Week17 : Wild Card Composites

Group Work

We made some coupon in goup work. Group assignmet is here

Composites

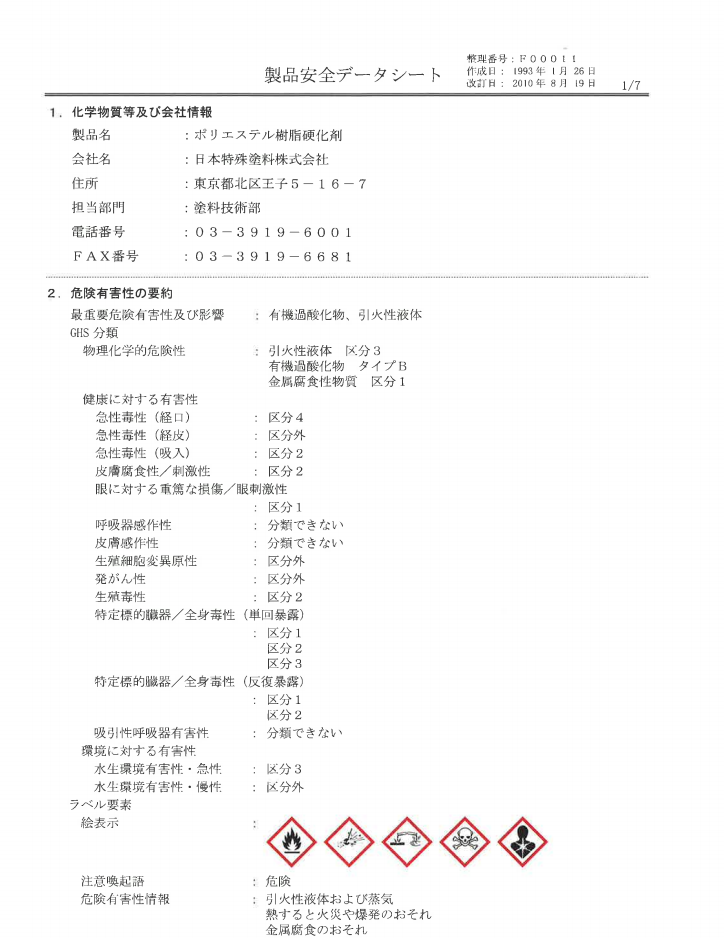

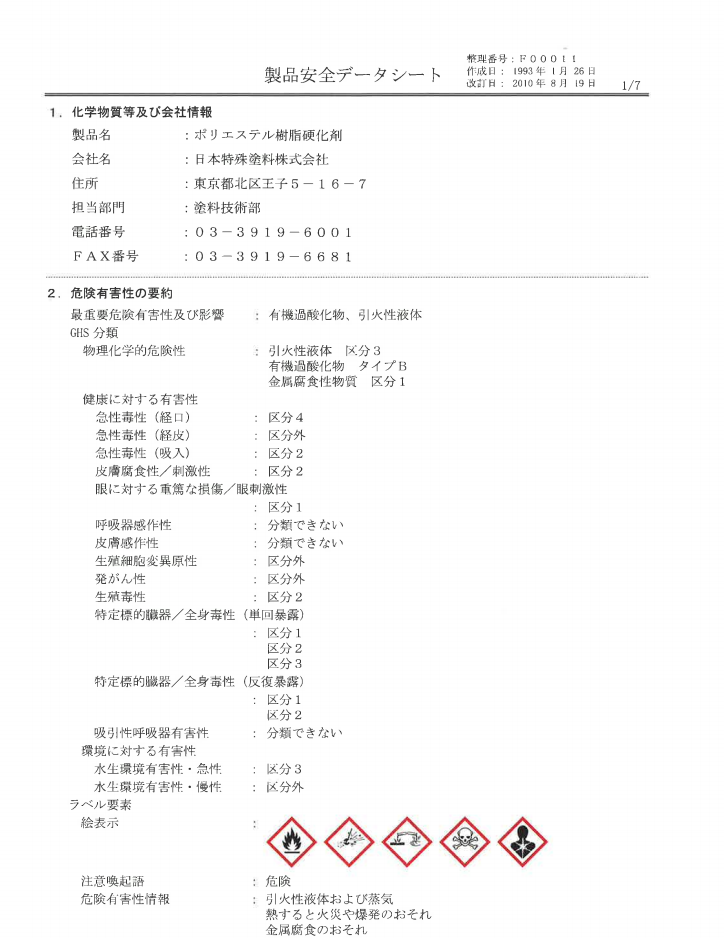

I select composites as a wildard. The resin that we used was polyester resin as follows.

This resin is hardened by mixing hardener. The time for become solid is about 3 hours.

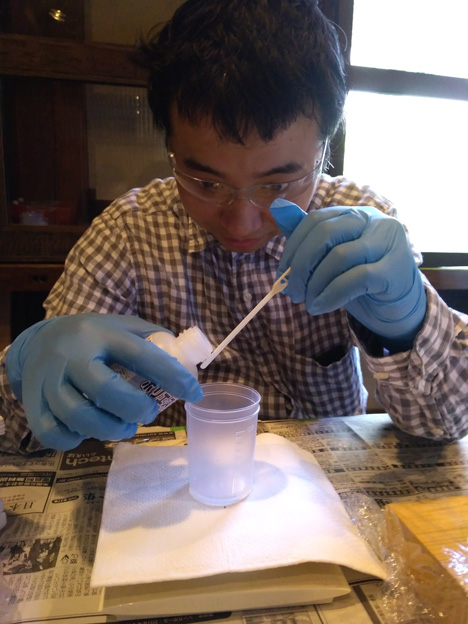

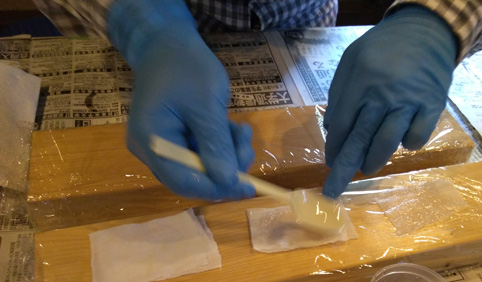

We read SDS at first. The resin is Japanese one, so there is only Japanese SDS (Safety Data Sheet). As described in SDS, we opened the window and made a state with good ventilation. Actually the smell was pretty intense. And we prepared we prepared protective glasses and disposable gloves.

This resin is hardened by mixing hardener. The time for become solid is about 3 hours.

We read SDS at first. The resin is Japanese one, so there is only Japanese SDS (Safety Data Sheet). As described in SDS, we opened the window and made a state with good ventilation. Actually the smell was pretty intense. And we prepared we prepared protective glasses and disposable gloves.

Test (failure)

Some test coupones are made at first.

But after waiting 3 hours, those coupons did not become solid. The cause was considered to be insufficient stirring. I was using a small container, so I could not vigorously stir it. So, we changed the container for stir.

Coupon

After thoroughly stirring, I made some coupons. those were ,non-compaction one, compaction one, 1〜3 piece fabric.

The compaction ones were compressed with a clamp.

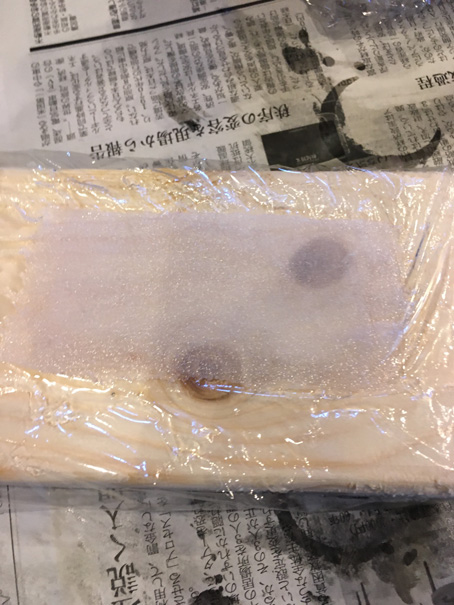

Following picture is non compaction one.

After making that coupon, I recognized that the hardness was insufficient with one piece of fabric. And non-compaction was not uniform in thickness.

The compaction ones were compressed with a clamp.

Following picture is non compaction one.

After making that coupon, I recognized that the hardness was insufficient with one piece of fabric. And non-compaction was not uniform in thickness.

Arm protector

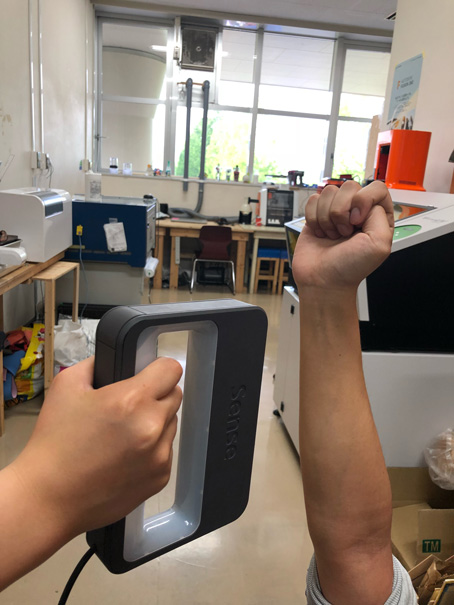

I decided to make arm protector that fits individual size.

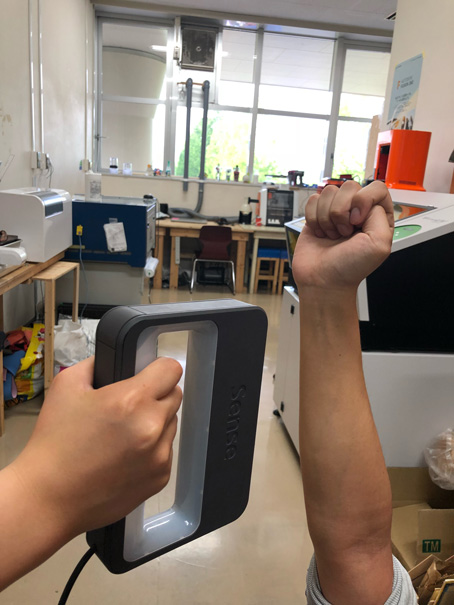

I used scanned data that I made week6.

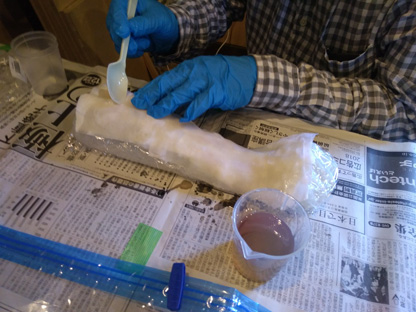

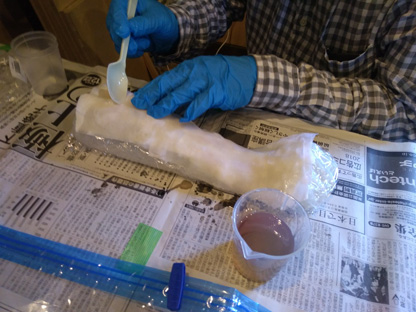

I applied resin to the mold as same process as making coupons.

After applying the resin, the mold and resin applied fabric was made compaction with a compaction bag. Furthermore, it pressed down from above with a bag containing water.

After waiting 3 hours, arim protector was completed !

I used scanned data that I made week6.

I applied resin to the mold as same process as making coupons.

After applying the resin, the mold and resin applied fabric was made compaction with a compaction bag. Furthermore, it pressed down from above with a bag containing water.

After waiting 3 hours, arim protector was completed !

Files

Files can be downloaded from here.