WEEK5 : Electronic Production

Group Assignment

materials

Milling

- SRM-20 : Roland

- chemical wood (sacrifice wood)

- solbent : MITSUWA PAPER CEMENT SOLVENT

- scraber (金属ヘラ)

- brash

- paper cutter

- steal wool

- ultrasonic cutter : 超音波小型カッター ZO-41(本多電子株式会社)

- two sided tape : Nitto No.5000NS

- board (FR1) : Sunhayato No.12 (カット基板 片面紙フェノール 100×150×1.6mm【NO12】)

- end mill bits (1/64 inch) : Carbi-Universal S/C MICROGRAIN 1/64 SE 2FL

- end mill bits (1/32 inch) : 1/32 SE 2FL

Preparation

Leveling sacrifice wood(面だし)

To get flat surface on sacrifice wood, you first need to slightly shave the top of the wood.

-

Detach materials on sacrifice wood.

Pour solvent in, use scraber to peal the board off.

-

Change bit to 6mm shank diamiter collet

Use two pliers to loosen collet.

-

Set 6mm bit to the collet

Use hex wrench.

-

Make test cut data

Major the size of the sacrifice wood and make test cut 3D data with the size can cover the wood (leveling.stl).

-

MODELA Player 4 CAM setting (discription in japanese)

新規工程の生成

ファイル > 機種選択:機種を選ぶ

設定 > 新規工程 > 面だし

切削面 > 上面

ツール > ビットの径とツールタイプ

面だし範囲※ > 捨て板をちょうどカーバーする範囲を設定(中心から考える)

深さ※ > 0.5mm

材料 > ケミカルウッド

切削種類 > 走査線※面出しの範囲と深さの設定

-

Mark the center of sacrifice wood with a pencil.

-

Trun-on SRM-20

-

Open VPanel for SRM-20

-

Set the origin point to the center of the sacrifice wood

-

go back to MODELA Player 4 / start milling(切削)

Done!!!

Try out test pattern

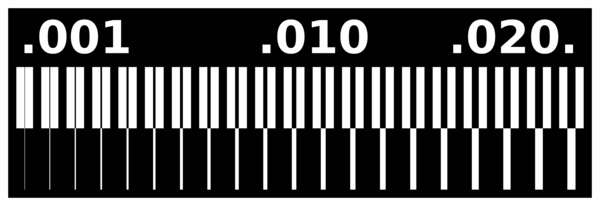

Fabacademy official test pattern

With the bottom row see how thin the line can go, and with the row above check how close the each line can be.

The lines in the bottom row starts from 0.50mm and get thinner in 0.02mm step till finally gets to 0.10mm.

The upper row follows the same dimension but with the gap between lines not thickness.

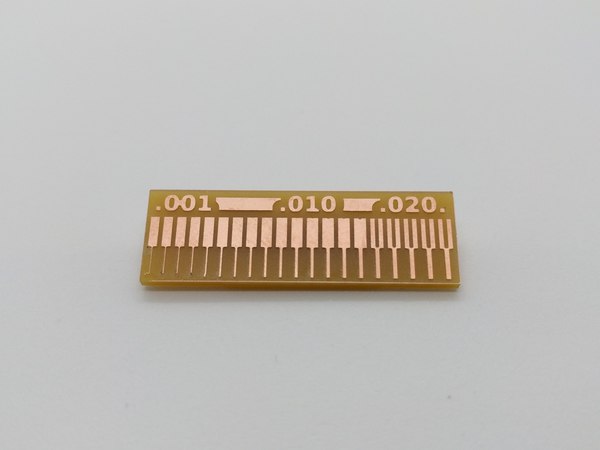

The result

For the line thickness, 0.22mm was the minimum thickness that our milling machine (with best condition) can mill.

0.4mm was the minimum for the gap between lines. (as the diameter of the bit used was 1/64 inch = 0.396875mm)