3D scanning and printing

Task:

- test the design rules for your 3D printer(s) (group project)

Lukas Part:

All the following test are made with our Ultimaker 3D-Printer. In Our Lab we have got more than ten types of Ultimakers, some Ultimaker Go, some extended and one with a additional extruder. All of them are the second version and we upgraded them to "2+". That makes the maintenance quite more easy. So lets start with the first test

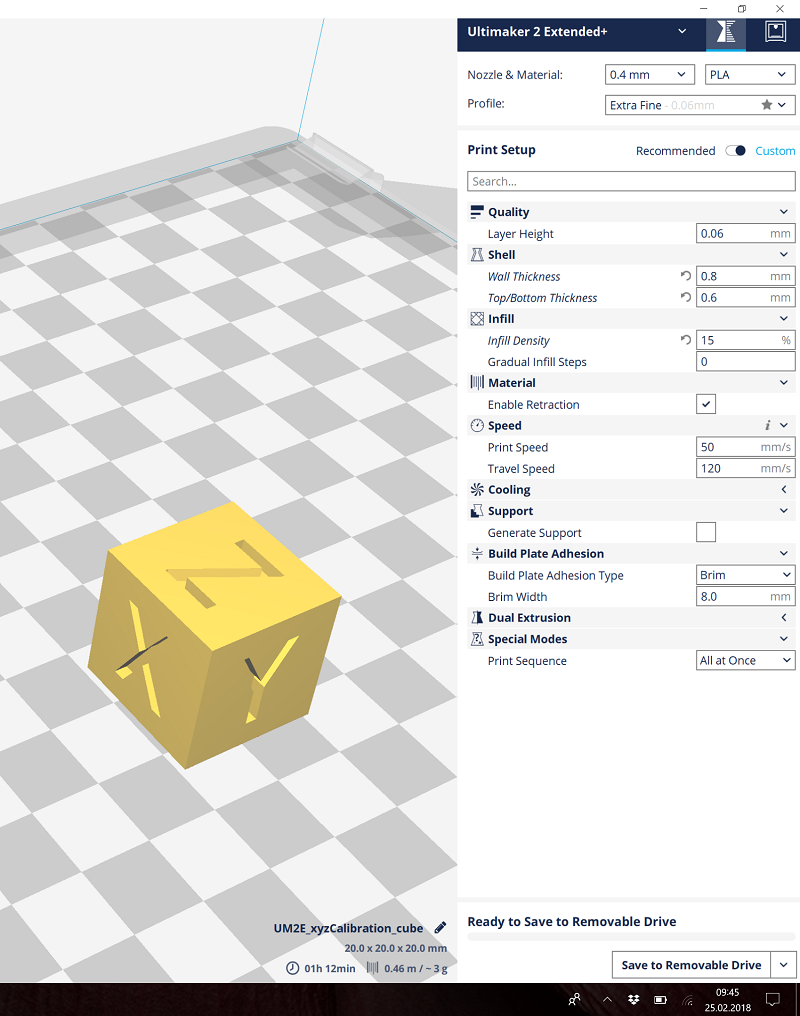

Printer setting

Before I started with my own test I startet a test print. This is useful to take a look at the calibration and if everything works well. I got this test-cube at Thingiverse, da huge platform with 3d dates. See in the pictures below the process of the printing and the final result.

As you see the result is with the chosen settings very good. The edge and the surface is plane and the letters are clearly readable. With a size of 19,9 x 19,9 x 20,1 mm it fits to the .stl data with 20mm. So let´s start with the real test.

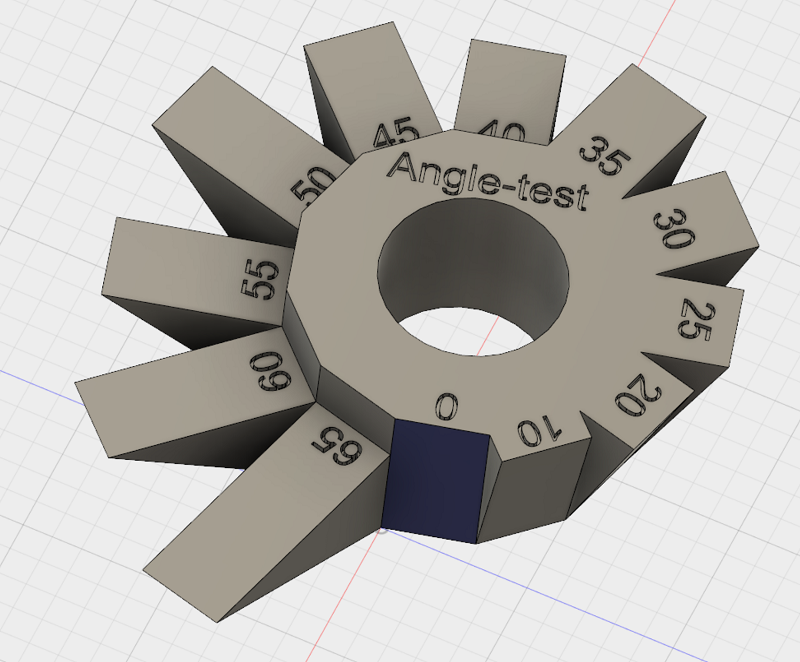

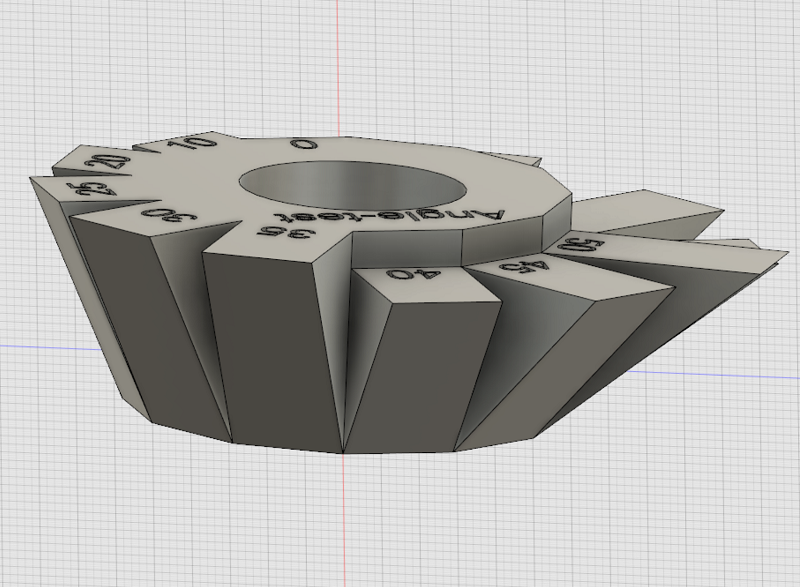

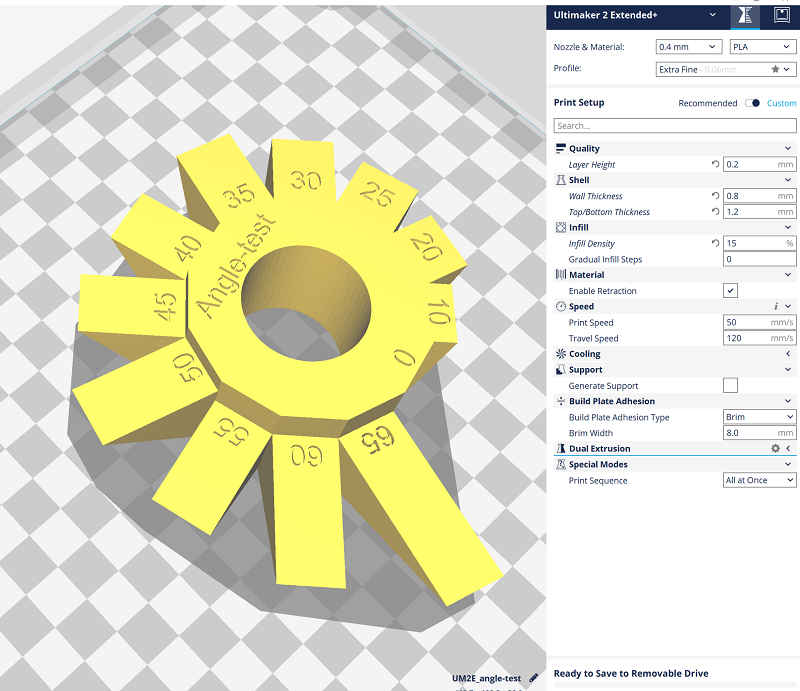

The FDM-technology has a problem with overhangs of objects. There is no natural support so if there is a to high angle of the overhang you need to generate a support structure you have to remove after the print. That decreases the surface quality. So I wanted to try how large the overhang angle can be to get a good quality. Therefore I designed the following angle-test with different overhang degrees from 0 to 65 degrees.

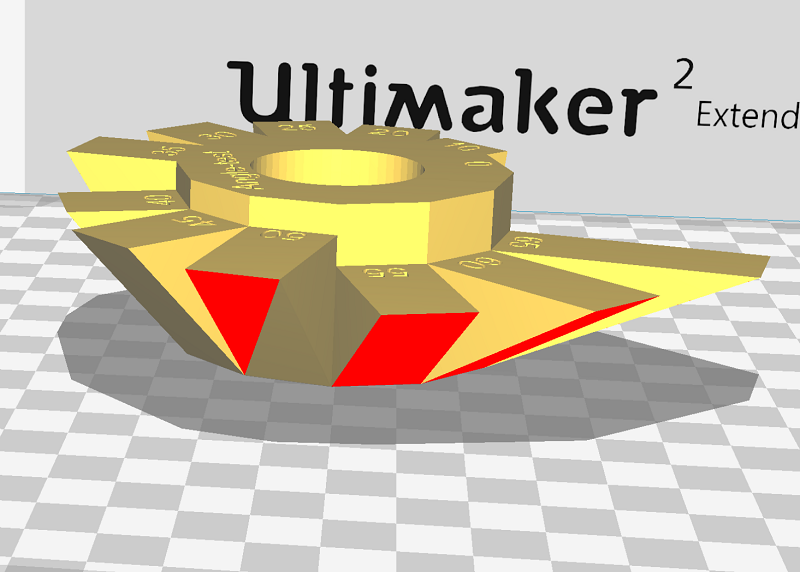

In the next step I used the ultimaker software cura to set the correct setting. See the setting below. Notice the missing point at “Generate Support”. As you see n the site-angle with more than 45 degrees cura notice a critical overhang and try to generate a support (red surface). But lets try it without the support.

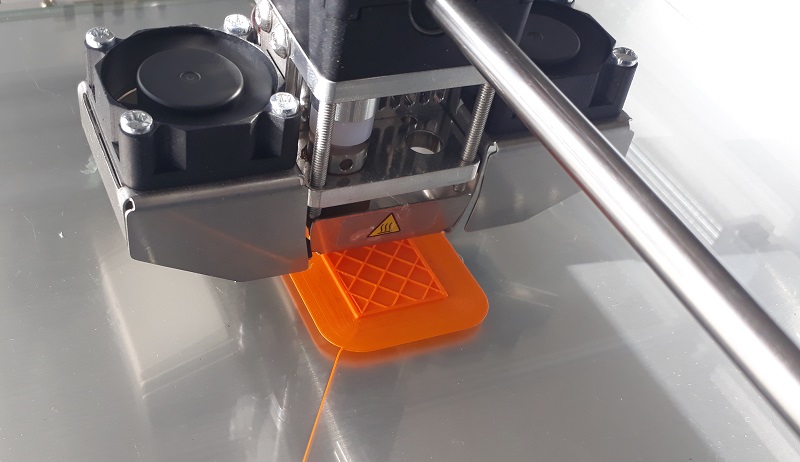

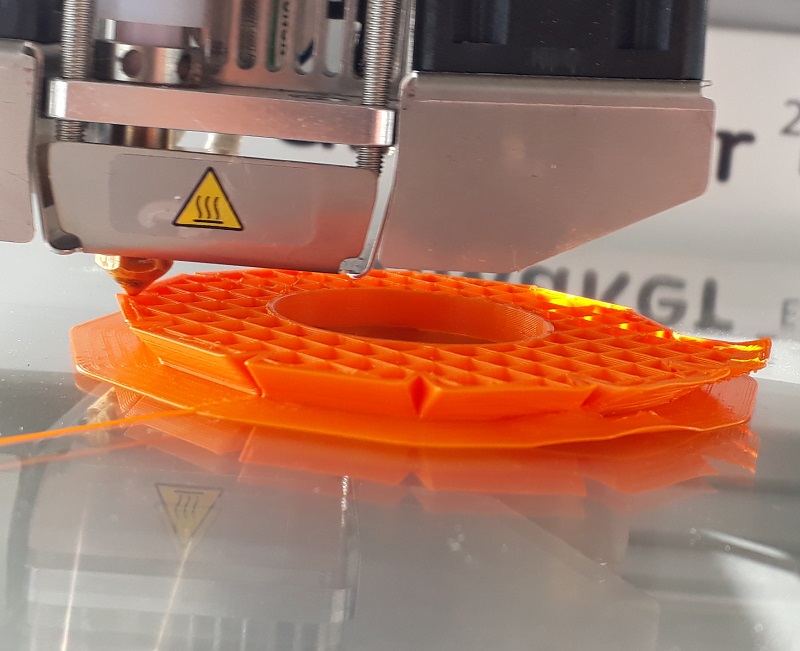

During the print I always take a look at the printer to abort the print if there is any critical point. As you see the end of the overhang with the higher angle doesn´t look stable but the material doesn’t fall down.

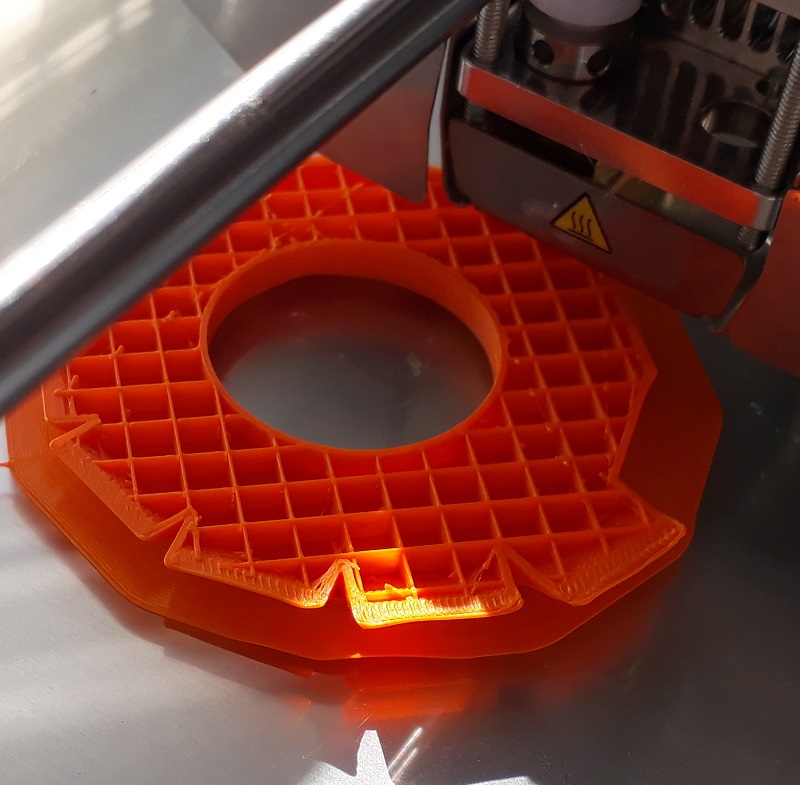

The print could finished without any problems so lets take a look at the result:

The test print looks quite good, all overhangs had been printed completely. So it is possible to print up to 65 degrees without support, but as you see in the second picture below, the quality of the surface decreases with any degree. Also the tip of the upsite isn´t really good quality. All in all I think with this setting is is possible to print overhangs with up to 65 degrees. At the end it depends on the needed surface quality if you need a support or not.

Downloads

| Angle-Tests(zip) | download |

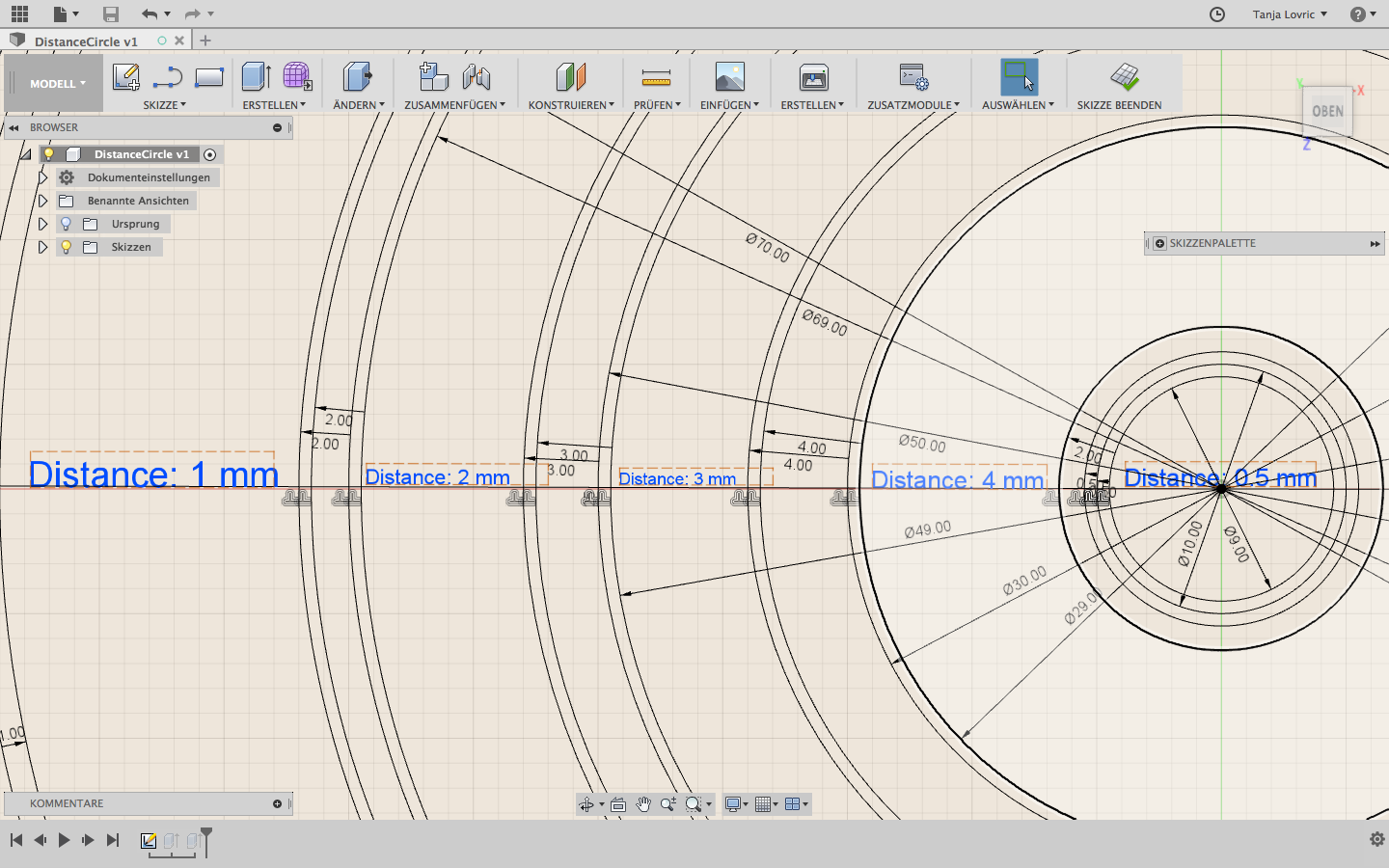

Tanjas Part: Distance Tests

First Test

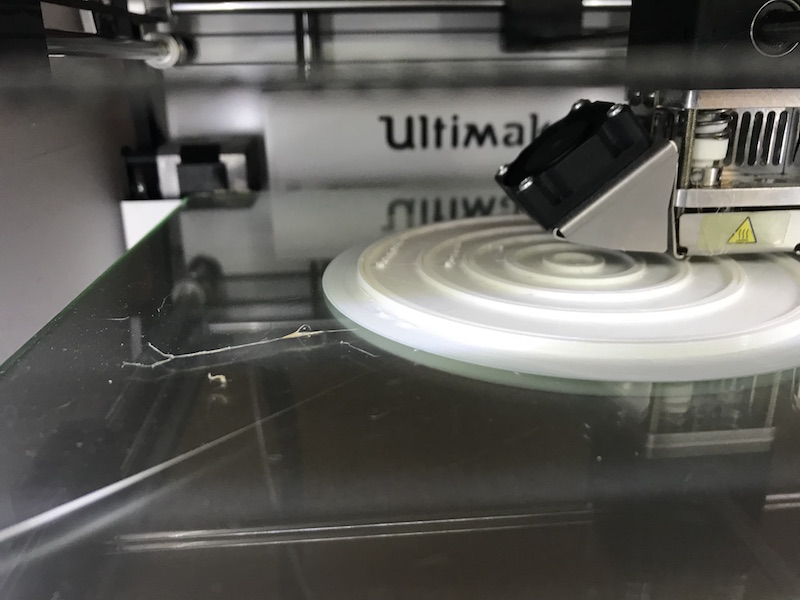

Part of my group task was to test the distances the printer can still make without the walls sticking together. For this I have created a 3D model in Fusion 360 and saved this in stl format. This was necessary to be able to open the drawing with the 3D-print program Cura. The following is the link to the manufacturer of the 3D printer and to the software Ultimaker and Download Cura for Ultimaker 3D Printer.I have shown the following distances between two circles:

0.2 / 0.3 / 0.4 / 0.5 /0.6 mm.

I also included the appropriate description on the surface as an extrusion of the text. Unfortunately, the text on the print has not been readable.

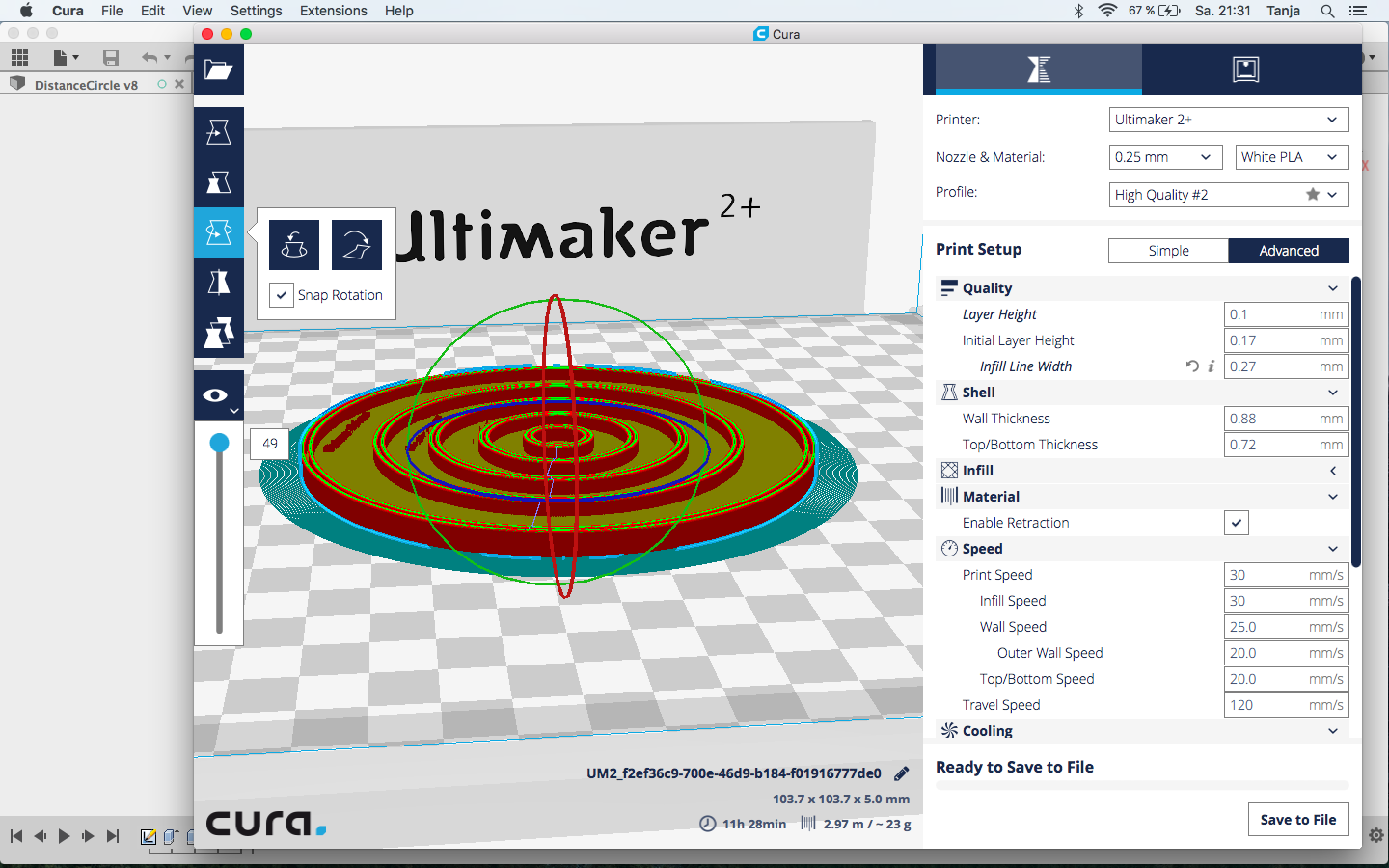

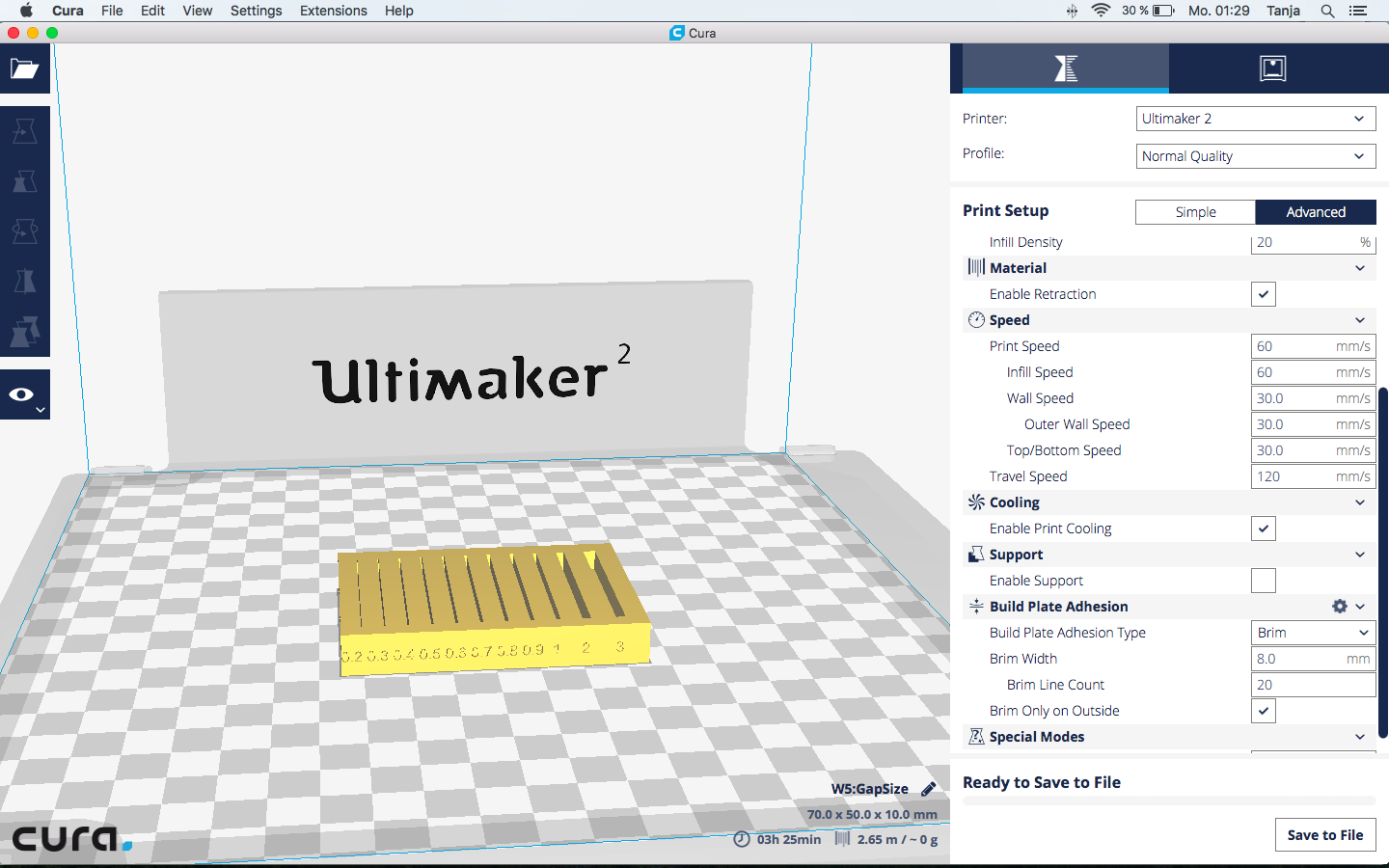

The following image shows the settings in the slicer software for printing. I had set a high print quality and accordingly the 3D printing had lasted about 6 hours. The layer height was set to 0.1 mm and the print speed to 30 mm / s. As a Build Plate Adhesion I had chosen "Brim" and for it a width of 8 mm. The brim had not been so important at this print but with taller, narrower bodies it is very important to adjust as otherwise the pressure in the middle or at the beginning could be moved through the nozzle and be torn away from the heating plate. I made this experience in another test print.

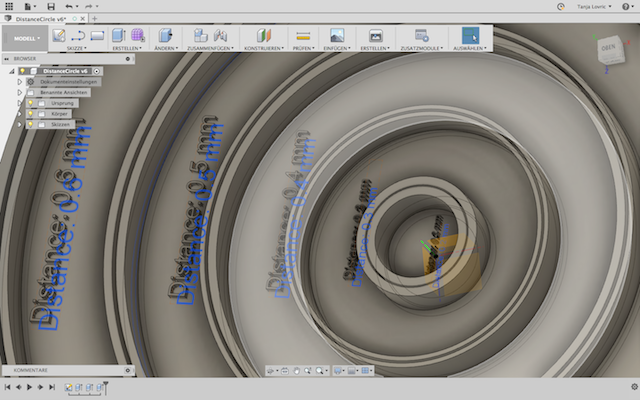

Second Test

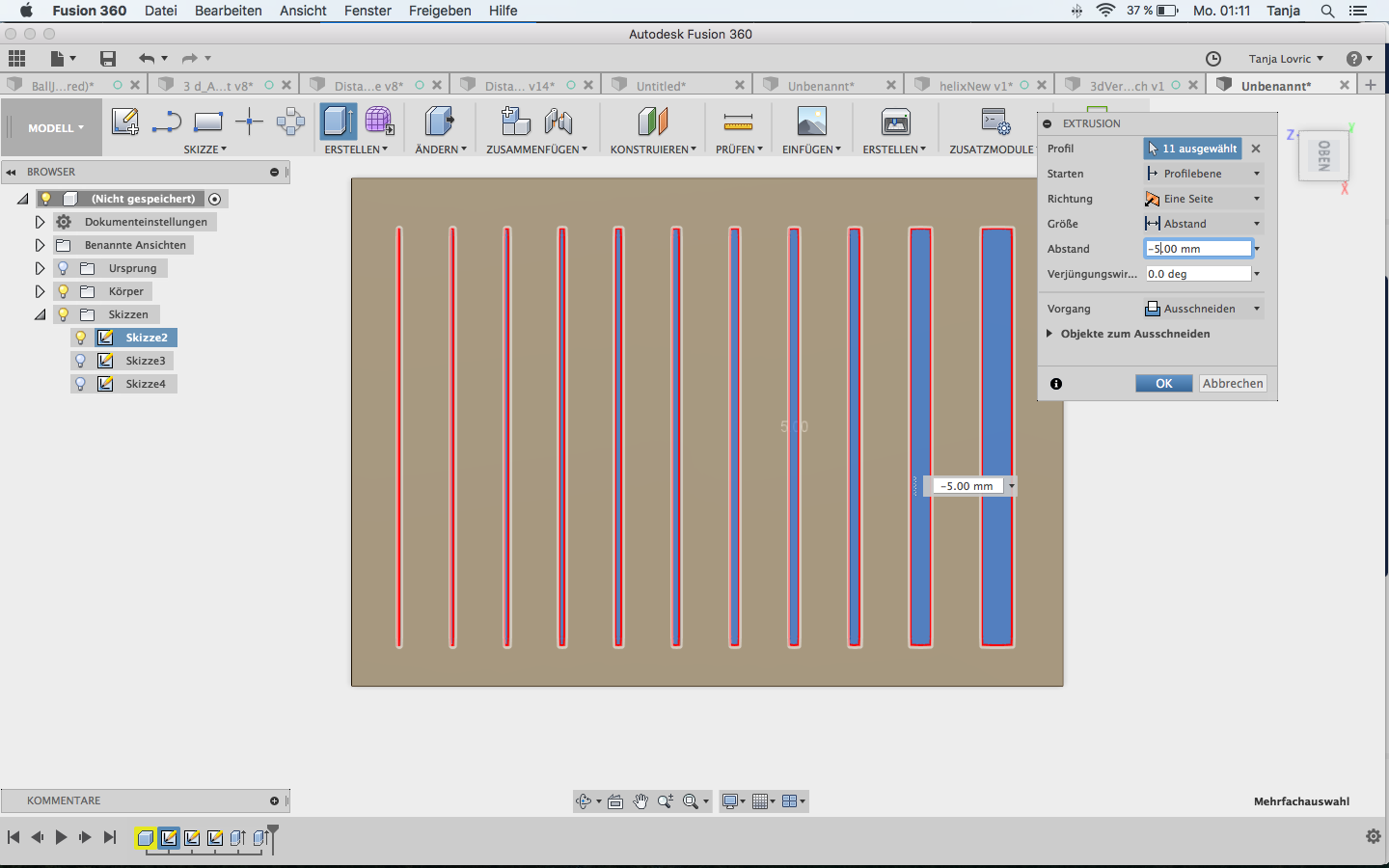

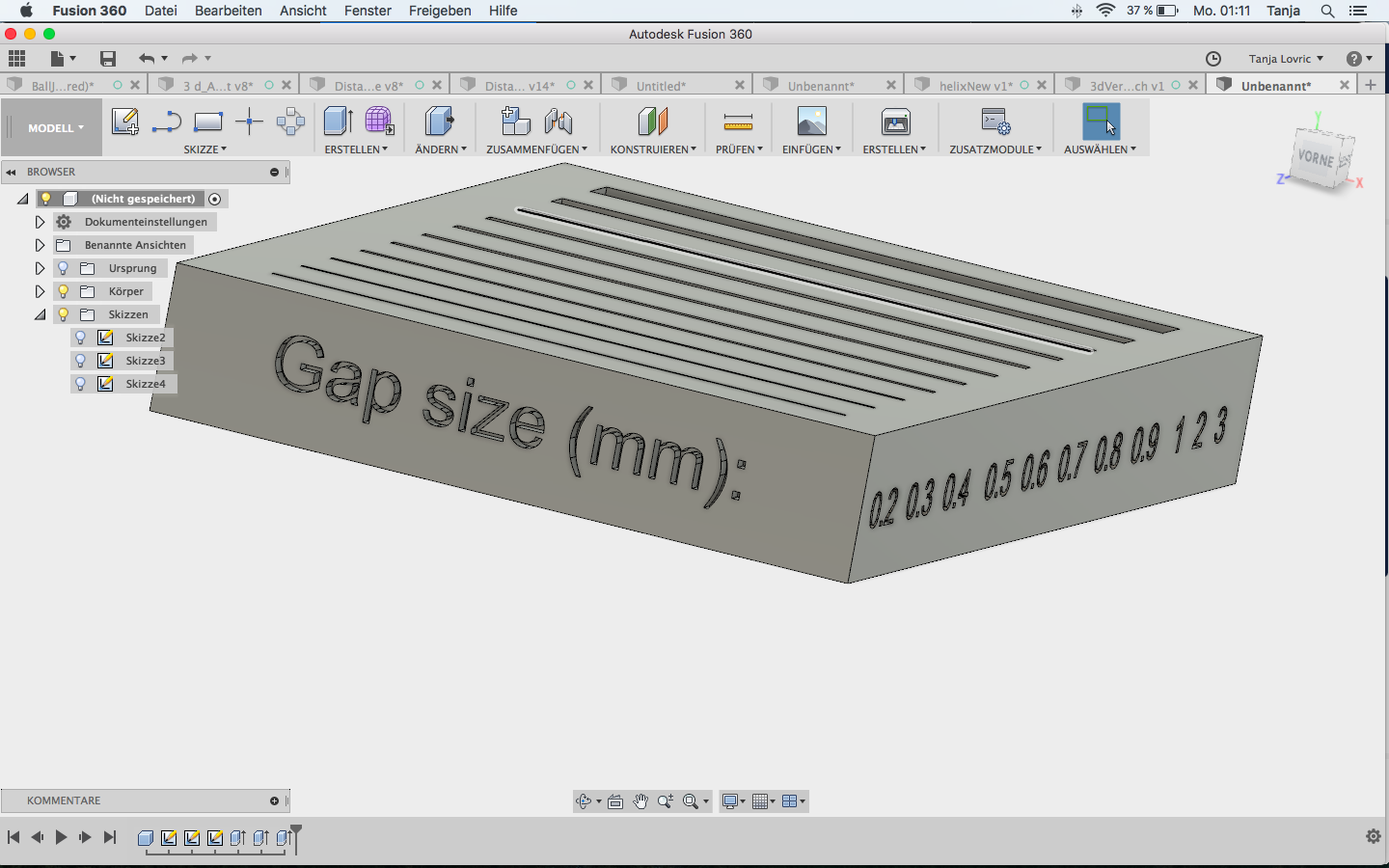

In this test, I had chosen similar settings, except that this time it was a text inserted into the body. The label I had chosen at desem tst as an extrusion inside and as a cut from the existing Köprer. As you can see in the following images this is much better than in the first test. Here I had chosen the single column in the following distances and at a distance of 5 mm from each other:0.2 / 0.3 / 0.4 / 0.5 / 0.6 / 0.7 / 0.8 / 0.9 / 1/ 2/ 3 mm.

This time I had chosen normal quality for printing. Layer Height was 0.1 mm and print speed 60 mm/s. The 3D print lasted 3 hours and 25 minutes.

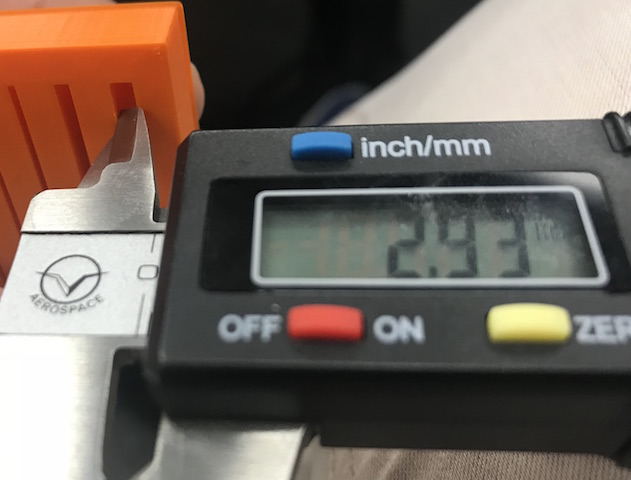

The deviation from the given measurement data (for 2 mm and 3 mm Gap) can be seen in the following images.

Downloads

| Circle Distance Test Circle (zip) | download |

| Gap Test (zip) | download |

Jimenas Part:

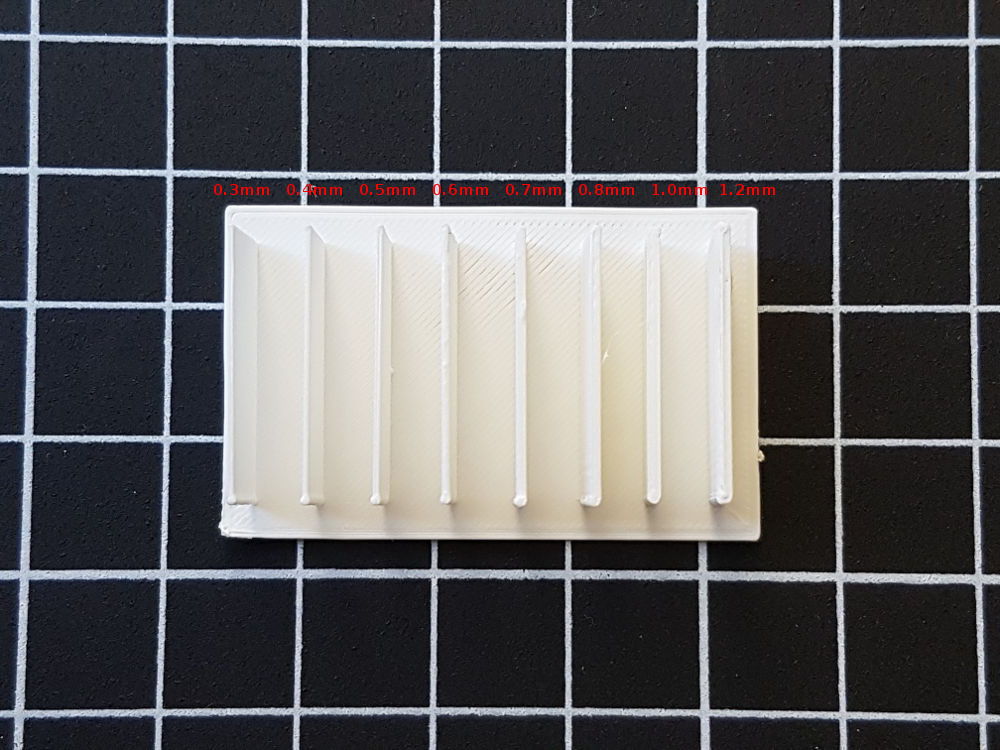

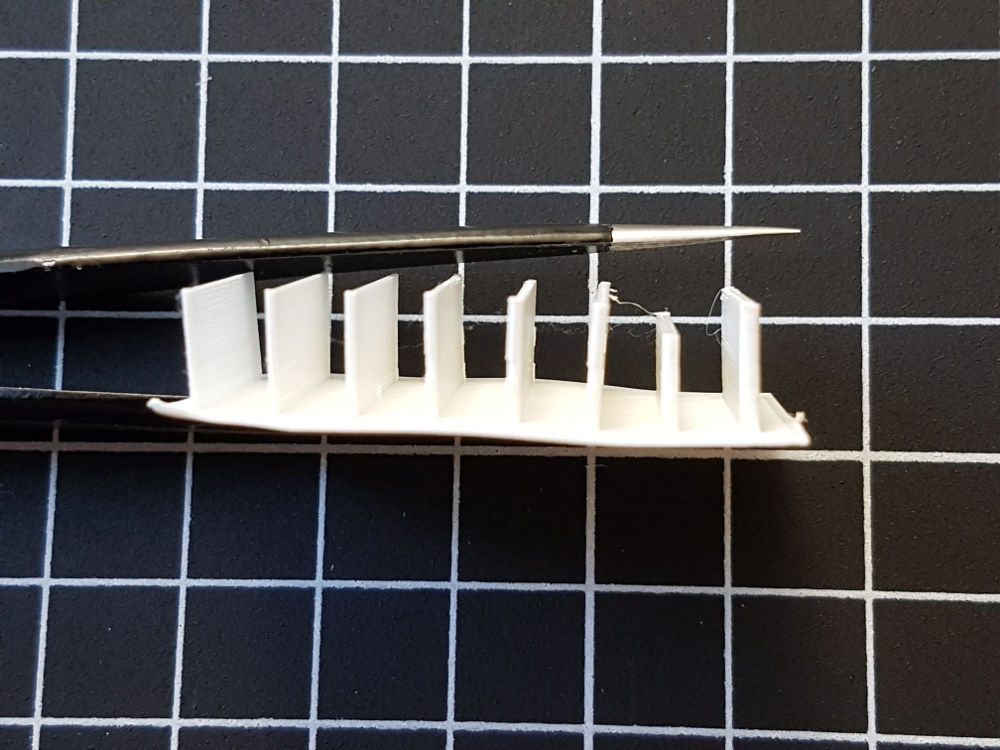

Printer tests: wall thickness

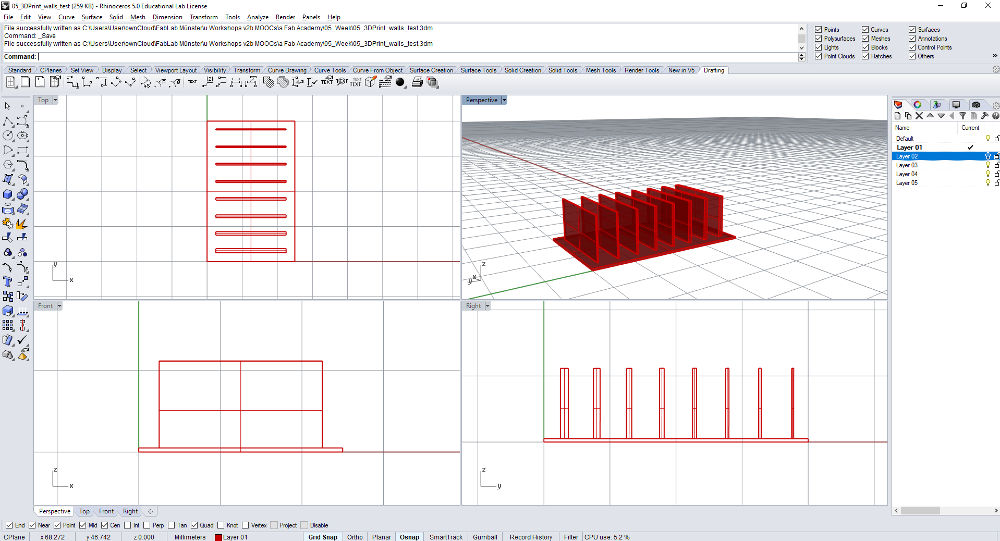

Rhino

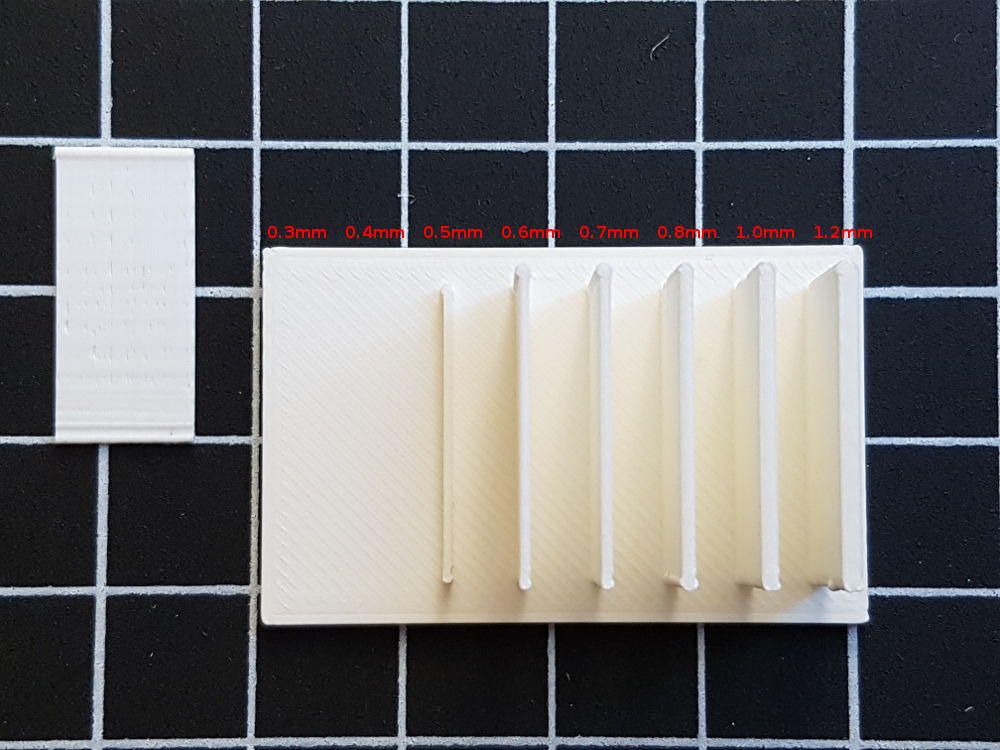

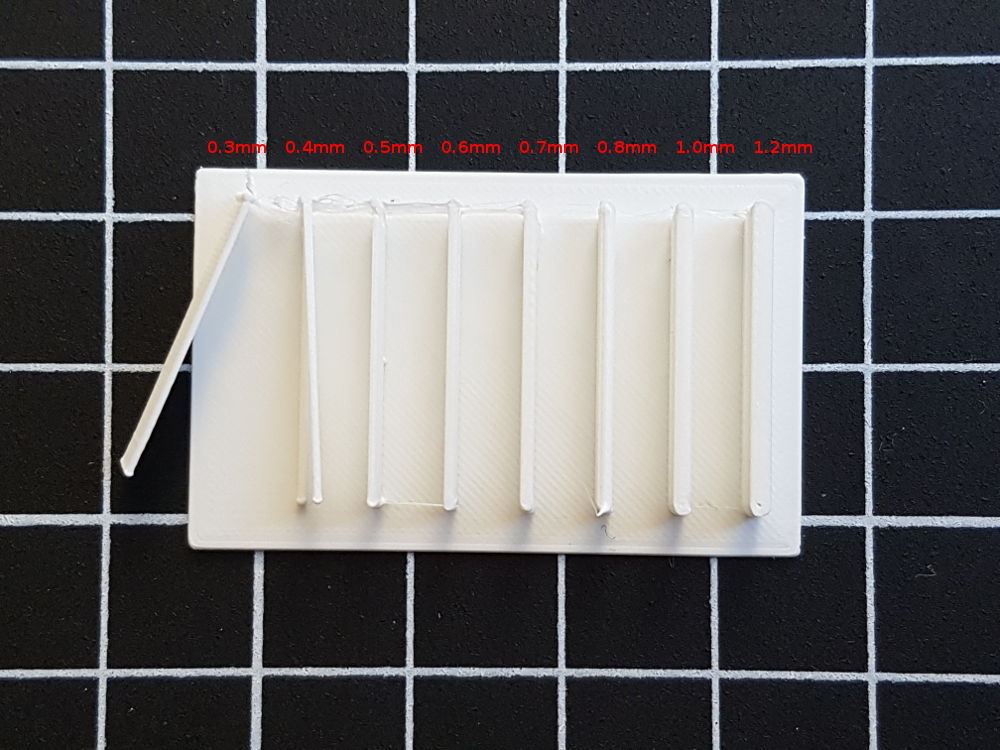

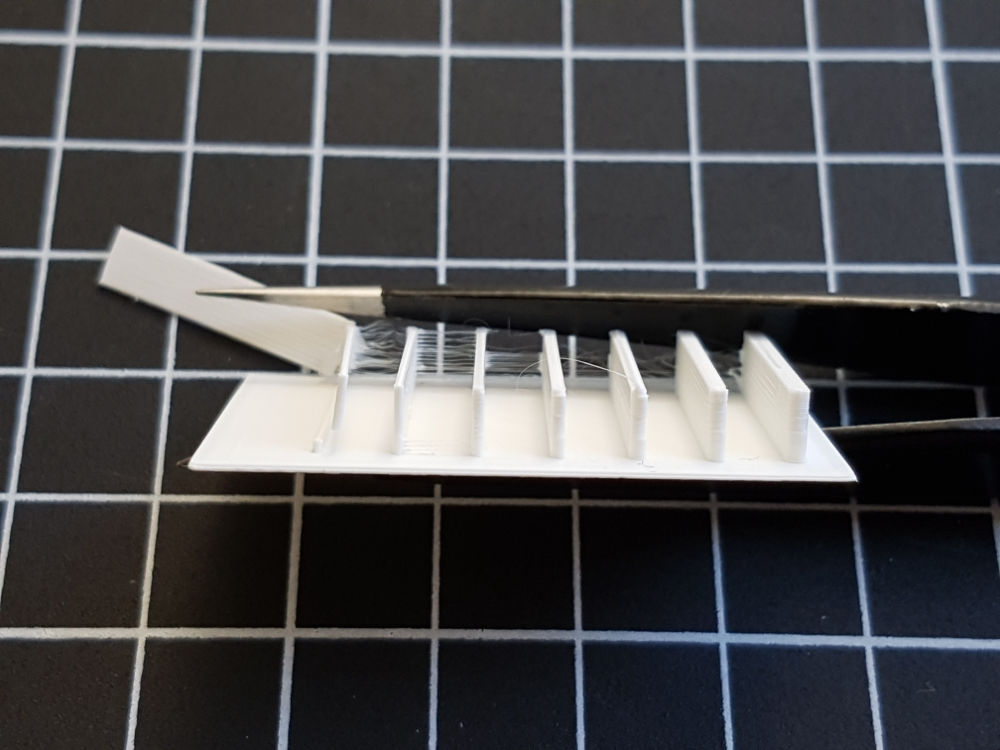

The wall thickness tests were printed with an Ultimaker 2+.

But first I created the 3D geometry in Rhino with the commands: Box (Solid), Boolean Union and then check if the volume has holes with

>Analyze >Mass Properties >Volume

If Rhino shows the volume in the command line, there are no errors (holes) in the geometry. Export the geometry as an STL file for Cura.

Description of the 3D geometry in mm

Base-plate with the size 25x40x1.5 mm

Thickness of the Walls: 0.3/0.4/0.5/0.6/0.7/0.8/1.0/1.2 mm

Height of the walls. 10 mm

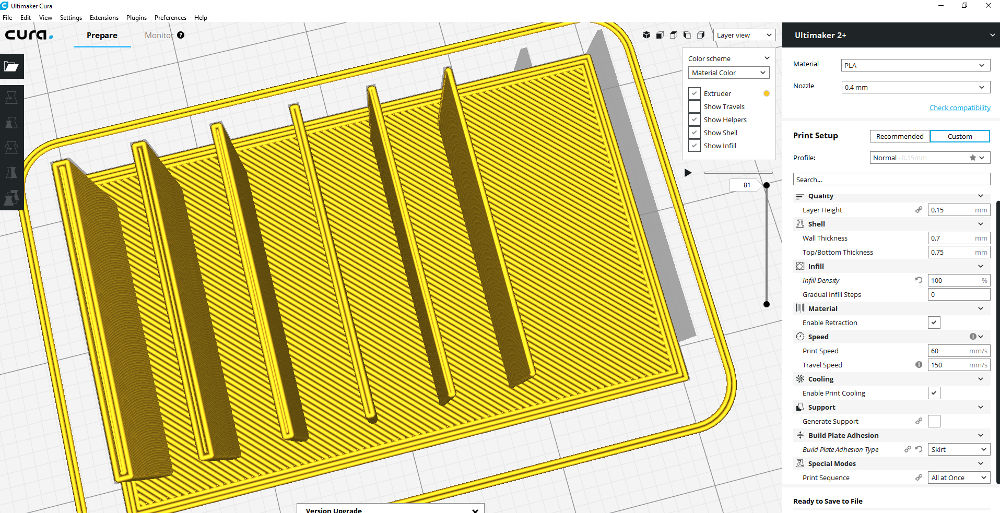

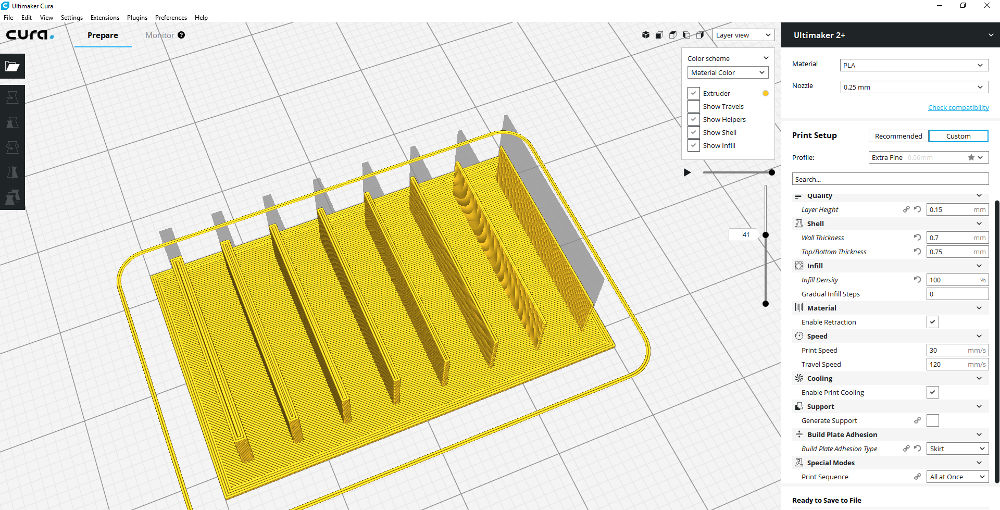

Cura

Cura is a 3D printer slicing application. You can use this software with many 3D printers.

In Cura, you open the STL file and check the Print Setup. For the first print test I chose the layer view, standard nozzle 0.40mm and the Profile Normal 0.15mm.

You can see that Cura doesn’t “print” the thin walls (0.3 and 0.4)and won’t export them as a GCode file. .

For the second print I chose the smallest nozzle 0.25mm. Cura doesn’t have a problem with the wall thickness and “print” all the walls.

I exported both Print Setups as GCode files and saved them in a SD card.

Recommendation: the wall thickness should be a multiple of the nozzle diameter. The most common nozzle diameter is 0.4mm. The recommended wall thickness is 0.8mm.

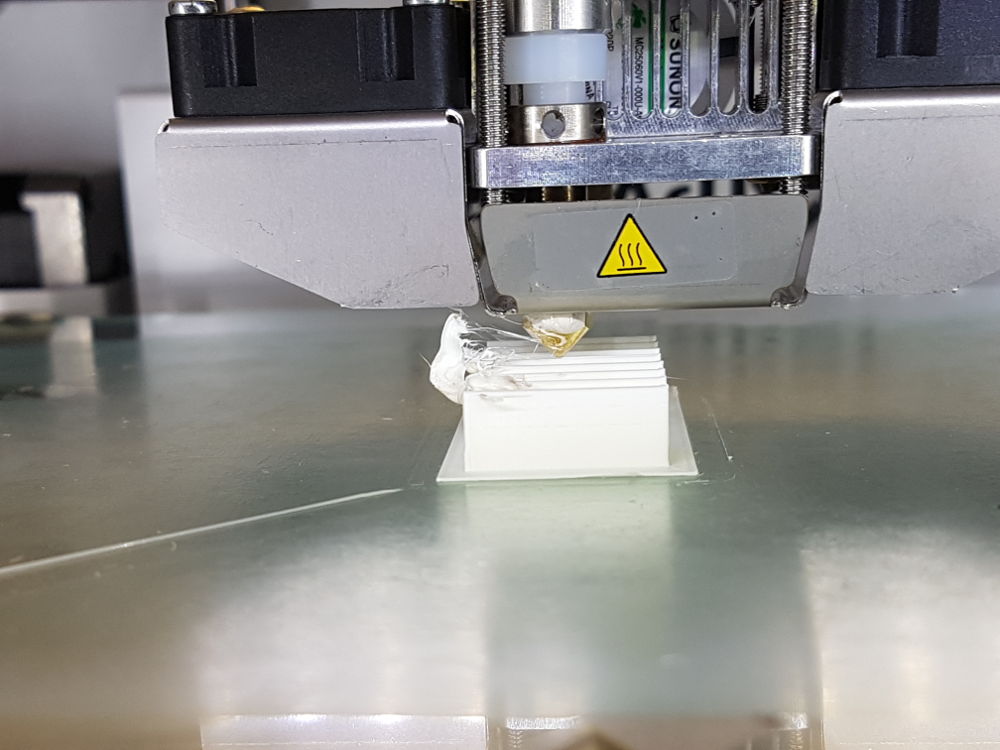

Start printing

Preparing the Build-Plate:

I put a thin layer of glue stick on the Build Plate of glass. This will keep the print in place and allows to remove it easily. As next step I put the build-plate back to the Ultimaker and did the maintenance steps shown in the display to re-level it.

Start:

You have to insert the SD card and select the print. The printer has to preheat for a few minutes till it starts printing….

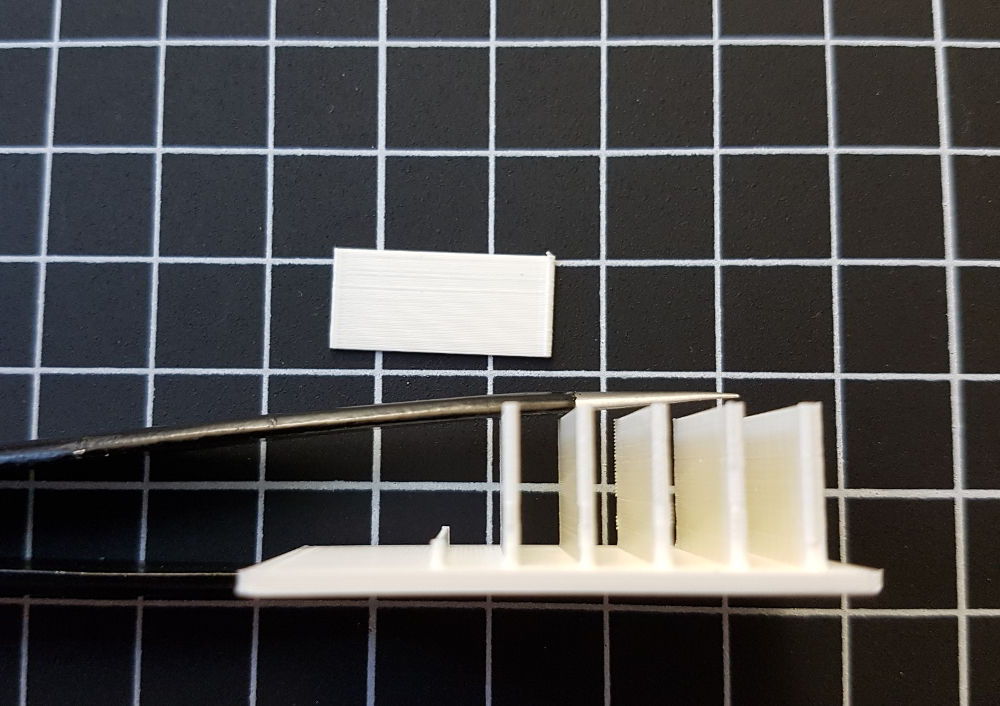

For the second print with the nozzle 0.25 the layer didn’t stick on the glass plate. My instructor explained me, that there wasn’t enough space between the nozzle and the glass plate. I could change this easily without stopping the print with the level screws under the build-plate.

Note: Check if the first layer sticks on the build-plate. If not, perhaps you have to level the plate with the screws on the front.

Remove the piece:

You have to wait until the plate has to cooled down to remove the print. Perhaps you have to remove the glass plate from the printer.

Tests for the wall thickness | Conclusion

With a 0.40 nozzle you can’t print walls with a thickness smaller than the nozzle diameter. Cura will not recognize and export them as GCode. These walls break easily because they only have one or two layers of material.

(The 0.5 mm wall printed with the 0.4 nozzle broke easily.)

Another observation is that the test with the 0.25 nozzle was not stable.

Recommendation: the wall thickness should be a multiple of the nozzle diameter. The most common nozzle diameter is 0.4mm. The recommended wall thickness is 0.8mm

Downloads

| Wall Thickness Test (zip) | Download |

Peters Part:

Thread test

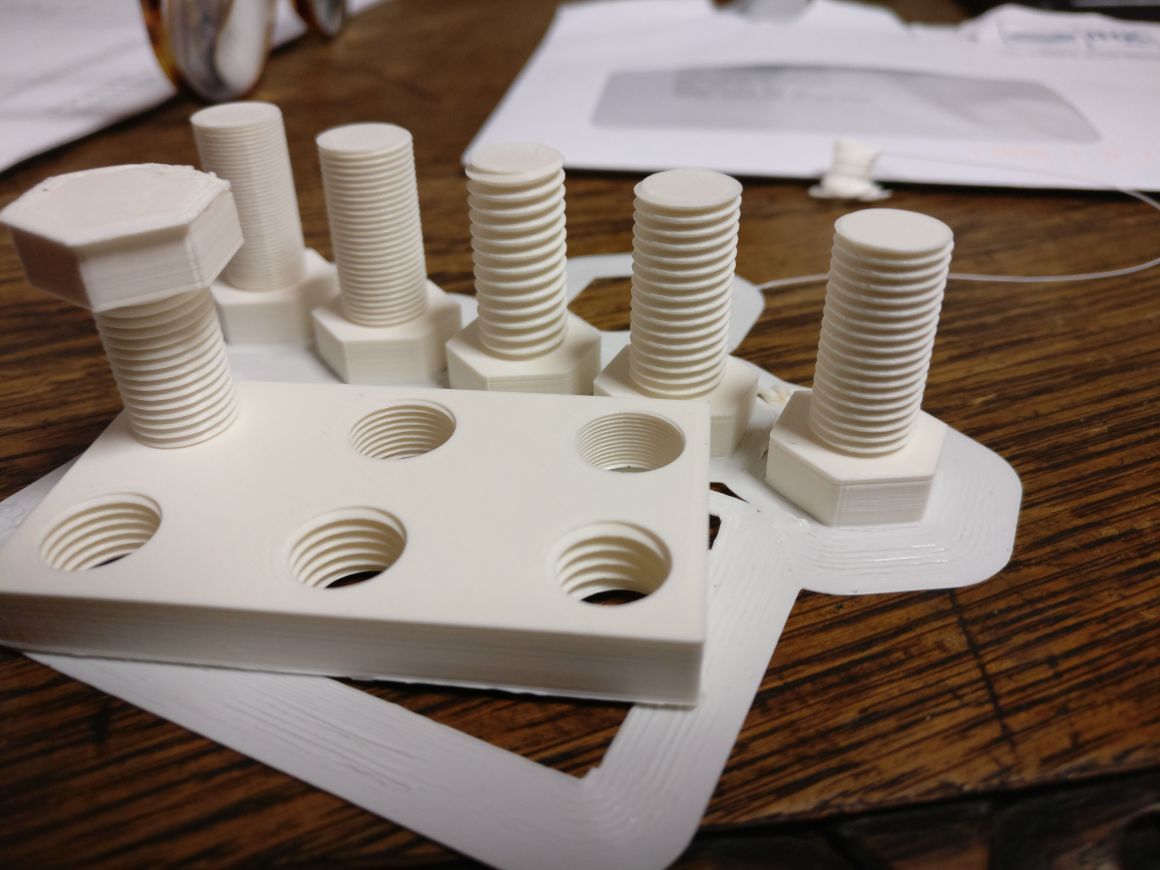

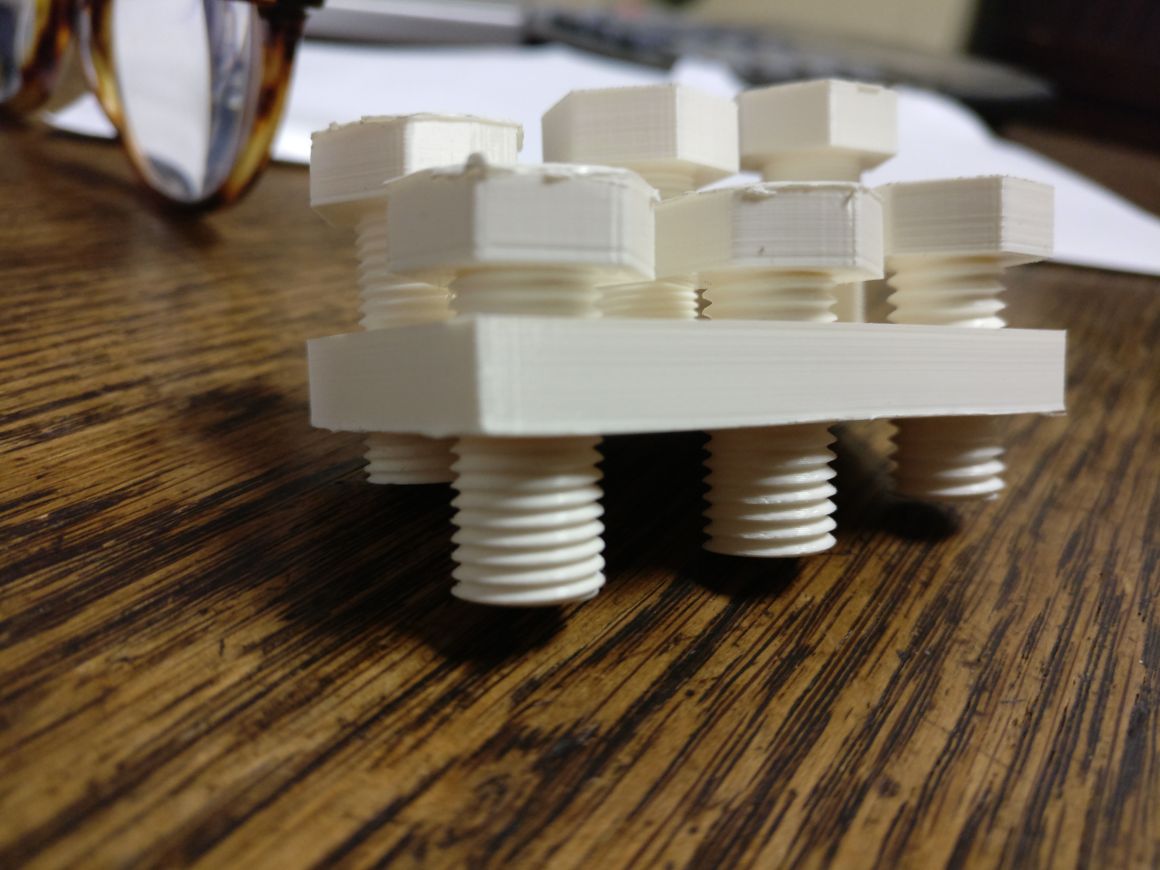

I printed as a test ISO thread.

And wanted to test up to which slope you can print.

My test setup consisted of a plate with the common 6 ISO gradients all threads are M10.

And the matching 6 screws.

🖐drag and move🖐

The finished test.

The process of creating:

The head of the screw.

Extrude the screw.

Make thread on the screws.

Draw base plate.

finished test.

In order to have everything in a stl file, I combined all the bodies into one component with the Combine Tool.

The printed result surprised me a lot.

ISO threads are described by two values once by the diameter of this is given with M and the pitch this is written behind it (M10x1.5) that means that the tool has a diameter of 10mm and with one turn the screw move 1.5mm into the thread.

In the test I tested the following thread pitches:

1) M10x1.5

2) M10x1.25

3) M10x1.12

4) M10x1.1

5) M10x0.75

6) M10x0.5

These are the common ISO pitches.

The result i could turn all 6 screws in.

All the screws were easy to turn in, only the last one was a bit heavy.

Downloads

| Thread test(zip) | Download |

Christoph's Part:

I did this assignment with Daniel and Chrii, which helped a lot since both of them have more than enough experience with 4D printing.

To get a feel for the process and what the quality settings can do (and, even more important, can not do) I started off by printing angels - A nice 3D scan I had found on thingiverse some time ago. It doesn't seem to be optimized for printing in any way, and with its complex form with lots of different overhangs should show any problem zones nicely. Also, it looks cool.

What Cura's settings do

A first impression of the printer's abilities was gained from the results of printing the angels:

Those are, from left to right (click the images for larger ones):

The "Normal Print" setting actually does just that - a pretty OK result. There are some problems with the sharp edge of the angel's skirt (bottom center part of the image) as the overhang got pulled up, but the overall impression of the print is good and there are no eye-stabbing faults. The model surface looks smooth, but you see the layers in some areas. It took roughly 11 hours to print.

The "Quick Print" setting is a lot quicker than the normal one, mainly by doing thicker layers and less infill. Surface finish is rough with visible layering everywhere, especially at smaller structures like the feet. On the other hand, this setting got the edge of the angel's skirt right. It took roughly 6 hours to print.

The "Ulti Quality" setting does very fine layers and gets a great surface finish with almost no visible layering in most places. It really f***s up overhangs, though - they will either be pulled up (like the edge of the skirt, which was worst in this setting) or get a sawtooth pattern. Also, it takes ages to print - roughly 28 hours.

My own "Some quality, but somewhat quicker" settings gave a result comparable to the Normal Print, and took only marginally less time to print - roughly 10 hours. The edge of the skirt and the feathers at the back are marginally worse than the Standard Print.

That one was funny, as all three of us were more or less convinced that it could only go horribly wrong. It didn't, and it turned out OK for a quick test print. It has a few small holes in places where there was nothing to print on, like between the feet. A lot of overhangs have just dropped (like parts of the hair and almost all of the feathers), but the model is there and good enough to get an impression of its form. Surface finish is not a thing to talk about as it's gone missing, on the other hand the print took less than three hours.

That one was funny, as all three of us were more or less convinced that it could only go horribly wrong. It didn't, and it turned out OK for a quick test print. It has a few small holes in places where there was nothing to print on, like between the feet. A lot of overhangs have just dropped (like parts of the hair and almost all of the feathers), but the model is there and good enough to get an impression of its form. Surface finish is not a thing to talk about as it's gone missing, on the other hand the print took less than three hours.

Test Parts

As a group, we had to agree on some standard test part to get comparable results. After a bit of looking around we found a ready made one on thingiverse that had all the features we wanted to test, so we didn't invest time to reinvent the wheel. There is one aspect missing in it, as there is no sharp edge to test how far the printer can do a (stable) result. A test set in that problem could be done in the future, but given the results we had when printing our impossible-to-do-subtracitvely parts those sharp edges seem to be more of a problem of getting the print settings right than a general problem.

I'm quite sure Daniel (see below) will do an in-depth analysis of them including all the ones I did not do, so I will only collect here what I pulled from printing them and watching others being printed:

- The combination of an Ultimaker and Cura can do incredibly smooth surfaces - If, and only if the object is not too small, solid and you have time to spare.

- Cura sucks at doing bridges, as it doesn't treat them special. Skeinforge and even Slic3r do a lot better at that if configured correctly.

- Small, overhanging structures are prone to "stand up" to near vertical. The tilted blocks in the test part ended up being at almost the same angle in some prints, leading to the conclusion that roughly 20° from vertical is the limit for such structures. I think the origin of this problem is rather generic and not printer specific, it is less pronounced when printing slow so layers can cool down, though.

- Large overhanging structures like the bottom side of a sphere are less problematic, most of the time they "just work" as there is enough material to keep them in shape. Other structures will start to look bad at something like 35° from vertical (as seen with some of the angels and the domes), but they will print and stay roughly in shape. Also, thicker bridges seem to be fine, even spanning 25mm without much breakup. Again, their bottom side will not look good...

- Cura sucks at generating support structures. While they do support the printed part, they end up hard to remove. Skeinforge can do that way better, if set up correctly.

- Small vertical structures are problematic as they tend to deform when the next layer is applied to them. A 2x1mm "tower" will not work (at least not with Cura), while a bunch of 3mm round struts do work flawlessly at slow speeds when printing my domes.

Daniels Part:

Overhang / Resolution test

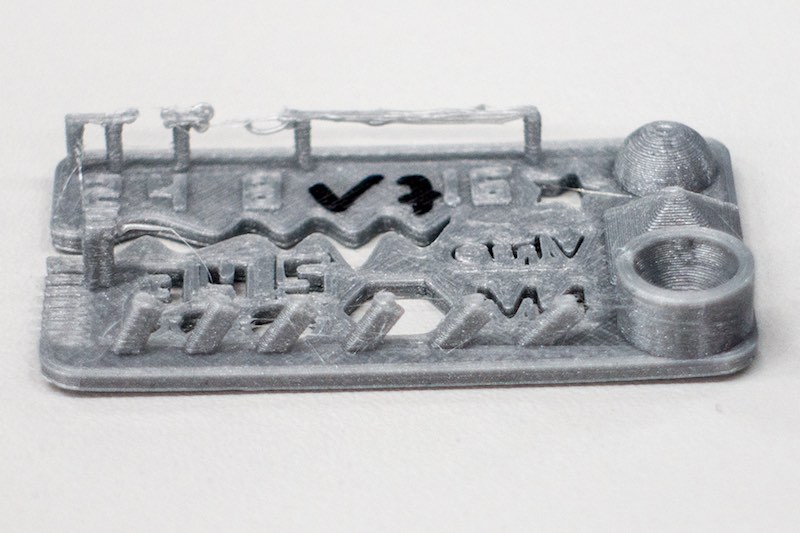

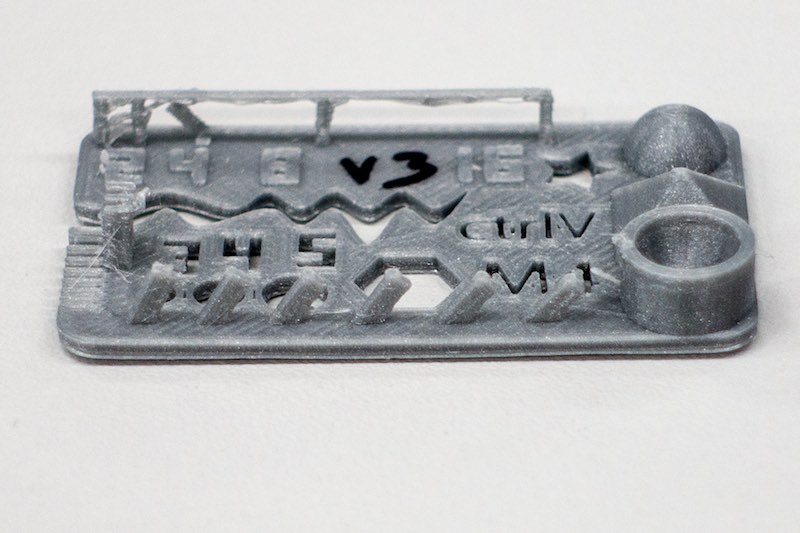

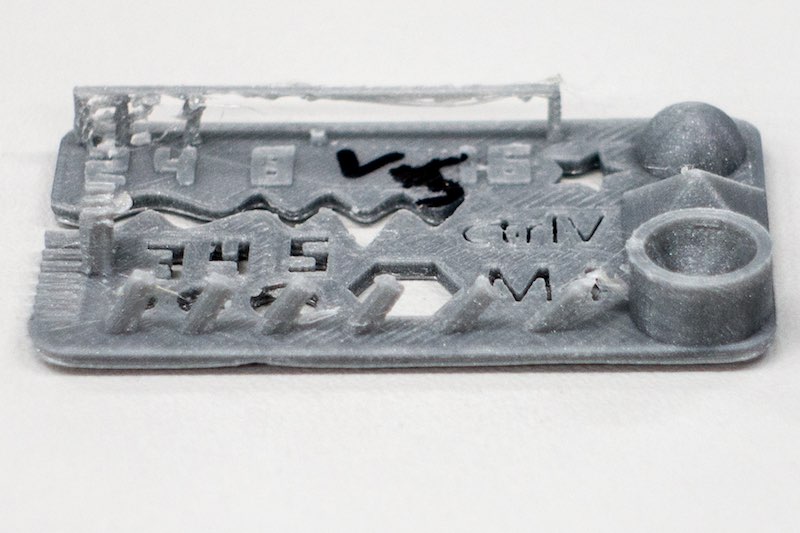

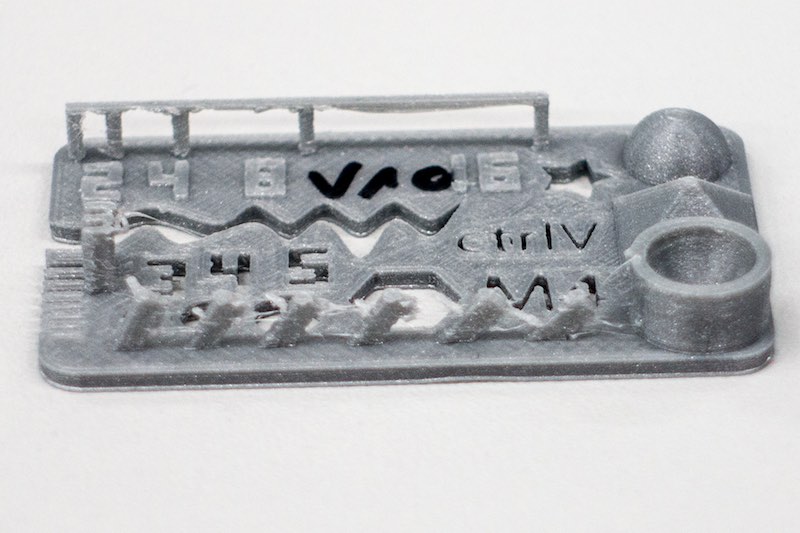

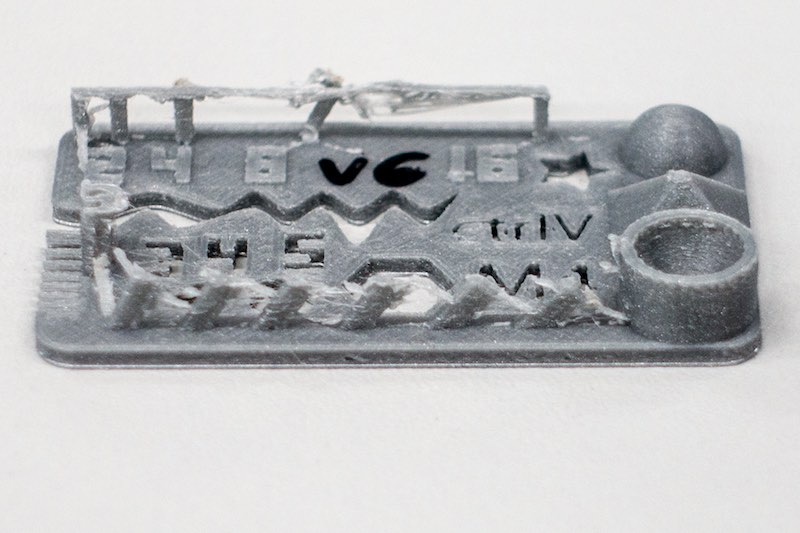

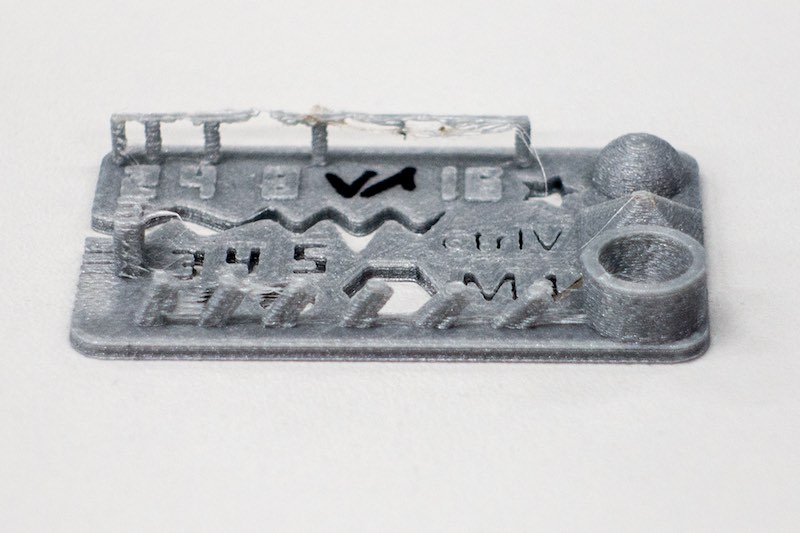

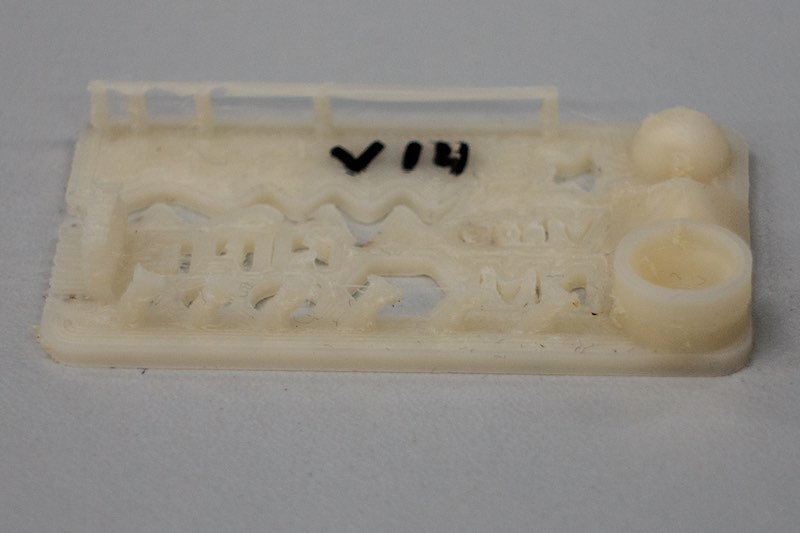

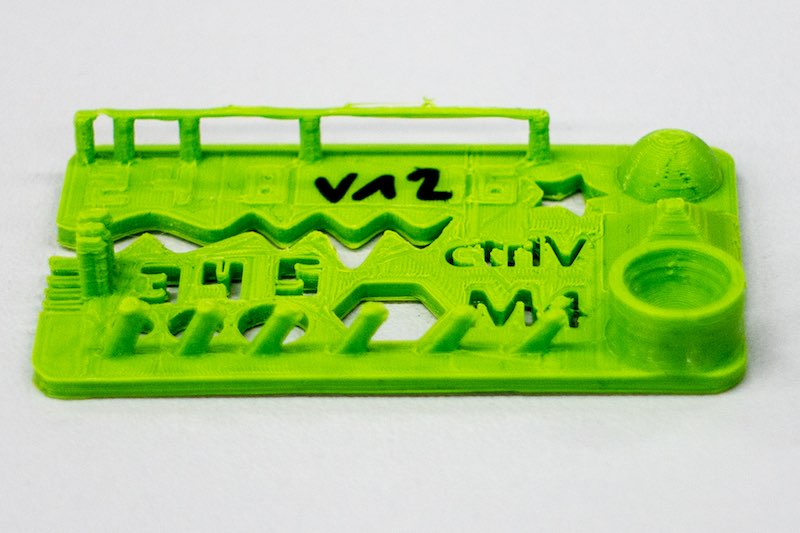

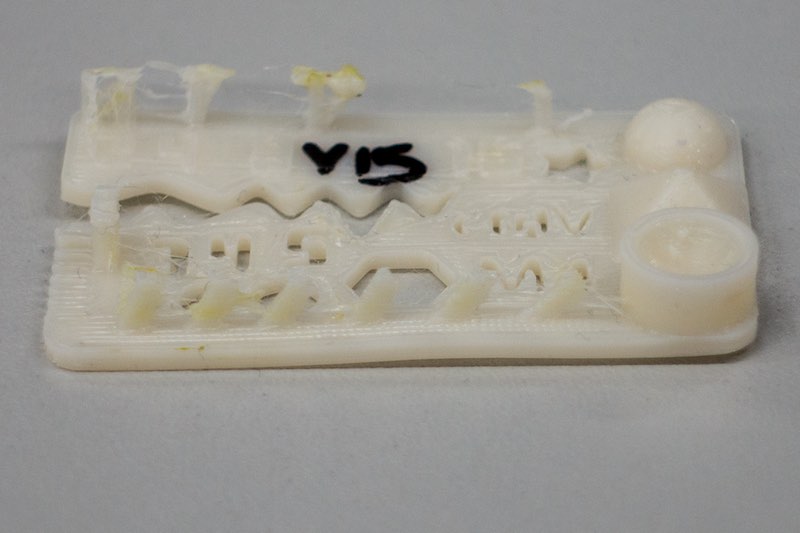

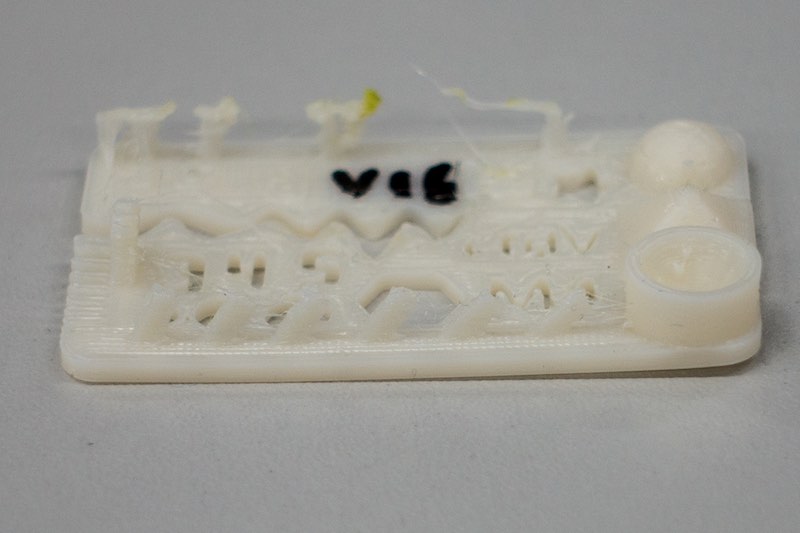

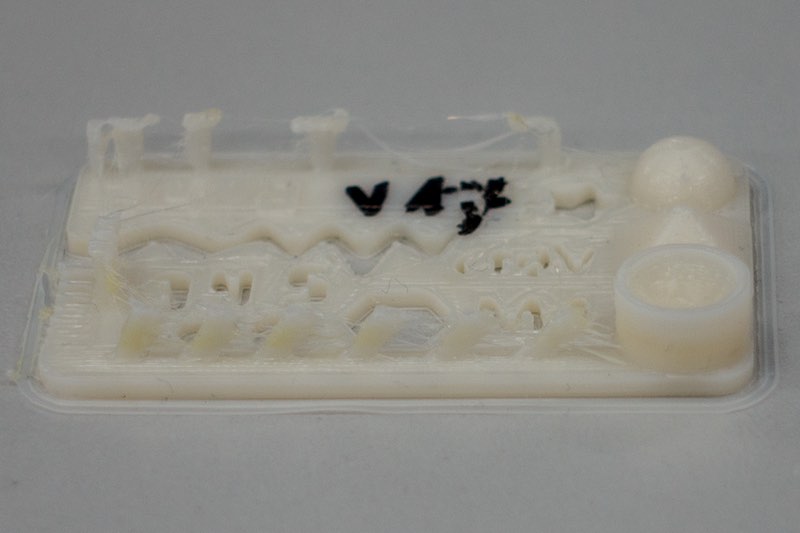

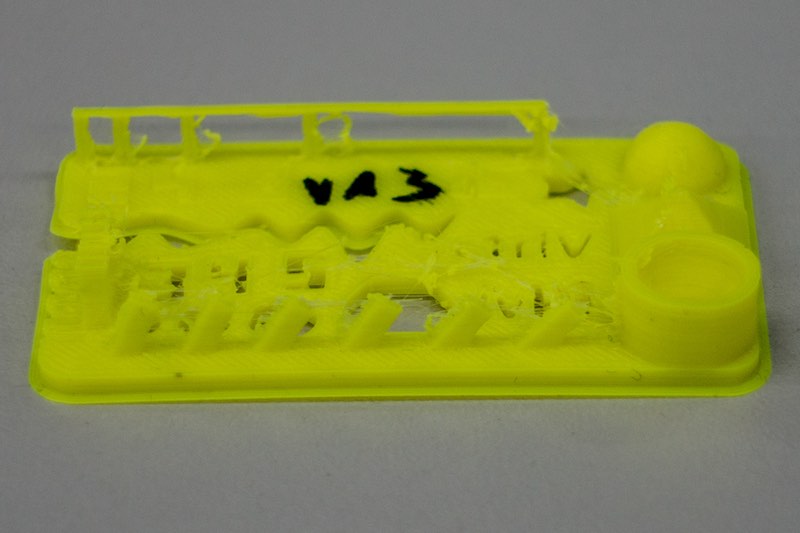

To do a proper overhang / resolution test, I've found a very nice part, some years ago.

It's called Test your 3D printer! v2 and combines a lot of different tests, without wasting too much material.

The finished testparts.

In this test, several printers were used to test all possible options:

Ultimaker 2 Go

Ultimaker 2

Ultimaker 2 extended

Orca v0.40 (after the last owner sold his company, there is no infomation or reference left)

Orca XXL

Beiwagerl

Ultimaker 2 Go, PLA, Cura, fast setting, cooling on, 20 minutes

The resolution (even in x and y direction) is bad, there is a lot of space between perimeter and infill at the numbers. The long bridge is ok, the shorter not. This might be result out of the fast movement. The overhang is nearly perfect. The minimum distance walls on the left side failed. only 2 of 7 were printed! This setting is only useful for rough, fast prints.

Ultimaker 2 Go, PLA, Cura, normal setting, cooling on, 51 minutes

This is one of our most interesting test prints. You'll see a lot of oozing - this is the only print where this printer had this failure. The resolution is a bit better, but not that good. I would not count this try.

Ultimaker 2 Go, PLA, Cura, high setting, cooling on, 1h22

This result is much better than the results above. All bridges were printed correctly and really flat. The over all resolution is much better. This setting might be a good mixture of print time and quality.

Ultimaker 2 Go, PLA, Cura, ulti setting, cooling on, 2h01

This setting is not worth the extra time, you only gain 0.02mm extra resolution. Yes, it looks a bit better than the high setting, but it costs a lot more time.

Ultimaker 2 Go Conclusion:

If you don't need a heated bed for Nylon, ABS or whatever and your parts don't exceed 120x120x115mm, use this machine. It is fairly fast but does not reach the 300mm/s under real world conditions. Above 100mm/s the print with PLA is sloppy. Due to the fact that PLA has an other melting type than for example ABS or Nylon, we should try this also.

The Freakshow: Ultimaker 2 Go mod., PLA, 0.25 Nozzle, 1.75mm filament, high setting, cooling on, 50min

During our tests, I modified our second Ultimaker 2 Go from 2.85mm to 1.75mm and changed the normal hotend and nozzle to a olsson block.

I had to change the filament diameter in the extended settings in Cura and in the printer itself. Without any correction at the flow setting or something else, I printed a testpart.

It looks nice, all the edges are sharp due to the smaller nozzle. I should adjust and tweak the line width more and with more time, due to the fact that there are gaps between the perimeter and infill. This is on my to-do list. The 1.75mm version does not require that much force to print due to the smaller filament diameter. This might increase the bowden extruders reliability. It was just a small test beside our assignment. :)

Ultimaker 2, PLA, 230°C, Cura, fast setting, cooling on, 18 minutes

The normal Ultimaker with heated bed is not better in the fast setting than his smaller brother. The result looks like the 2 Go version of this print.

Ultimaker 2, PLA, 230°C, Cura, normal setting, cooling on, 48 minutes

In this setting, the normal Ultimaker 2 printed a lot better, there is not that much oozing, the bridge is nearly perfect and stable. There is only little oozing in the overhang section. This is a good setting for functional prints. With the 0.1mm layer height, there is enough resolution for small or high detail models.

Ultimaker 2, PLA, 230°C, Cura, high setting, cooling on, 1h19

This is a interesting print. The normal print looked way better than this high setting print. The print has a rougher surface. I would not count this failed print. There are many options which can cause this behaviour.

Ultimaker 2, PLA, 230°C, Cura, ulti setting, cooling on, 1h58

This print failed completely. The bridge is not correctly printed. A lot of oozing. The surface is as rough as the high settings print. As I said above, we got a bad batch of filament, this could be such a spot in this spool.

Ultimaker 2 extended, PLA, 230°C, Cura, normal setting, cooling on, 51 minutes

There is even a very rough surface. If you compare this to the 2 Go print (which was supplied with a newer batch of filament!), you don't believe that the only real difference between those 2 printers is a nearly 10cm longer bowden tube. We had a lot of spools which printed sometimes perfectly and sometime the clogged the hotend every 5 minutes.

Ultimaker 2 extended, PLA, 230°C, Cura, high setting, cooling on, 1h22

Eh... this spool is trash.

Orca XXL, ABS, 250°C, Slic3r, 0.1mm layer, 0.4mm nozzle, no cooling, ~30 minutes

This result is nice. We used Slic3r as CAM software, which generated a gcode with 6 out of 7 of the minimum distance walls. There is only little oozing. The bridge is nice and flat. None of the overhangs was a problem for this printer. For a printer without cooling, this result is impressive.

Orca v0.40, PLA, 230°C, Skeinforge, 0.1mm layer, 0.4mm nozzle, no cooling, ~45 minutes

As you can see, both Orca printer were not made for PLA and shiny printing. They are tools to produce mechanical stuff out of Nylon, ABS or flexible material. This print is even very nice. It is made out of PLA, the bridges are fine, the surface is nearly flat and really closed. The PLA we used in this printer looks like a better quality than the Ultimaker original one. There is no oozing. The perimeter are completely connected to the infill. There is absolutely no gap. This function lags really in Cura! Looks nice, smells nice. :)

Orca v0.40, Arnitel 45 Shore D, 250°C, Skeinforge, 0.1mm layer, 0.4mm nozzle, no cooling, ~45 minutes

Due to the fact that both Orcas use a direct drive extruder, we were able to print flexible material also. In 1.75mm we had Arnitel material, which was supplied by the Orca manufacturer some years ago. This is a very nice material. It contains out of 50% rapeseed oil instead of mineral oil. The Material is due to its softness hard to print. The bridges failed completely at 40mm/s and even slower. The other test sections are nice. Even the resolution for a 0.4mm nozzle with flexible material is ok. We did 3 test parts with this material. They vary in speed from 40mm/s to 20mm/s. In the last print, you can see some beginning from the bridges. Printing even slower could end in better results.

Beiwagerl, ABS, 250°C, Slic3r, 0.1mm layer, 0.4mm nozzle, no cooling, ~30 minutes

This is our Beiwagerl, a friend of me and I designed it in fall 2012. It is small, has 100x100x100mm print volume, a heated printbed and is able to print even ABS or Nylon. It is made for high-speed printing. Watch this video. We printed a test part on it. The spool was very old (one of the first shippings from china - must be 2013 or so), but it printed - ok, there was a bit oozing - nice. The surface is closed, the bridge is solid and the overhang is ok. This print was done with 50mm/s.

Conclusion:

All our printers have positive and negative aspects. The design rules to use our printers with the 0.4mm nozzles are relatively easy.

The minimum wall thickness must be over 0.4mm. Bridges up to 16mm are not a problem, overhangs up to 45 degree are even absolutely no problem. Above this, use support material (normally Skeinforge and Slic3r are set to use support material above 60 degree). The Ultimaker (all of them) printing 0.3mm to large, the Orcas 0.05mm to small (we calibrated them...), the Beiwagerl is even 0.3mm to large in its printing dimensions.