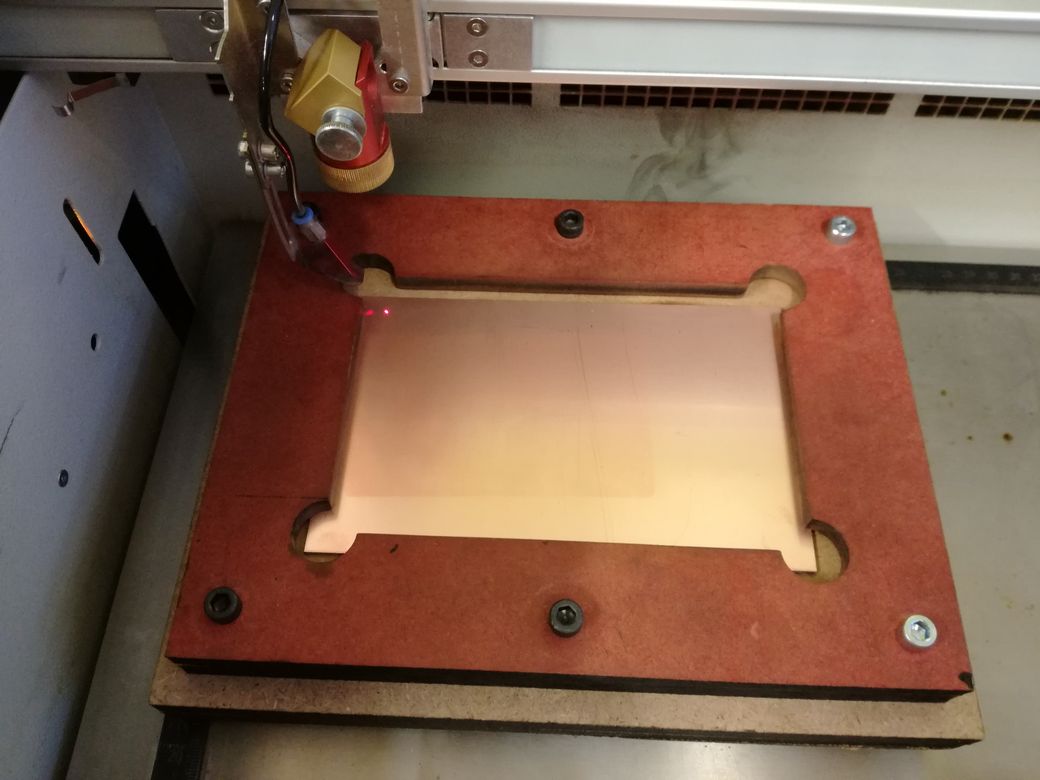

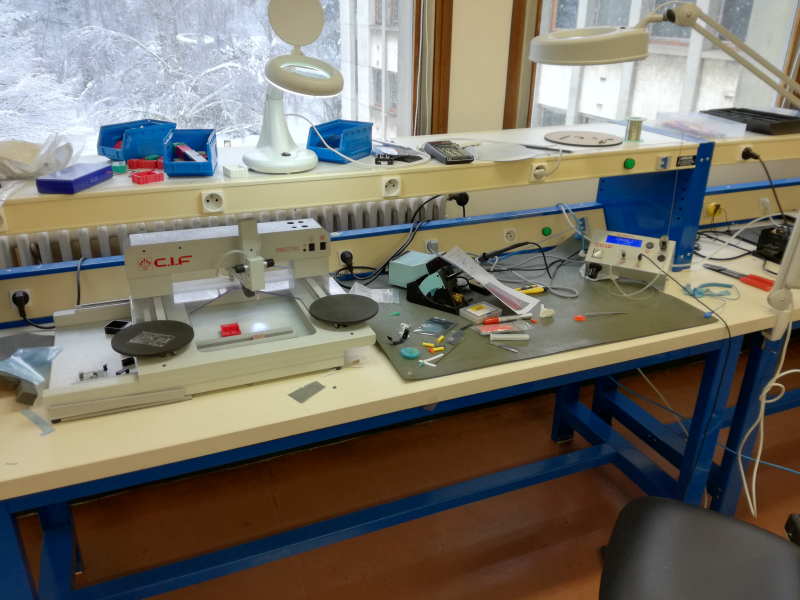

Using the Trotec Speedy 100 Flexx af the Photonic FabLab, Adrian and I studied the

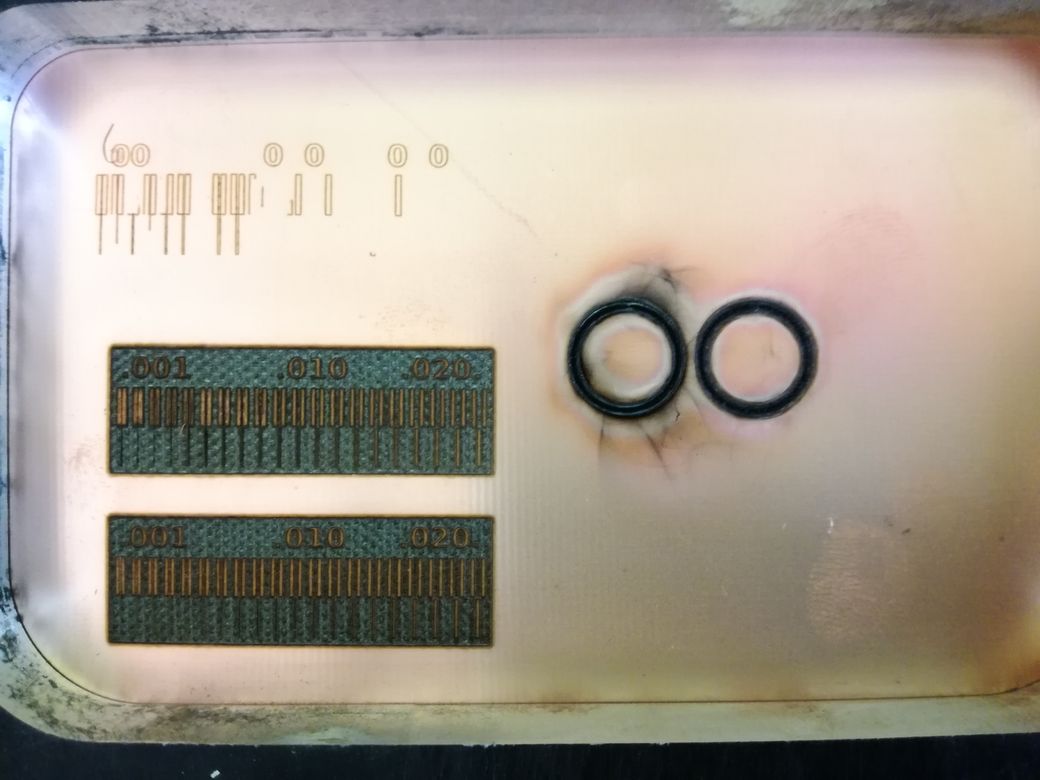

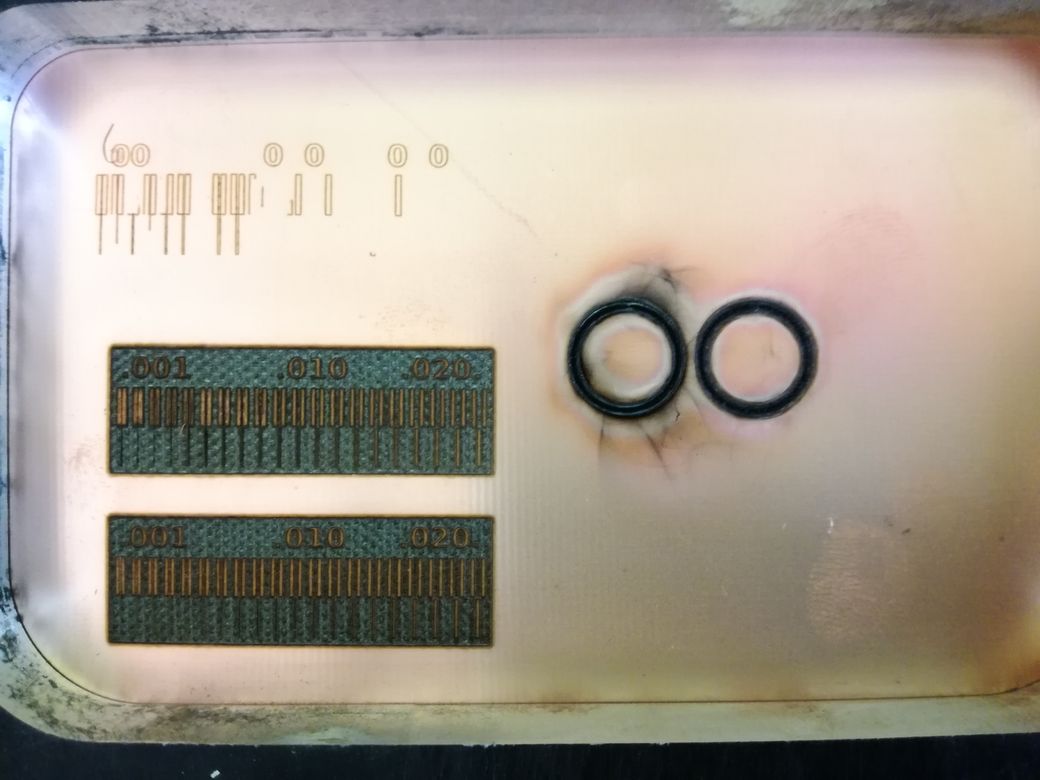

line test

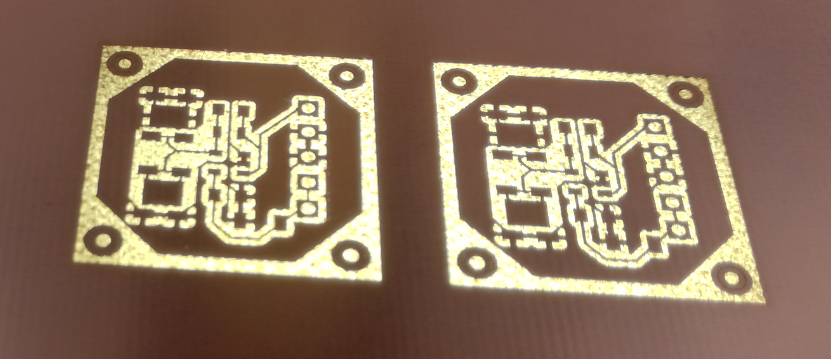

With the "Cut then engrave x6" process we achieved a 127um resolution. Look at Adrian's page for full details and pictures.

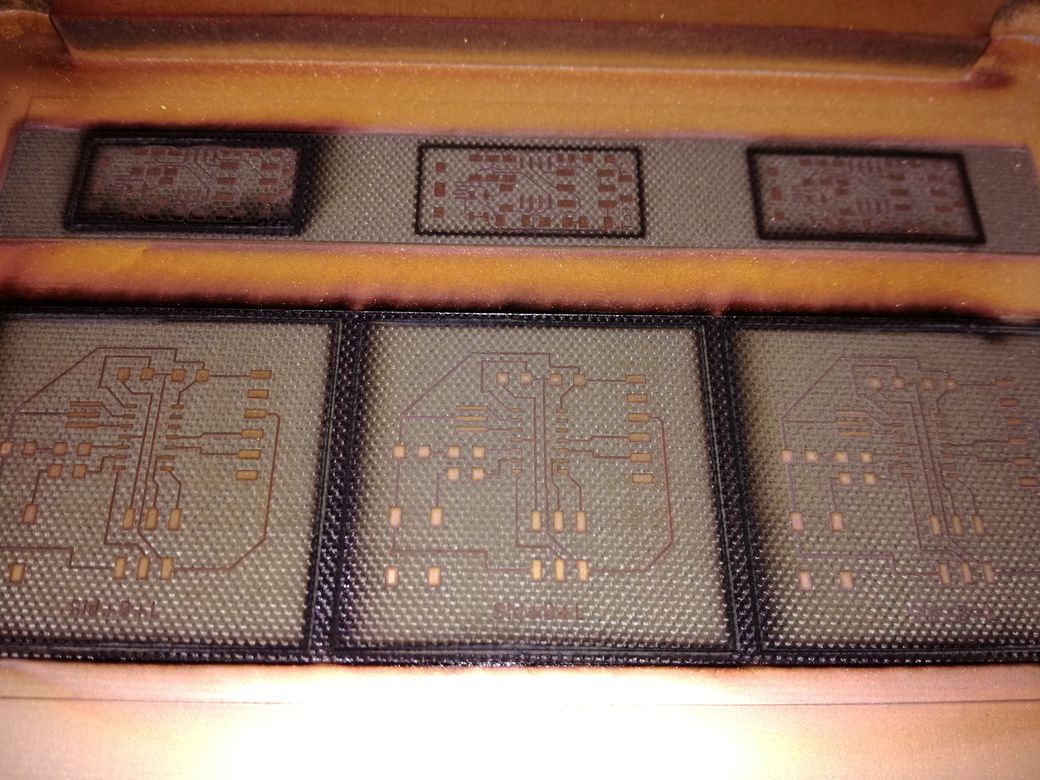

Cutting holes with the CO2 laser is very durty.

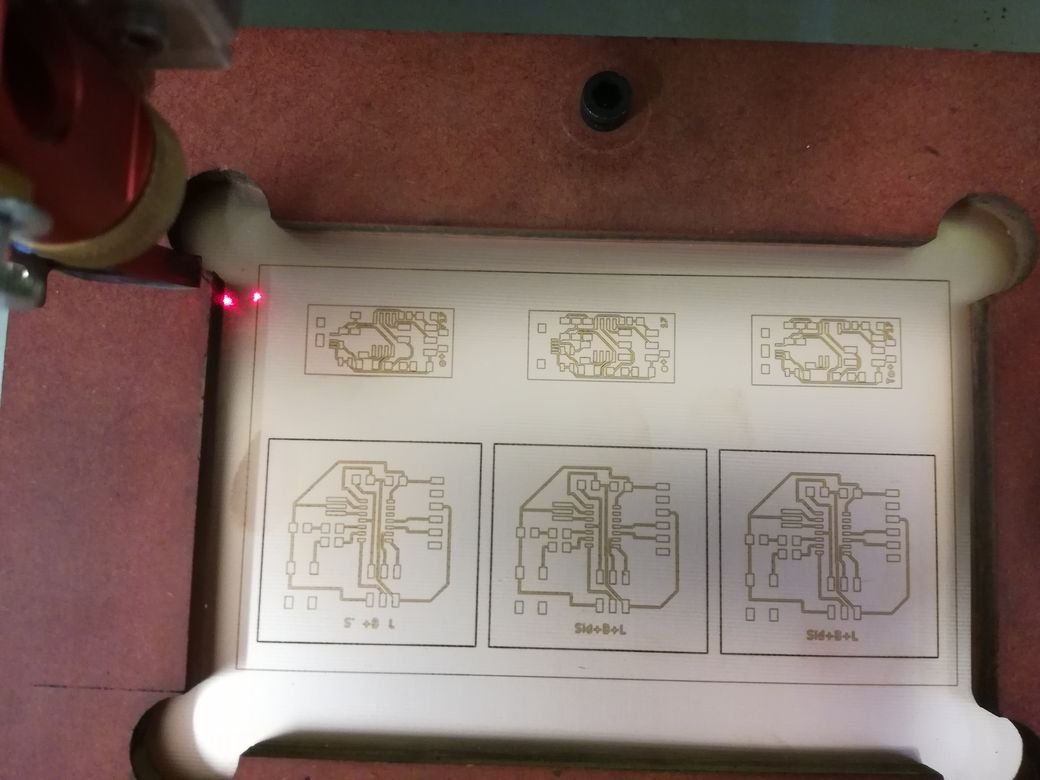

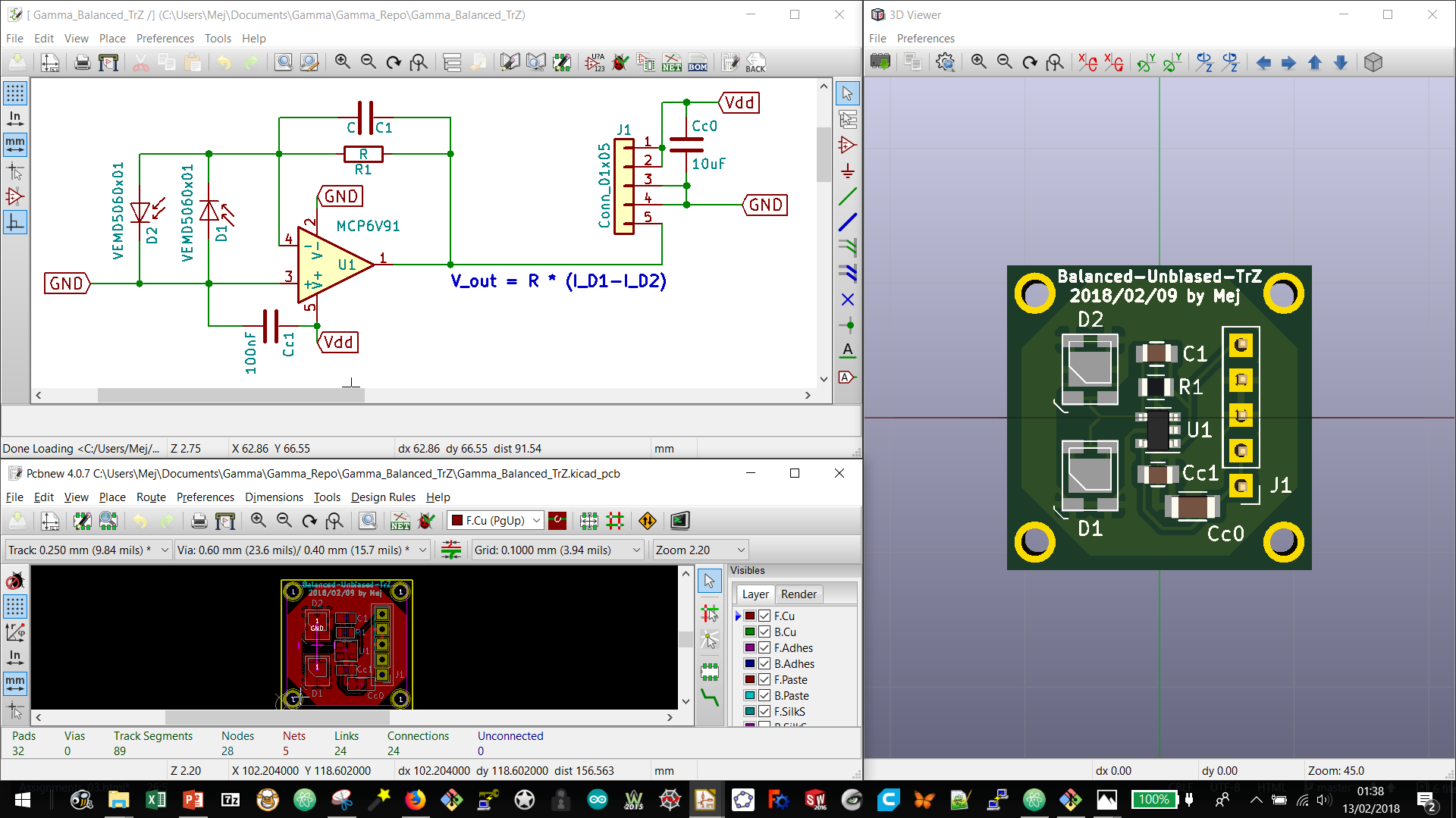

I used Kicad to draw a PCB shematic and root it.

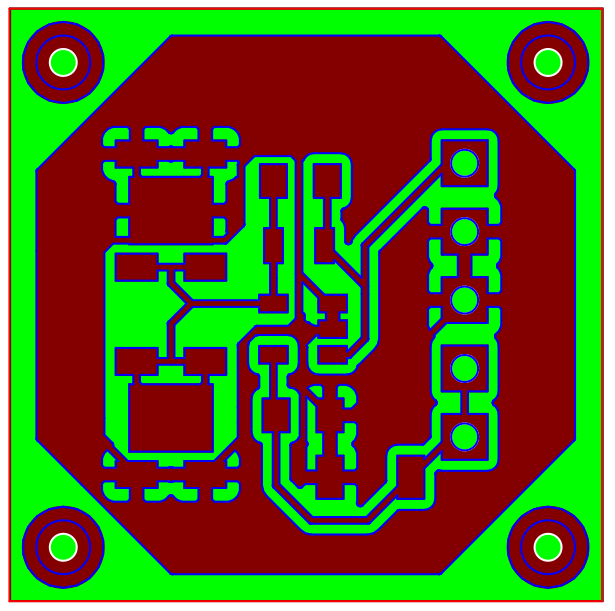

Then I exported the PCB in two file formats: colored *.svg for the Cu layer, and *.dxf for the Cu outline

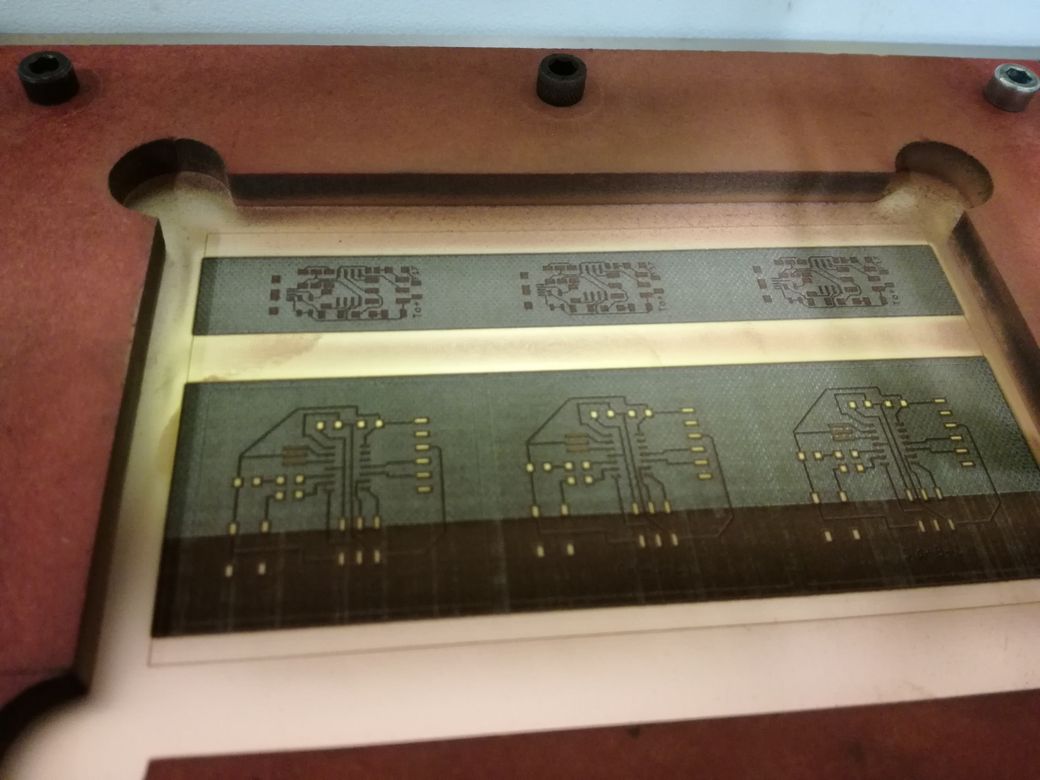

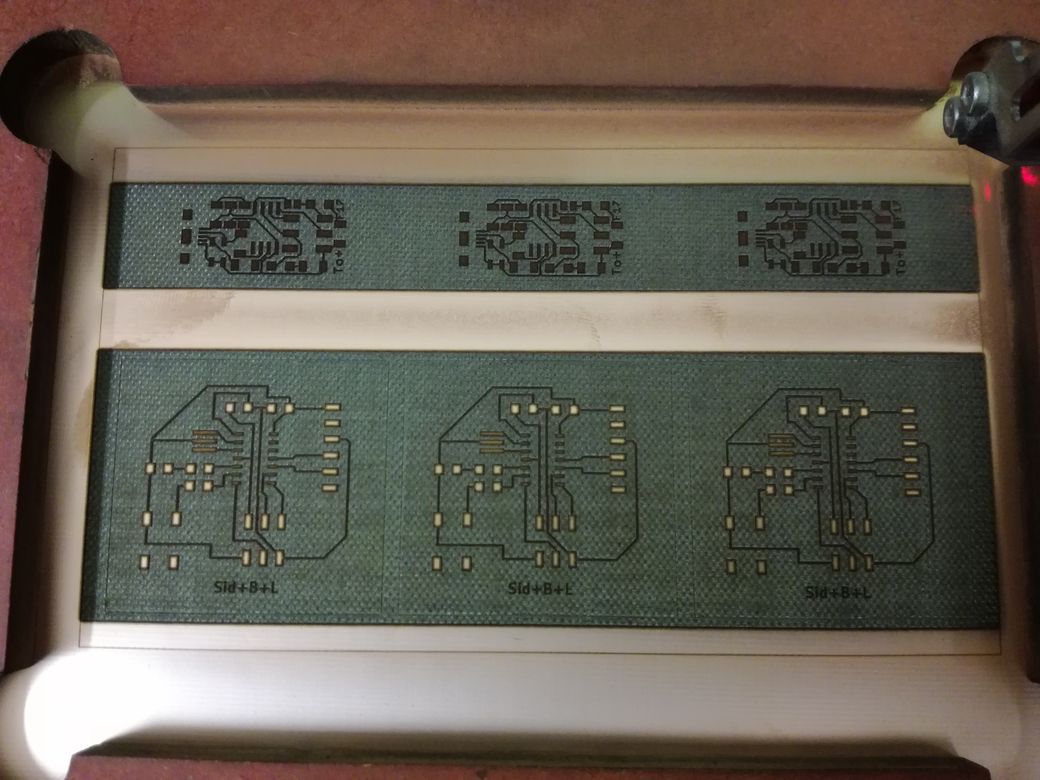

Then using an image editor software, I fusioned those files on a green background:

NB: I used CorelDraw for the editing. I wanted to use Inkscape, but it wouldn't open the *.dxf files nor *.gerber files generated with KiCad... :/

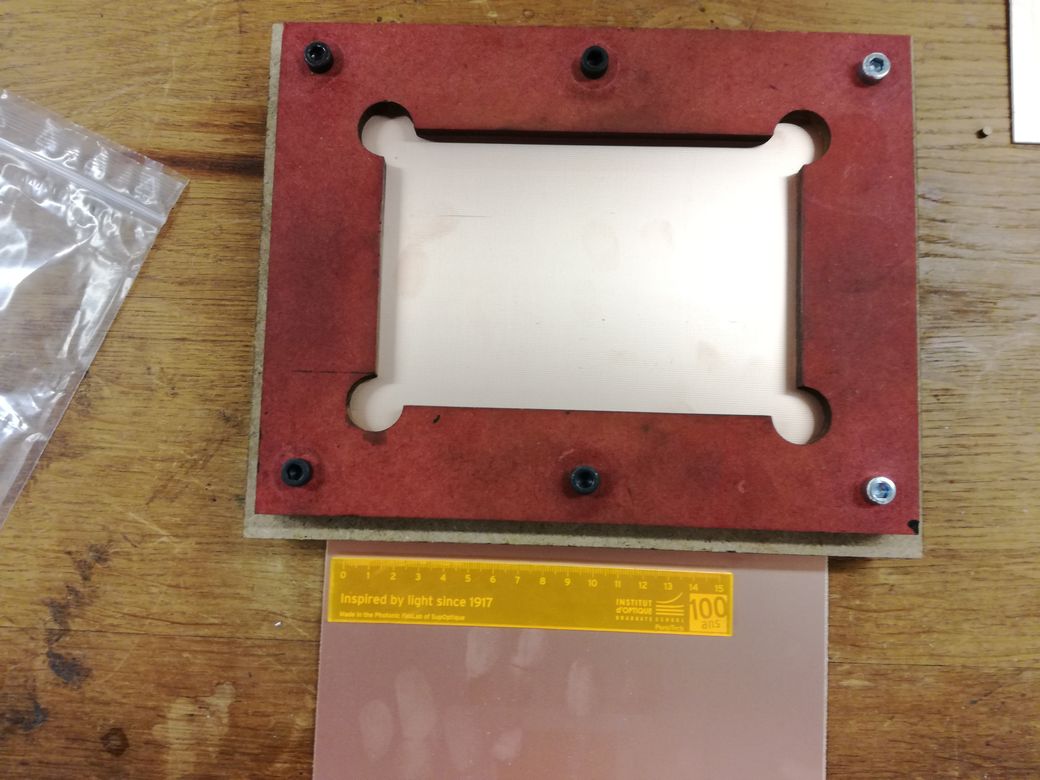

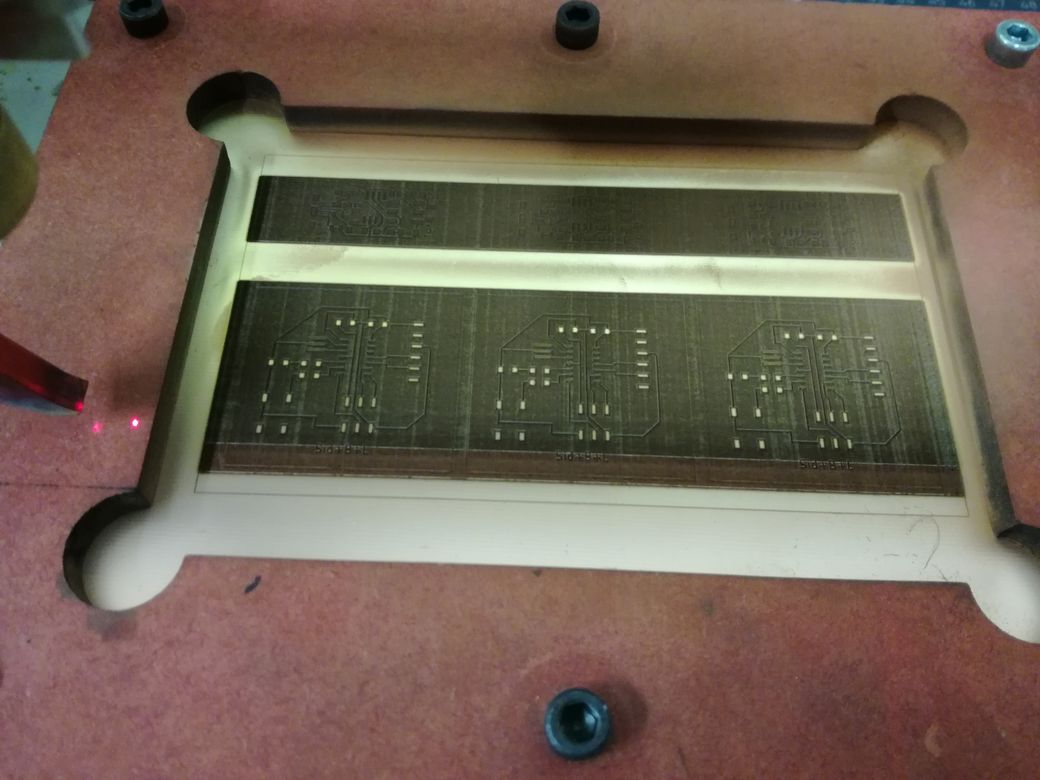

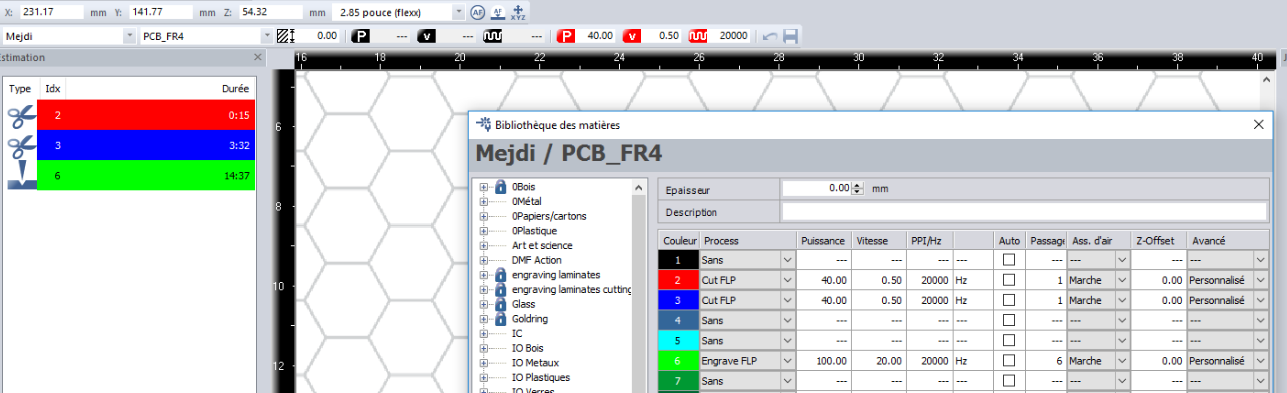

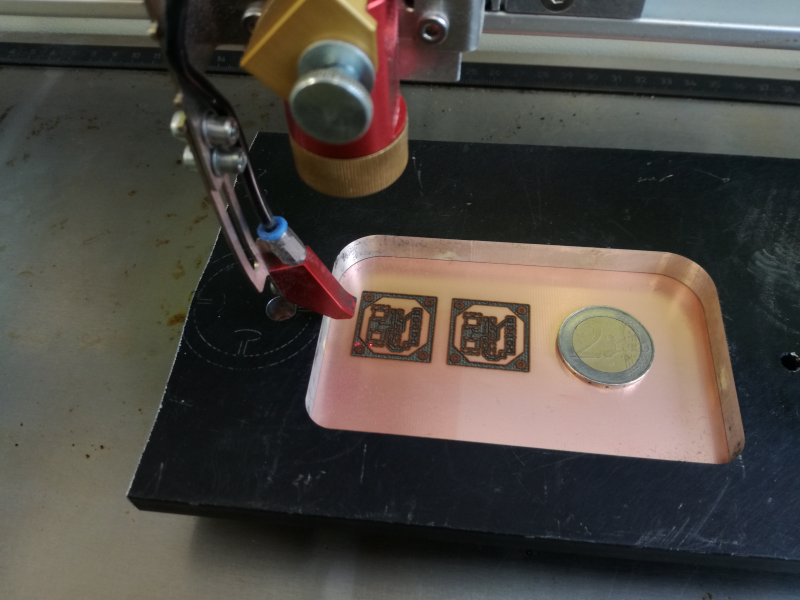

I printed with the fibre laser (1um, 25W) of a Trotec Speedy 100 Flexx going through the API 'JobControl'.

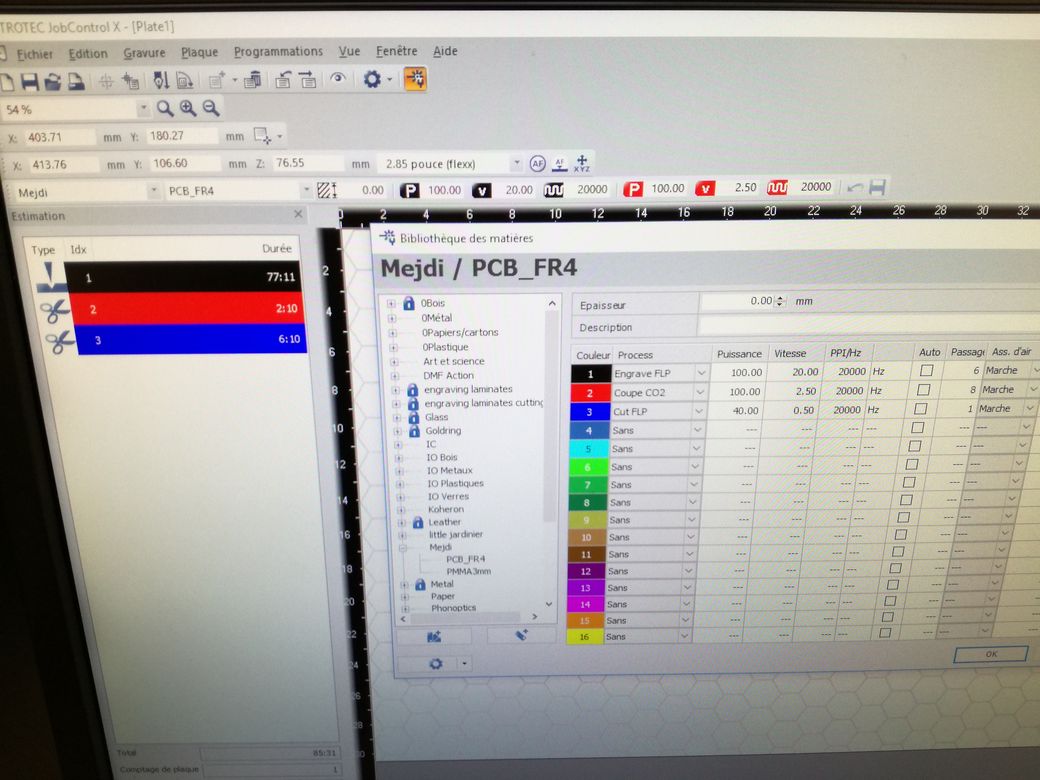

Thanks to "JobControl" it is possible top associate a type of machining (power/speed/frequency) to each color.

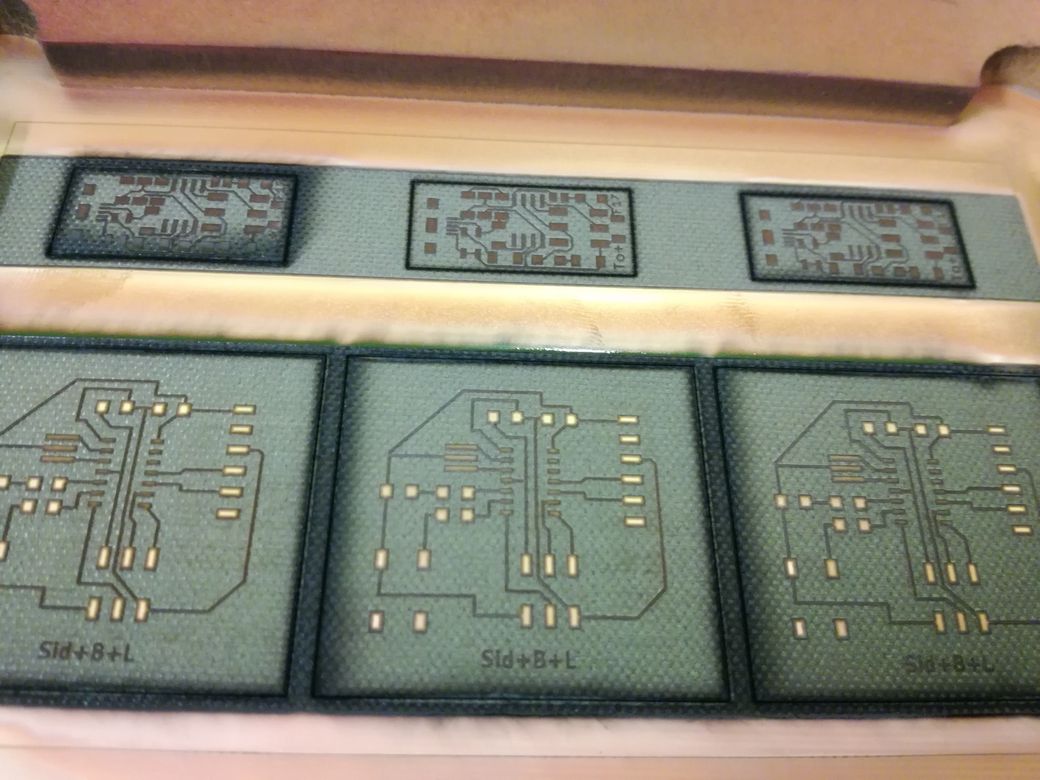

It takes about 20min to print 2 PCBs

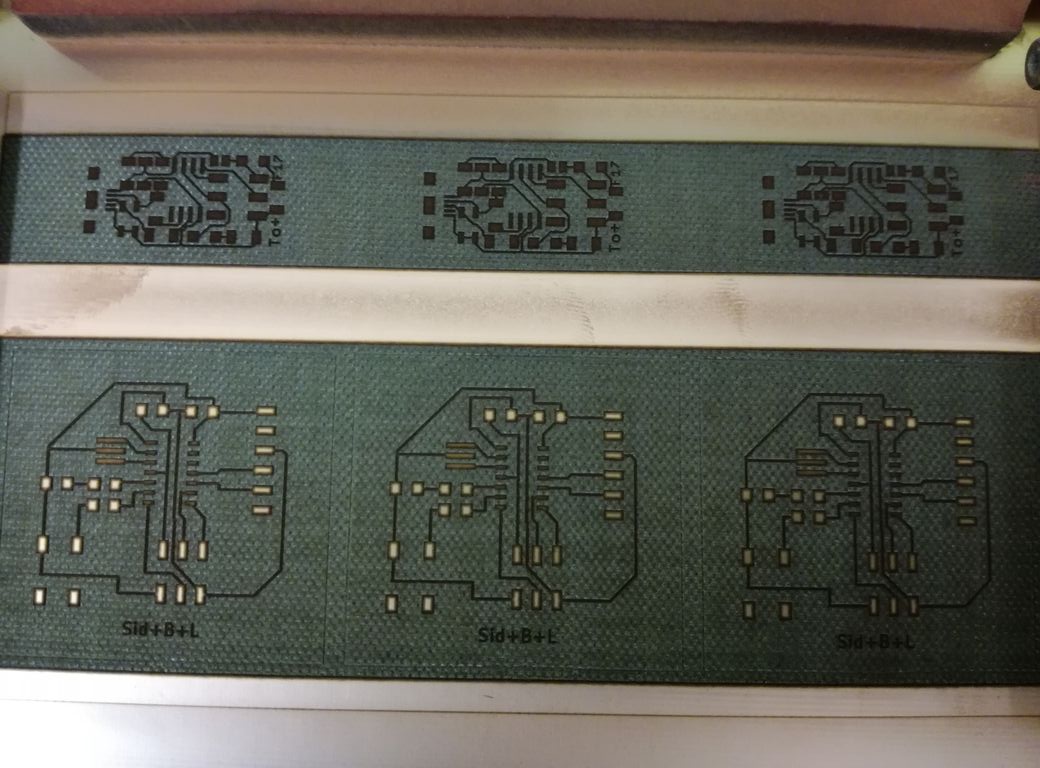

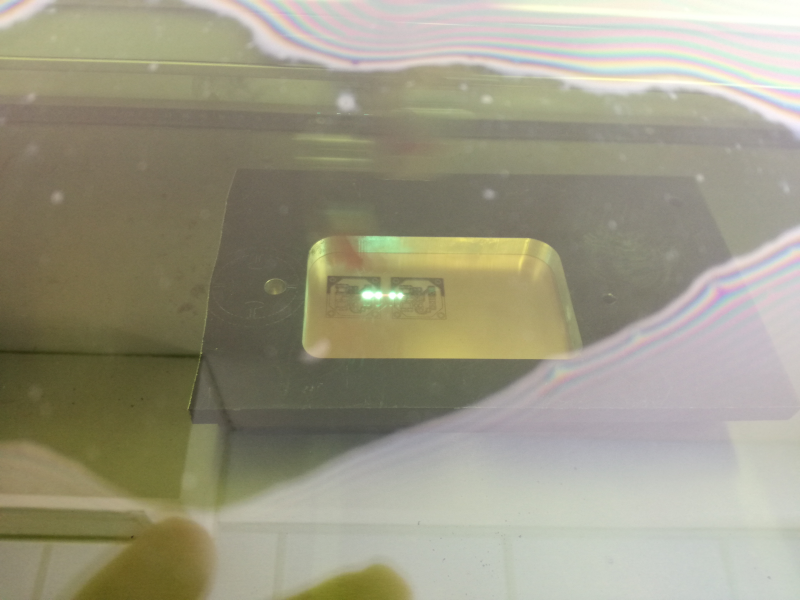

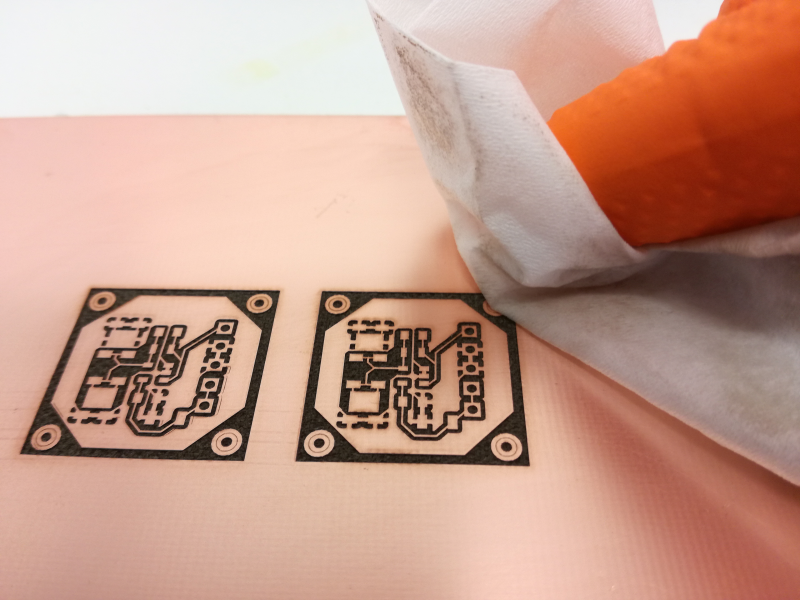

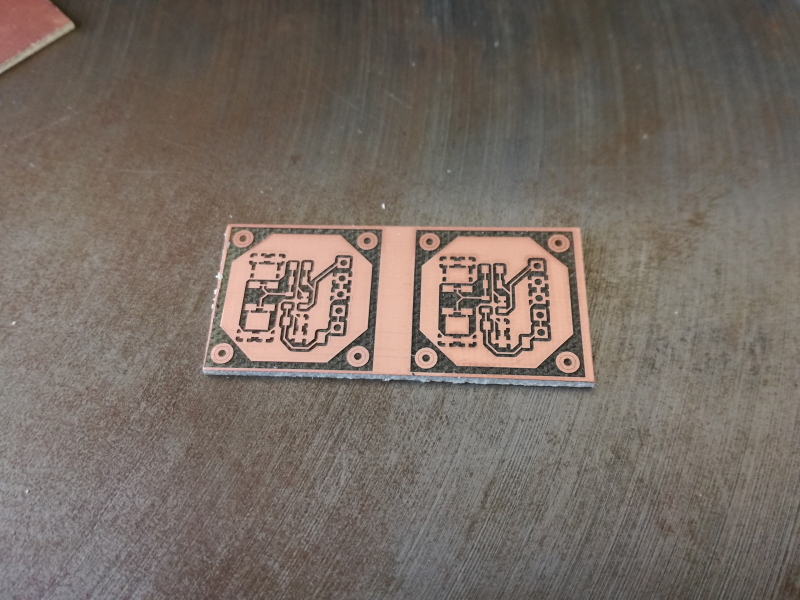

When the engraving is done, the PCBs are dirty. I cleaned them with propanol.

I cut the edge using a manual cutter (faster and cleaner than CO2 cut through FR4). Since there are only few holes, I also drill them manually.

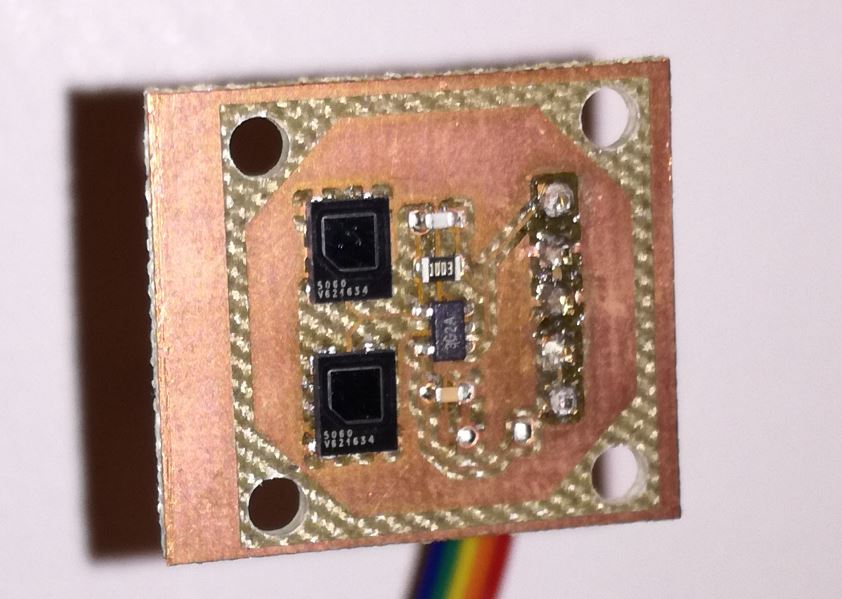

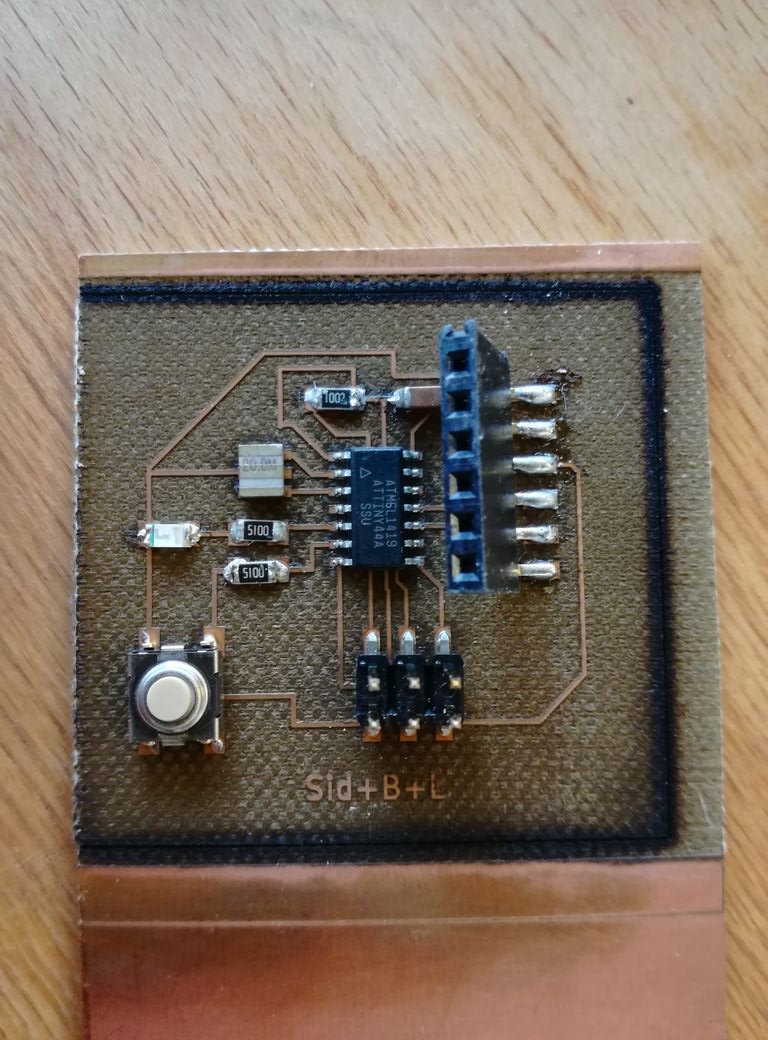

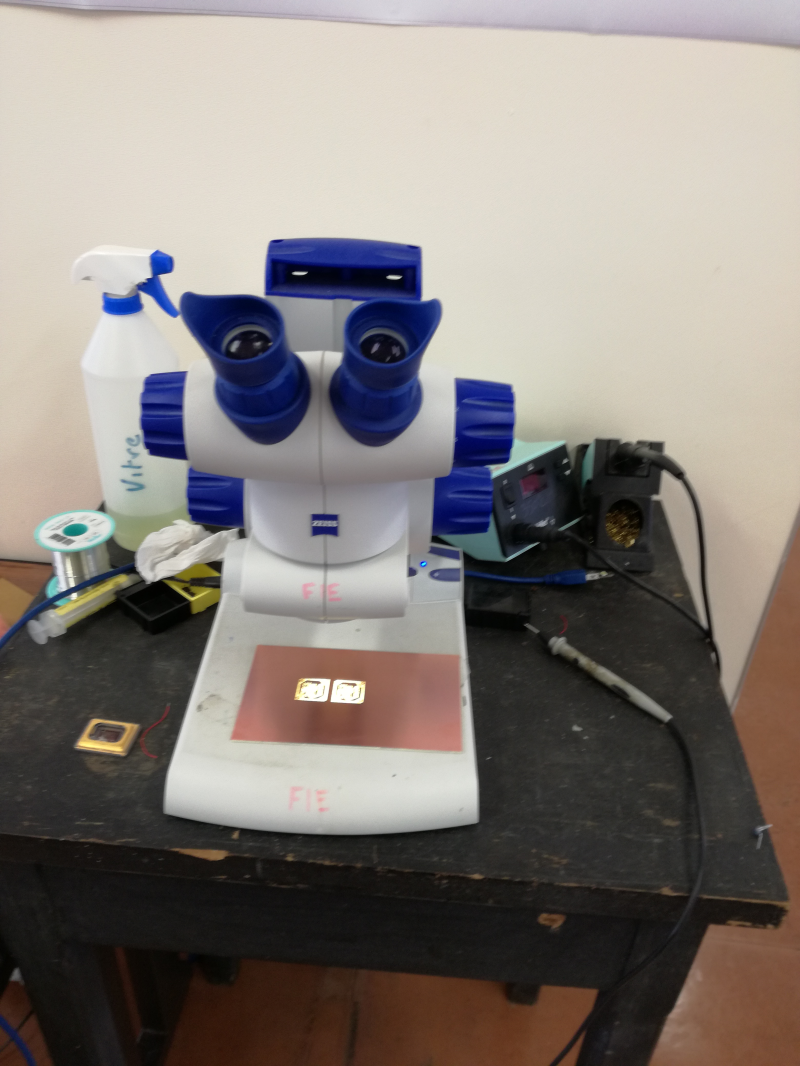

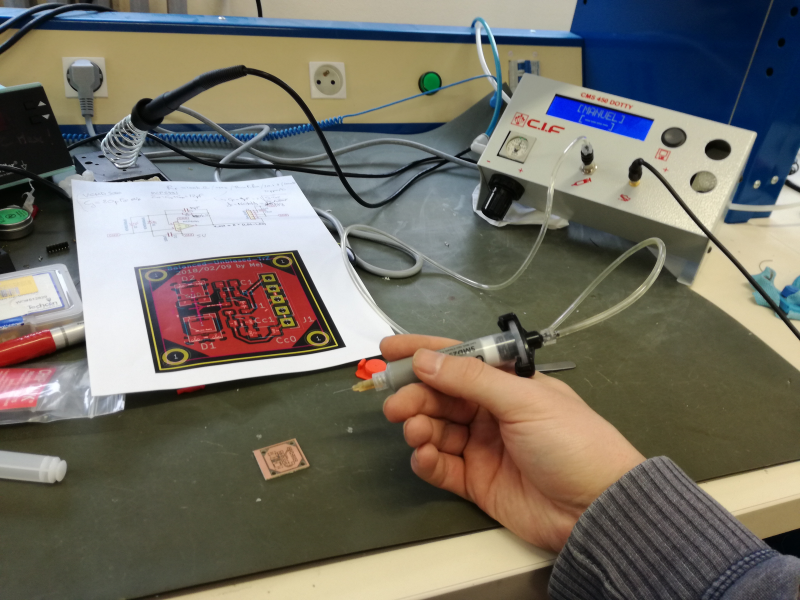

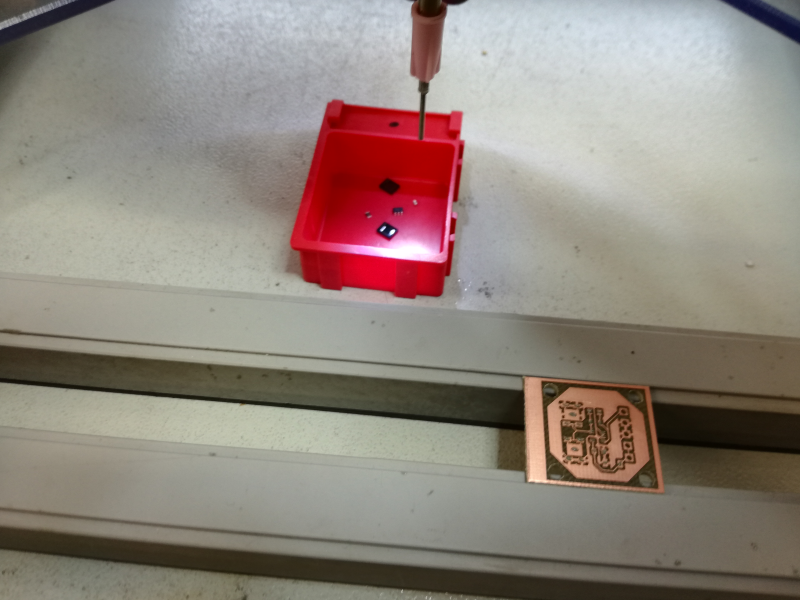

Finally, I solder the PCB using solder paste, manual pick&place and a reflow oven.

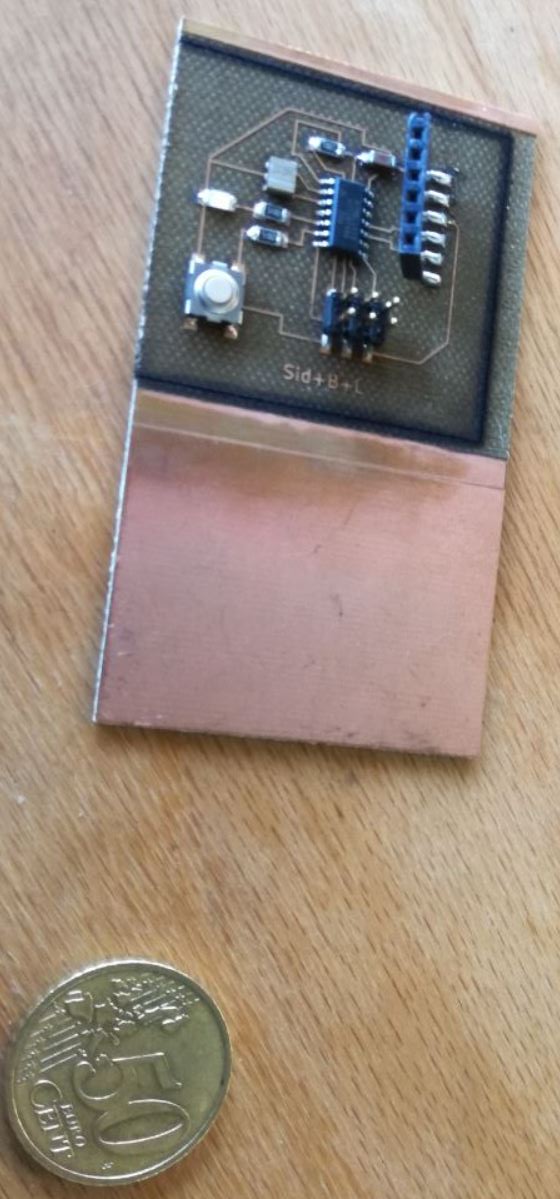

Here's what the finished PCB looks like: