This weeks assignment is to create a 3D model of an object and mill the design and build a mould for the corresponding design, then cast the object in plastic or metallic material. I decided to try plastic casting first.

The idea was to use InstaMold but having a 3D model was a prerequisite for using InstaMold. I could either use a 3D object lying around or I could create my own design. I had this idea of making a key chain . For this I choose the cost effective method of cutting the design on Acrylic. The Acrylic used was 6mm. While designing I got this idea of using the Acrylic itself as a mould material.

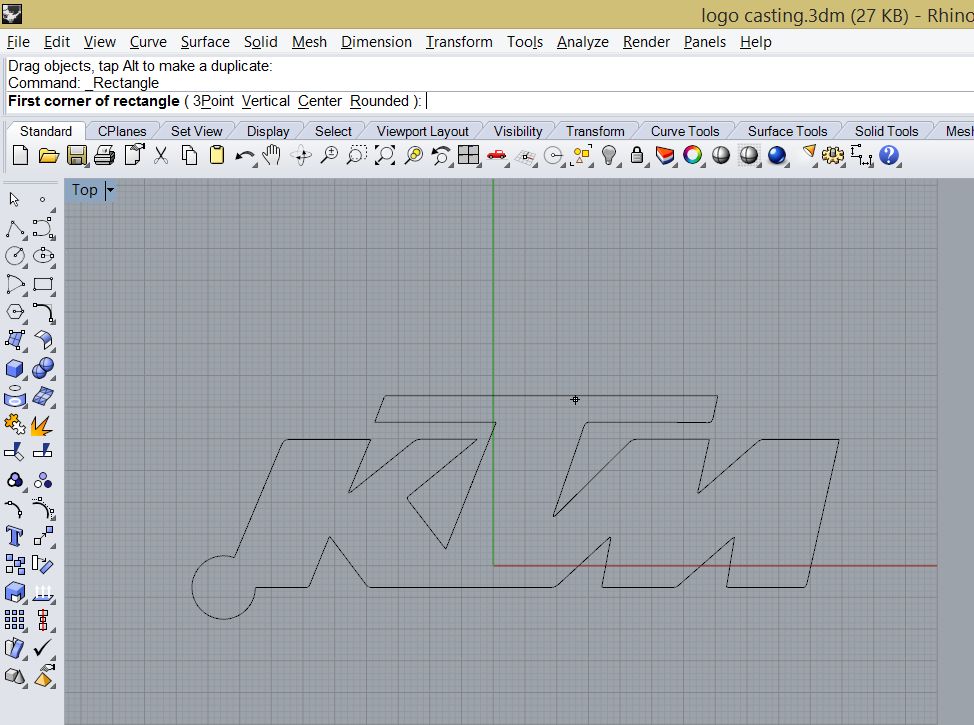

I was planning to create a key chain for my bike. I used Rhinocerous to do that and set necessary dimensions.

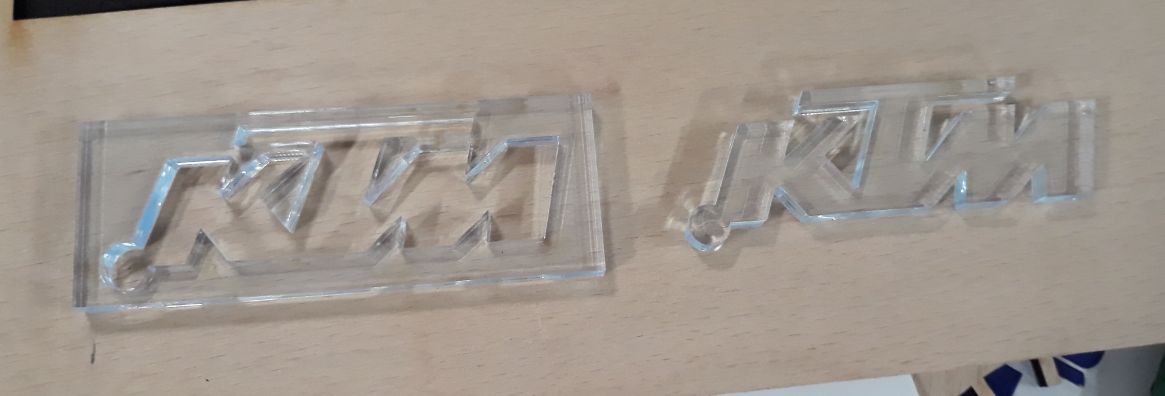

It was cut in 6mm Acrylic

The Acrylic itself could be used as a mould. In order to do that I stuck it to a plywood using hot glue. The problem with hot glue is that it creates a clearance between the piece and the surface. Hence I had to seal the edges in contact as well.

Once this was done the next step is to pour in the casting material

I wanted the cast to be orange in color. The option available in the lab to get the color you desire is by mixing dyes. Since orange color was not available I had to mix both Red and yellow to get orange.

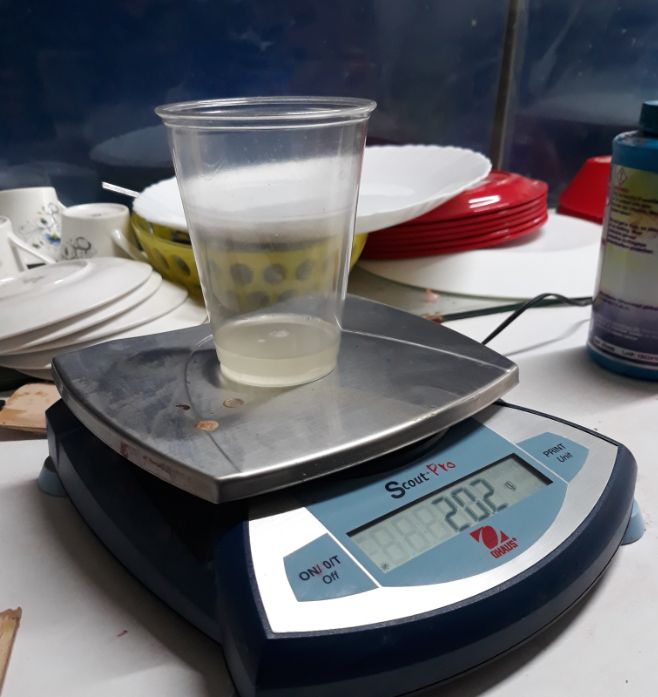

The casting material has two parts , A and B. The materail solidifies when the two parts are mixed together. The mixing ratio of 1:1. We use a desktop scale to accurately measure the quantity of material poured.

For mixing the two parts I made a stirrer using the steel wire lying around. The stirrer was fitted to the drill machine and a high speed stirrer was made. Was fun doing it though.

Once this is completed the mixture is poured into the mould and allow to set.

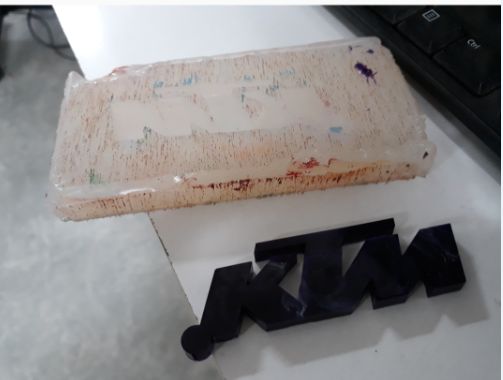

The next thing I wanted to try was to make a mould using Silicon Rubber. For this I used the laser cut model of the key chain. To contain the solution the 3D model is put in a box.

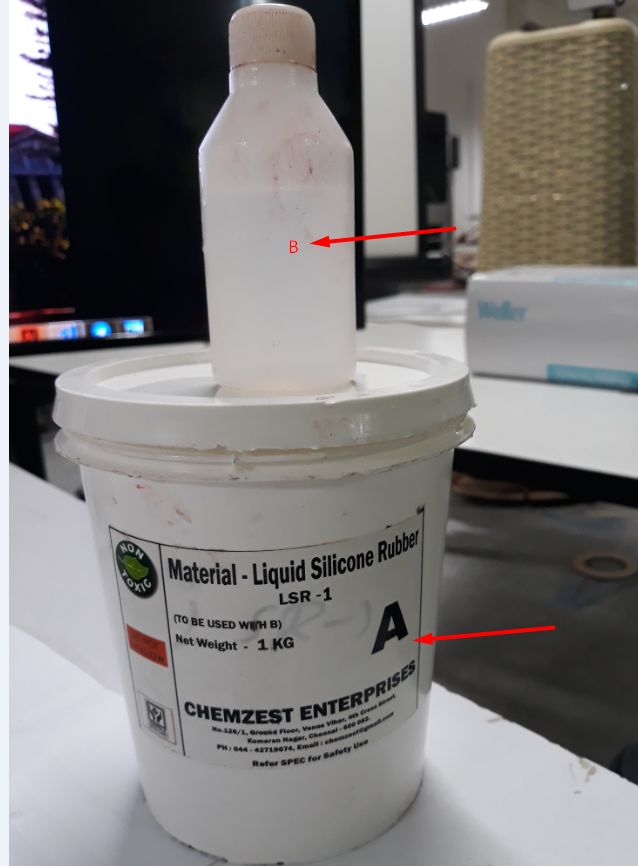

The material used is Silicone Rubber. This also has two parts, A and B. The part quantity of part B is 10% of part A. It is mixed thoroughly and the mixture is poured into the box.

The setting time was close to 24 hrs under room temperature. I then carefully removed the mould and it came out perfectly. Next task is to pour casting material into the mould cavity.

The mixing ratio for this is 100A:60B. I mixed it with dark blue dye. The setting time for plastic resin is close to 24 hours.

The cast was clean and precise. The finish is unbelievably fantastic.

InstaMold is very easy to use. The procedure is very simple here. The matter is in the powder form. It has to mixed with water.

Once it is mixed it takes about 2-3 minutes to set. While it is in the liquid form and is not sticking to the hand make a impression of the

object you want to cast.

First a box is made using the waste wood lying around in the lab

The InstaMold powder is mixed with warm water and made in the form of smooth paste without leaving any lumps. The matter is then transferred to the box and is left for about 10 minutes. By this time the material begins to solidify and is ready to make impressions.

After the impression is made , the object can be removed. I used the laser cut model of the object to obtain the mould. The material used for making the cast was Bismuth alloy available in the lab. The metal is melted using the electric furnace in the lab at a temperature of 700 degree celsius. The alloy melts in about 10 minutes. The molten alloy is then poured into the InstaMold mold made.

Since the surface finish was very poor it's surface had to be finished with the sanding/grinding tools available in the lab.

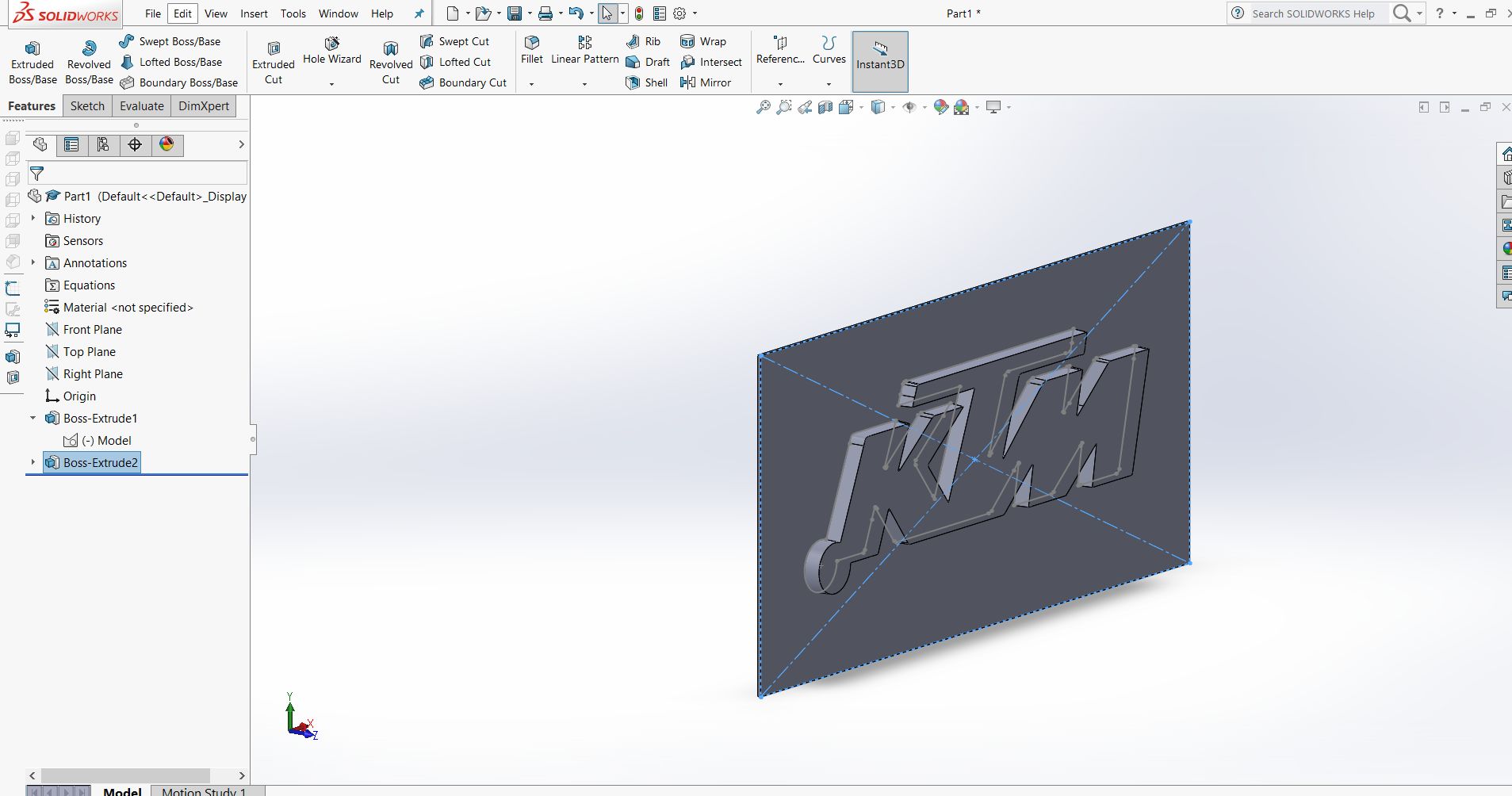

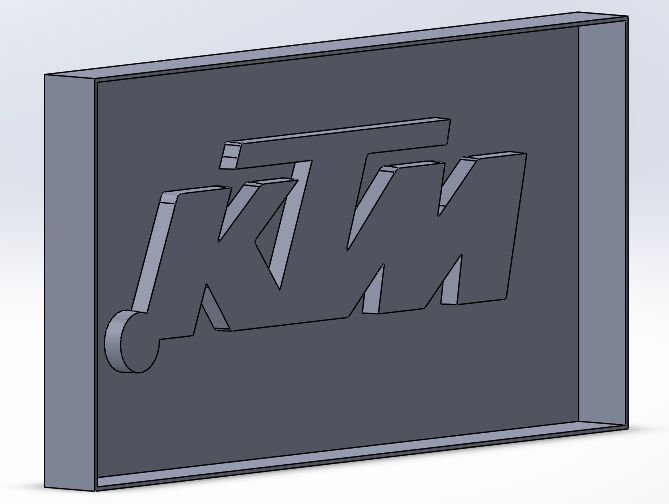

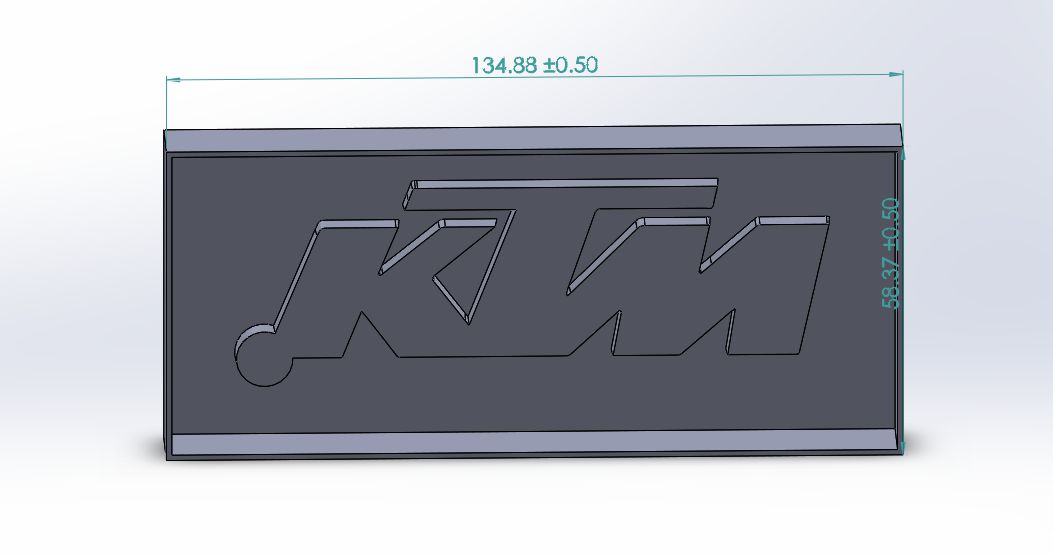

Unlike the direct method i used to create a mold , in this method a 3D design is

milled on wax to make a mould using which another mould can be made. The design of

the logo is extruded in Soild works to a depth of 5mm

Since the liquid Moudling material is to be poured around the 3D shape and cavity needs

to be created. For this a wall is built around the 3D mold in its design as shown below which will help hold the liquid around the

3D logo.

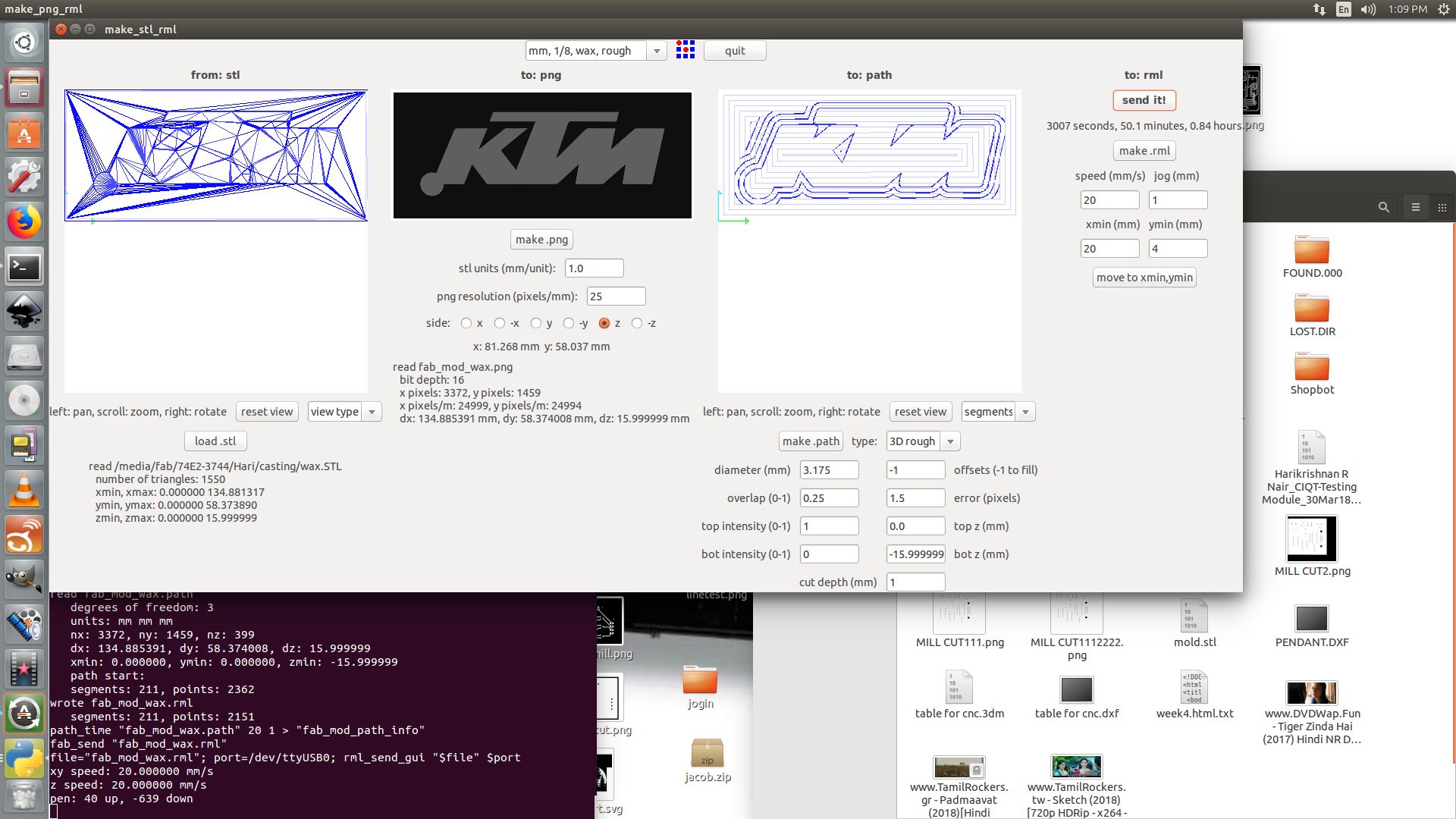

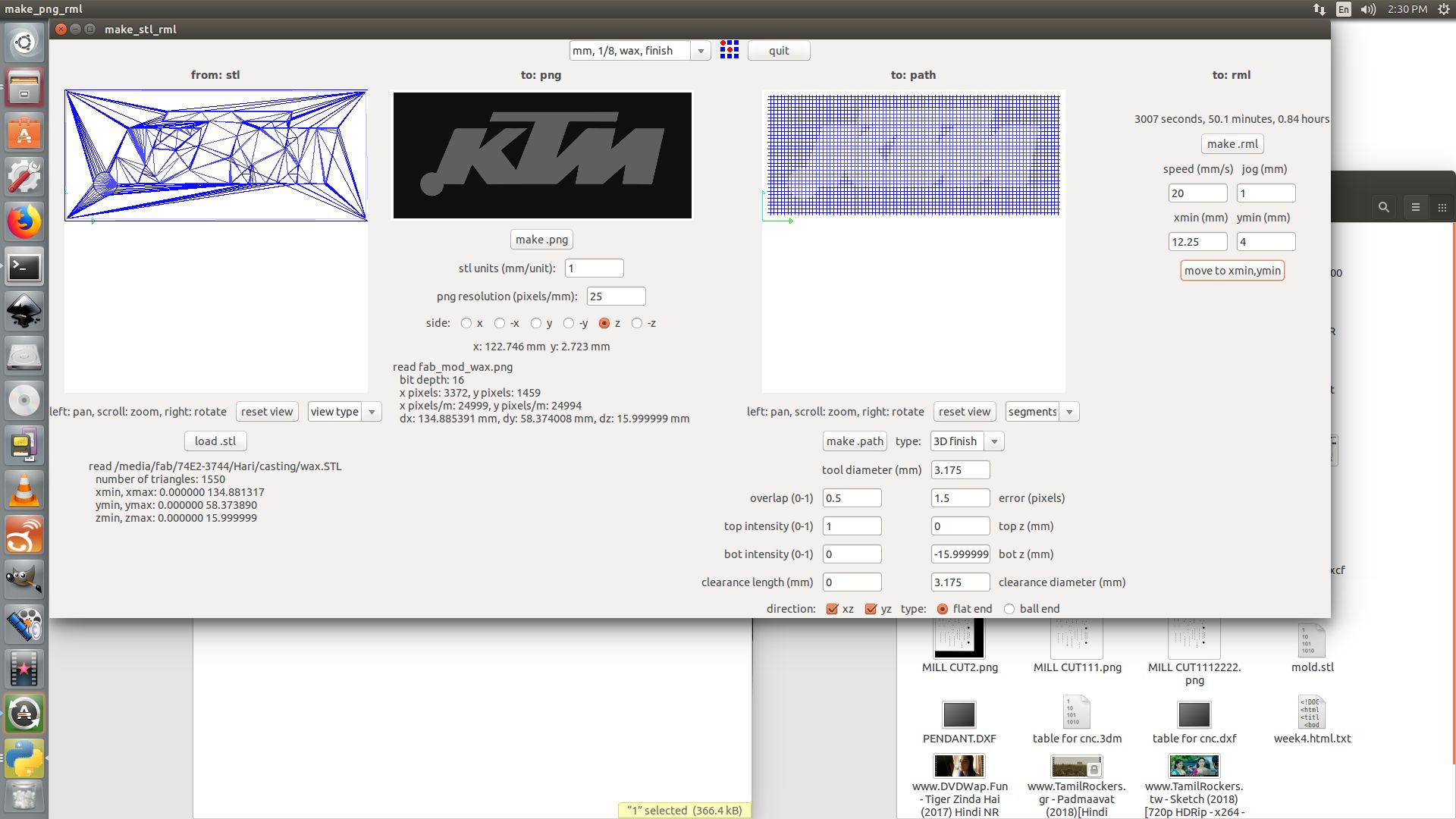

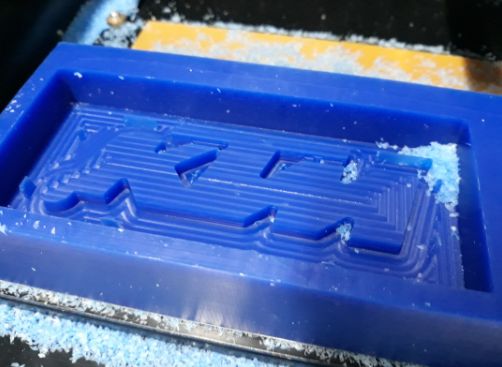

The design is coverted to .STL file and loaded to fab. The process is rough cut The bit used is flat end since it had sharp edges.

After finshing the rough cut process , Modella was showing some software issues. The bit was not going back to its initial origin postition. Hence i had to manually set the origin to initial postition for finishing cut.

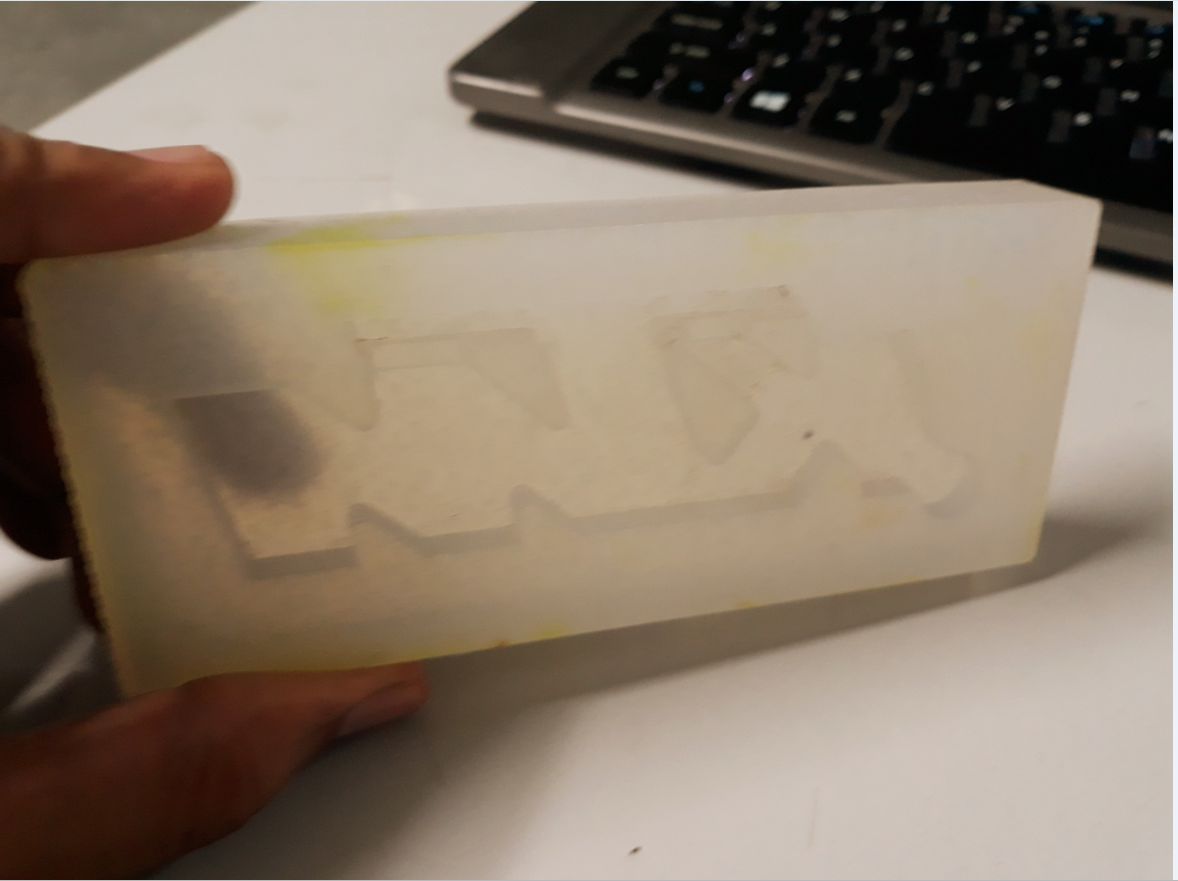

The cavity was filled with Silicone Rubber by the processes mentioned above.

The mold was taken out the next day.

For casting this key chain I used Smooth Cast 305 liquid plastic

Casting with Smmoth cast is easy. Like the processes mentioned above both Part A and Part B are mixed in equal quantities. I wanted the color to be orange so i mixed equal amounts of red and yellow dyes into the mixture. The curing time for Smooth cast is roughly 30 minutes.

The casting was perfect. All contours were perfect. Here is the final result.

This weeks group assignment was to review the safety data sheet of each of the components that we are using this week.

I started with Smooth-On SORTA-clear Silicone rubber. SORTA-Clearâ„¢ Series rubbers are premium water white translucent silicone rubbers (platinum catalyst) which cure at room temperature with negligible shrinkage.Here is the safety data sheet from the company website

It has a mixing ratio of 1A:1B by volume .

The Smooth-Cast® 300 Series of liquid plastics are ultra-low viscosity casting resins that yield castings that are bright white and virtually bubble free. Vacuum degassing is not necessary. They offer the convenience of a 1A:1B by volume or 100A:90B by weight mix ratio.

Download its safety data sheet from here.

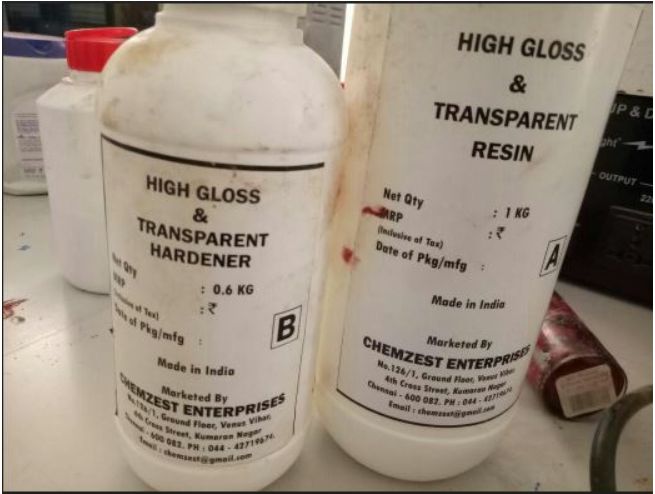

Epoxy Resins are thermosetting resins, which cure by internally generated heat. Epoxy systemsconsist of two parts, resin and hardener. When mixed together, the resin and hardener activate,causing a chemical reaction, which cures (hardens) the material.(source :- https://www.chemzest.com/high-gloss-and-transparent-epoxy-resin/)

In our lab we use a locally baught resin it has a mixing ratio of 100A:60B and setting time is about 2hrs

The PMC®-121 Series urethane rubbers feature convenient one-to-one by volume mix ratios. PMC®-121/30 Wet is exceptionally strong and abrasion resistant for soft urethane mold rubbers.

You can download the Safety data sheet here.