wildcard

This assignment is to Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to) composites, textiles,biotechnology, robotics, and cooking.

concept

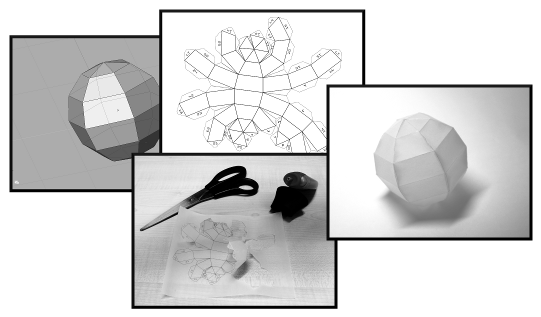

For this week i want to use Pepakura since we have a license in the fab lab computer. Pepakura is a program that creates buildable papercraft models. Using 3 dimensional data, Pepakura allows the model to be unfolded to a flat template to be cut, folded, and glued together.

It takes 3D file > turns to 2D > gets cut in 2D > gets constructed and becomes 3D

3D design

I like statistics. Statistics is a form of mathematical analysis that uses quantified models, representations and synopses for a given set of experimental data or real-life studies. a basic way people learn about statistics math when they first get started is by statistics of rolling a dice. Normally people think of 6 side dice but there are more kinds. Most popular is dice with four sides, six sides, 8, 10, 12, 20. I decided to try and make my own own dice.

First step is to create a 3D design to use. Pepakura takes stl files. There are some design guidelines and considerations that i saw from reaserching about it:

*design has to have a low number of faces and not so smooth edges so Pepakura can turn it to 2d right.

*the design should be simple so it wont have too many complex parts to assemble

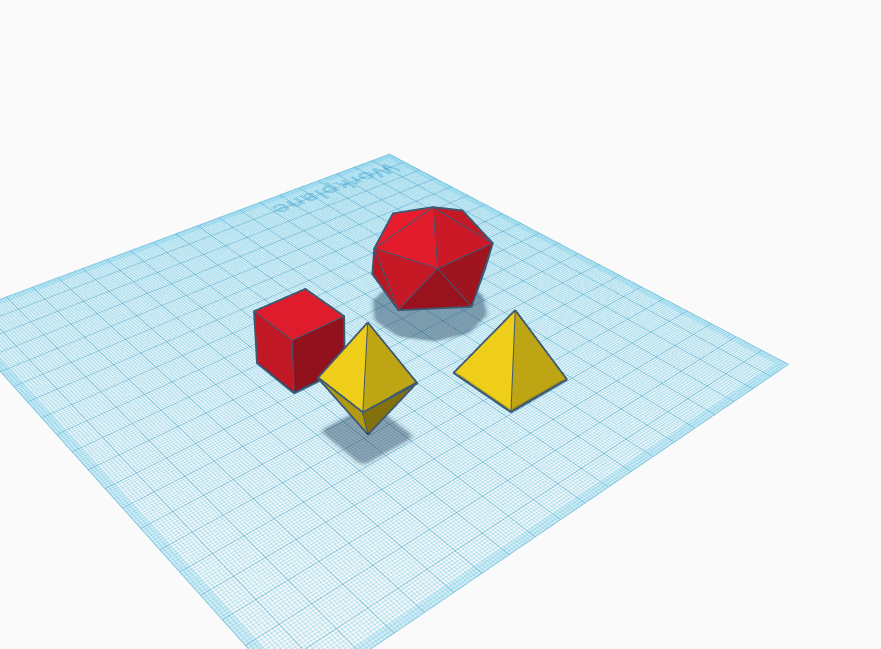

I made the design in tinkercad which is a very simple software and really good for simple designs but bad for complex ones that need accuracy. I prefer solidworks normally but i didnt have it this time and tinkercad works in browser.

I made the design in tinkercad by dragging and dropping existing parts and reshaping and stacking them on top of each other.

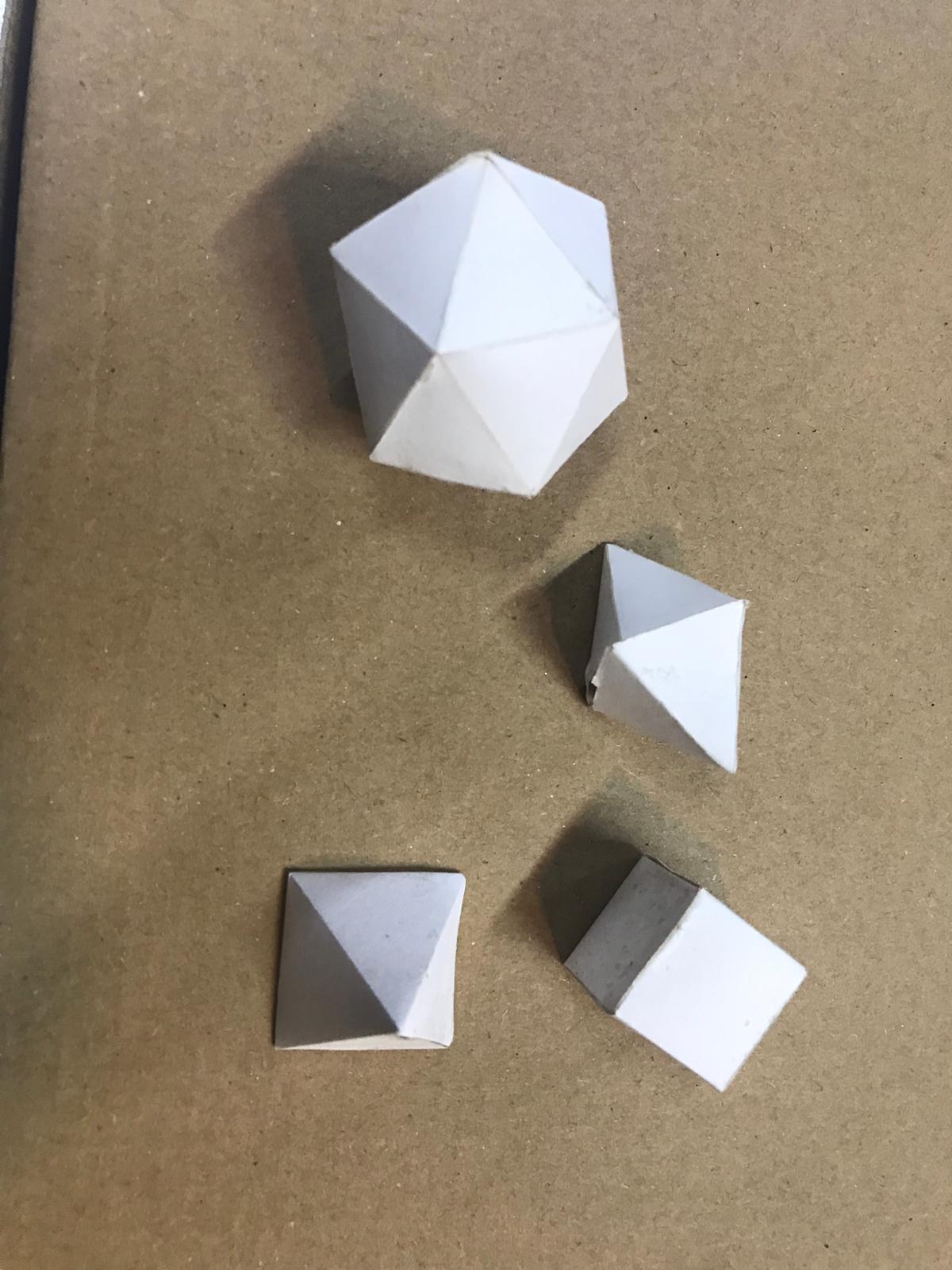

I made 4, 6, 8, 20 sided dice.

download stl

design tinker link

turn to 2D

There are multiple softwares available that have the ability to turn 3D files to a 2D foldable file (a papercraft model). papercraft models are 3D models built from paper or cardboard. papercraft models involve cutting a cut-out sheet and connecting faces using glue. It is mainly used to create solid objects with an explicit interior and exterior being completely separated by the paper. the result is a flattened pattern of connected polygons. All edges of a polygon which are unconnected get a glue-tab in addition. after all pairs of tabs have been glued together the paper model corresponds to the 3D object. i did some search on the most popular options

DXF2papercraft

DXF2papercraft is a command line tool to do the conversion. it works using a DXF file input and converts it.

DXF2papercraft

DXF2papercraft only accepts DXF 3D files for the conversion.

after more reaserch on DXF2papercraft. i found that it offers little to no flexibility with the settings of the file, how the output turns out and the size of the paper sheet so i did not use it.

after more reaserch on DXF2papercraft. i found that it offers little to no flexibility with the settings of the file, how the output turns out and the size of the paper sheet so i did not use it.

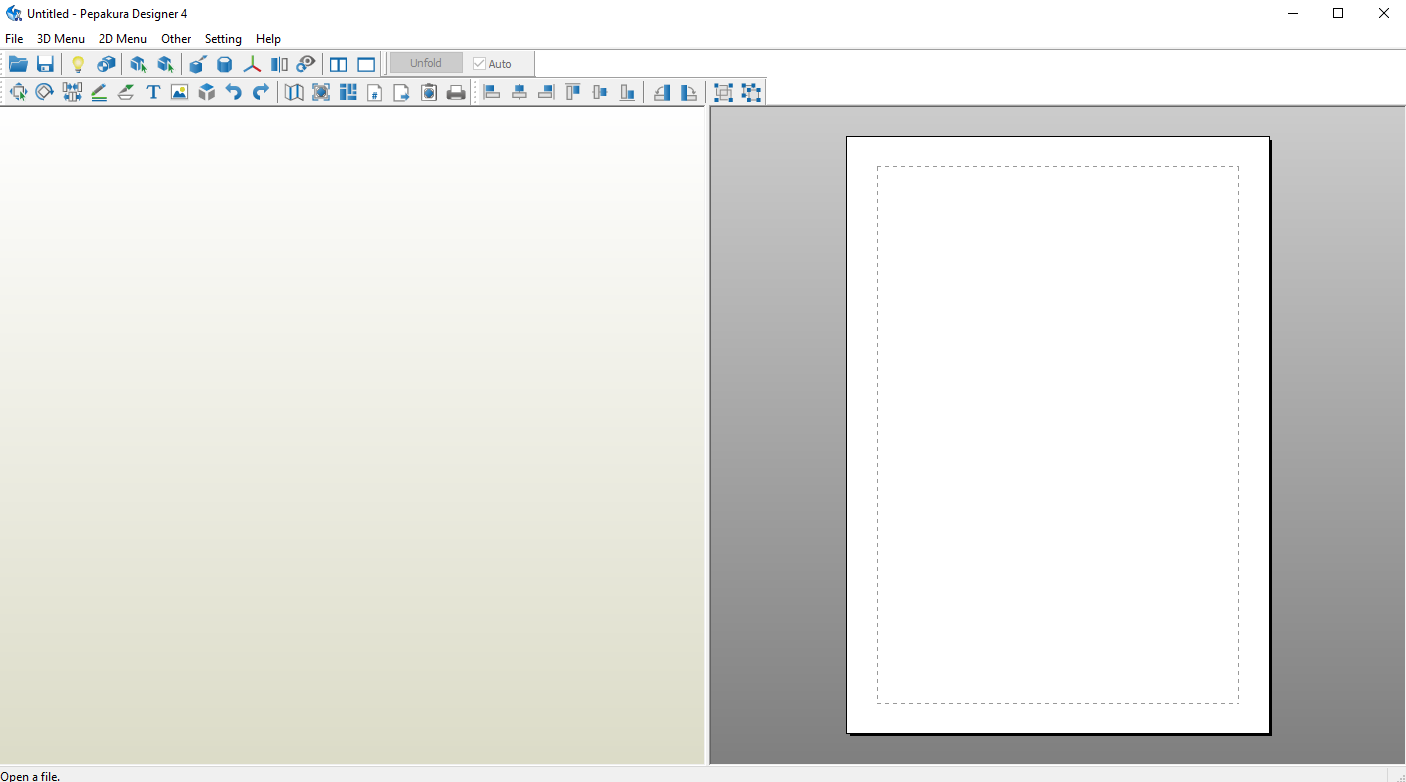

Pepakura

Pepakura is easy to use software to turn the 3d files to 2d. I imported the stl file and it went through some import steps. My shapes are the same from every side so the import steps were not that important for me

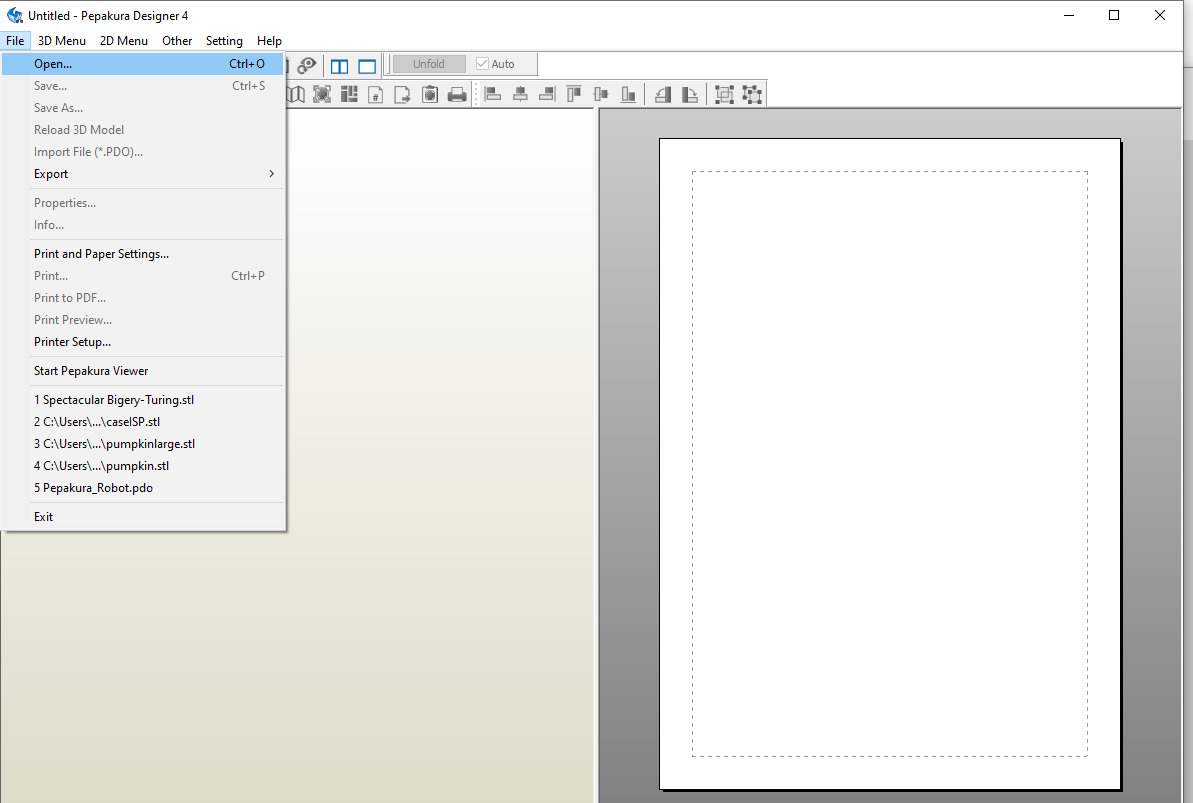

The first step is to open the 3D STL file in the pepakura software

The first step is to open the 3D STL file in the pepakura software

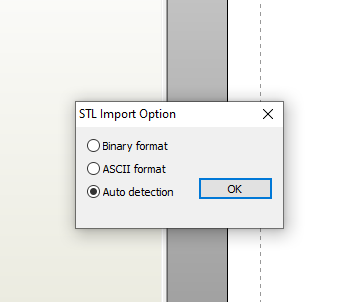

The software begins by giving the option between importing ASCII or Binray STL.

STL files can store information in two different ways. These are Binary encoding and ASCII encoding. Binary files are smaller and easier to share while ASCII files are visually easy to read and check.

I am not sure what encoding my file is. it is most likely binary becuase binary format is recommended to use for 3D printing and tinkercad is primarely meant to produce 3d files for 3D printing. i picked autodetect binary.

The software begins by giving the option between importing ASCII or Binray STL.

STL files can store information in two different ways. These are Binary encoding and ASCII encoding. Binary files are smaller and easier to share while ASCII files are visually easy to read and check.

I am not sure what encoding my file is. it is most likely binary becuase binary format is recommended to use for 3D printing and tinkercad is primarely meant to produce 3d files for 3D printing. i picked autodetect binary.

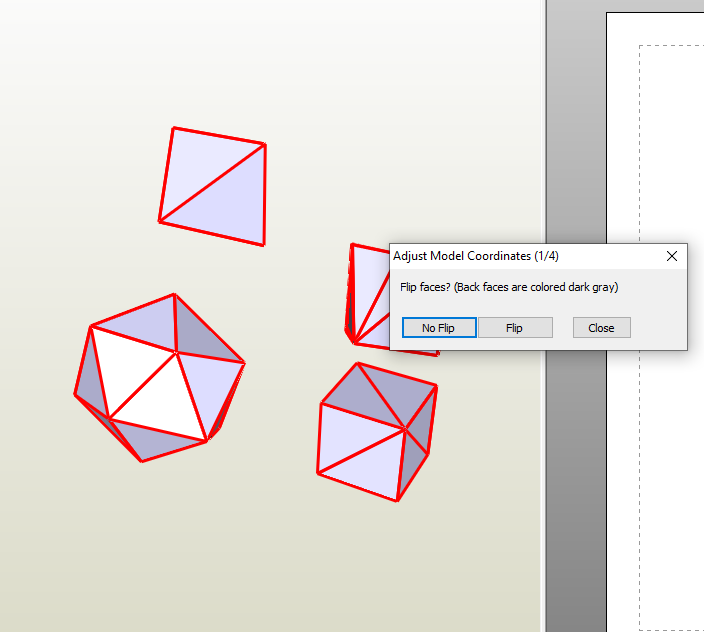

the flip faces option gives the option to invert the direction of faces with dark grey indicating back faces. i select no flip becuase it was showing correctly.

the flip faces option gives the option to invert the direction of faces with dark grey indicating back faces. i select no flip becuase it was showing correctly.

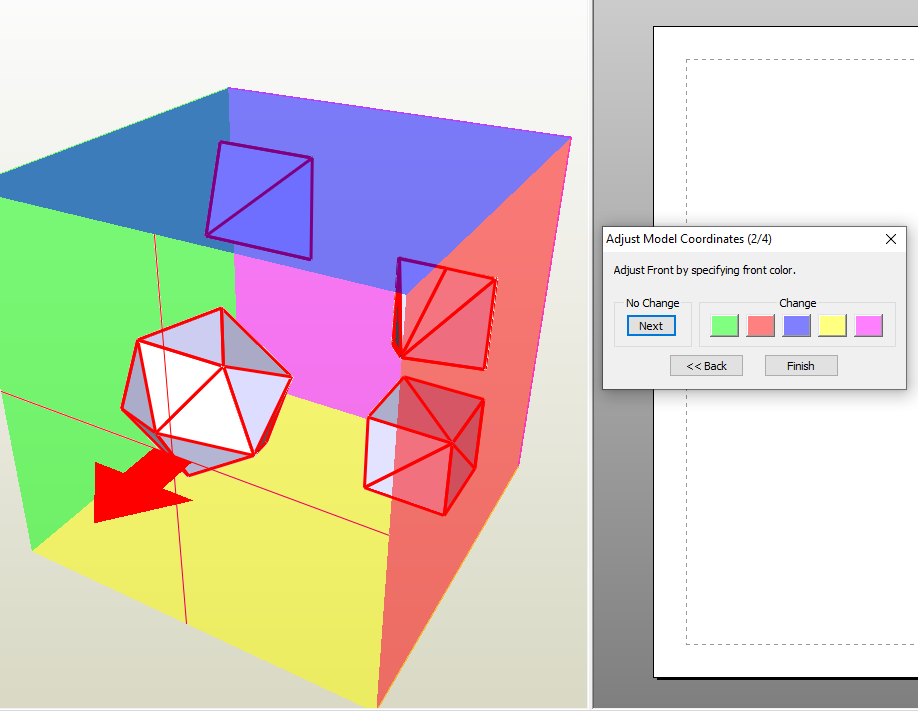

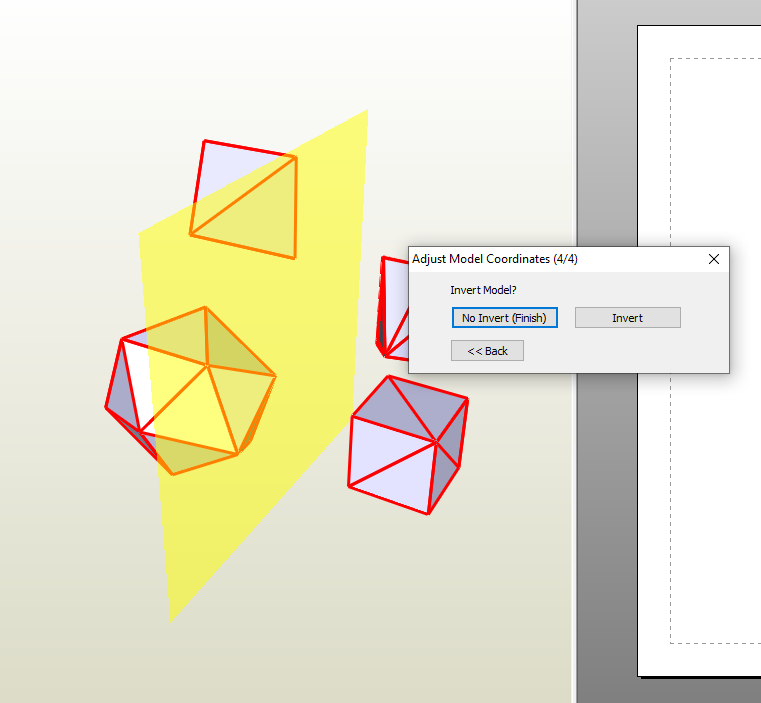

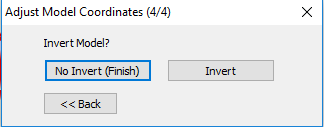

next is the option to adjust model coordinates. it shows colors that indicate what side is front and back and so on. the dice dont really have a front and bottom per say as every side of the dice is supposed to be identical. i selected no change.

next is the option to adjust model coordinates. it shows colors that indicate what side is front and back and so on. the dice dont really have a front and bottom per say as every side of the dice is supposed to be identical. i selected no change.

and again for the rest of the sides

and again for the rest of the sides

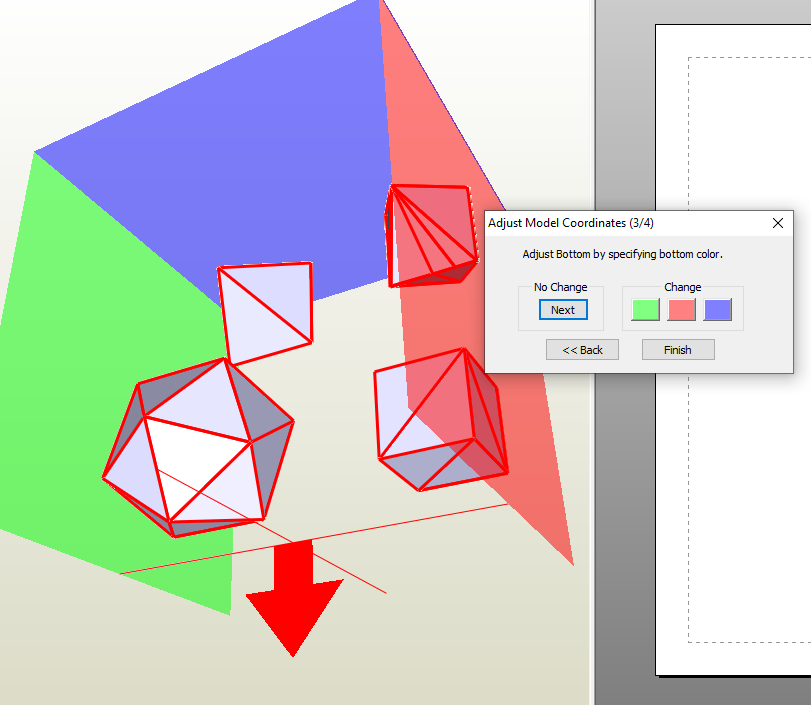

next step is to adjust model coordinates again. again i pick no flip and that ends the import steps.

next step is to adjust model coordinates again. again i pick no flip and that ends the import steps.

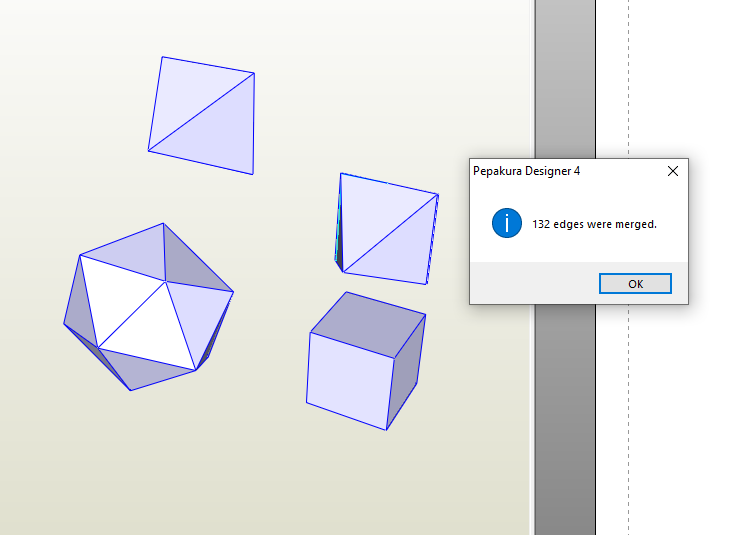

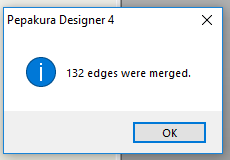

next it displays the number of edges that were merged in the model. for this model it was 132.

next it displays the number of edges that were merged in the model. for this model it was 132.

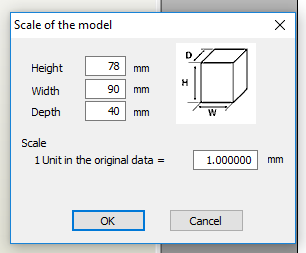

next it gives the choice to scale the model. as in it can be the same size of the 3d model by default (scxale = 1) or can be made bigger or smaller. i am happy with the size i made the 3d files so i kept it at scale 1.

next it gives the choice to scale the model. as in it can be the same size of the 3d model by default (scxale = 1) or can be made bigger or smaller. i am happy with the size i made the 3d files so i kept it at scale 1.

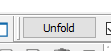

Then when its done i click on unfold and got the result

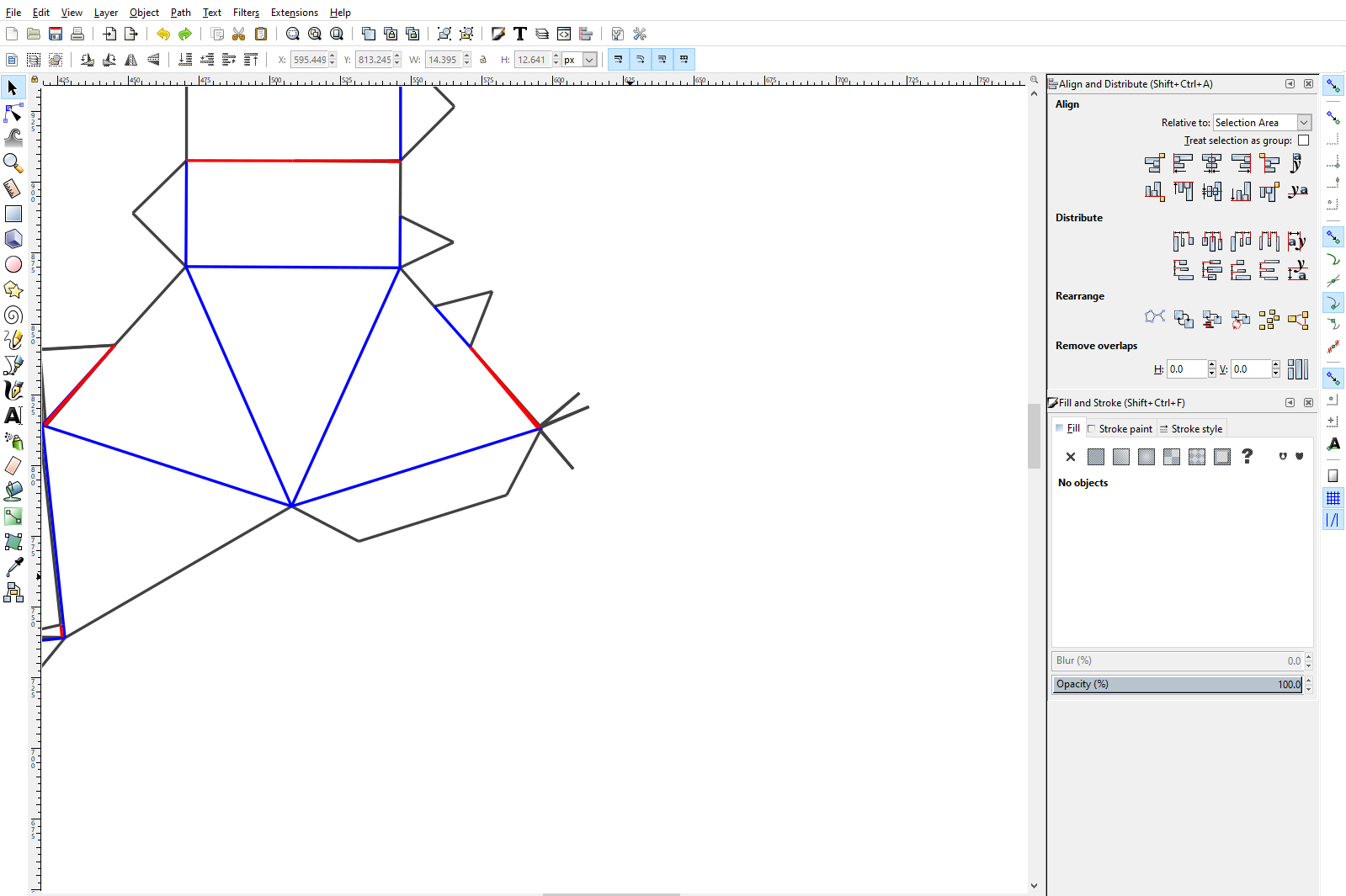

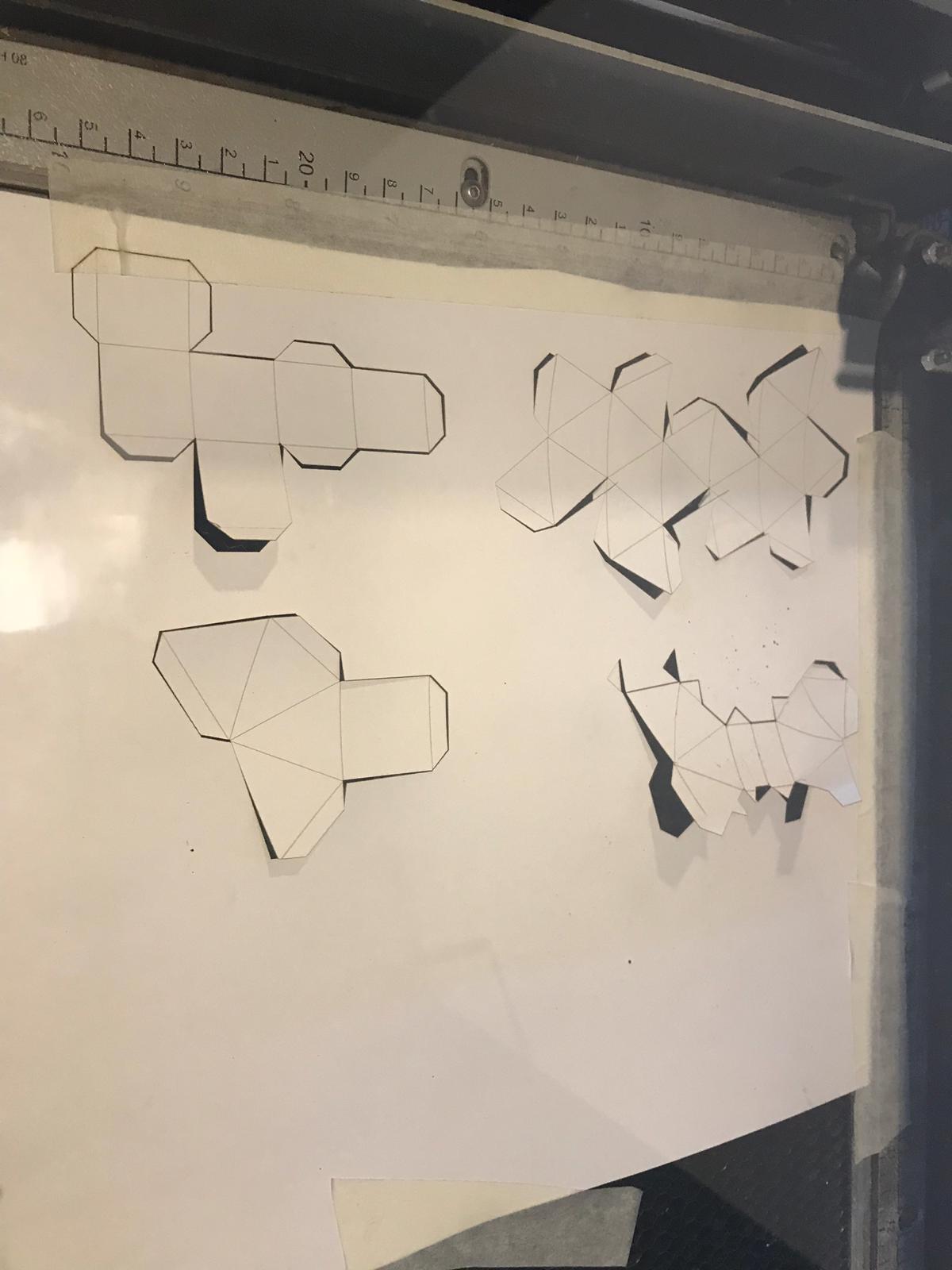

you can see in the results that there are two types of lines. continuous and scattered lines. continuous indicate cut and scattered mean fold. the program generated tabs for the glueing when folding to construct.

you can see in the results that there are two types of lines. continuous and scattered lines. continuous indicate cut and scattered mean fold. the program generated tabs for the glueing when folding to construct.

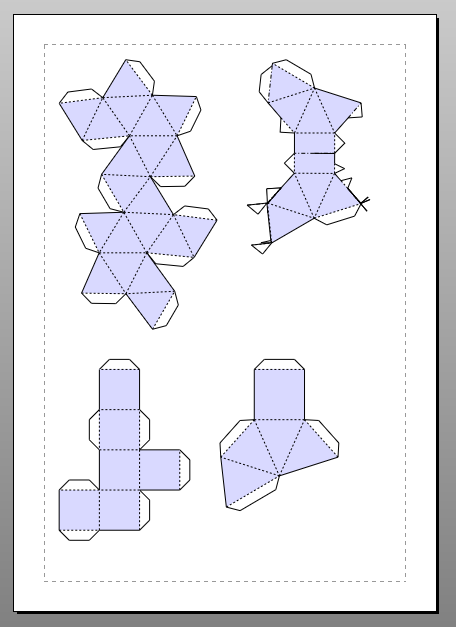

last step is to save in dxf.

one other cool feature in pepekura is that it shows the folding method as animation which is helpful for complex shapes where its hard to figure out where each tab and fold goes.

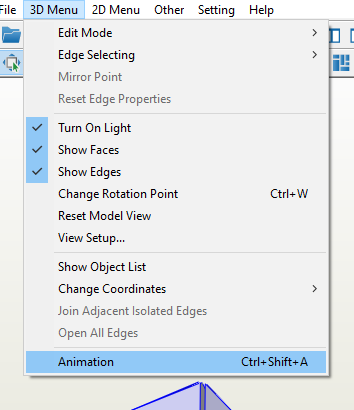

to get the animation go to 3D menue > animation

cut 2D

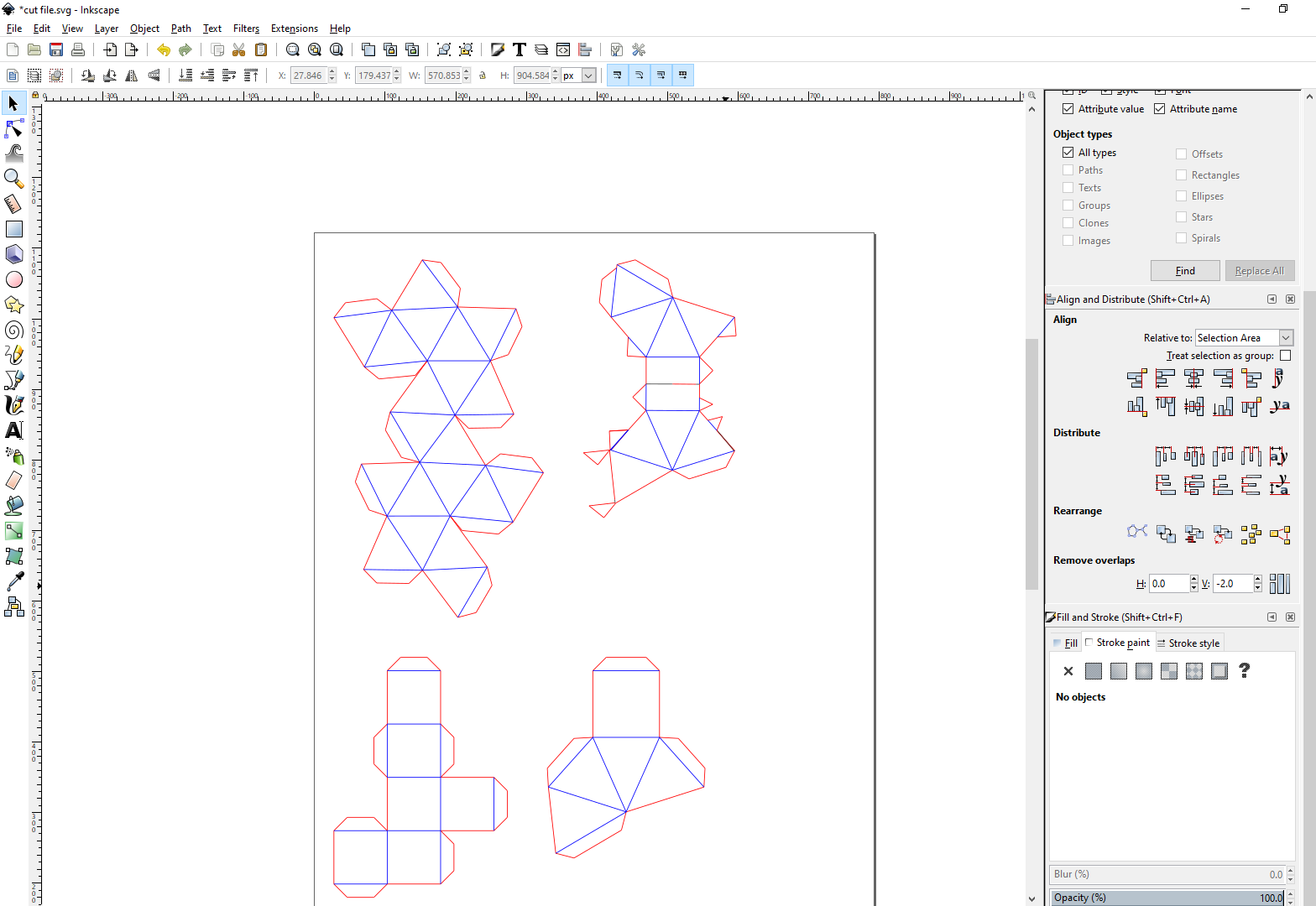

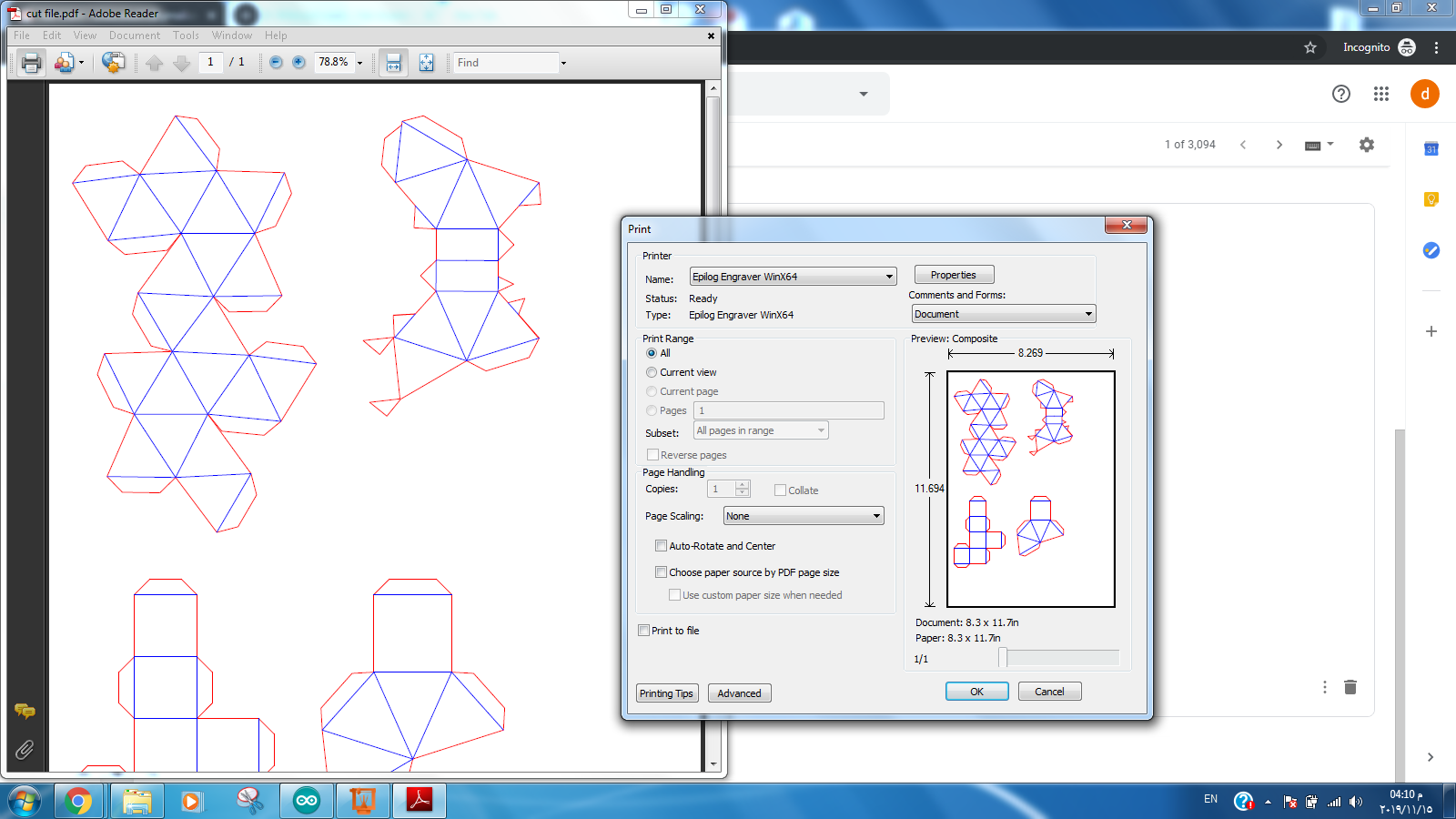

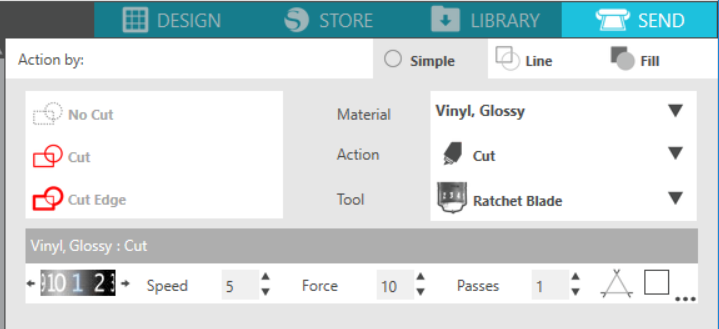

I am cutting using laser cutter. I opened the dxf in inkscape, cleaned some lines a little, and changed colors to blue and red. And changed line width to cut on the laser cutter. It needs to cut the outline and cut the folding lines with less strength (not cut through) to create fold lines

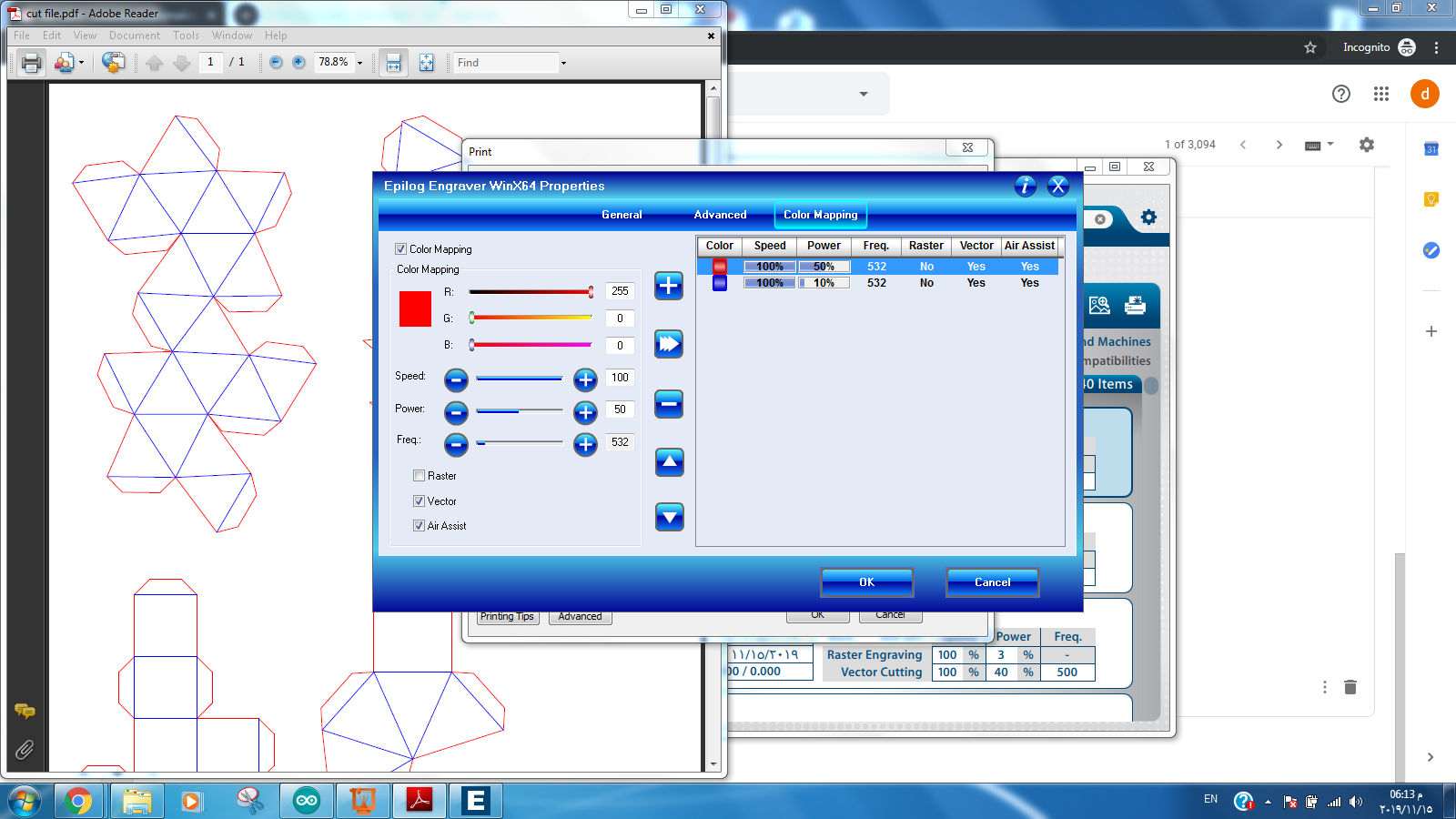

I cut on thick paper. Settings i used are different per color. I used color mapping Cut line Speed 100 power 50 freq 500 Fold line Speed 100 power 4 freq 500

construct 3D shape

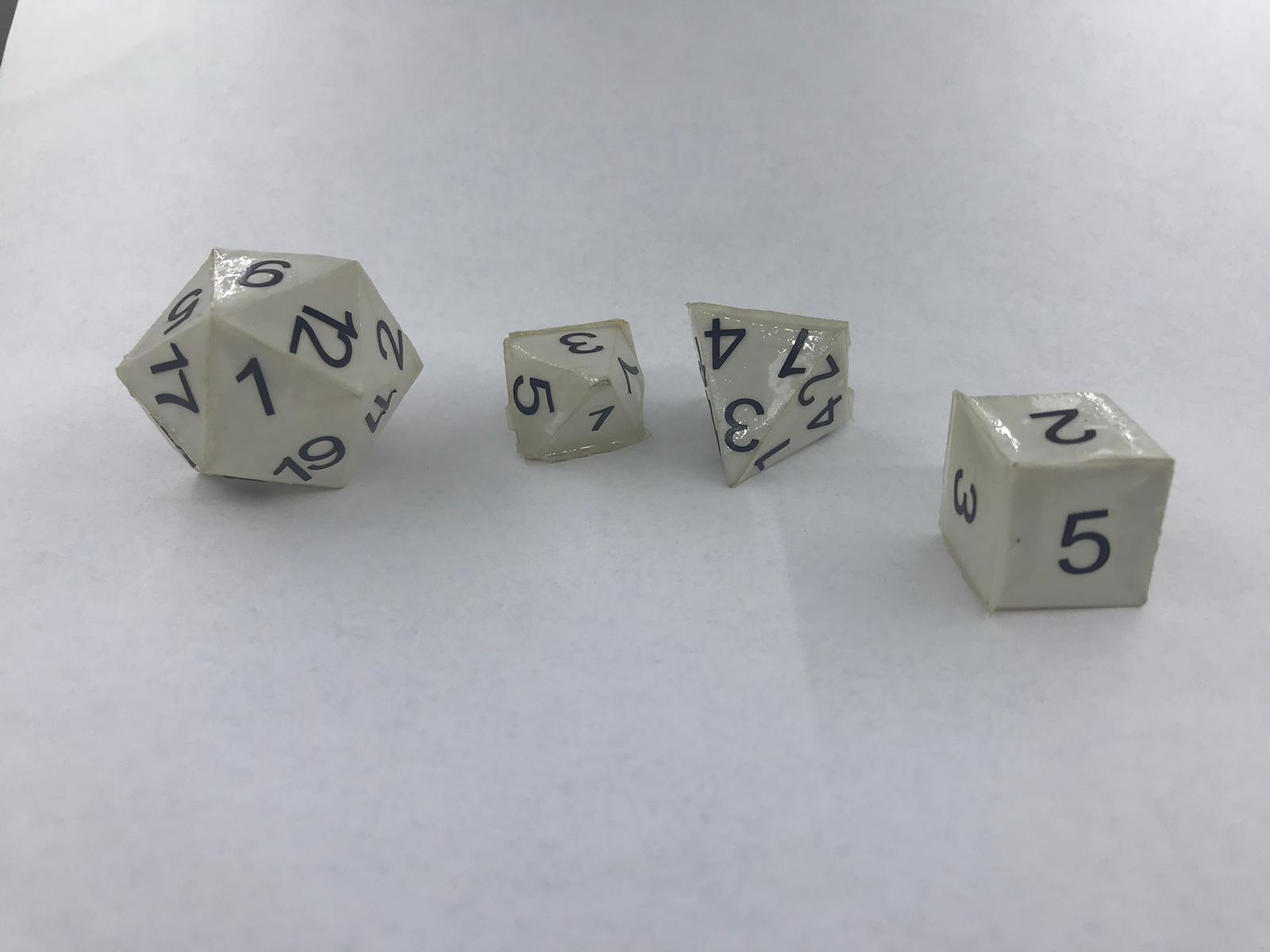

To construct it there are fold lines that you fold against. Tthere are flaps that are meant to be glued to hold everything together. I used universal white glue to glue everything. Its good for this purpose. It was straight forward to construct and the glue needed some time to dry. They are a little small so the ones with higher number of folds didnt work as well and got a little weird

final touches

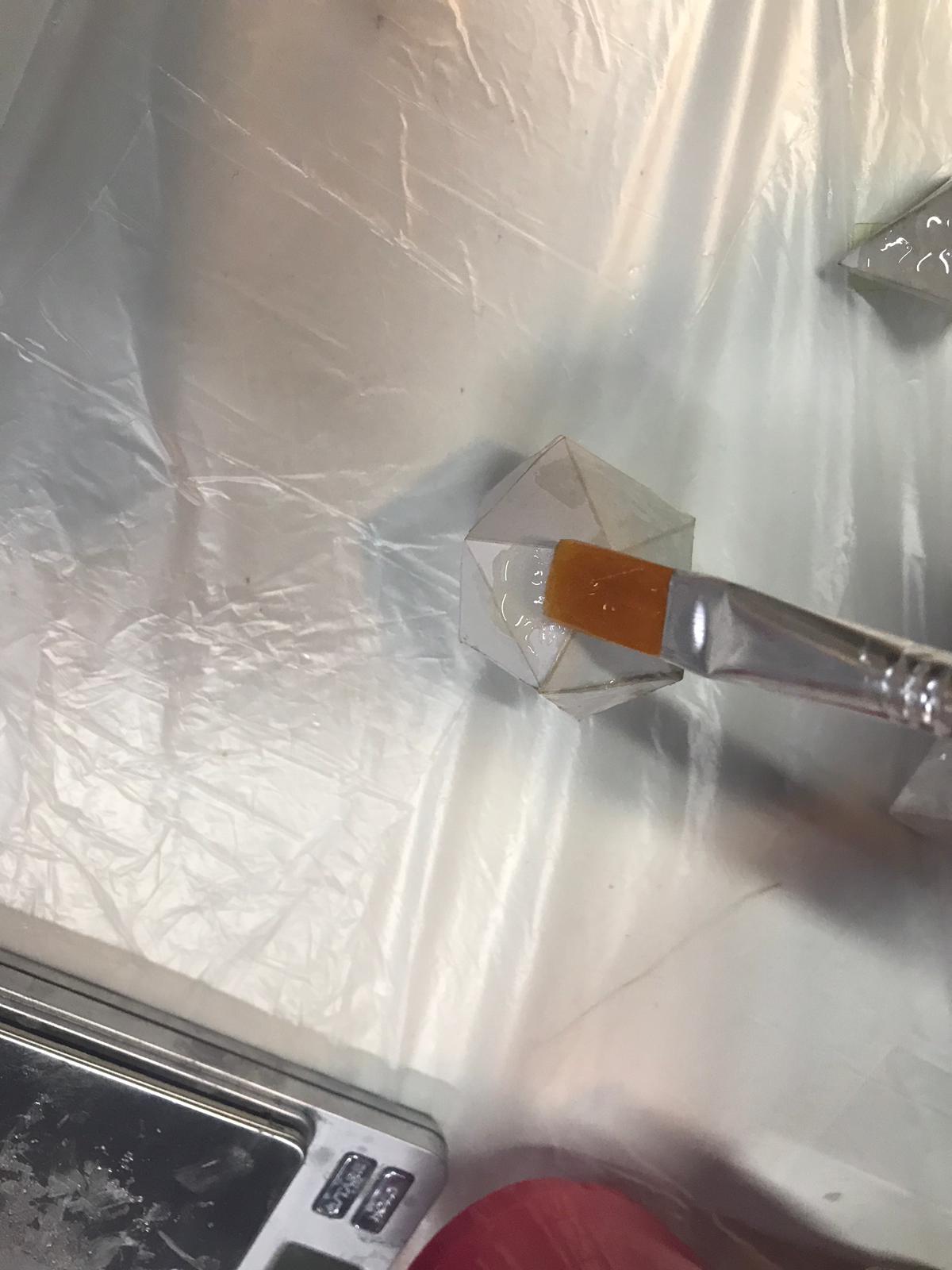

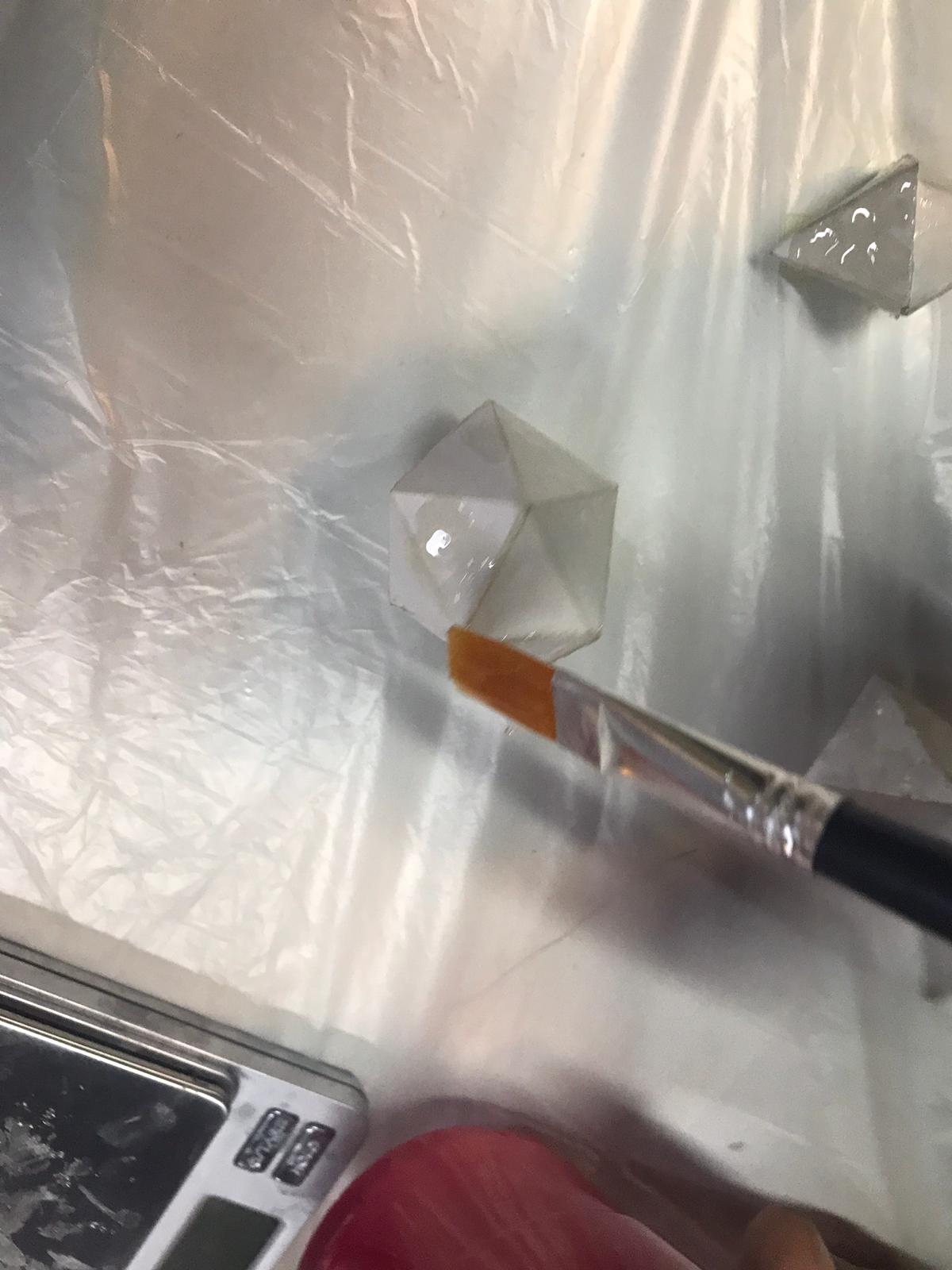

It is made of paper which is weak material. I decided to cover it in resin to harden it up so it can be used as real dice. I used Alumilite’s Amazing Clear Cast epoxy. I had to ccover it in resin and leave it for 24 hours to get harder design

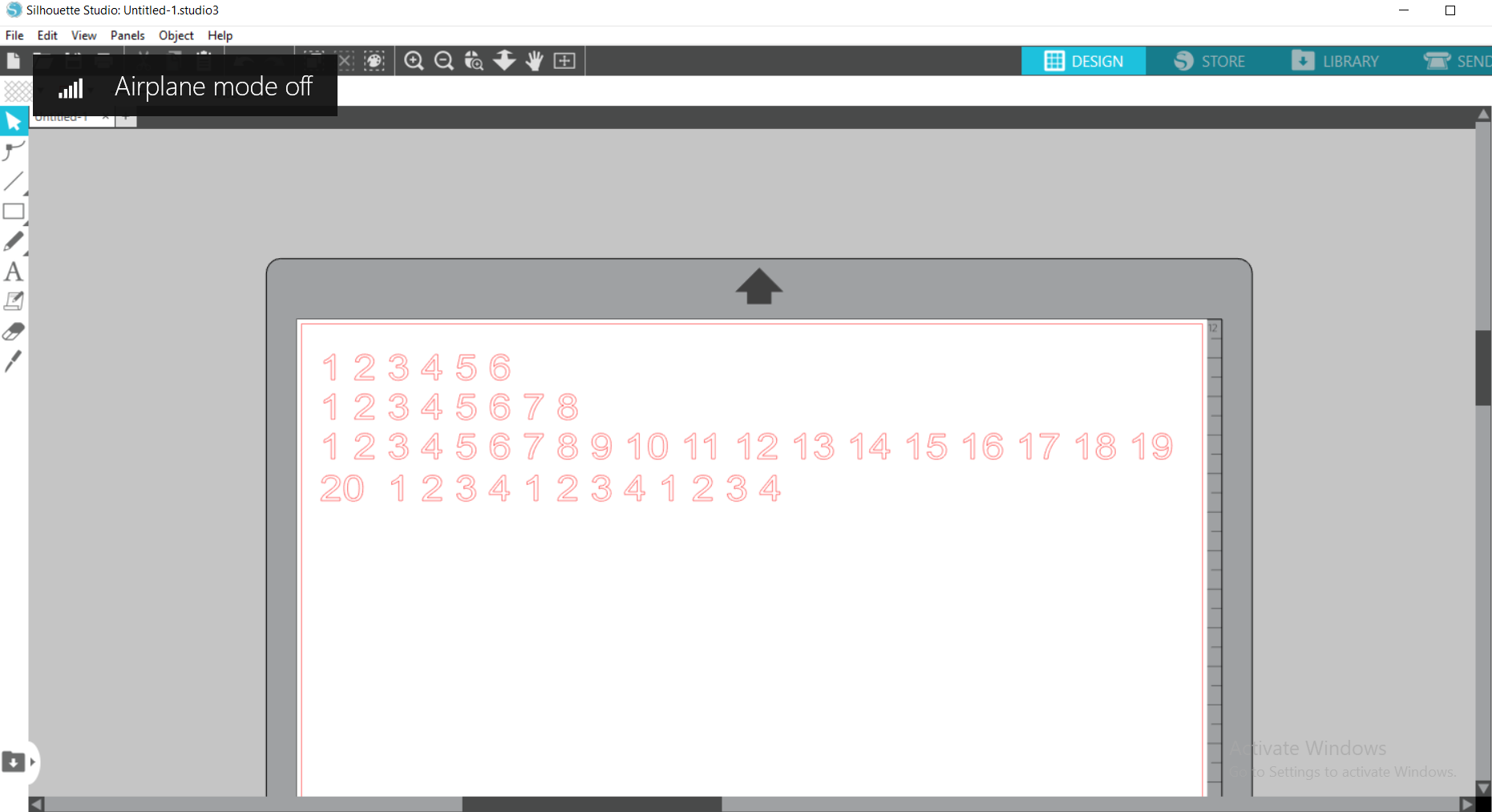

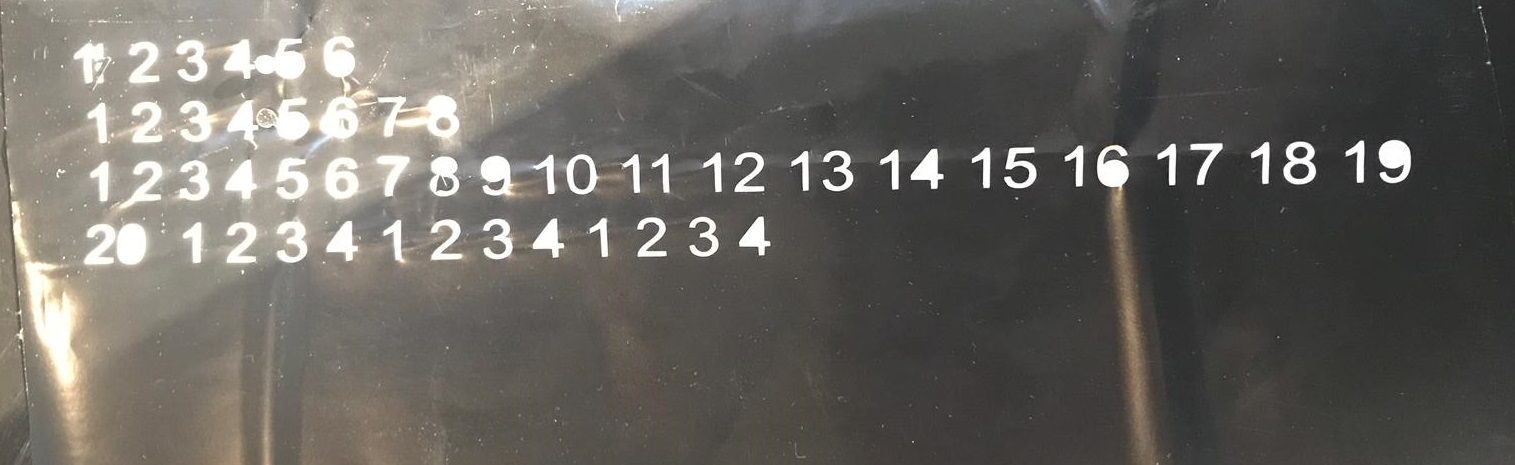

i add numbers on the dice sides to make them more like dice. i used venyl cutting machine to cut the numbers to the size i want on black sticker venyl.

is it a dice?

The dice i made “statistically” speaking are not actually dice. Dice needs to have equal probability to land on each side. There are folding imprefections here and maybe there is more resin on one side of the dice there is no way to really know its equal amount so it would weight it down and make it more likely to go to the ground facing that side.

Technically none of those are actually dice but i still think it is a cool concept and i like them