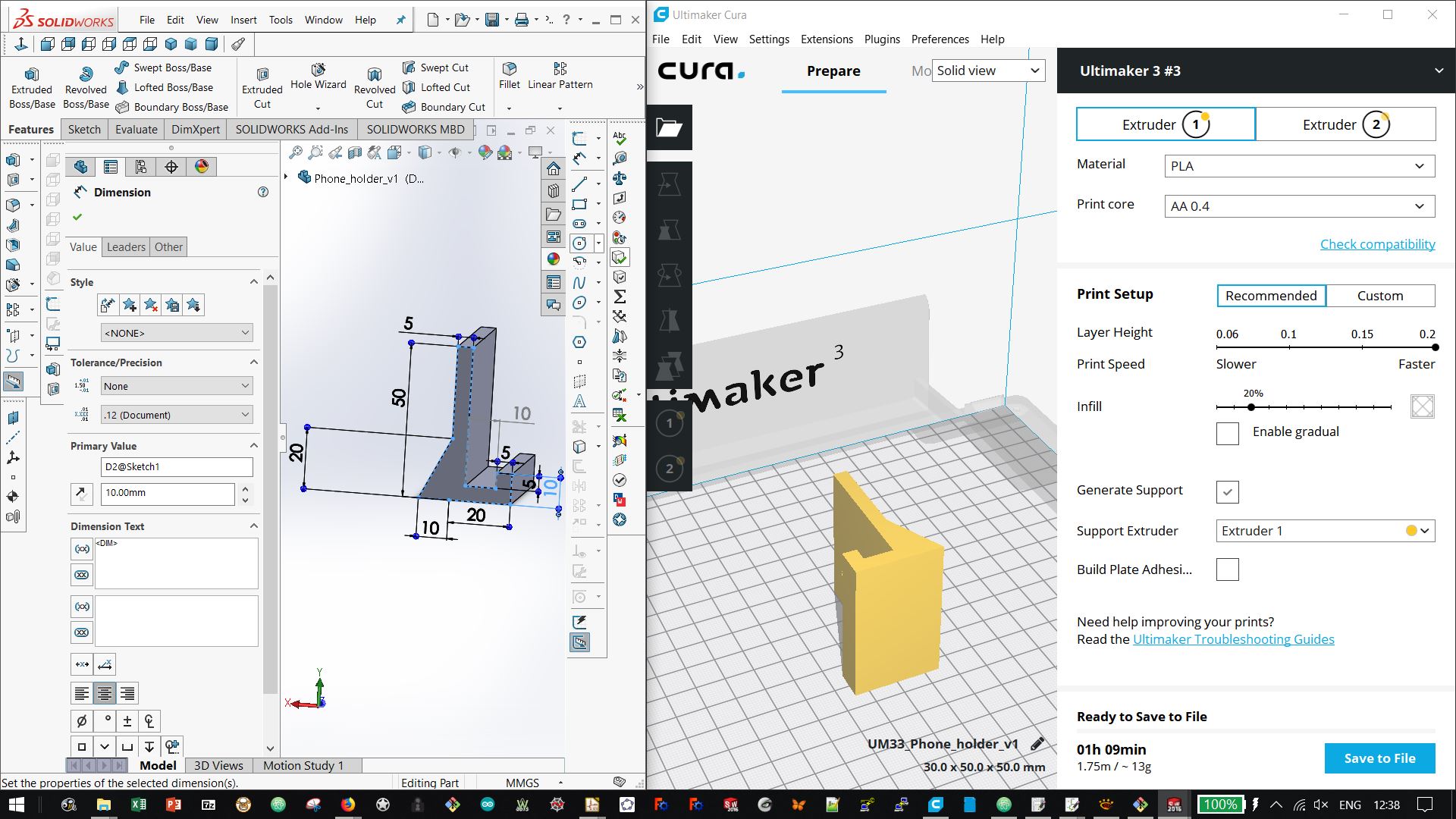

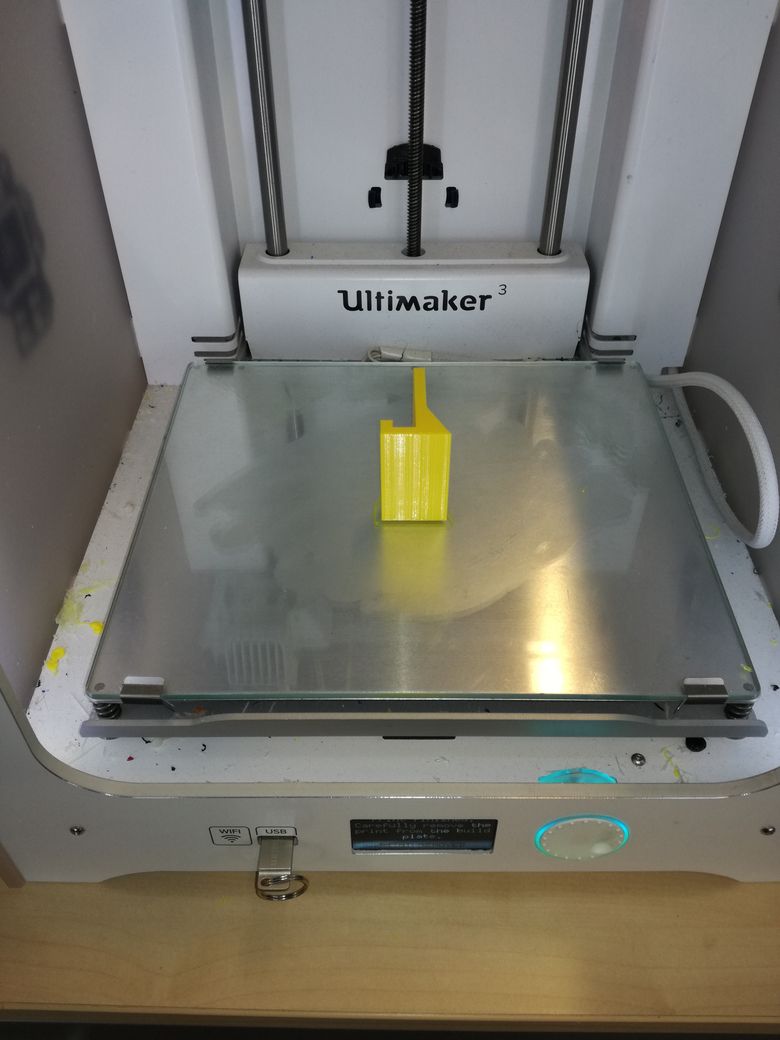

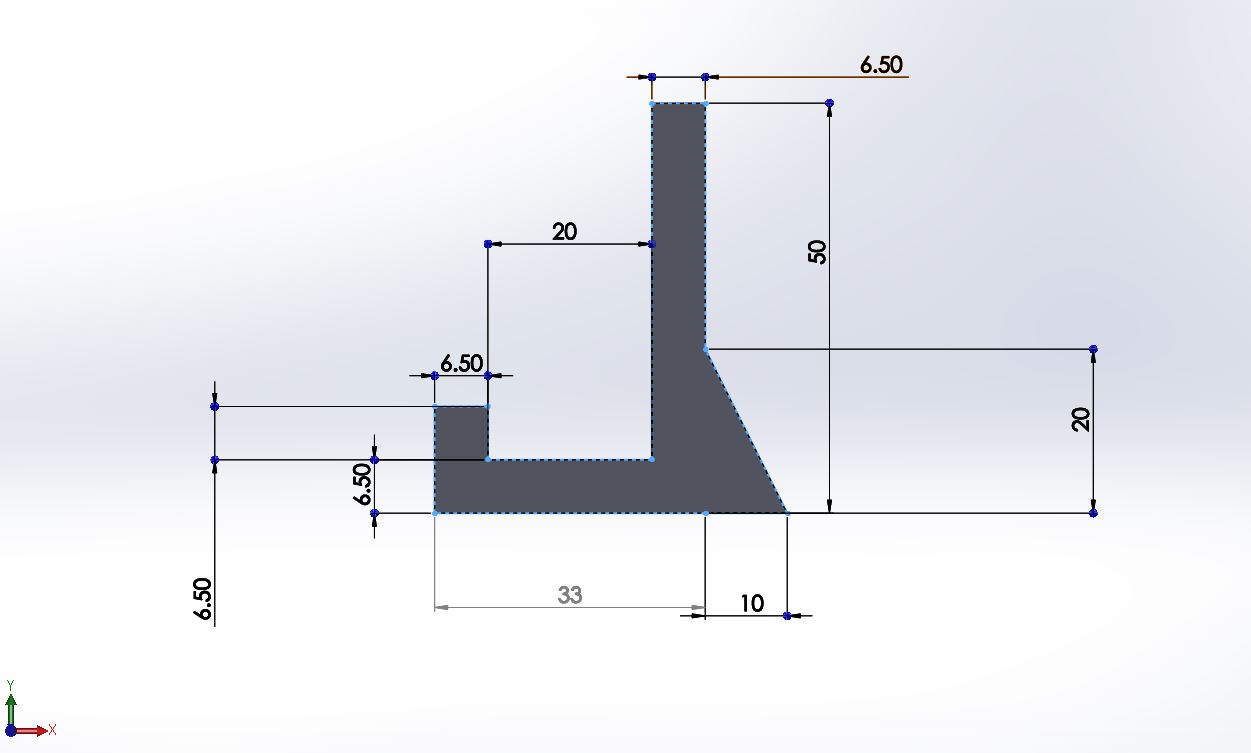

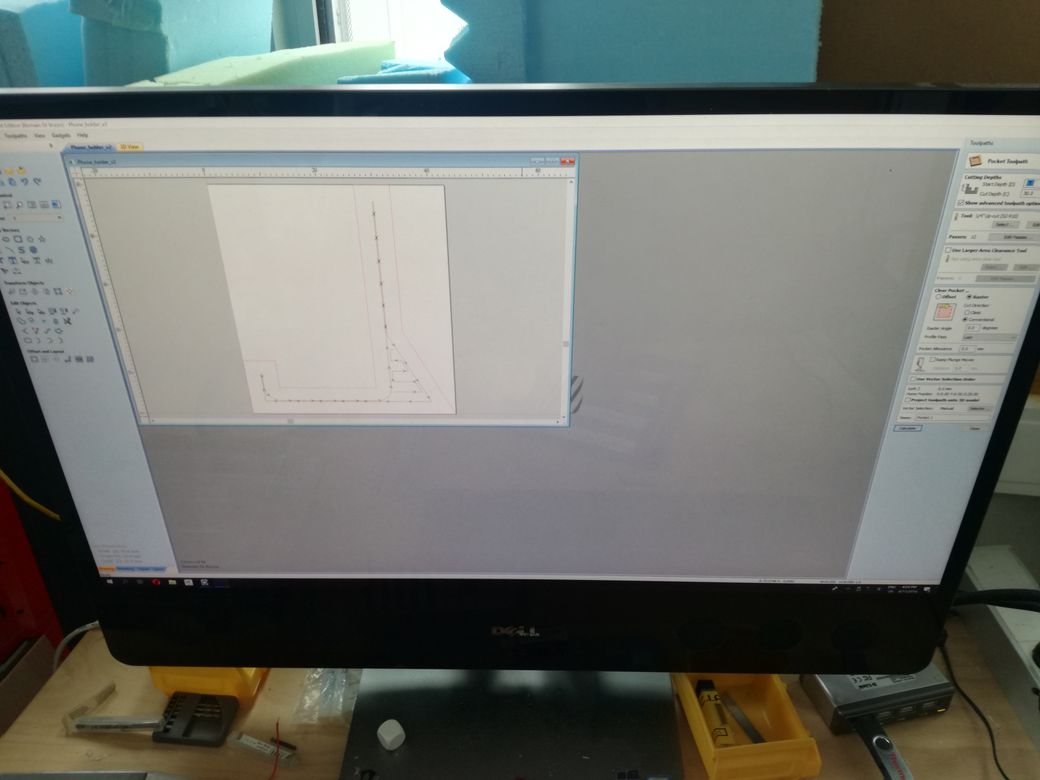

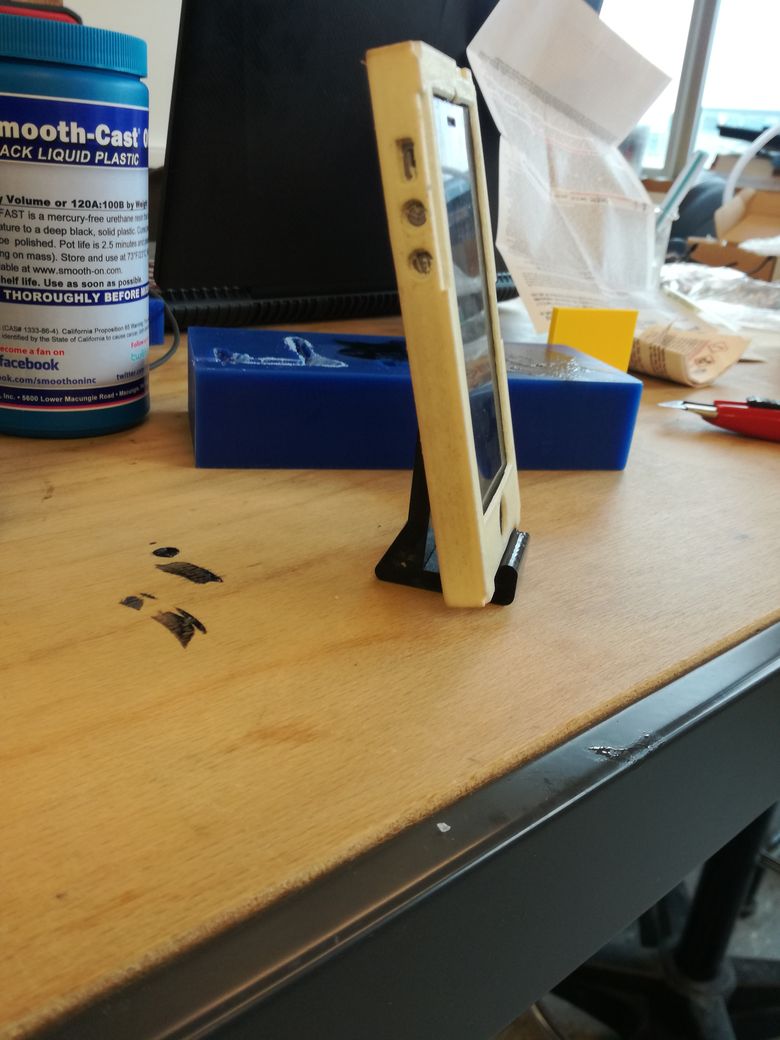

I adapted the 1st design to have a bigger tilt of the smartphone; and to be able to pocket-mill the mold using a 1/4 inch (6.35mm) bit.

Source files are available in this folder on gitlab.

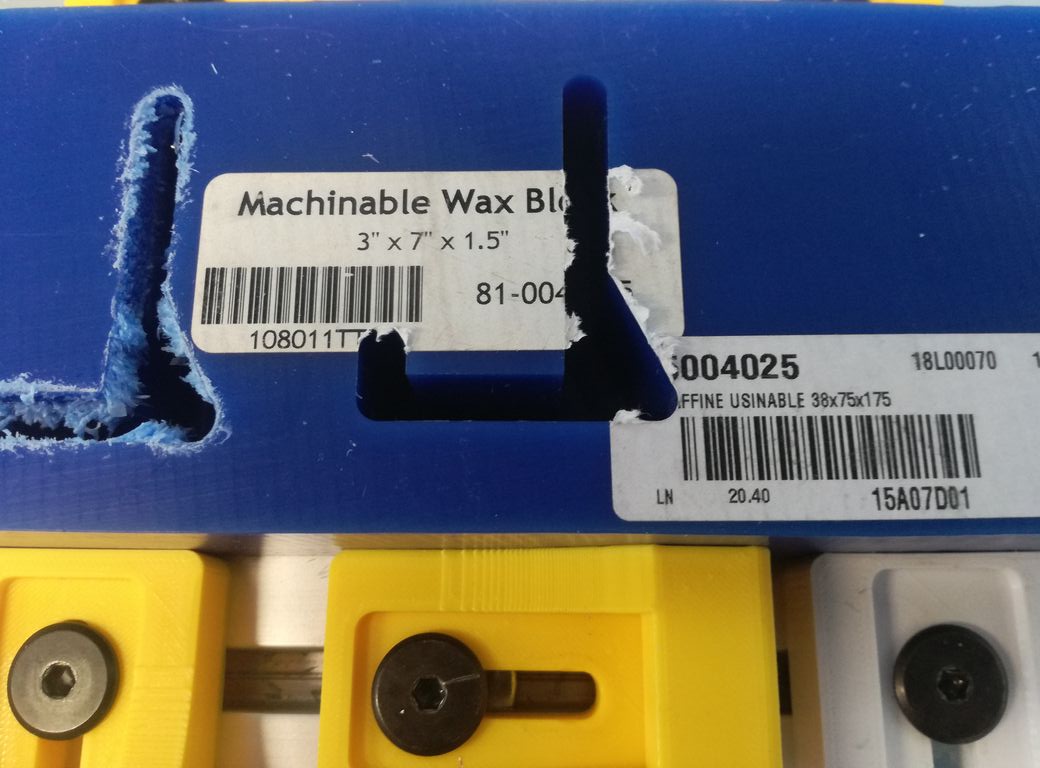

As the design is very simple, the essential fabrication file is this dxf contour.

One can adapt the depth of machining directly in the CNC software (V-Carve for instance). I used 30mm. 20mm would certainly work.

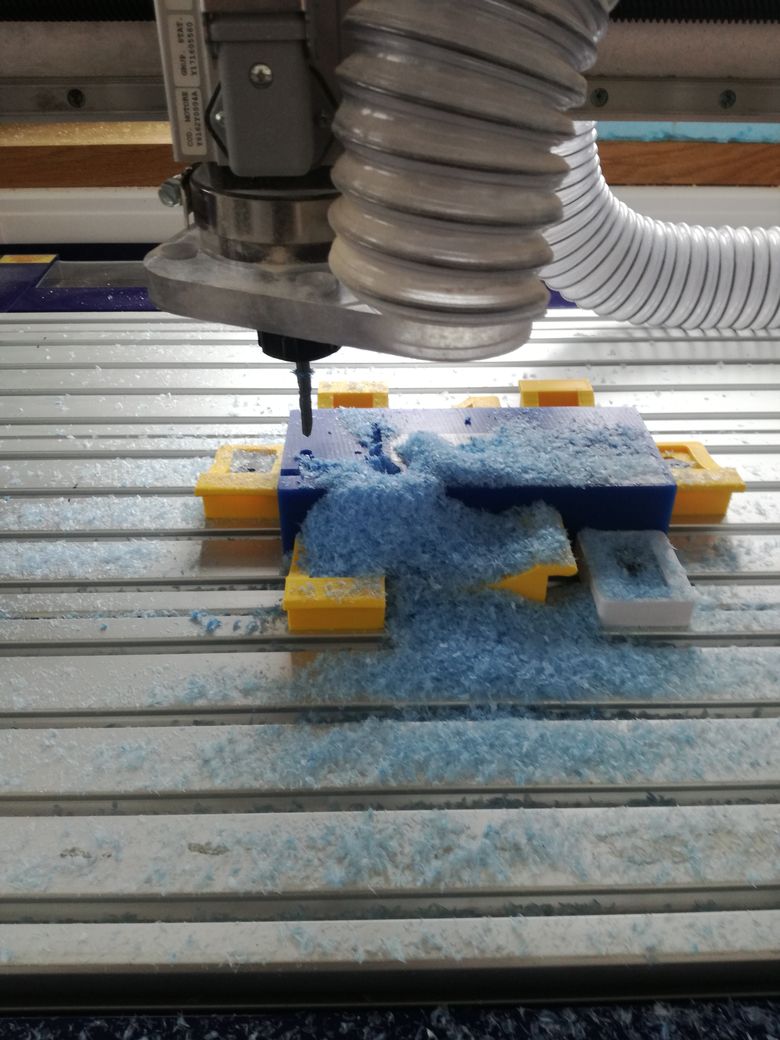

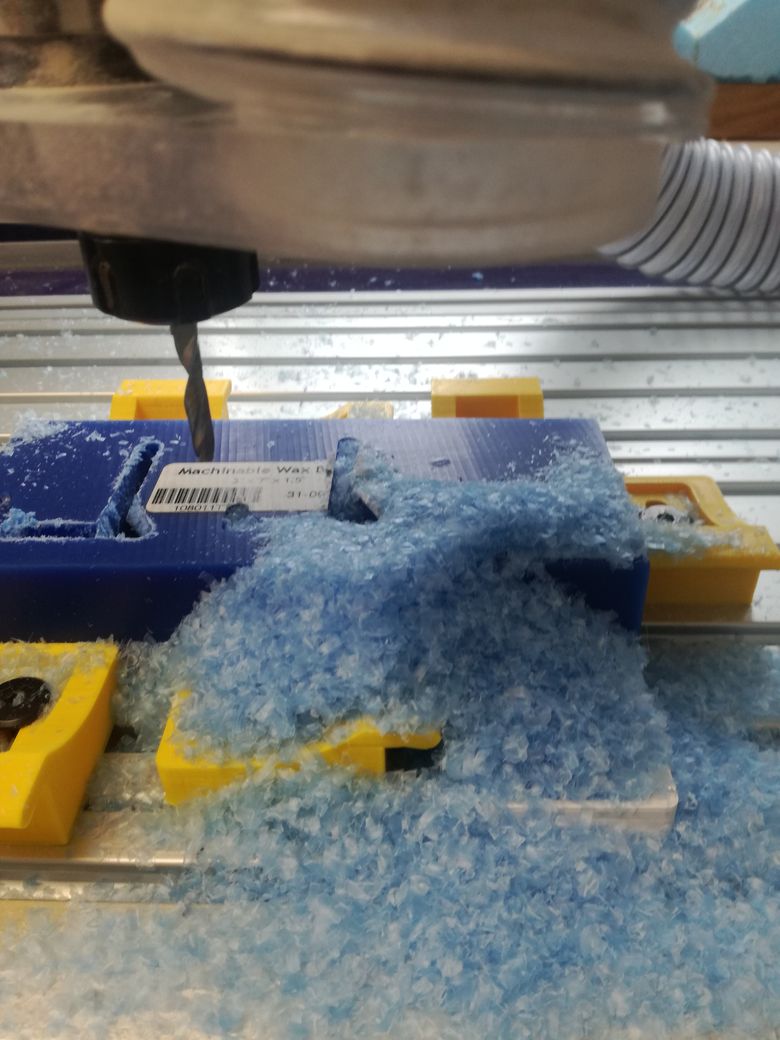

At the first milling I used a bit that was shorter than the cast depth (30mm). For the second milling i used a longuer bit.

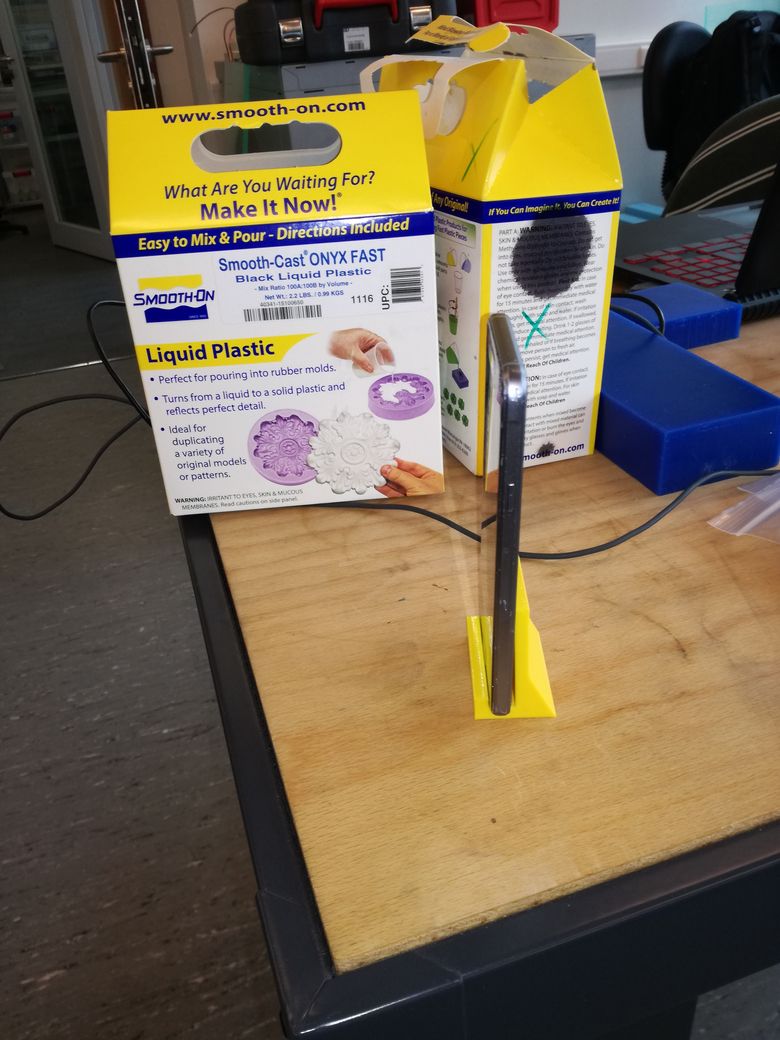

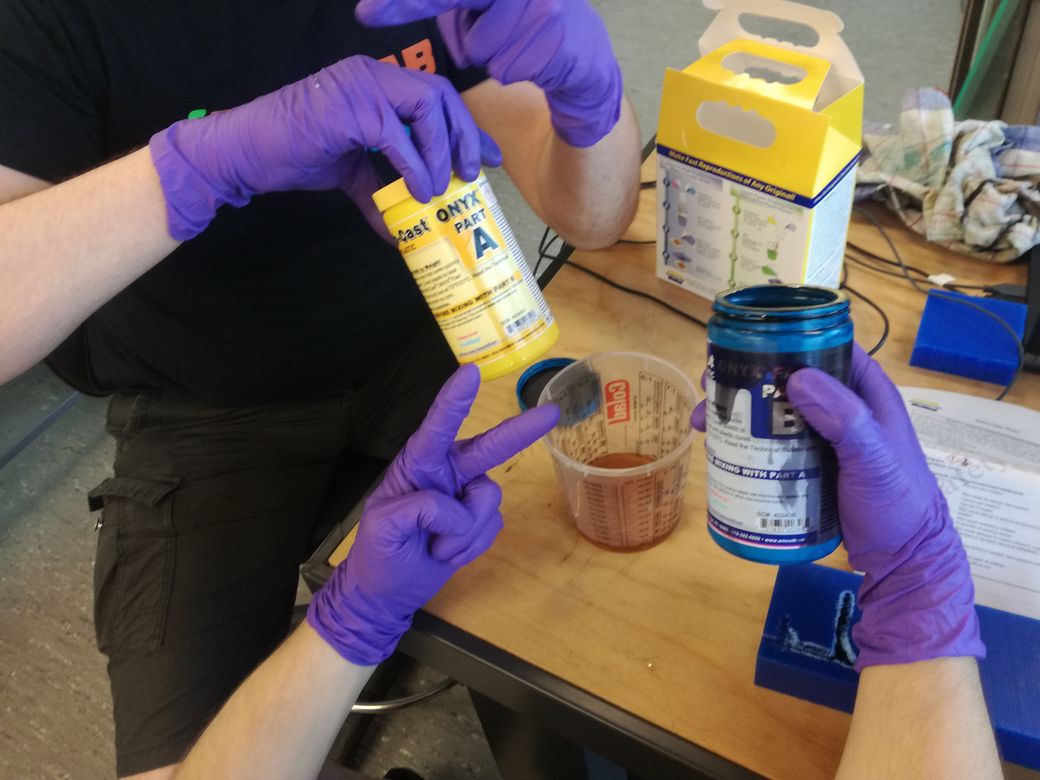

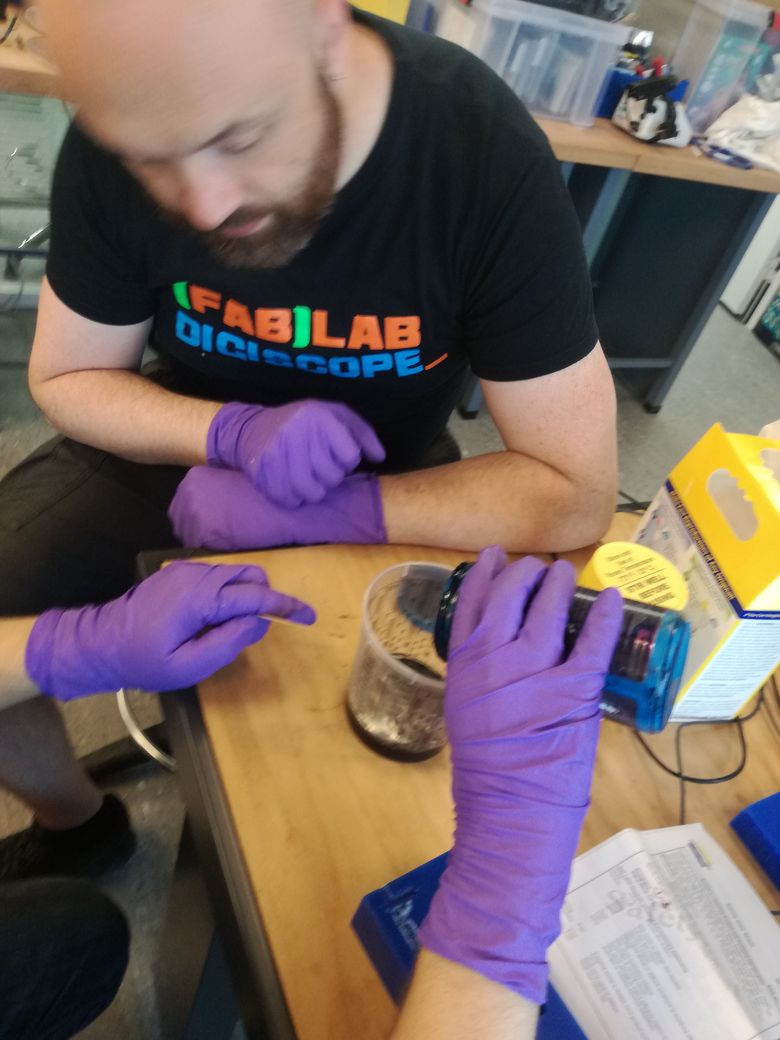

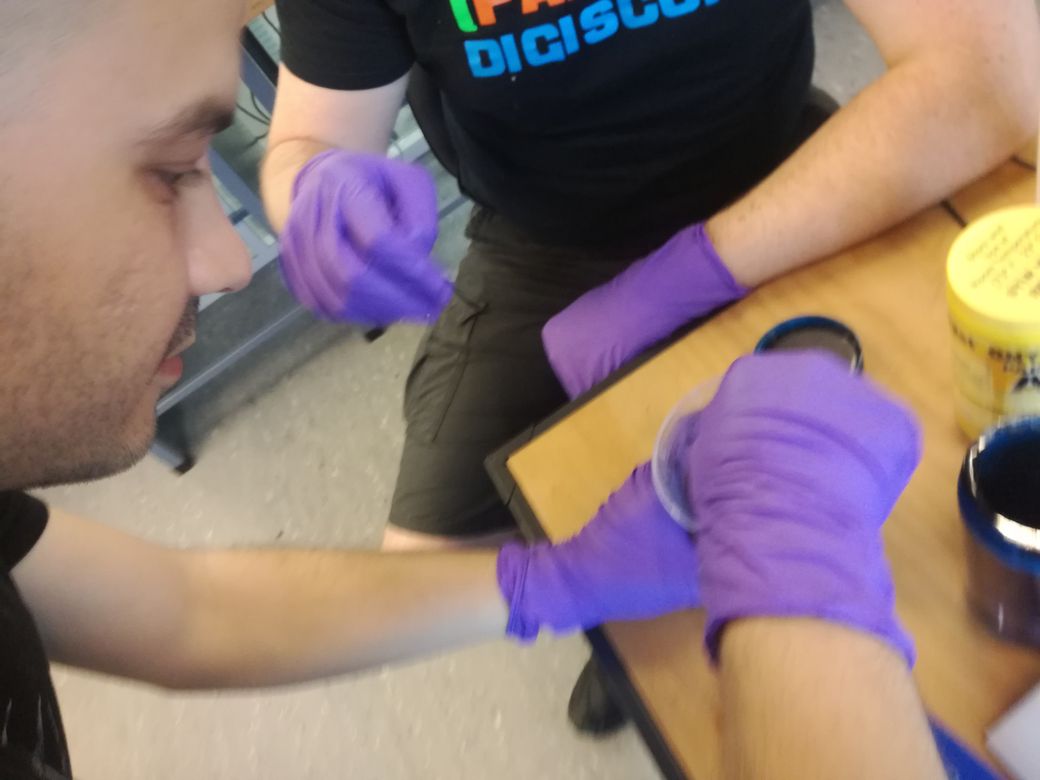

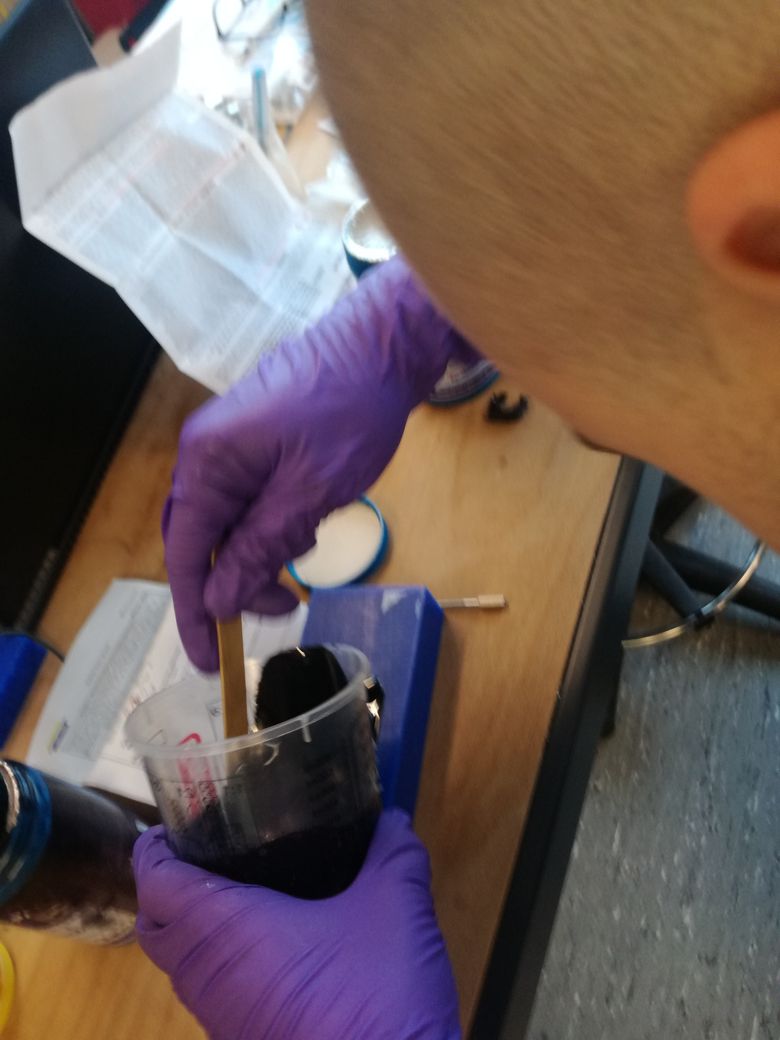

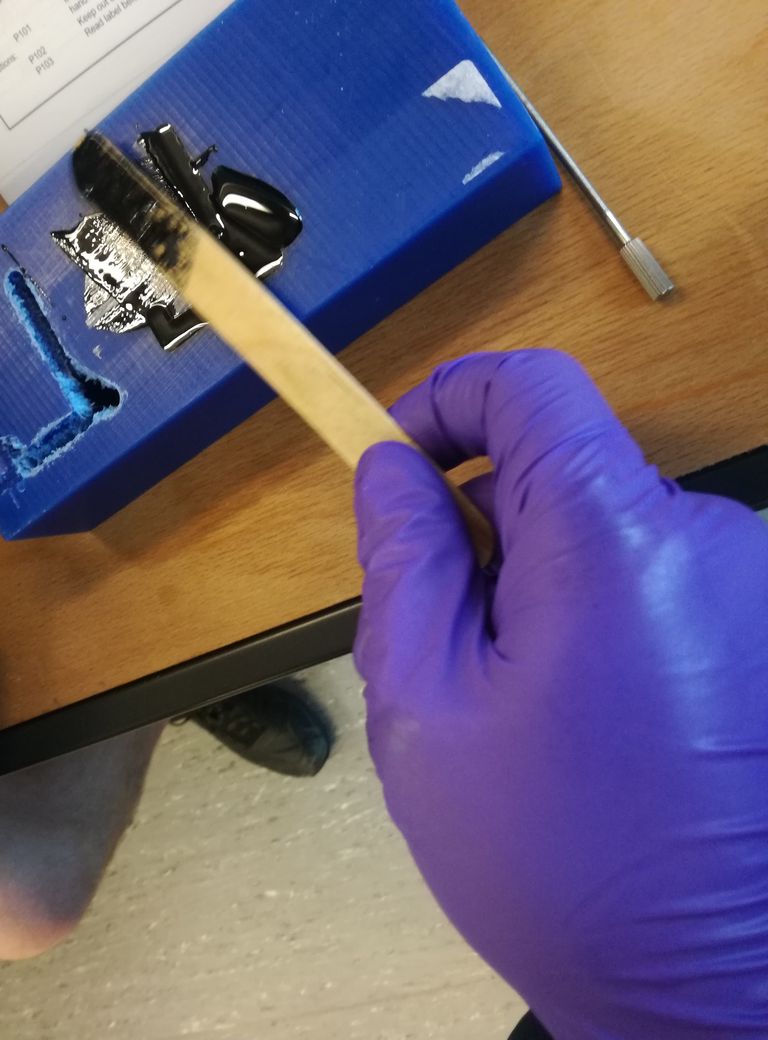

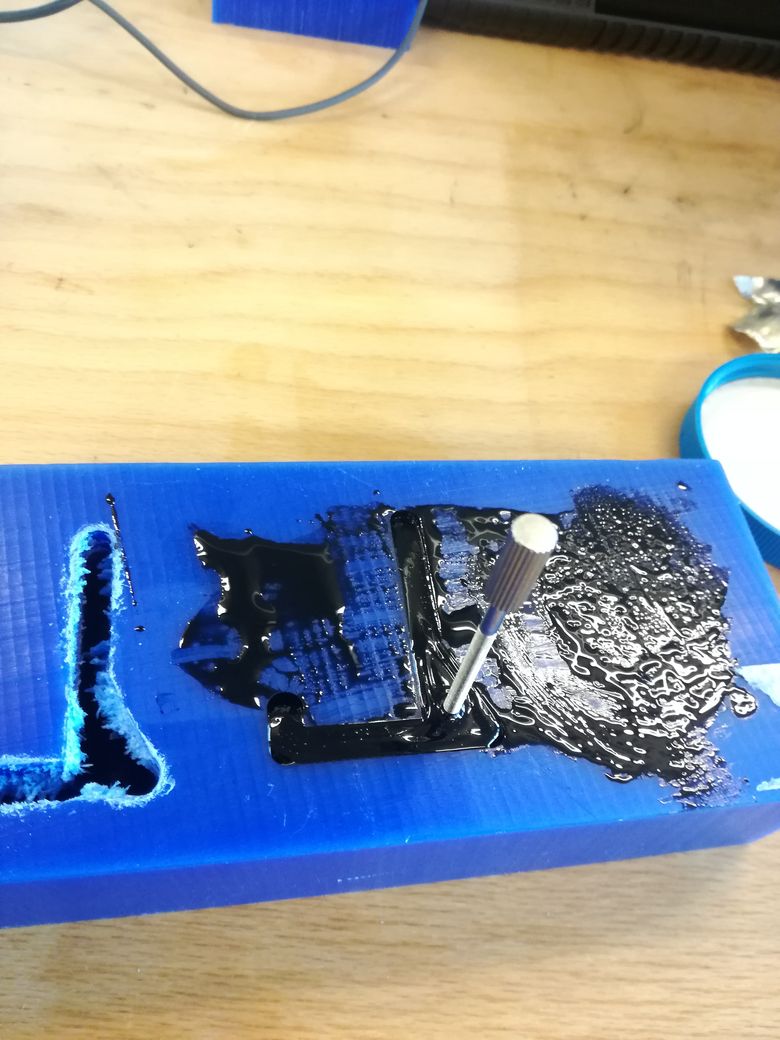

I casted using the black Onyx Fast liquid plastic.

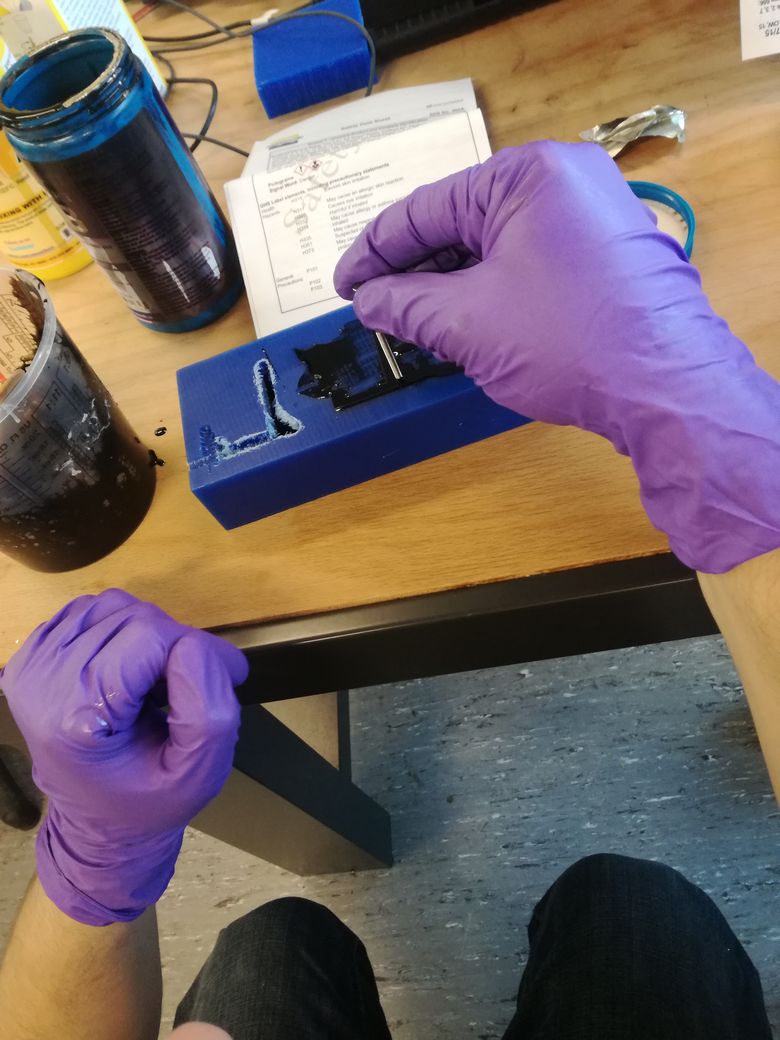

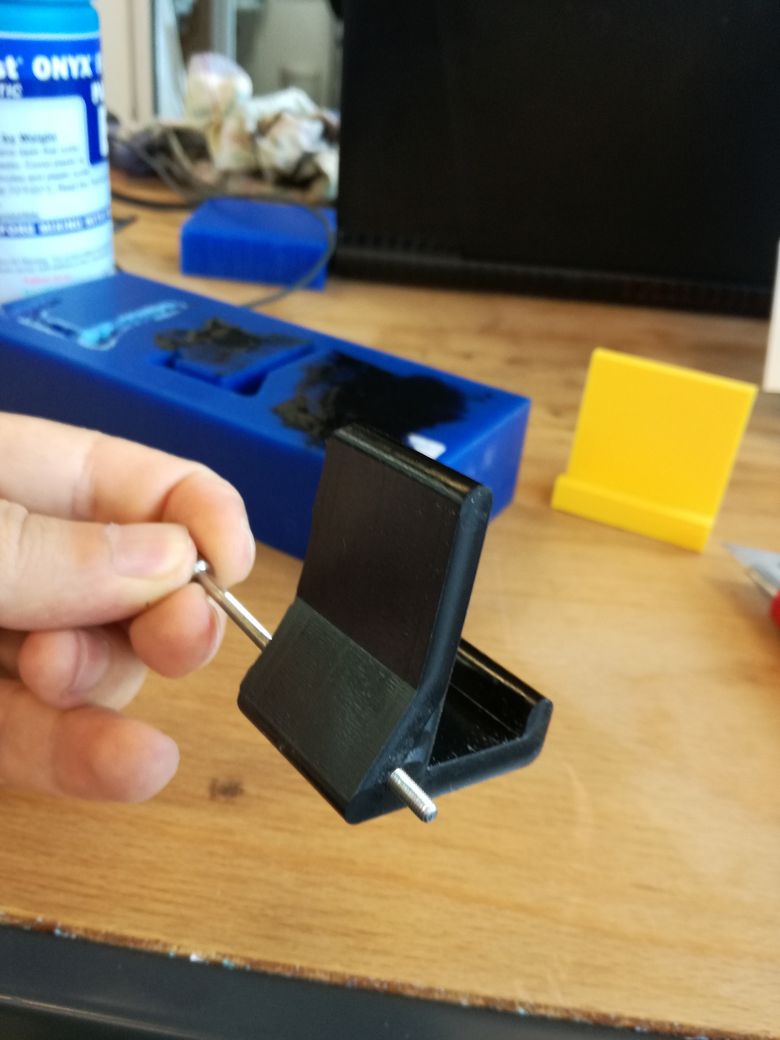

I inserted a screw in order to be able to pull the cast out of the mold. The thread got casted and it is possible to get a screw in and out of the cast!

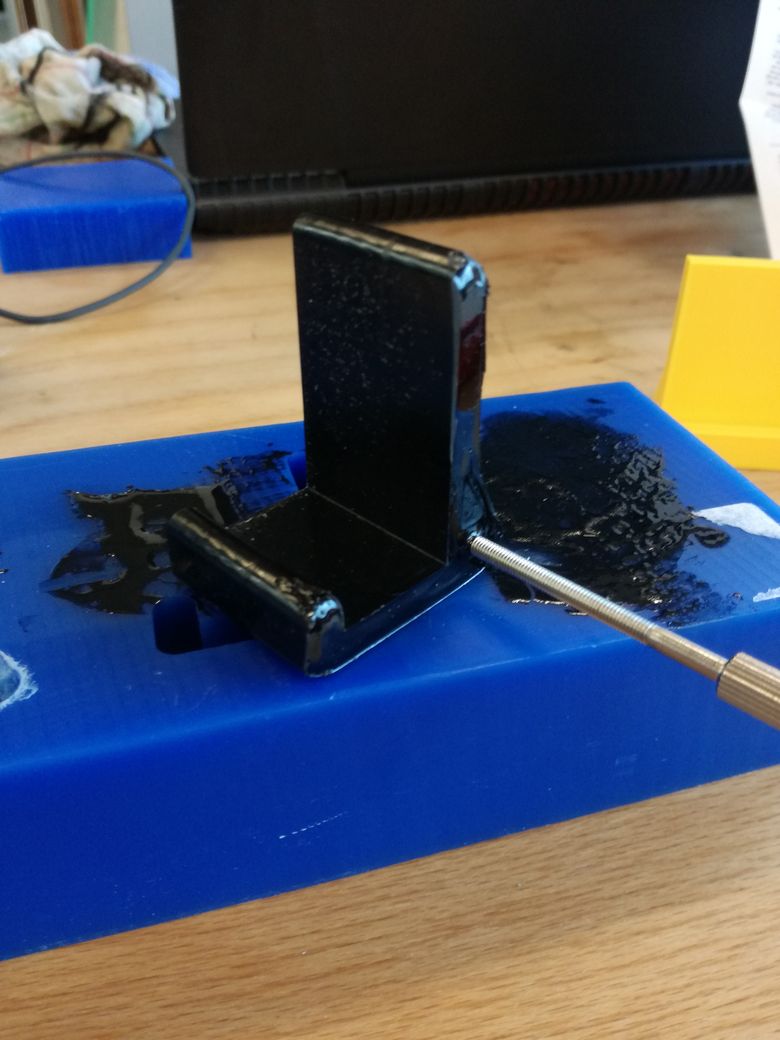

Finished product:

The mold volume is about 20mL. With 1L of liquid plastic, it would be possible to cast 50 smartphane holders...