Quorage

02

What will it do?

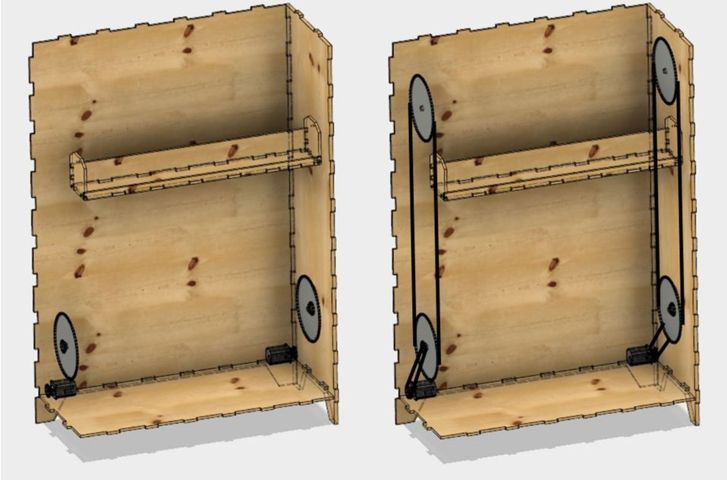

The project will be based on an electronic locker where a user presses a button and the locker will display the level where the object is located. Each level will have a color or identification code, where the user can organize their things by category, for parts storage and carriers can be subdivided for a customizable solution. for example: electronic parts, office article, tools and etc.

Who's done what beforehand?

After all the research he did, I have not found any project of equal cost, if not companies that offer these types of products on an industrial scale. such as Vertical Storage USA and Kardexremstar. In any case I have found personal projects but they do not share the complete information if not a company that offers this type of product on a domestic and personalized scale (StorageMotion).

What will you design?

I have designed a more optimal mechanical system but at the same time it is low cost and efficient. for this system I had to watch several videos on Youtube as a reference to the mechanical system. the system will be based on bicycle chains, wood,

What materials and components will be used?

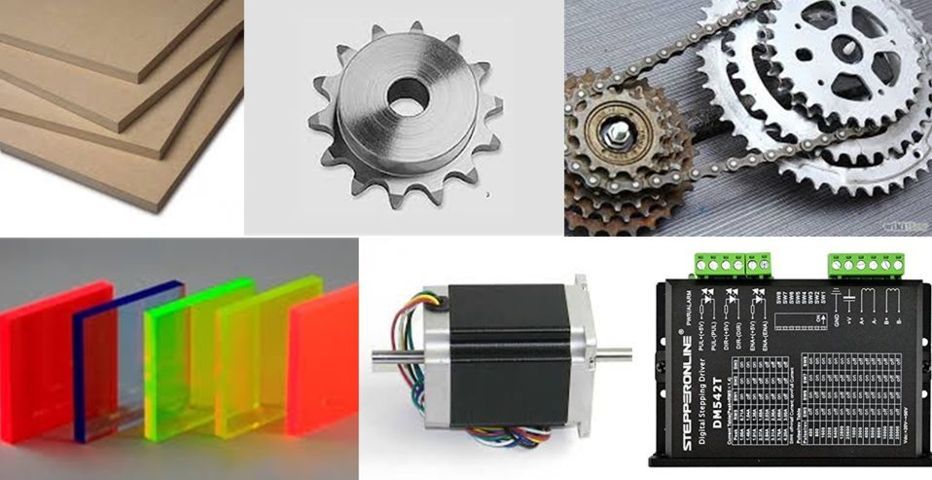

-- MDF Wood 19mm

-- MDF Wood 3mm

-- UCFL Type Pillow Block Bearing

-- 2 x Roller Chain Sprocket

-- 4 x Big gear bycicle Chain

-- 5 x Small gear Chain

-- Acrylic

-- Fabduino

-- Stepper motor double shaft / NEMA 23 & driver

-- Power supply 110v to 24v

-- Power bank 5v

-- keypad

-- 3D print enclousure for electronic components

Where will come from?

some materials I got it for free because I have an uncle who has a hardware store and the melo donates the materials.

-- MDF Wood 19mm = donated by my uncle

-- MDF Wood 3mm = donated by my uncle

-- 2 x Roller Chain Sprocket = Amazon (This piece will have to be manufactured in the FabLab because it has not arrived on the 3D printer)

-- 4 x Gear Chain = bycicle store

-- 5 x Bycicle Chain = bycicle store

-- Acrylic = From leftovers from Fab Lab

-- Fabduino = board make it in the fab

-- stepper motor double shaft / NEMA 17& driver = a friend who works in mechanics workshops offered it to me

-- keypad = board make it in the fab

-- 3D print enclousure for electronic components< = pieces make it in the fab

-- Power supply 110v to 24v = From leftovers from Fab Lab

-- Power bank 5v = From leftovers from Fab Lab

-- UCFL Type Pillow Block Bearing = Dimar / Hardware industry store

How much will they cost?

-- MDF Wood 19mm = 0$

-- MDF Wood 3mm = 0$

-- 2 x Roller Chain Sprocket = 20$

-- 4 x Gear Chain = 4 x 2$ = 8$

--5 x Bycicle Chain = 7 x 2$ = 10$

-- Acrylic = 0$

-- Fabduino = 0$

-- stepper motor double shaft / NEMA 17 & driver = 0$

-- keypad = 0$

-- 3D print enclousure for electronic components = 0$

-- Power supply 110v to 24v = 0$

-- Power bank 5v = 0$

-- UCFL Type Pillow Block Bearing = 16 x 2 = 32$

Total = 70$ aprox.

What parts and systems will be made?

-- keypad with 3D print part

-- FabDuino

-- LCD adapter

-- Roller Chain Sprocket (Metal Casting )

What processes will be used?

-- CNC ROUTER

-- Electronic Design

-- 3D Printing

-- Laser Cut

-- Input & Output

What questions need to be answered?

if the stepper motor NEMA 17 will have enough torque to be able to move the chain system of the locker?

How will it be evaluated?

Checking the best application or method of different digital manufacturing techniques in their global function.