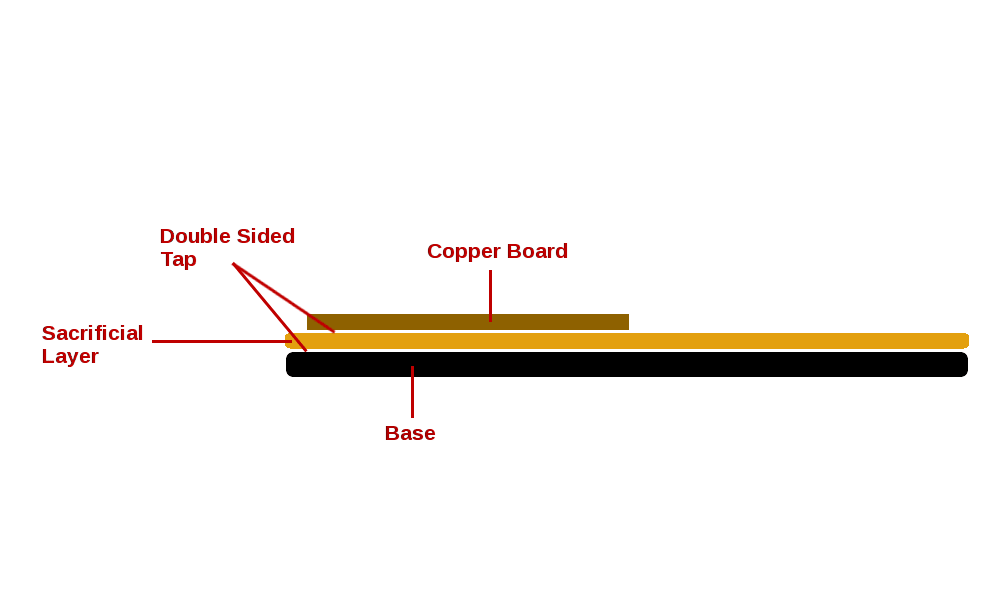

The machine has a metal base which moves. Our PCB is placed on this base.

The bit usedd for milling and cutting operations and very delicate.

If the bit comes in contact with the metal plate,there are chances that the

bit get damaged hence a sacrificial layer is placed on top of the

metal plate and our PCB is placed on the top of this layer and held in position

using a double sided tape.

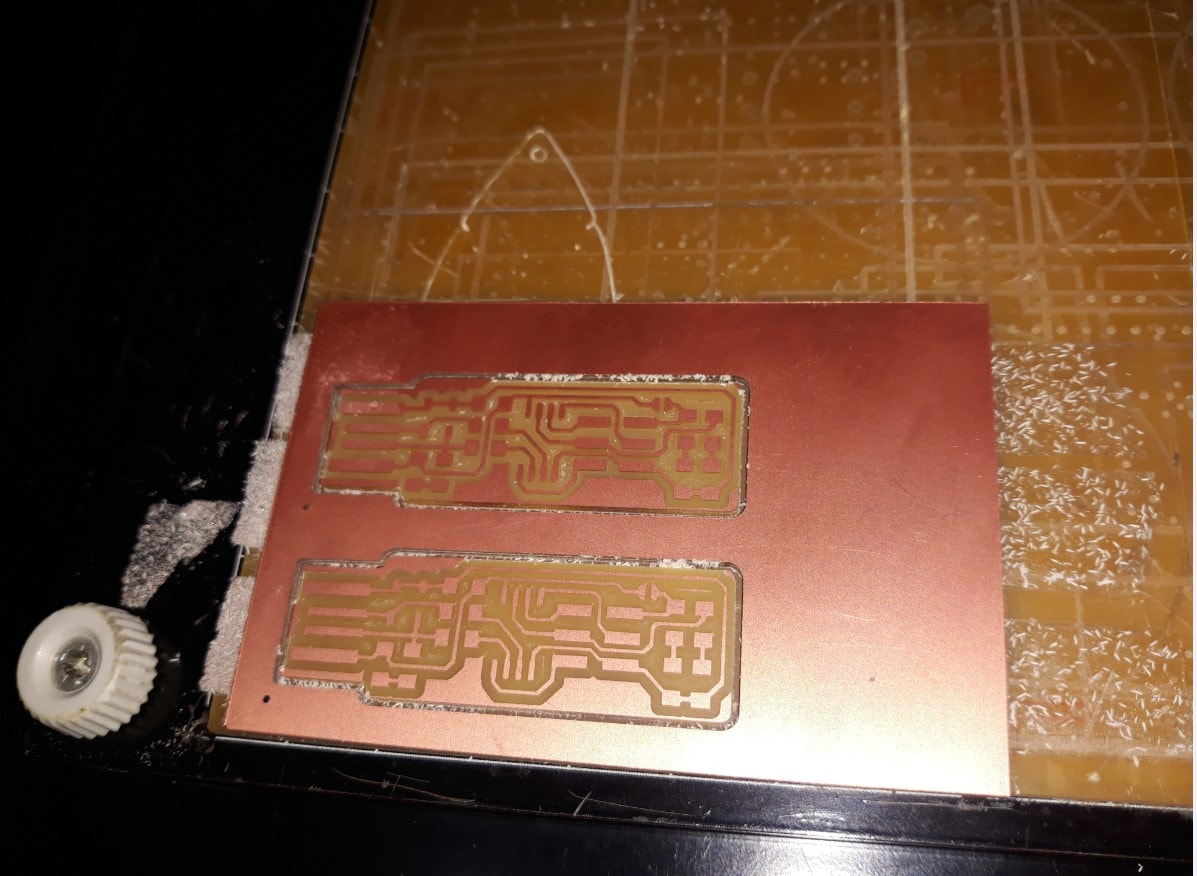

Making the PCB

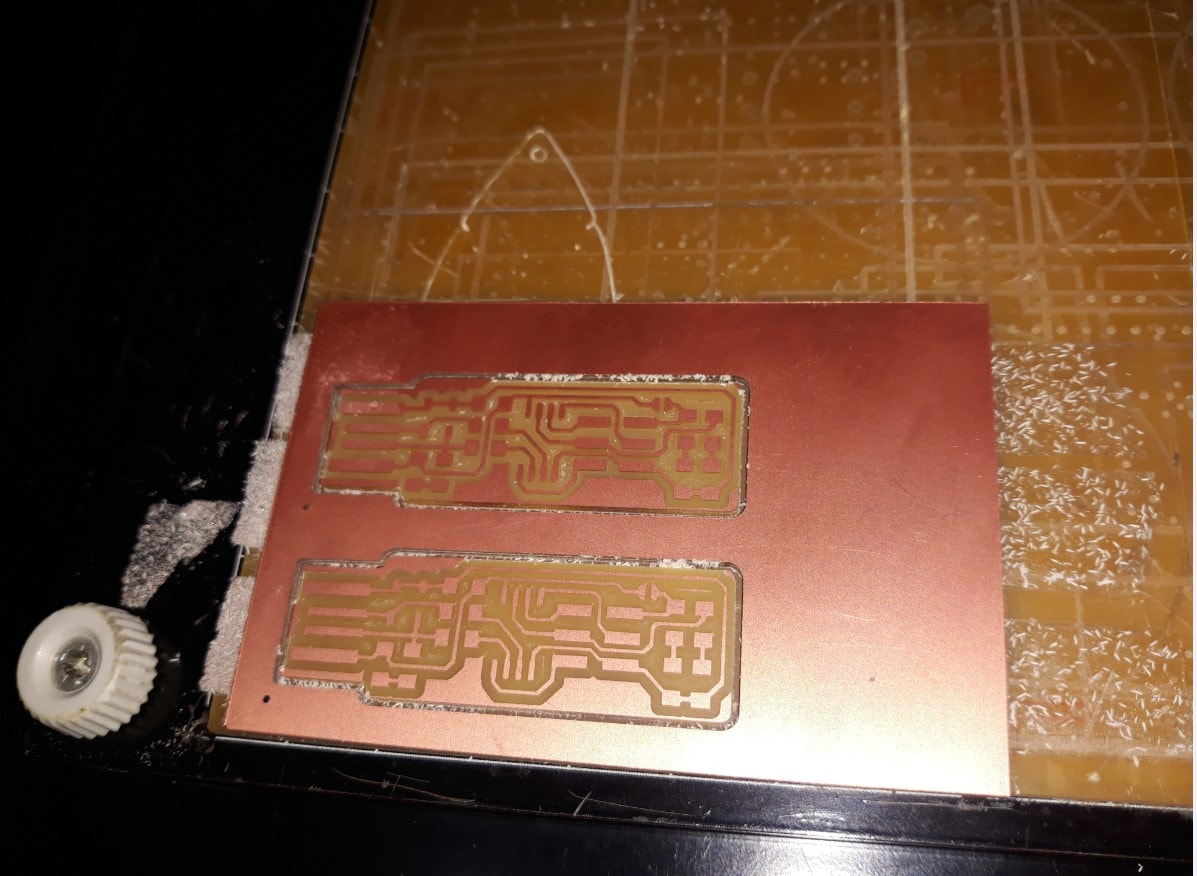

For making the PCB we perform both milling and cutting. Different bits are used for

achieving these purposes. Milling operation is carried out first.

- Milling

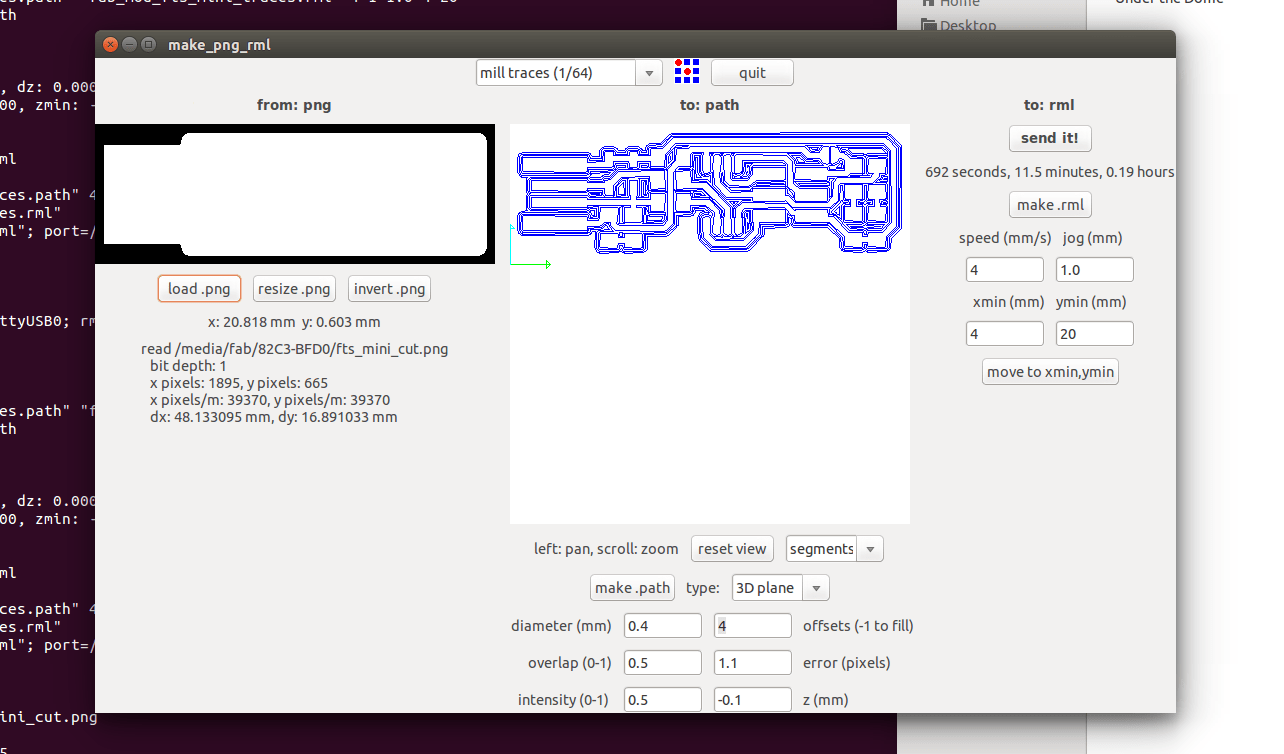

For milling operation drill bit of 1/64 is used. Below are the step by step

operations that are carried out.

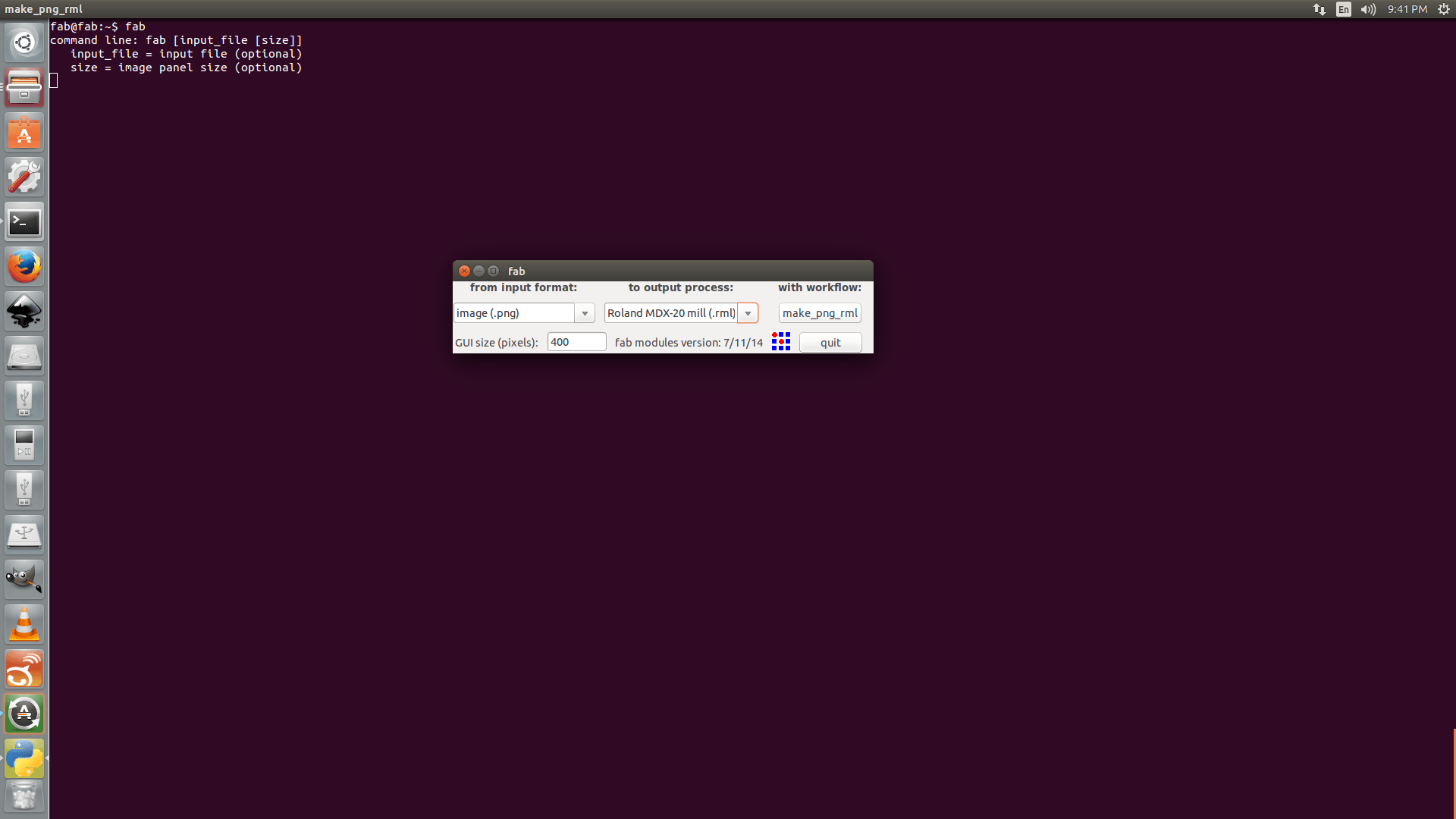

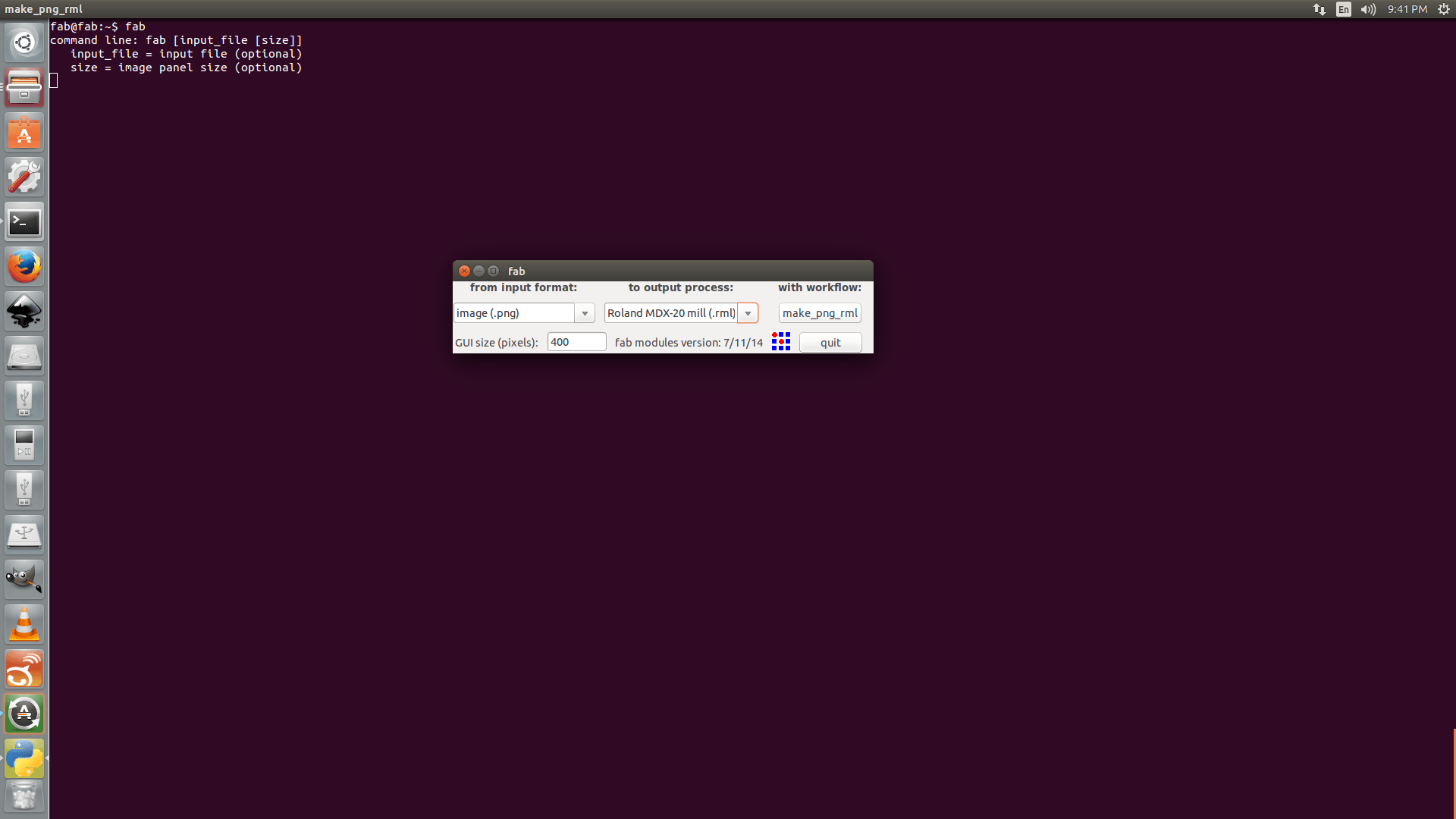

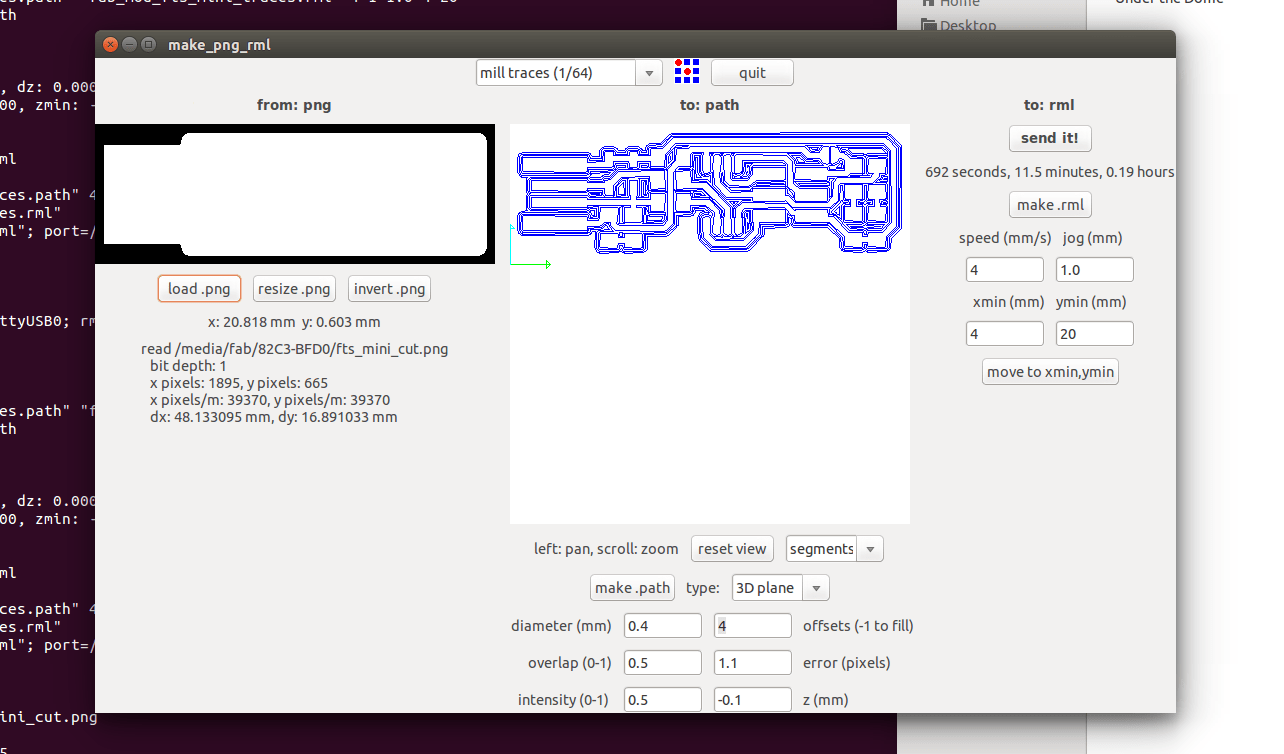

- Open Fab module using the command fab and select 'png' in the input format

and 'Roland MDX-20 mill' in 'output process' boxes.

- Load mill image to the software and click on make path

button to draw paths. Adjust X and Y positions of driller using

Xmin and Ymin options in thw window. To adjust the Z axis, use UP & down

buttons on the Modella Machine.

-

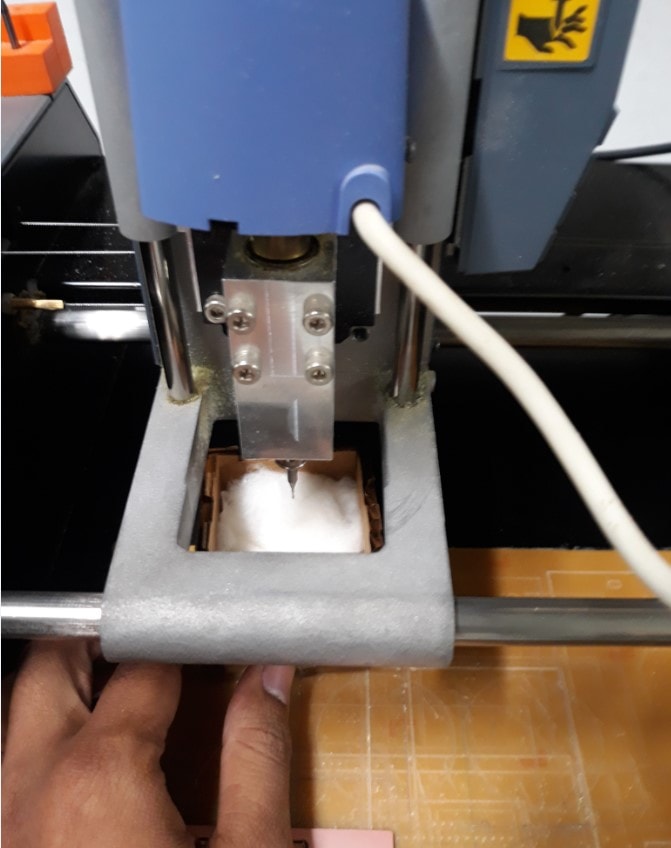

The bit has to be adjusted such that it just touches the board. For this

the bit has to be loosened using allen key. Special care has to be taken

while removing the bit. It should be made sure that the bit does not fall

down to the base while changing as this impact can easily break the tip

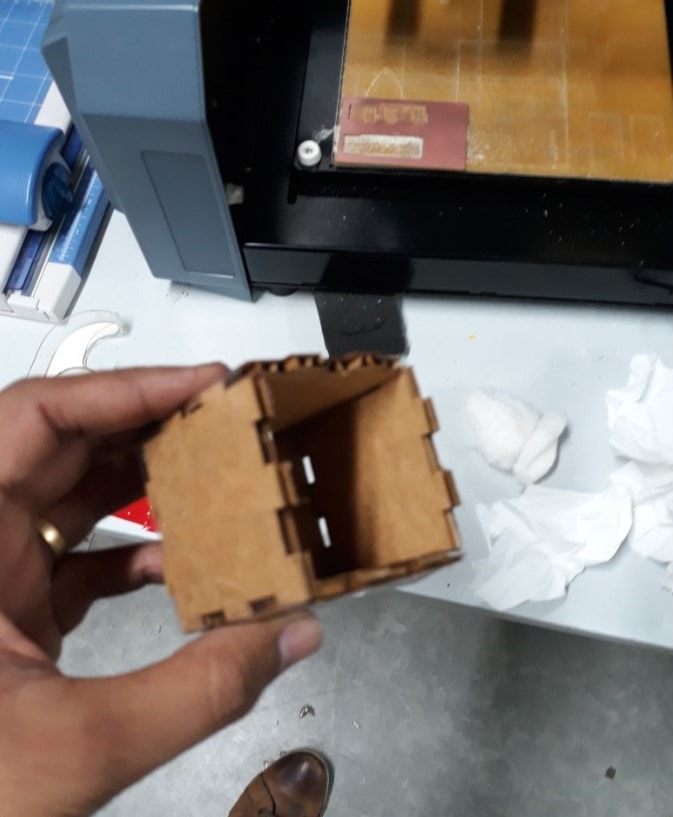

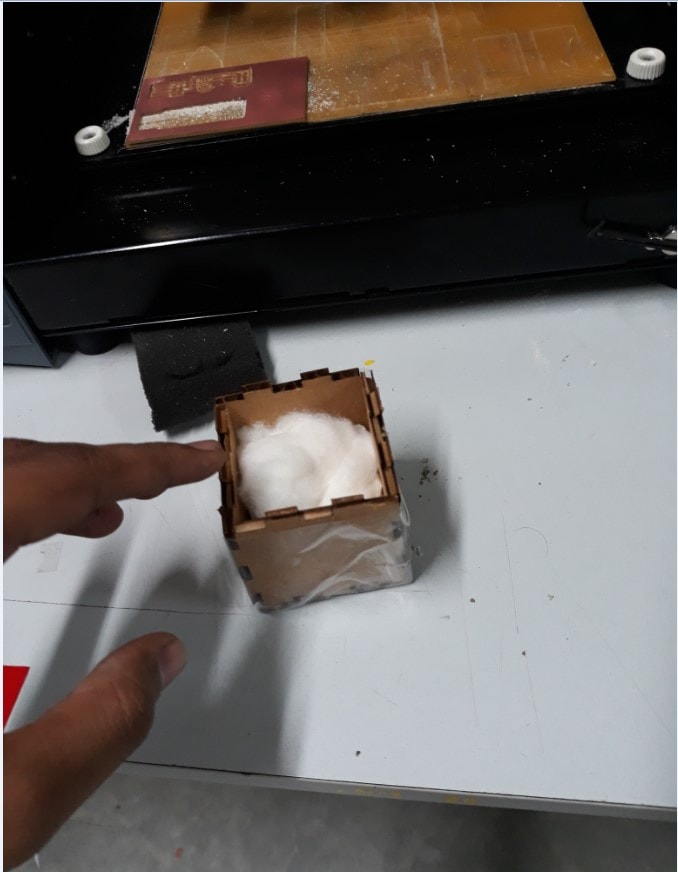

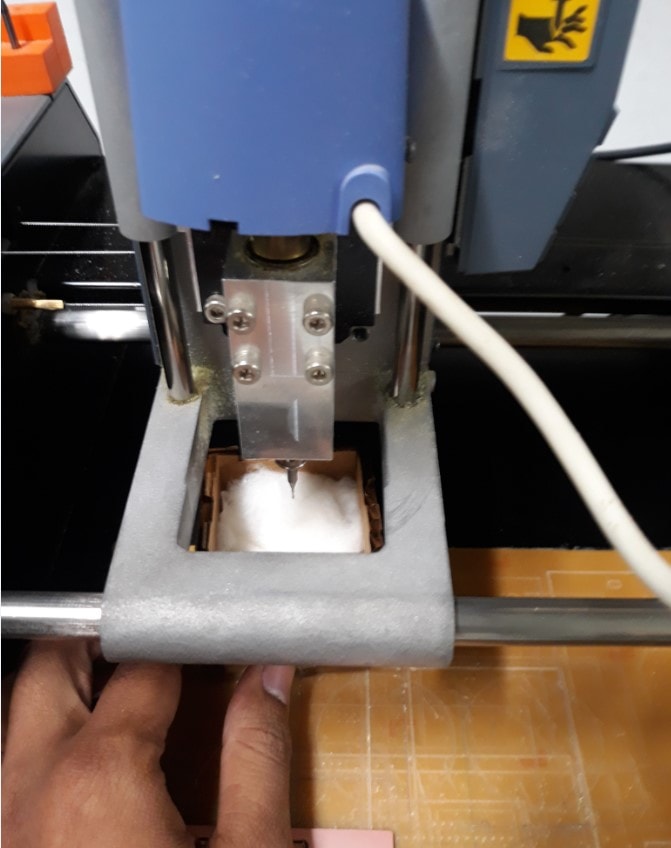

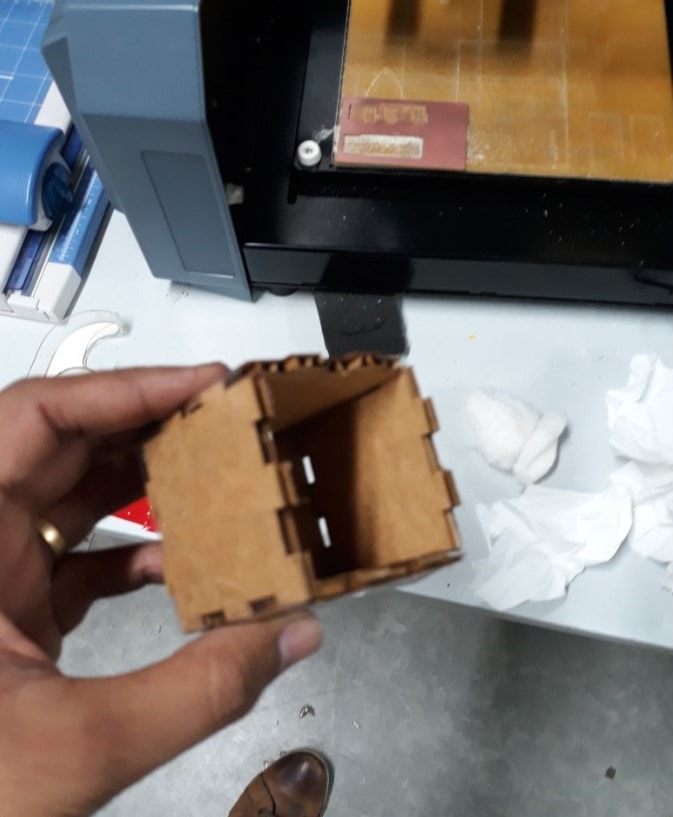

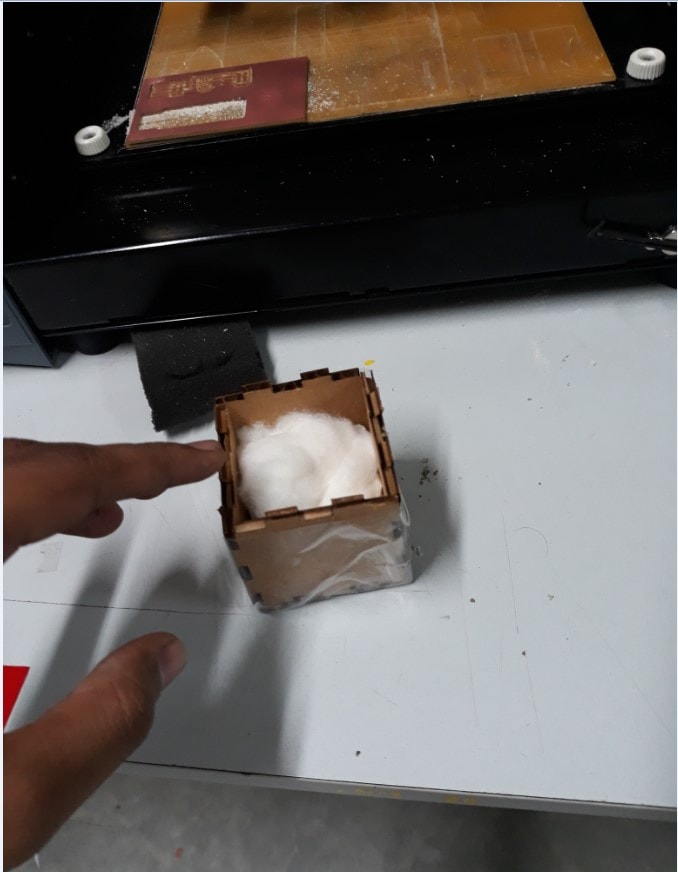

- I decided to make a Safety drop box(as i would like to call it) to make the bit

removal process a little more safer. I used some unused laser cut cardboard pieces

to make a box out of it. I then filled the box with cotton and tissue paper. This box is

now placed under the bit during its removal process so that even if the bit drops, it's

tip is not broken.

-

Select mill bit size as 1/64 from select box. Now click on make.rml

button and then send it button, then click on Begin Milling

on the new window opened. Now the machine will start milling. The total

time taken is diplayed on the screen.

-

Next step is cutting. The steps involved are same as that mentioned above,

however this time the bit has to be changed to Cutting bit 1/34.

Move the header up using Up button on modella machine menu.

Bring the bit to initial point like we did previously and change the bit

Then bring the header down using Down button, so that there is some distance between the bit and the copper plate.

Now adjust the bit such that it touches the board and tighten the screw using allen key.

Load the new image for cutting.

Final outcome

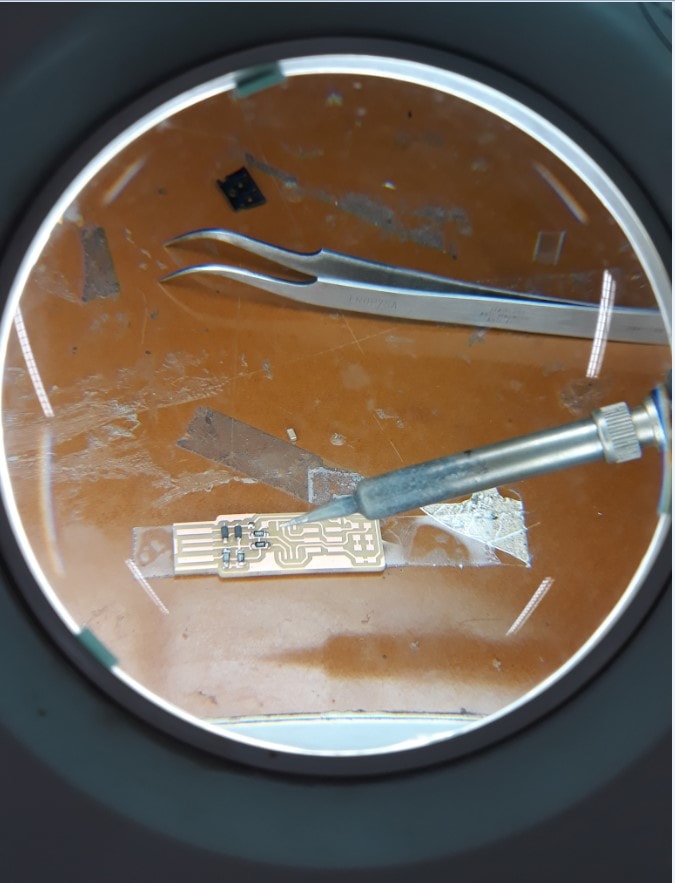

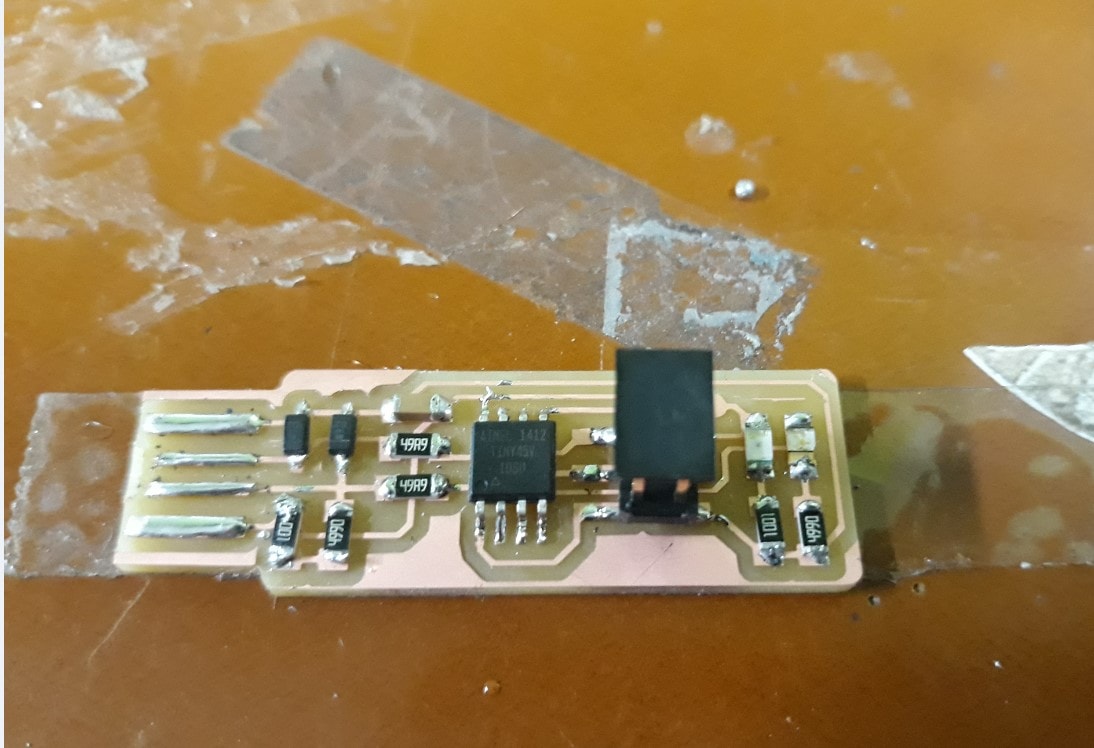

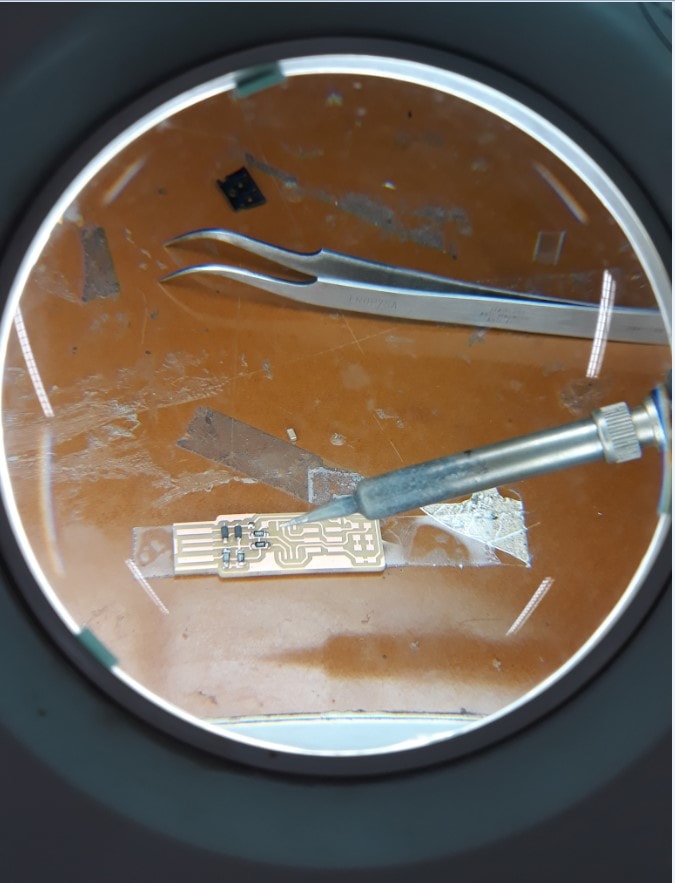

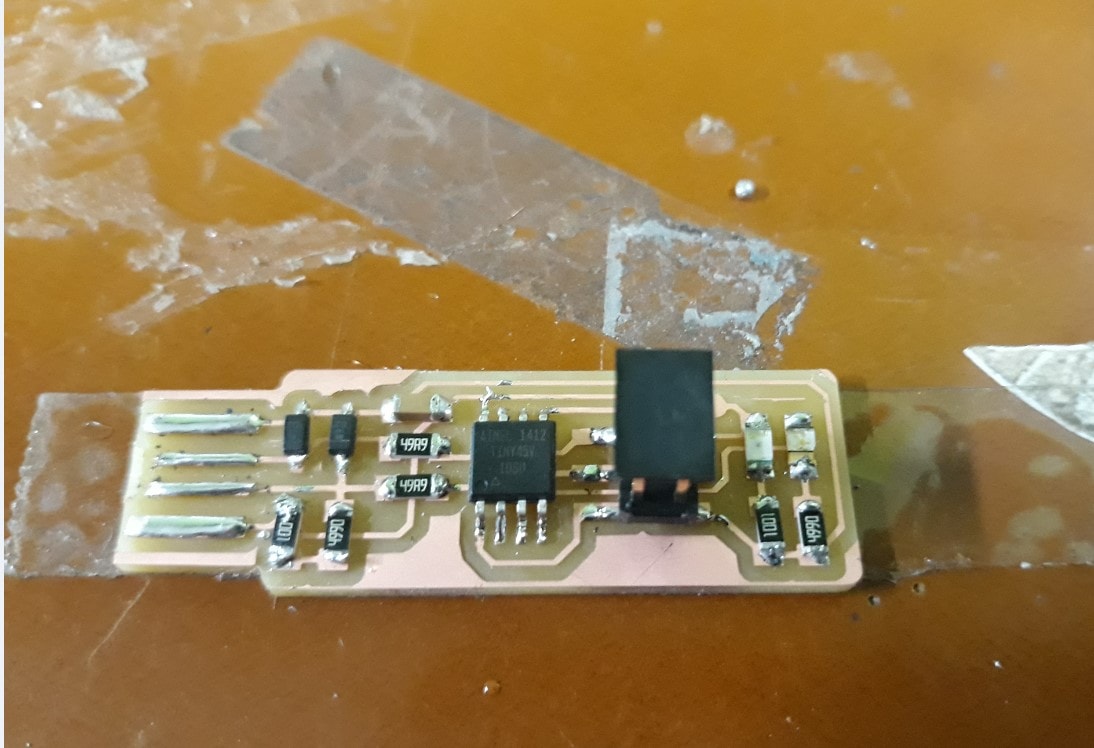

Soldering

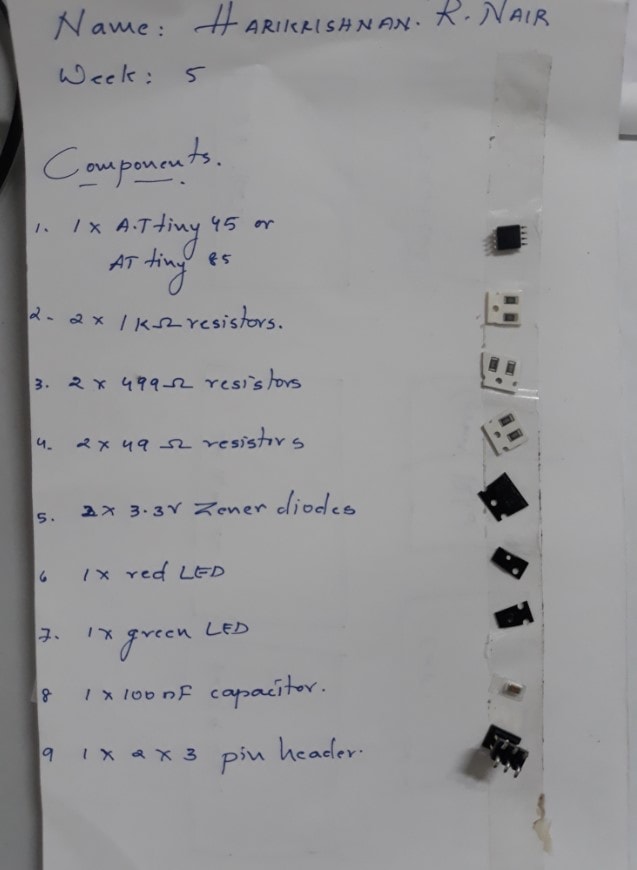

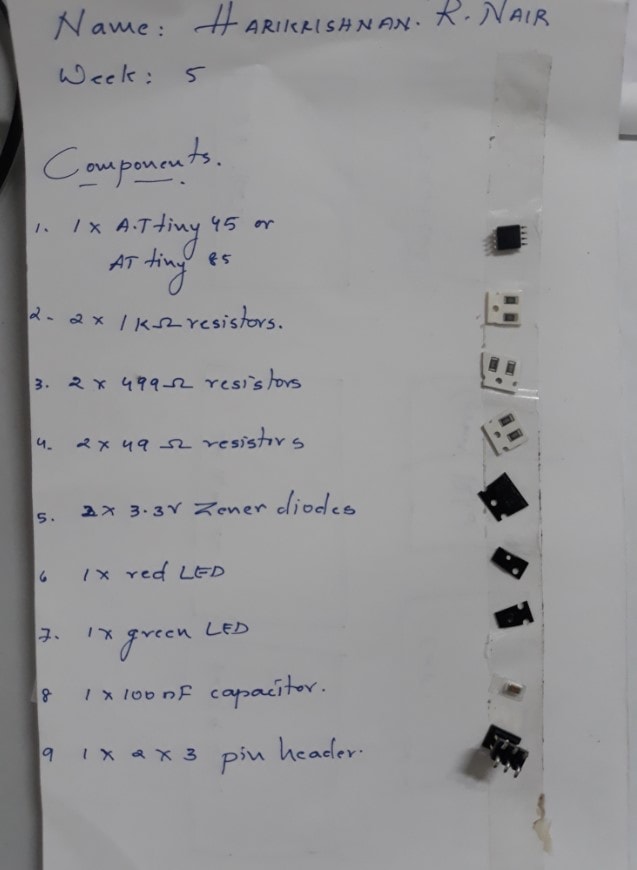

Now the next thing is to solder the components on to the board. As the

instructors suggested I wrote the component names on a sheet of paper

and stuck the components onto the sheet before starting the soldering.

This method is helpful in preventing the components from getting mixed up

Final product

Programming the ISP

After succesful completion of the ISP fabrication the next step is to install

necessary modules.

For installing the modules,use the code - sudo apt install avrdude gcc-avr avr-libc make

The firmare was available in the fabacdemy site. I downloaded it and moved

it to folder.

For burning the firmware into the chip another programmer is used. The programmer

is connected to the PC via usb port and the ISP is connected to the programmer

using IDC cable.

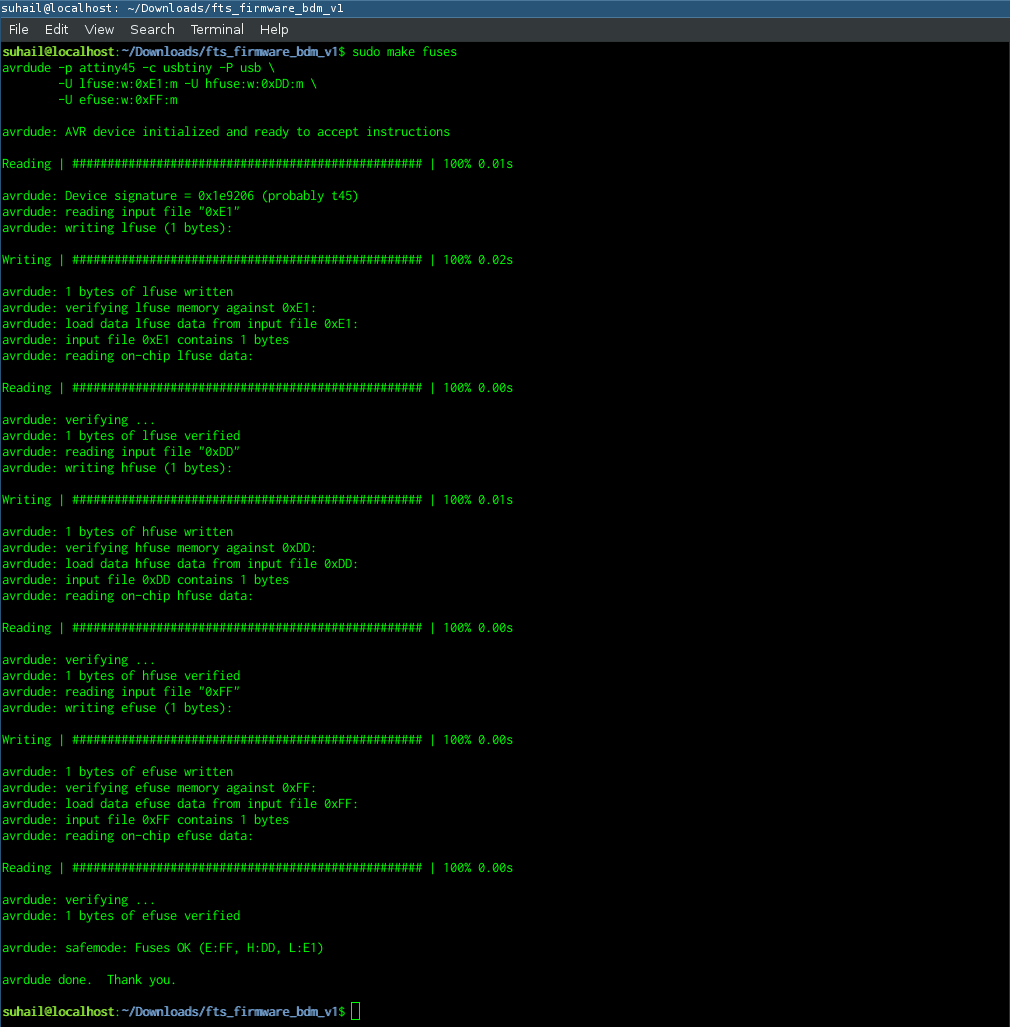

Below are the steps for burning the firmware to the ISP.

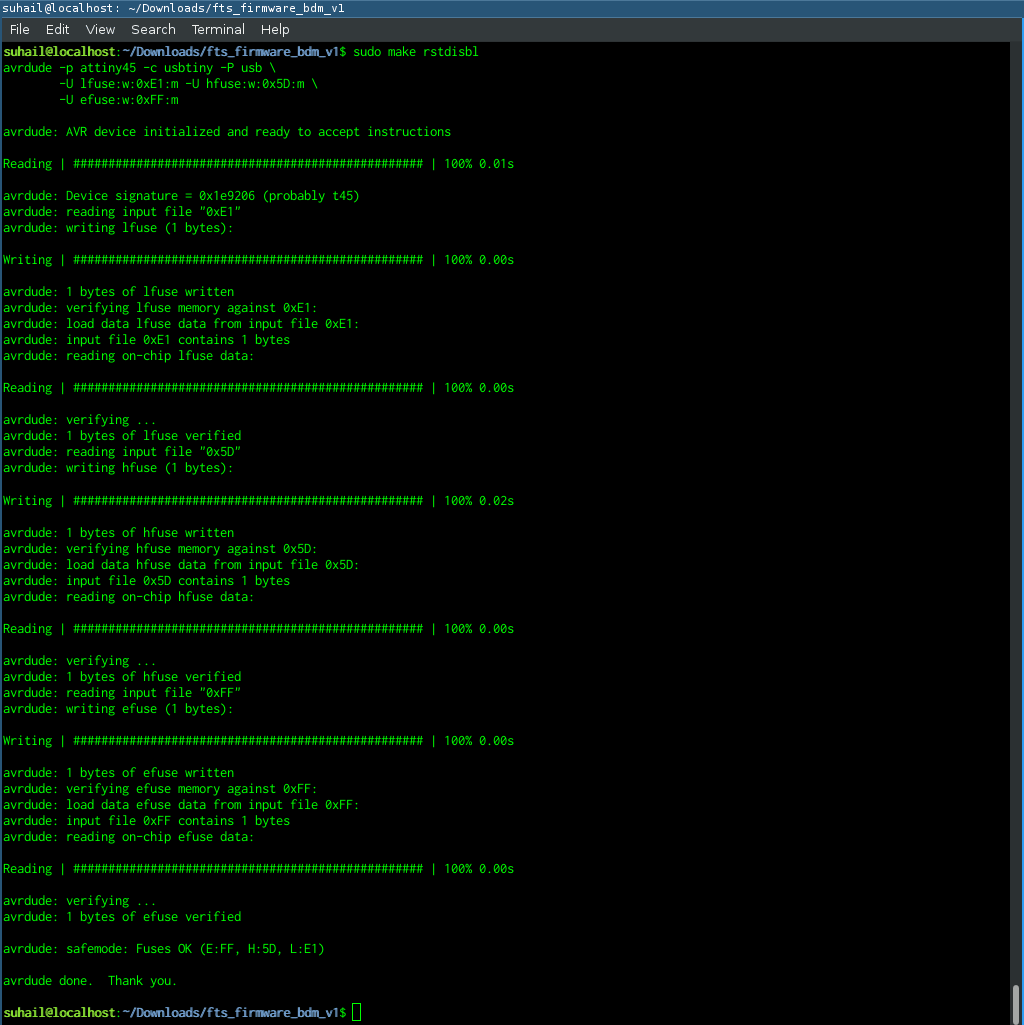

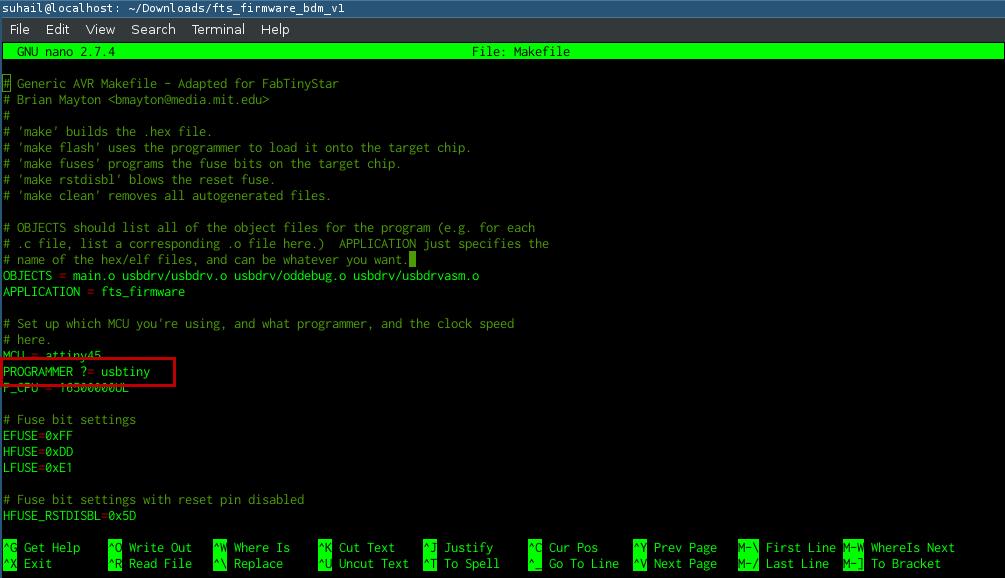

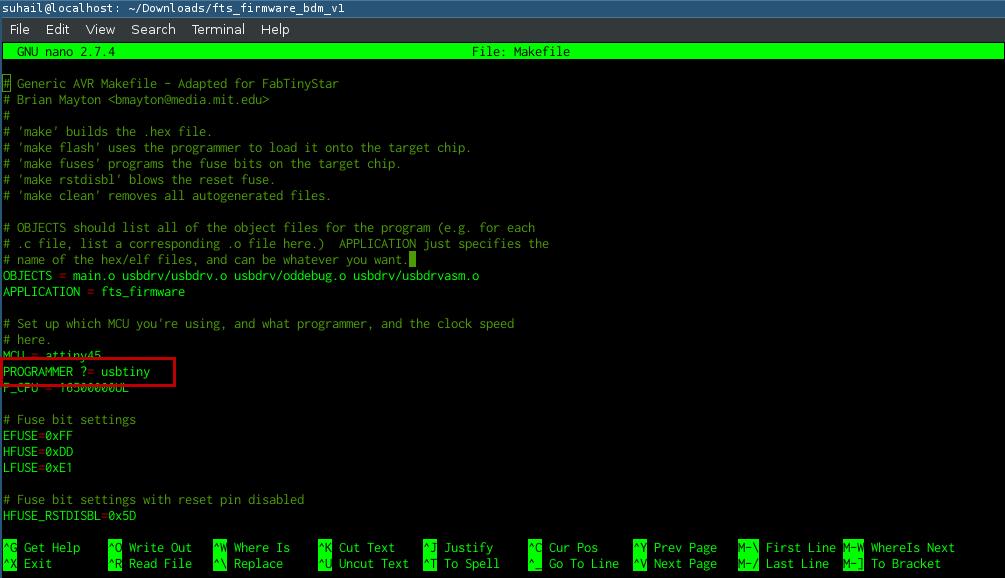

- Go to the firmware directory and check if Makefile contains 'PROGRAMMER',

as 'usbtiny'.

-

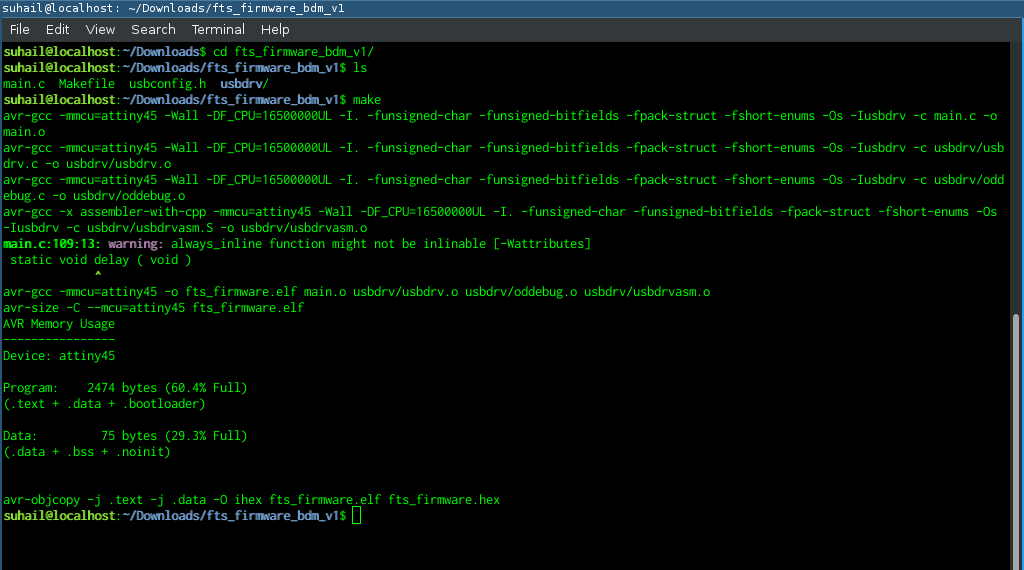

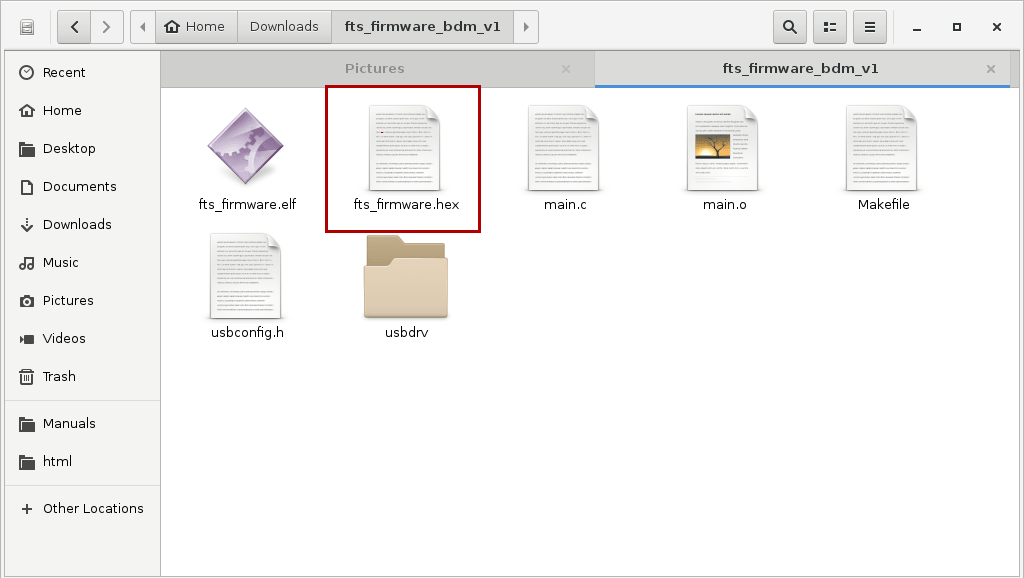

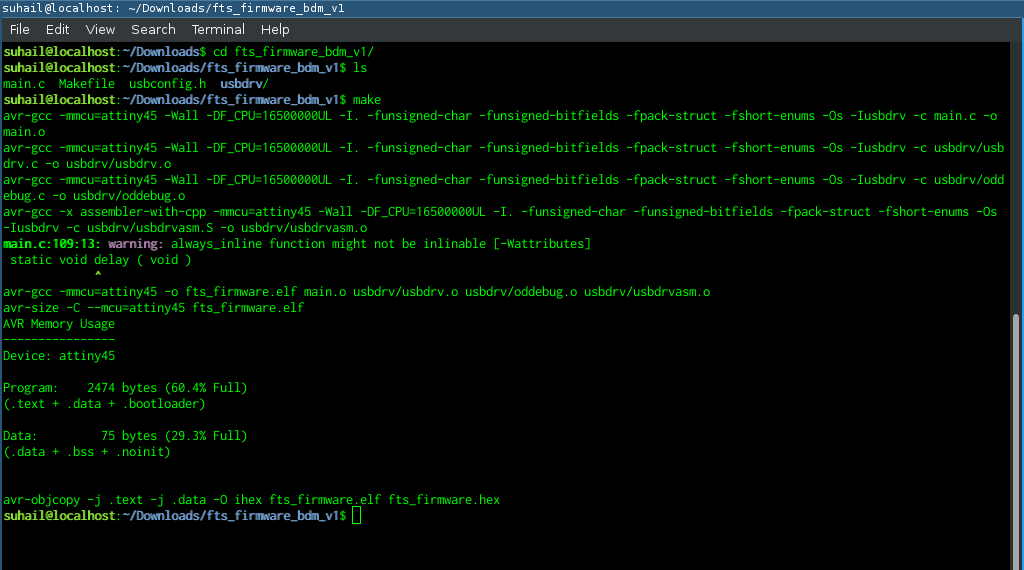

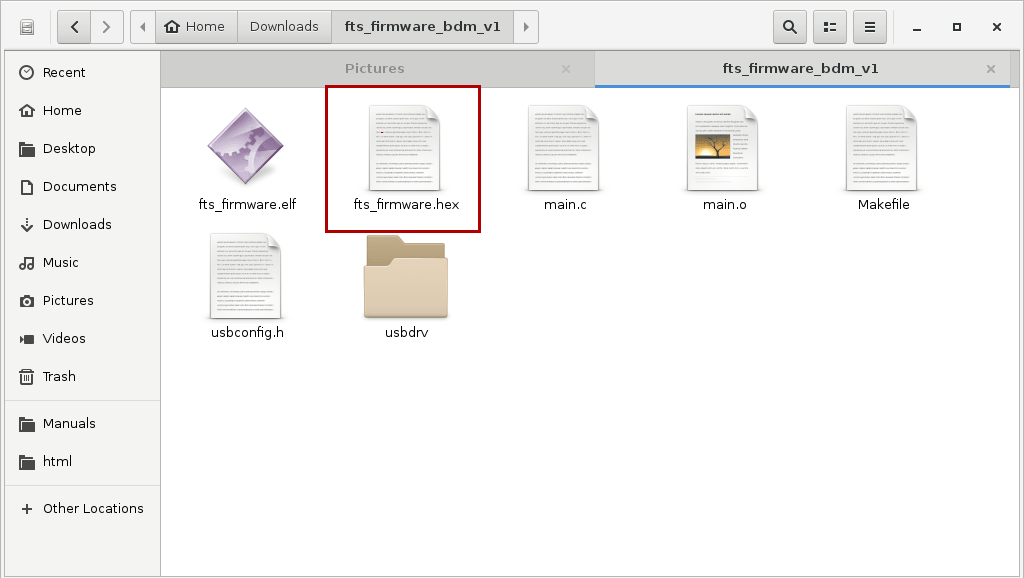

Run make command to generate hex file. After running this command, our

directory now contain a file named fts_firmware.hex.

-

Run make flash to flash hex file to the chip. Use code

sudo make flash

-

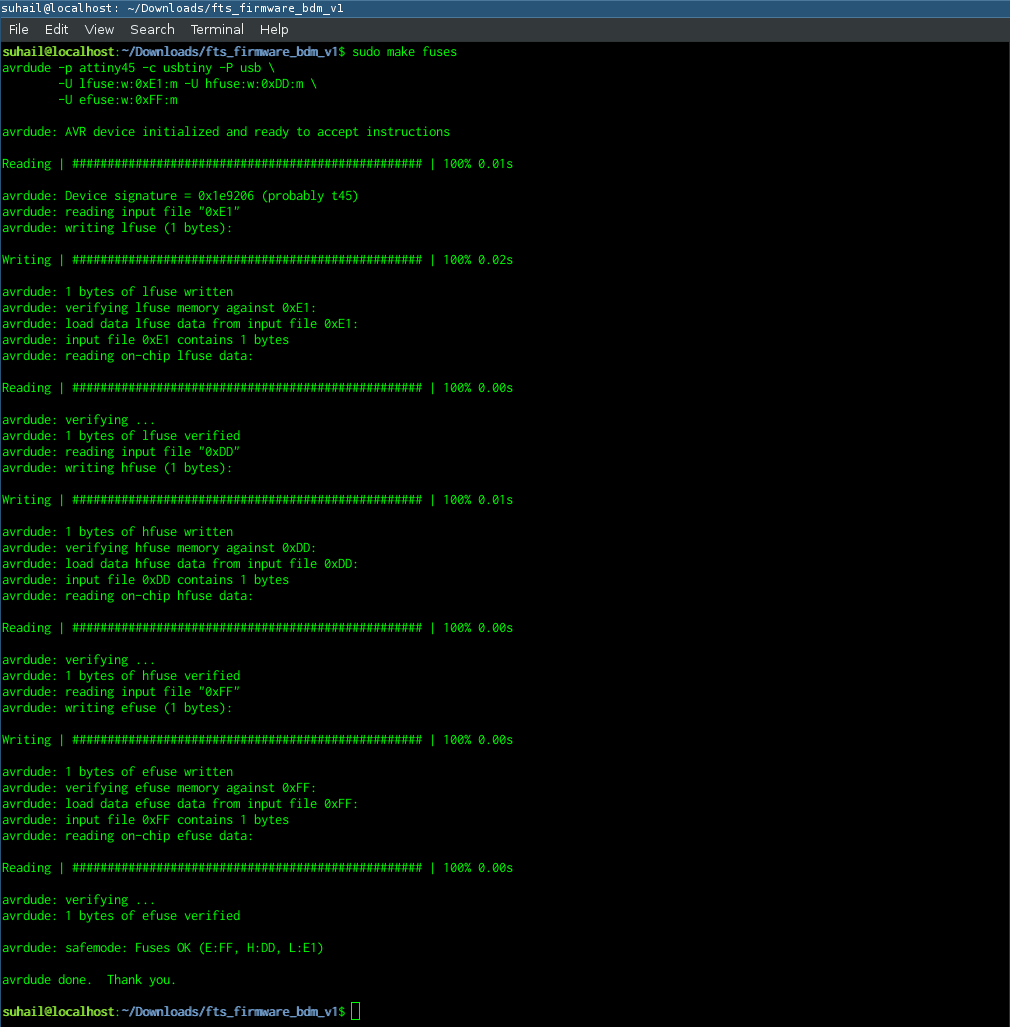

Run make fusesto setup the fuses. Use code

Testing

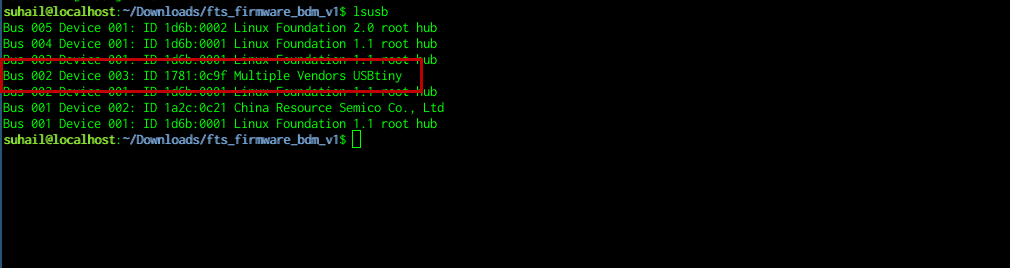

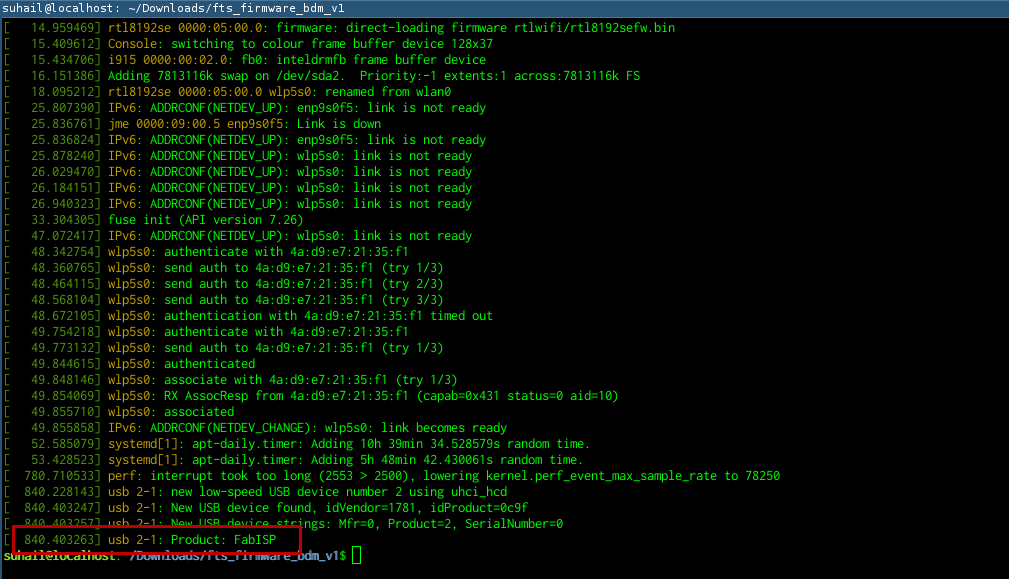

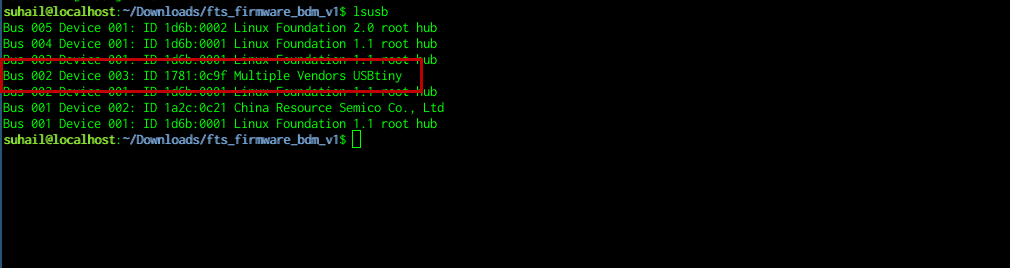

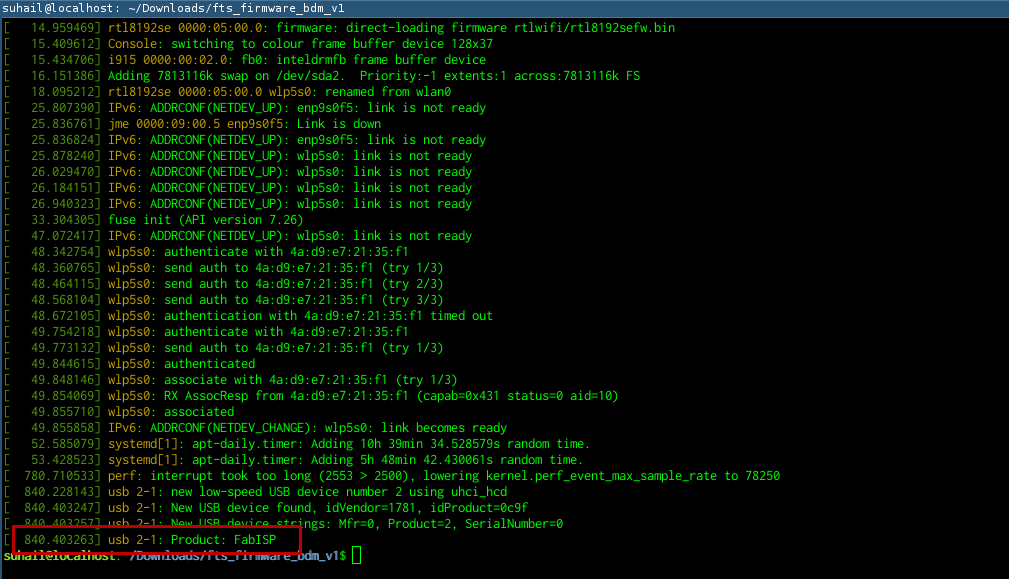

For testing the ISP,I removed the ISP from the programmer and connected it

directly to the PC. The LED turned on. Now, to check if the system is detecting

detecting the USB device, I used the lsusb command.This should list

all the usb devices connected. dmesg command might be useful to

check if there are any issues with the device.

This command prints kernal messages.

The ISP has been succesfully detected by the system. This means

that the ISP is working fine. Next step is to disable the reset pin

so that it can be used as an IO pin.

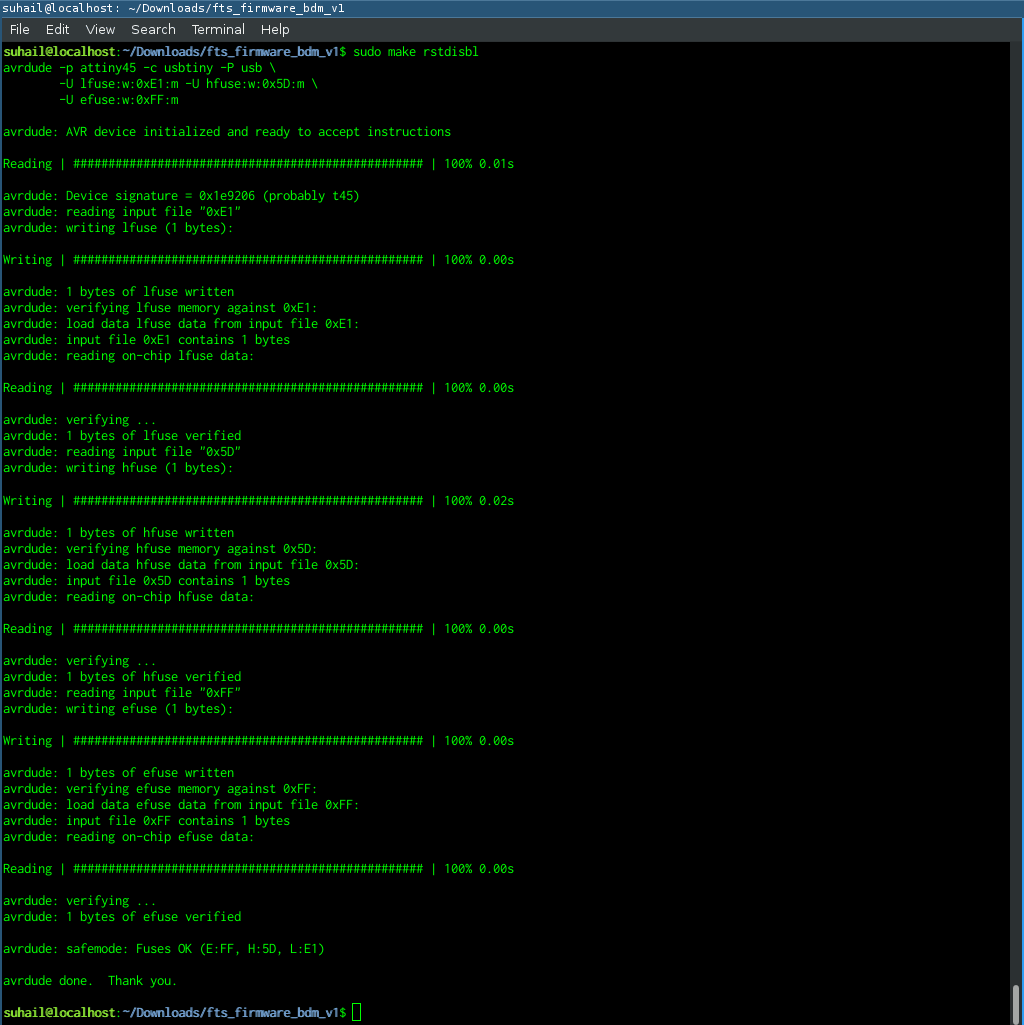

Disable Reset

To disable the reset pin run the command make rstdisbl. Use command

sudo make rstdisbl