I have set the deadline for 16th of june 2018 as it is our final presentation on 18th so that I get atleast a day for reviewing any issues with the project. As of today I have three more days left.

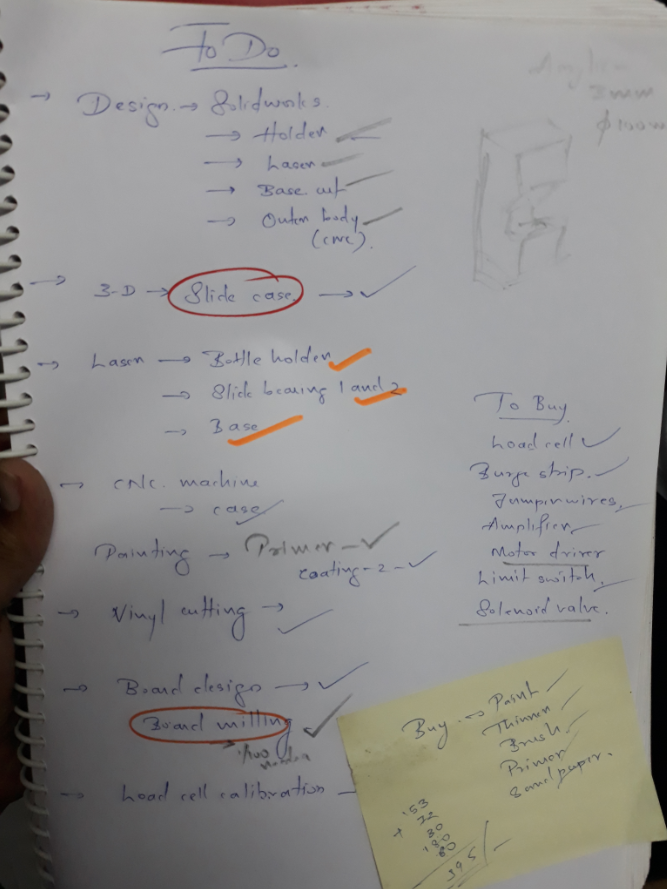

I have made a checklist for each day to keep track of my progress. Also I'm spending more time in the lab theses days, sometimes working overnight. Also in order to save time , I am documenting simutaneously.

Apart from a test 3D printed case for the solenoid, everything else so far is working just fine.

The 1/62 regular bit in the lab was exhauste. So I had to use 1/64 V bit which was not good for milling

really fine traces. I had two failed boards. Finally got it right by reducing the speed to 1mm/s.

The 3D printers in the lab failed. Larger parts could not be printer with the faulty machine. I had to design bottle for the machine. Since the

I then switched to glasses that can hold the resin in the machine.Solenoid valve- I had chosen to use solenoid valve instead of Perislatic pump because of the its unavailability. However it is not the perfect choice for such a small machine. Even though it activates according to the program it does not dispense the fluid in a rate as expected.

I have to confirm the setup to mount the load cell. I missed the part where the load cell actually had to be placed at a right height to function properly. I had not paid much attention to that. Need to fix it immediately.

The load cell was fixed to the bottom of the pad using plywood and screws. It was not that hard as I expected

I dont know if I can answer this question correctly because there is no limit to things I learned from Fablab. I learned a lot about electronics. Its production and programming. I learned to use the 3D design tools a lot and also i to fabricate them. Also I with the global network I was introduced to lot of new technologies around the world. Fablab is the best decision of my life. I have changed a lot. My perspective towards digital fabrication has really changed. I am thankful to all the members of this community.

The concept of the machine could be successfully prototyped. The fact that a machine had to be build from scratch is something that I could never foresee and how challenging it would be.

Looking back at the processes involved in the making of the machine I would say patience and time management skills are pre-requisites There are several things that could stop you from building anything. It could be your design failure, faulty machine or even you own health can cause you to slow down.

The 3D printers in my lab were faulty during the project development. Certain type of milling bits were exhausted in the invetory. The limit switch of CNC malfuntioned. These are certains things that are beyond our control but we certainly adapted to the situtation. Anticipating that such things could happen was necessary but unfortunately we didn't. But we were fortunate enough to get it working finally.

End result, the machine was working fine though it could only dispense water in the prototype stage. I learned more about programming and also electronics. My friends and instructors were very helpful.

Things that went well in single attempt - Laser cutting, vinyl cutting, painting and finishing

The time consuming tasks that worked after nultiple attempts were- board design, board milling, 3D printing , load cell calibration, elecronic programming and assembling.