Week 18 - Applications and implications

Individual assignment

propose a final project that integrates the range of units covered. Projects can be separate or joint, but need to show individual mastery of the range of skills covered. Where possible, you should make rather than buy the parts of your project. Topics for this week are included below.

what will it do? Specification

The product must:

- cure carbon fibre parts using open and closed moulds at a minimum of 80 deg C up to 14 hours

- accomodate an internal volume of at least 300 x 200 x 200 mm

- be programmable according to a set temperature/time schedule

- be mains powered

- have a safety cutoff??

- allow for local control of temperature via simple 'set' temperature using a simple 'bang-bang' thermostatic control

- allow for remote control via computer programme with wired/wireless connectivity, including PID temperature control

- accomodate a vacuum pump connection

- regulate temperature in at least two internal locations to within 2.0 deg C

- include relevant heat transfer, electrical and electronics theory - and be a useful exemplar for students wanting to carry out a project which includes these topics

- have sufficient documentation to allow for this to be reproducable with similar equipment

The product will ideally:

- have a programme to load .csv files for the temperature/time schedule

- plot the set and actual temperatures in a live feed

- accomodate curing cycles up to 130 deg C

- include 'smart' capability, whereby PID 'tuning' is based on performance history and some learning/AI capability

- not include the subframe of an existing product (but be designed/made by me)

- not include the heating element of an existing product (but be designed/made by me)

- not include the fan of an existing product (but be designed/made by me)

Who's done what beforehand? Research and competitor analysis

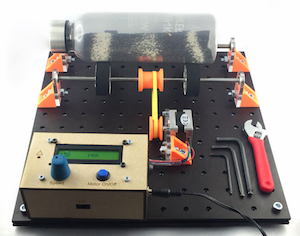

I was quite inspired by Denis Terwagne's 2017 final project

which was a physics tinking kit, to provide a cleverly designed platform for students to play with various aspects relating to physics theory. I also found this PID controlled carbon fibre curing oven (here's the link).

This was a really useful project to learn from, I'm aiming to do something similar, hopefully more sophisticated but smaller since I will only really work with small samples.

I was also impressed by this project:here's a good project in terms of presentation, it's a light display.

And here's a good tutorial for writing code in arduino IDE to create a PID controller

And here's a link to an open source PID controller with all the documentation.

Here's another project where they've made a PID controlled oven - although they bought the PID controller.

And here's an interesting paper on testing smart thermostats. Finally, this guide explains how to go about tuning the PID in a systematic way...I wonder if this can be automated?

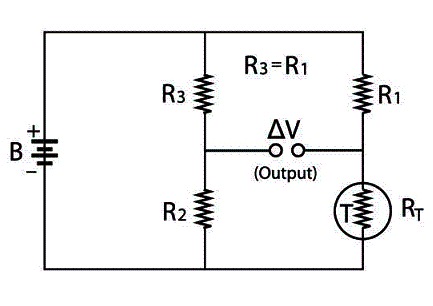

On a slightly different note, here's a useful guide I will need to put my thermistor measurements into a Wheatstone bridge. Since the relationship between the voltage reading across a thermistor and temperature is highly non-linear, we'll need to use a bridge to do this correctly.

Raw materials and components, sources and costs...Bill of Materials

| Classification | Part name | Source | Cost per item | Number required |

|---|---|---|---|---|

| ELECTRONICS | ATMega32U4 | FABLAB INVENTORY | £3.32 | 1 |

| RED LEDS: 1206 | FABLAB INVENTORY | £0.24 | 3 | |

| 22 OHM RESISTOR: RES-US1206FAB | FABLAB INVENTORY | £0.007 | 2 | |

| 499 OHM 1206 RESISTOR | FABLAB INVENTORY | £0.007 | 3 | |

| RES-US1206FAB 680 OHM RESISTOR | FABLAB INVENTORY | £0.007 | 1 | |

| 10K OHM RESISTOR1206 RESISTOR | FABLAB INVENTORY | £0.007 | 3 | |

| 10uF CAP-US1206FAB CAPACITORS | FABLAB INVENTORY | £0.24 | 1 | |

| 1uF CAP-US1206FAB CAPACITORS | FABLAB INVENTORY | £0.24 | 2 | |

| 0.1uF CAP-US1206FAB CAPACITORS | FABLAB INVENTORY | £0.24 | 1 | |

| 18pF CAP-US1206FAB CAPACITORS | FABLAB INVENTORY | £0.24 | 2 | |

| CSM-7X-DU 16 MHZ CRYSTAL | FABLAB INVENTORY | £0.88 | 1 | |

| MINI-B USB CONNECTOR | FABLAB INVENTORY | £0.77 | 1 | |

| CONNECTORS (FTDI) | FABLAB INVENTORY | £0.02 | 1 | |

| SPST_TACT-EVQQ2 BUTTONS | FABLAB INVENTORY | £0.34 | 3 | |

| 24V 10 A RELAY | EBAY | £3.23 | 1 | |

| 6 pin OLED SCREEN | amazon | £4.95 | 1 | |

| HEATING SYSTEM | MAO5 - 5 V DC FAN | EBAY | £4.49 | 1 |

| 24 V DC, 10 A HEATING ELEMENT | EBAY | £4.88 | 1 | |

| 24 V DC, 10 A Universal Regulated Switching Power Supply | INDUSTRY MALL - EBAY - https://www.ebay.co.uk/itm/181881169501 | £12.99 | 1 | |

| 3pin active temperature sensor | ebay | £0.96 | 1 | |

| MAIN CASING | 13 MM HIGH TEMPERATURE INSULATION, 6 X 61cm x 366cm x 13mm | EBAY | £30.00 | 1 |

| MAIN CASING | CARBON FIBRE VINYL COATING | EBAY | £6.26 | 1 |

what parts and systems will be made? and what processes will be used? Fabrication processes and materials

| Sub assembly | Part name | Material | Fabrication process | Number required |

|---|---|---|---|---|

| MAIN_CASING | FRONT_CONTROL_PANEL | 2 MM PLY | LASER CUT | 1 |

| FRONT_CONTROL_PANEL | 2 MM PLY | LASER CUT | 1 | |

| FRONT_TOP_PANEL | 2 MM PLY | LASER CUT | 1 | |

| FRONT_BOTTOM_PANEL | 2 MM PLY | LASER CUT | 1 | |

| SIDE_PANEL | 2 MM PLY | LASER CUT | 2 | |

| BACK_PANEL | 2 MM PLY | LASER CUT | 1 | |

| TOP_PANEL | 2 MM PLY | LASER CUT | 1 | |

| BOTTOM_PANEL | 2 MM PLY | LASER CUT | 1 | |

| BUTTONS | SILICONE | CAST | 1 (3 BUTTONS) | |

| FEET | PLA | 3D PRINTED | 4 | |

| HEATING SYSTEM | 2 MM PLY | LASER CUT | 1 |

what tasks need to be completed? Key tasks list

- design and make casing and frame (laser cut) - tested with cardboard 25/5/18

- design and make buttons (Mould+cast OR 3DP in elastomer) - designed and tested with 3DP 25/5/18

- design and make PCB

- write embedded programme to control heating

- design and carry out programme of tests

- evaluate and redesign

what is the schedule? Planning and management

week 1 (starting 21/5/18):

- do plan - done

- task list - done

- order materials and items needed - done

- draft electronics schematic - done

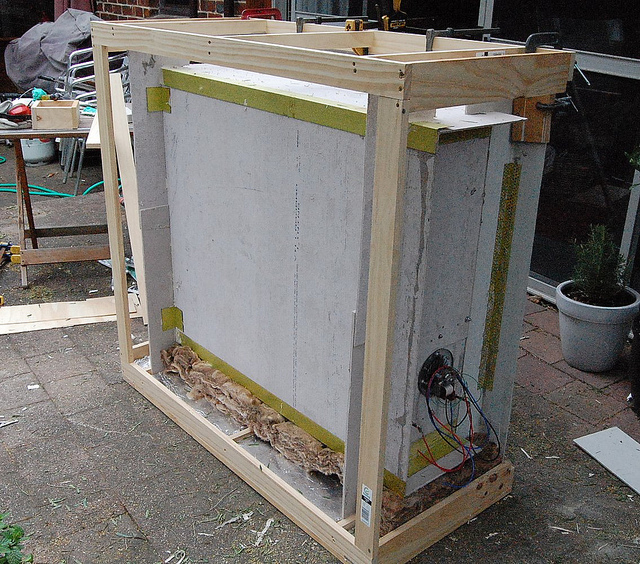

- create sketch models and reverse engineer existing oven - done

- document this phase - including material for final slide and video - done

week 2 (starting 28/5/18):

- design and make casing/subframe/buttons - done

- design and make PCB - done

- do basic heating tests to understand transient capabilities with oven's thermal mass - done

- programme board to control heat (locally and via programme)

- assemble and carry out basic structural and safety checks

- design testing programme and conduct tests

- initial product evaluation against specification

- document this phase - including material for final slide and video

FINAL WEEK (starting 4/6/18):

- make carbon fibre logo and other test parts using my oven

- redesign and improve capability

- compile video

- design final poster

- finish final slide and video

- tidy all documentation

- submit documentation

what questions need to be answered? Issues tracking

- electronics: what are the pullup-down resistors needed? calculate

- electronics: do I need a relay and/or transistor to control the heating element?

- electrical: how do I ensure this product is safe electrically?

- heating: how do I ensure this product is safe in terms of heating? for users, and all parts/electronics.

- heating: what are the losses in the system? how much power do I really need?

- heating: how best to orient/position the heater and fan inside the oven? above? below? behind?

How will it be evaluated? Critical review

- user testing with novice user to see if they can operate

- show product and documentation to current students and staff and get feedback on usefulness as an example for future projects

- compare against original specification...all items met?