The assignment for the first week of fablab was to plan and sketch a potential

final project. This was a little difficult for me as the final project should be

such a one whose fabrication should incorporate the outputs of all the machines

in the lab. I discussed with my fab instructors and they guided me in choosing a project.

I was informed that each week there will be an assignment to be completed and hence

choosing a complex project may cause delay in its submission. Members who usually choose a

complex project tend to change their project in between the course. This is not very desirable.

The instructors instructed me to come up with a project which I'm confident about and to prepare

strategic plan for its fabrication. This will help me understand the fabrication process better and I can take each

week's assignmnet to fabricate various components of the my potential final project. In this way each week

will take me one step closer to my final project.

I find the advise very worthwhile. Hence I've come up with a project that is not very complex but will incorporate

all the machines in the lab. I have briefed about my project below

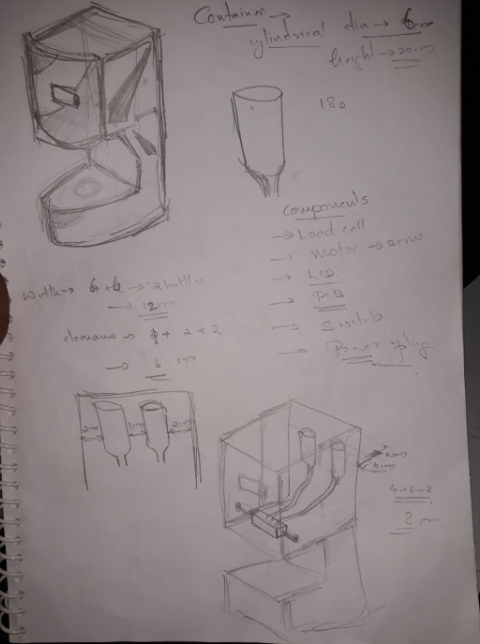

Down this course students have to learn about various casting techniques. For casting various new chemicals are used. Chemicals such as Silicon plastic , Transparent resin etc are to be mixed in various proportions to make the mold or to make the casting correctly. Mixing of these fluids are done manually also the calculations for taking the right amount for mixing are also done manually. Doing the calculations and mixing the fluids in the right proportions is a time consuming process and there are human errors involved

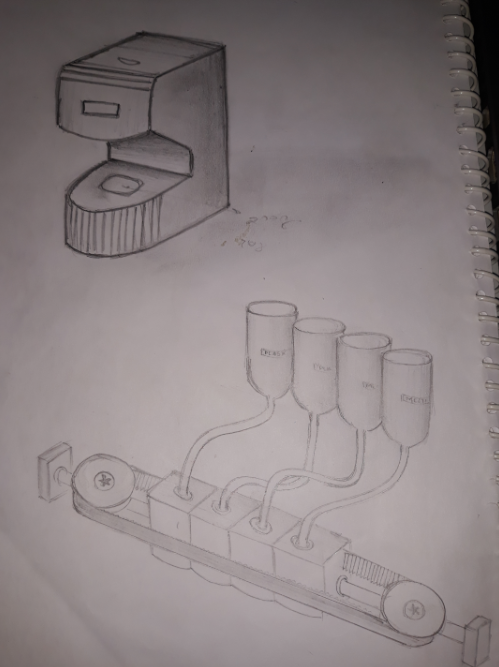

Casting material dispenser is designed for the Fablab that will help the students to precisely measure the amount of fluid falling into the container. The calculations will be done automatically by the machine. The user only need to specify the amount of fluid required. The machine will fill the container with the fluids in the right proportions.

The proposed dimension of DPs in 25x25x60 mm. The intial design as shown in the figure is subject to change according to

ease of fabrication.