Ideally - A six axis, fabbable robotic arm that can be controlled using grasshopper and with interchangeable heads for different tasks. The aim of this is to be able to replace multiple tools within a fab lab (milling, 3D printing, wire cutter.. and MORE!) with extra functionality (with extra axis) while also providing a platform to try out novel fabrication techniques e.g. clay printing

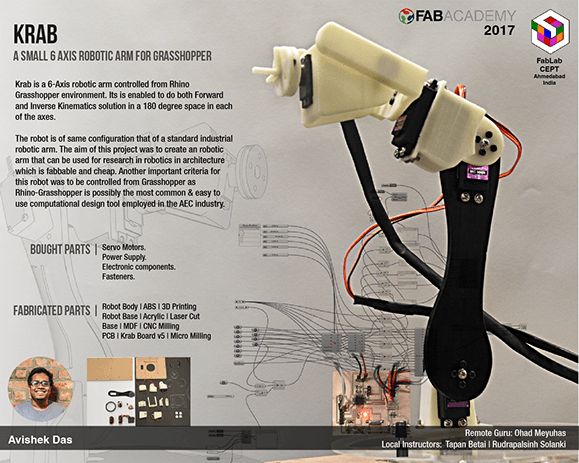

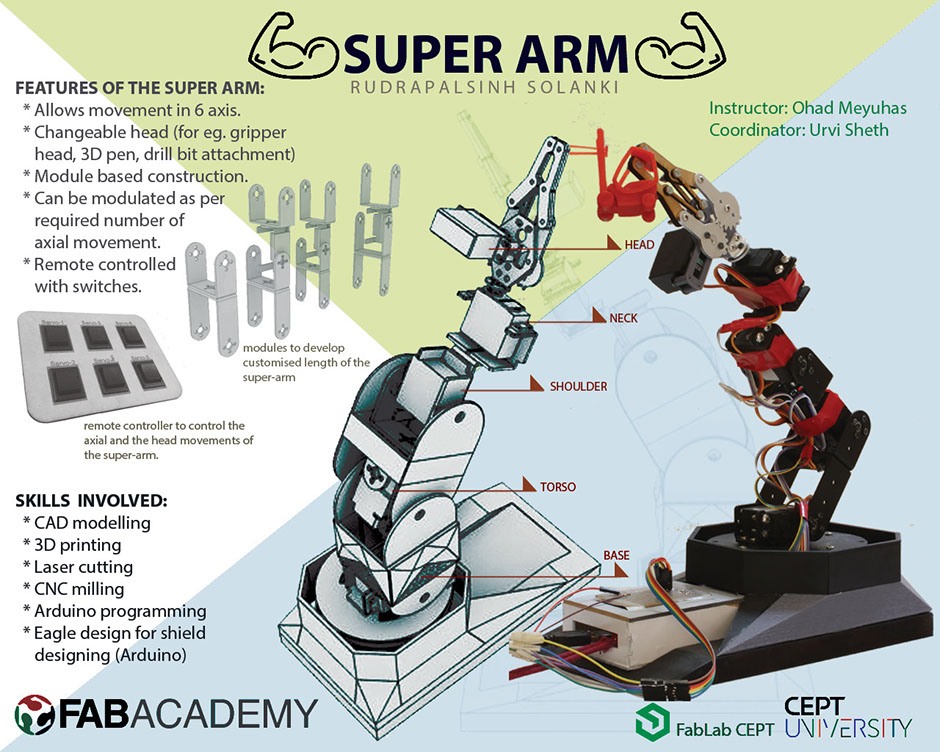

There are of course some commercial 6 and 7 axis robot makers such as ABB AND KUKA. Fab Academy 2017 saw a few robot arm projects which I hope to build on:

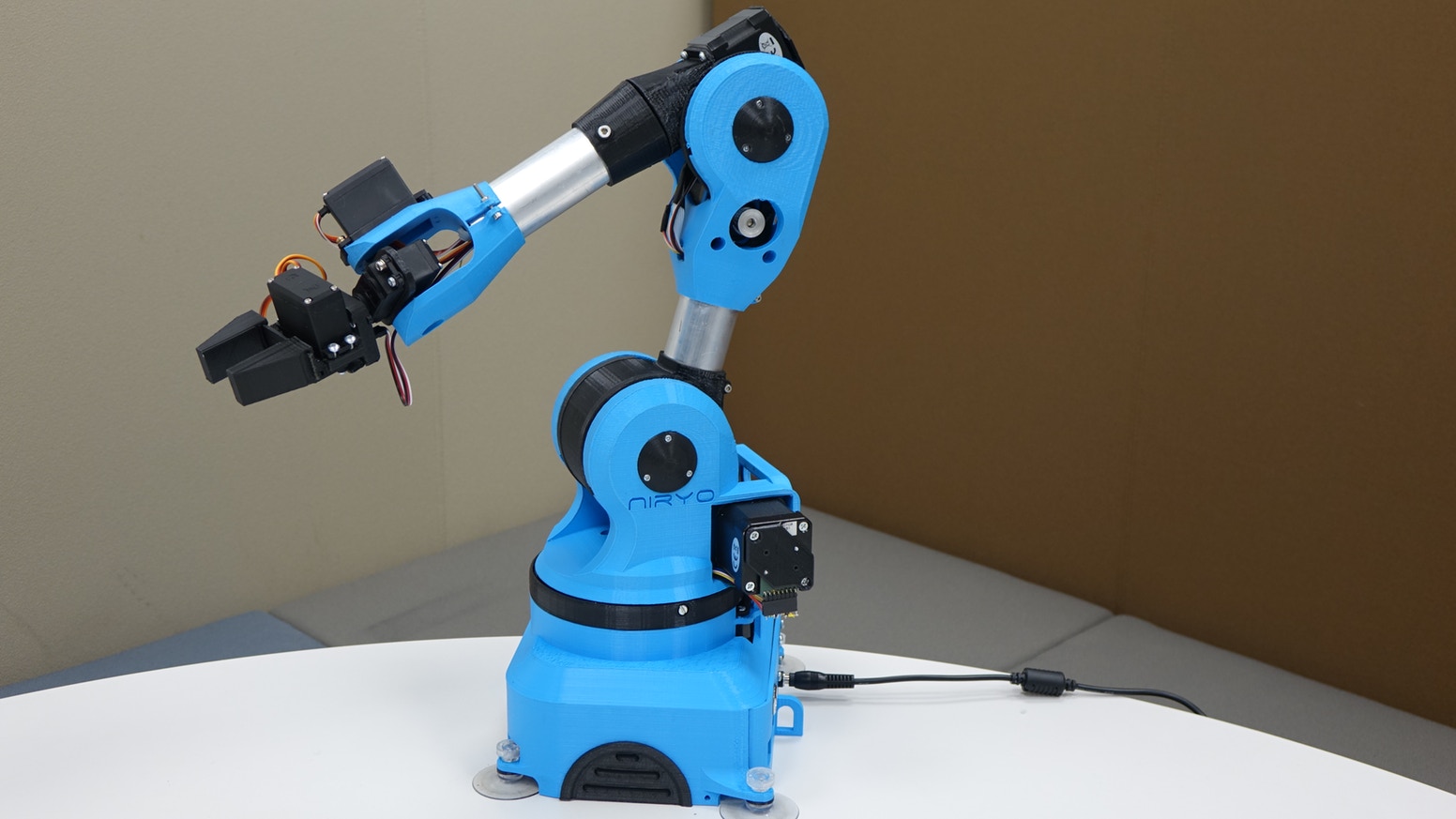

There are also other open source robot arm projects which I hope to be inspired by:

The electrical components required will be stepper motors, stepper drivers, Arduino Mega/RAMPS 1.4 shield, Attiny 85 for stop switches. The mechanical components will include planetary gears, bearings, nuts and bolts, lead screws, timing belts. All other components will be fabricated using 3D printing, milling or laser cutting.

The parts for the arm will either be ordered online (ebay/amazon/ooznest) or made within the fablab.

This initial prototype is proving to be quite expensive, hopefully this will mean the capabilities (e.g. for milling) will be great, but can probably be dramatically scaled back and thus the price reduced for future iterations.

Initially 3D printed PLA/ABS and wood. Further development of the design could see many of the parts replaced with milled aluminium. I like the idea of using 3D printing as much as possible to make it accessable to more people.

All the mechanical parts that will be milled, 3D printed or laser cut will be designed in Rhino and then converted to .stl or .dxf. This will also help in making the code for the arm as exact measurements can be retrieved from this model.

I will create the circuit boards in eagle and mill them using our Roland MDX-50, followed by soldering of the components. I will use my Pauduino board to control off the shelf pololu steppers and I hope to recreate the Satstep board by Daniele Ingrasia.

I will use I2C communication to receive data from stop switches. This will allow me use just 2 pins for multiple inputs.

I need to resolve the mechanical configuration. These level of mechanics is very complex and new to me. I have designed a lot of the arm based on the AR2 by Chris Annin and so the scale of my arm is similar. I was advised to work backwards from the end of the arm so I could scale the size of the steppers I required.

I also need to develop the Grasshopper interface. I have done some inital work on creating inverse kinematics and creating gcode for a milling machine and for Machine building week.

I was going to use the Marlin Firmware to move my robot, but I believe I will be able to create my own board to control my arm after completing Output devices week

Can I resolve the mechanical challenges?

Can I create a working Satstep?

Can I get a Pauduino to talk to Grasshopper?

Will be construction techniques give a machine with a low enough tolerance for anything meaningful?

documentation - can someone else build it?

accesability - who can build it and how open it is for further development?