Week - 06 3D Printing and Scanning

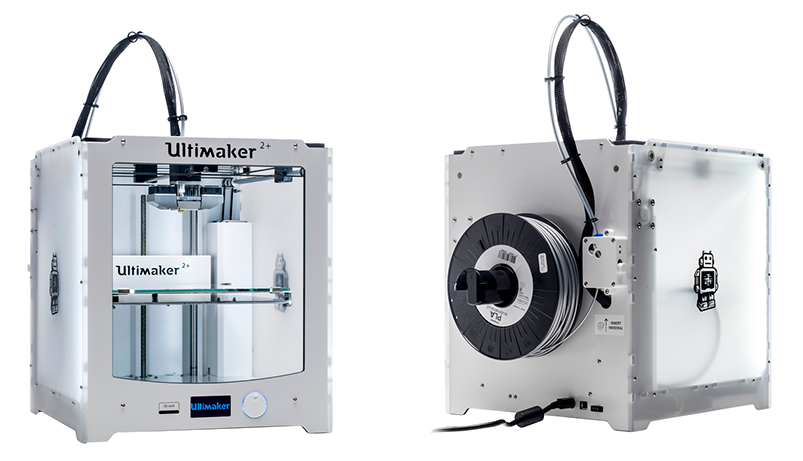

Machine specification ultimaker 2+

1 Build volume

Ultimaker 2+223 x 223 x 205 mm

2 Materials

Filament system:Open filament system

Optimized for: PLA, ABS, CPE, CPE+, PC, Nylon, TPU 95A with 2.85 mm material dia spool

3 Layer resolution

From: 600 micron Up to:20 micron

4 Speed

Build speed:Up to 24 mm³/s

Travel speed: Up to 300 mm/s

for more visit link you will find all details about machine in manual for ultimaker manual

About software

About Cura

Cura prepares your model for 3D printing. Optimized, expert-tested profiles for 3D printers and materials mean you can start printing reliably in no time. And with industry-standard software integration, you can streamline your workflow for maximum efficiency

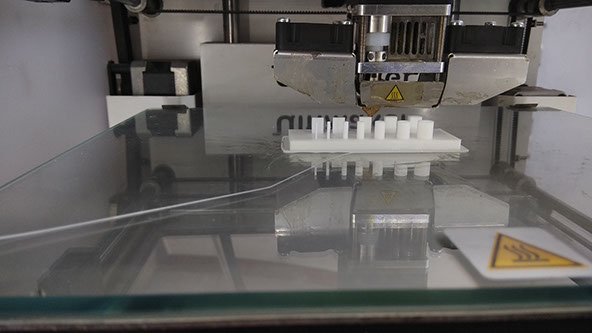

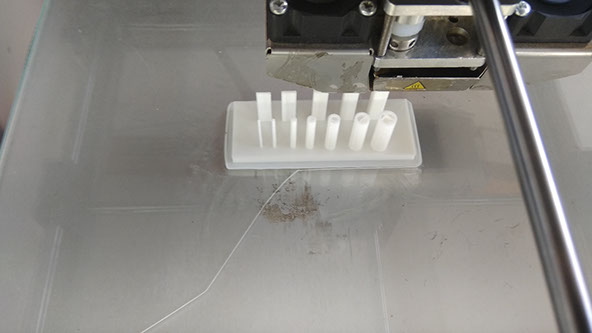

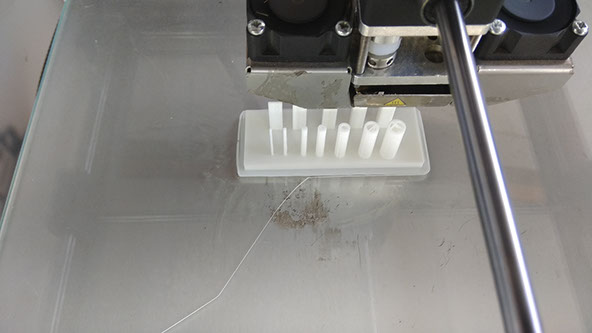

B. Wall and cylinder test

- Design parameters: 0.5, 1, 2, 3, 4, 5 and 6 mm diameter cylinders. And 0.5 to 4 mm thick wall

- Print resolution: 150 micron

- Wall thickness: 0.8 mm

- Print speed: 50 and 60 mm/sec print and travel respectively

- Print resolution: 150 micron

- Print fill: 15%

- Support: No

- Cooling: Yes

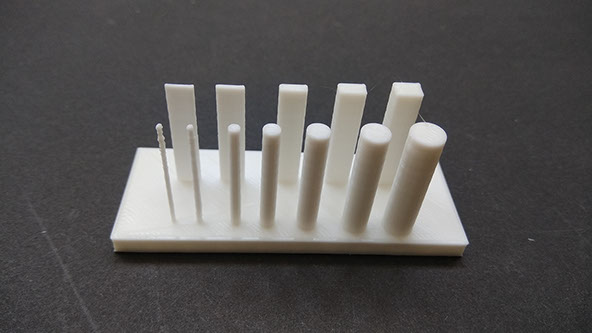

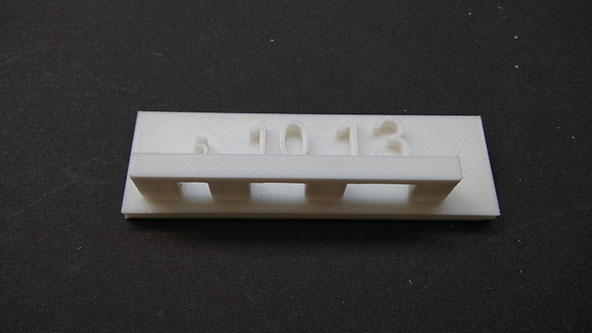

Result and Conclusion:

- Bridge can be printed without support upto ** distance with normal cooling. If fan turned off or reduce the cooling this distance may increase to 3 or 4 mm.

- Minimum thin wall can be printed is of 0.8 mm with speed of 40 and travel at 50 mm/sec

- Minimum cylinder diameter that can be printed is 2 mm.

- Overhang angle at which one can print is 55 or 60 degree max with speed 30 and 50 mm/sec without support.

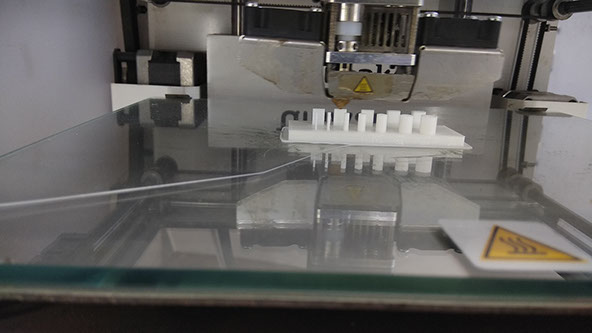

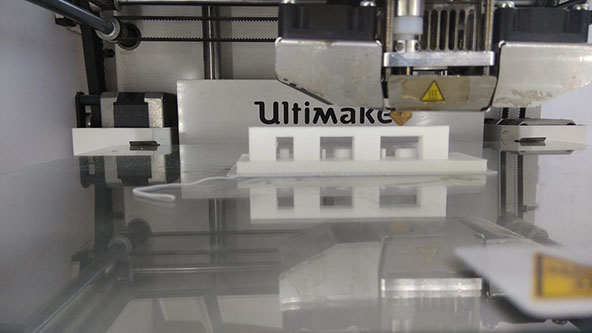

D. Universal Test:

- This I took reference from majda107 thingiverse (https://www.thingiverse.com/thing:2806295)

- I printed that with following parameters

- Resolution: 200 micron

- Print speed: 60 and 70 mm/sec print and travel respectively

- Infill: 100%

- Support: No

- Cooling: Yes

Observation:

- Overhang angle: Its printing well upto 50 degree, then its making bulge at the bottom, though it gets printed without support upto 80 degree!

- Bridge - It can make bridges upto 30 mm without support

- It can make cylinder minimum diameter upto 1 mm but very thin

- It can make holes up-to 1 mm diameter