What I did

Creating a mould

I was thinking of creating a text using chocolate. So i designed a mould that reads "FAB'14" usinh Rhino. The design was loaded in Modella and was milled on wax. Later the mould was created using SORTA CLEAR as it was food safe. The mould took 24 hrs to cure.

The next day I bought some baking chocolate for melting. Also i bought some baking paper for placing the chocolate.

Melting the chocolate

Melting the chocolate in the lab was a hard task to do. The lab did not have the right apparatus to do so. Chocolate cannot be melted by applying heat directly , the bottom most layer of the chocolate will be overheated and there are chances that it will stick to the appparatus.

So for melting the chocolate, double boiling technique should be employed. For this boil some water, place glass bowl above the boilng water and with this heat melt the chocolate.

Unfortunately things were not working very well with the melting part. The apparatus we had were not of the right size. I was facing issues with mixing the chocolate with spoon and also the heat was not supplied uniformly. So i shifted to home and used Microwave to melt the chocolate.

In a microwave it only takes about 20 seconds to completely melt the chocolate and get a smooth flowing form. The Silicon mold was cleaned using alcohol and the chocolate was poured in promptly. After pouring the excess chocolates were wiped out and the mould was placed in the Freezer for 20 min.

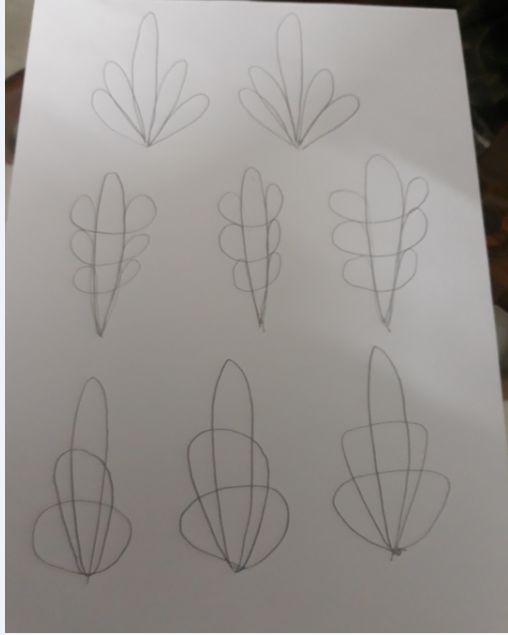

While the mold was getting ready I was experimenting with the remaining chocolate. The chocolate will start to become hard if kept outside for like 15min. So the remaining chocolated were melted again. I filled the chocolates into a piping bag and made few designs with it.

Wiping out excess chocolate from the mold

Making the designs with hand

For garnishing the final molded chocolate I decided to make some designs using hand. For this I drew some designs on a paper, placed a baking paper over it and then drew the designs using chocolates filled in a piping bag. While making the designs you need to act fast because as the chocolates begins to get hard it will become really difficult to push it through the piping bag.

While making the designs using chocolate , it became hard and I was finding it difficult to push it out of the bag. Then I applide some pressure on it and it broke. The whole chocolate was spilled on the sheet. Luckily I got few desings correctly.

Taking the mold out of the refrigerator

Arranging all the Chocolates

The final product

Redoing the week

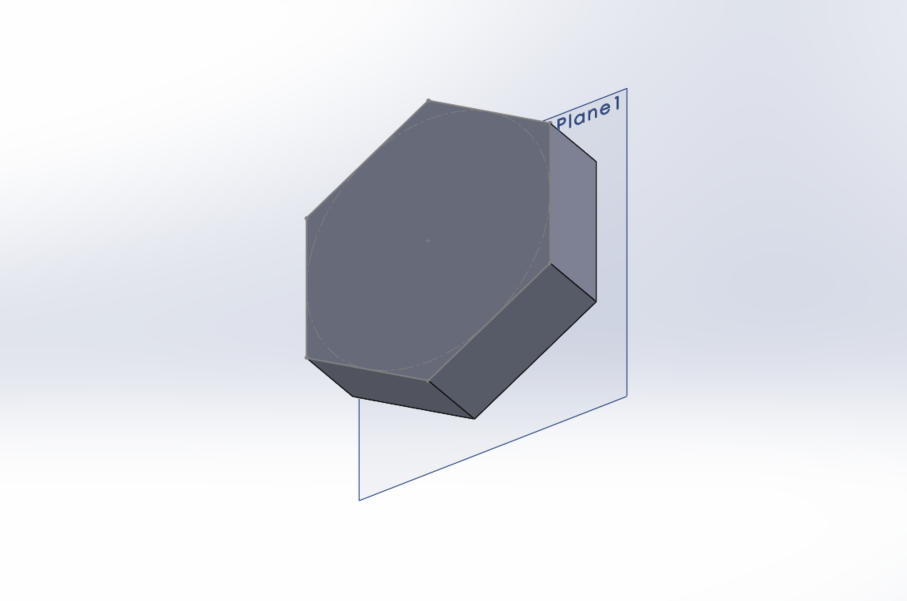

As per the feedback after Global Evaluation, the above mentioned project could not be considered as a Wild card week as this week is about creating something new that is not part of curriculum. The above assignment could be considered as a repetition of Molding and casting week. I was asked to redo the week. So following the feedback I decided to do composites for my wildcard week. I am making a table top plant pot shaped like a hexagon made from composites.

Composites

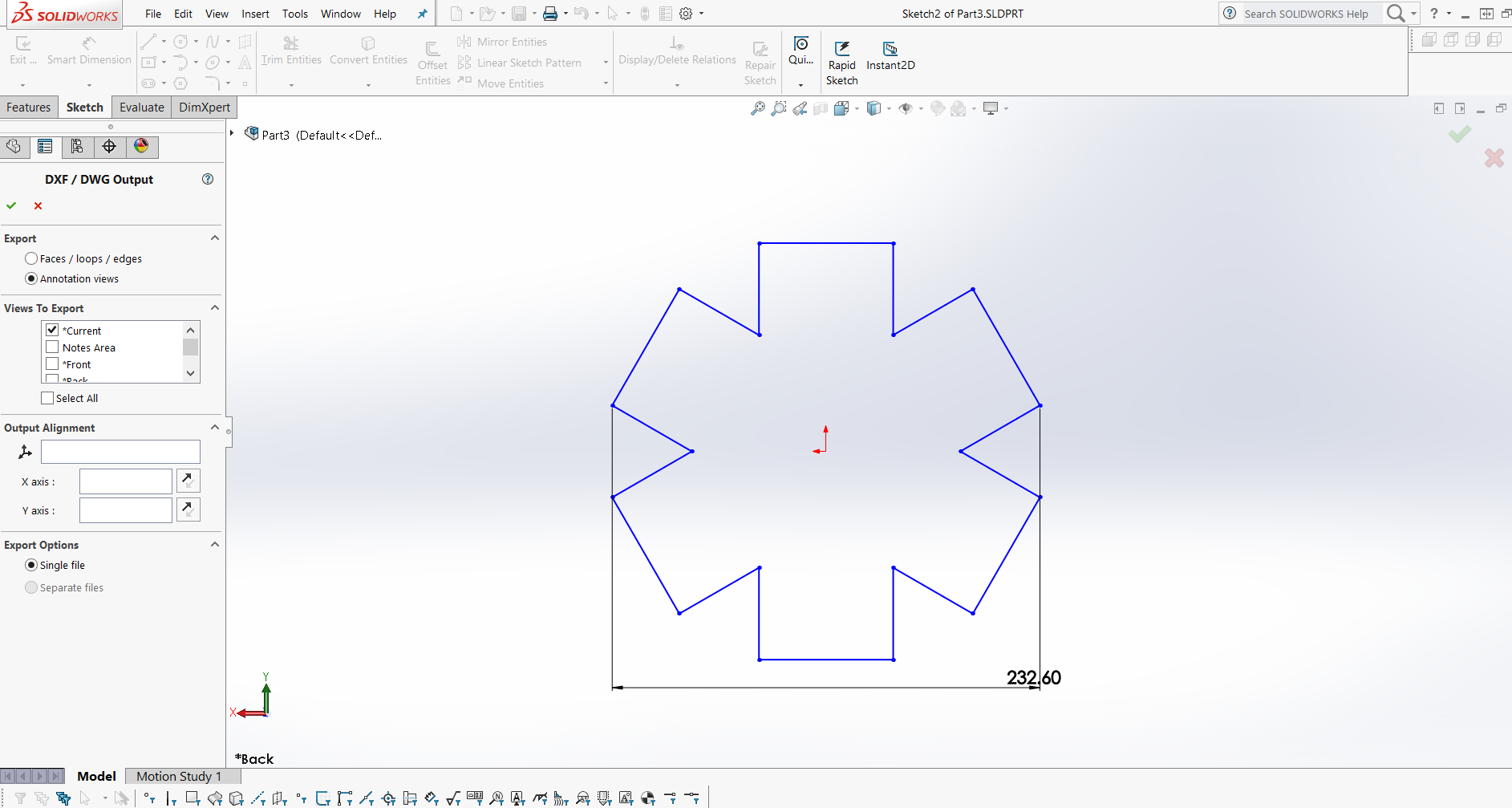

The design

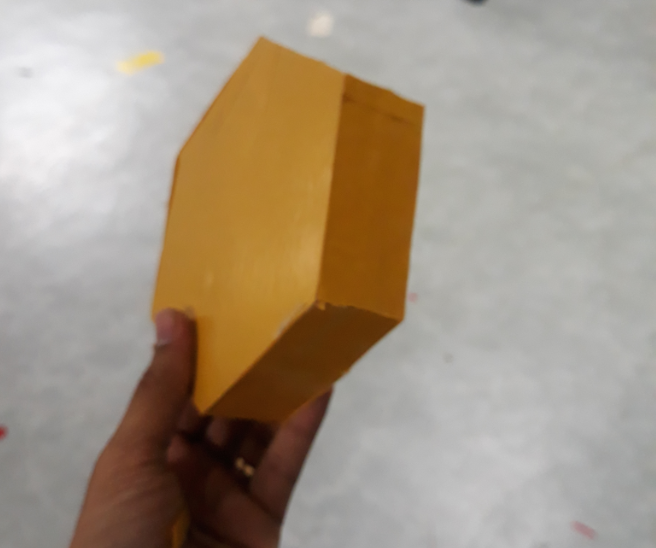

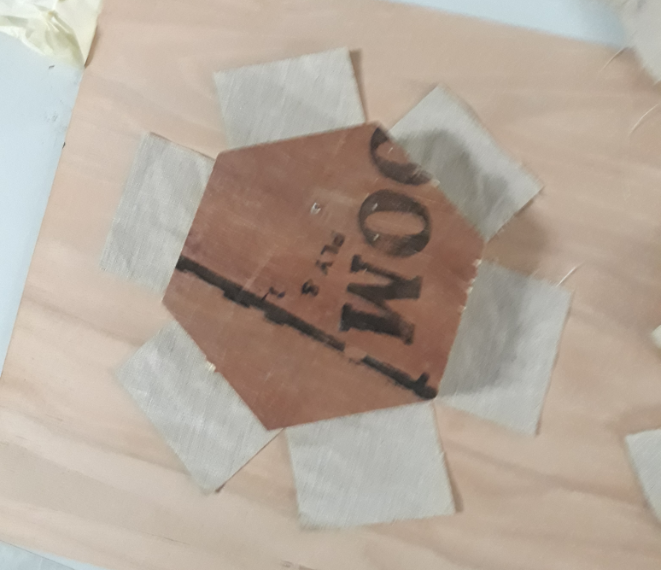

I used Solidworks to make the design. I designed 4 hexagons and exported as DXF and cut the shape on plywood using Vcarve. This was done to make the mold. The mold looks like a hexagonal prism which is made by stacking the pieces together. I used screws to join the pieces.

For making the composite the linen has to be soaked in resin before it is wrapped around the mold. For this assignment I am using epoxy resin. It is mixed in the ratio 2:1 as Part A: Part B as done in molding and casting week.

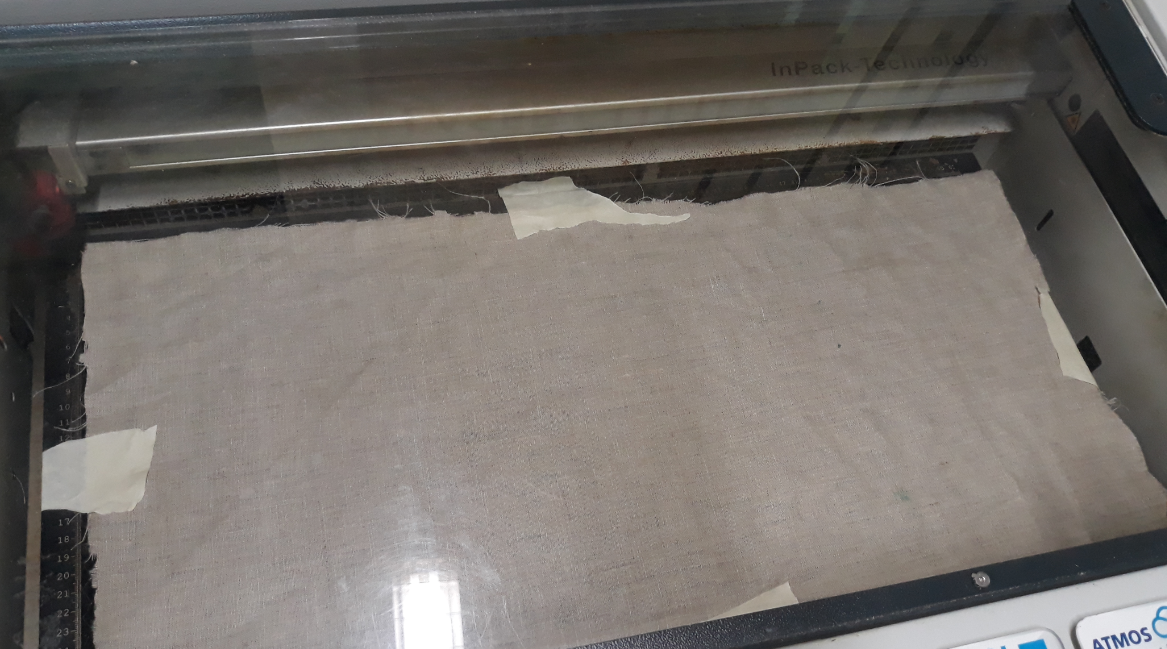

For the purpose of removing excess resin material the whole setup is kept inside a vacuum bag. We do not have vaccum bags here so we improvised and made a vacuum bag using plastic sheet. We have plastic sheets in the lab. It is stuck together to make a vaccum bag using double sided tape.

Once the resin is made a single coat of resin is applied on the mold covered with releasing agent. The each layer of linen is soaked in resin and is wrapped around the mold.

After all the layers are added, next we need to remove excess resin . For this I applied a "Release Peel Ply" on the top and then added a breathing layer above it.

Now the vacuum bag is sealed by placing the vaccum cleaners pipe inside it. The vaccum cleaner is turned on and then it removed all the air inside and causes the excess resin to smear out through the breathing layer

The Final output

kThe final product is taken after 24 hours.