Week 2: Intro to CAD tools

This week we explored and got an overview of different CAD tools and a little bit more in detailed presentation of 3D CAD tools.

We started with an overview of 2D editing tools: bitmap and vector based.

Later we dig into details of 3D tools understanding some of the key differences:

- mesh based vs NURBS: the first more used in digital art and video, the latter in mechanical manufacturing

- understanding constraints, hierarchical and parametric modeling features.

During the process I installed and tried:

- SolidWorks:

- Fusion 360: Autodesk, comprehensive CAD solution, still in early development stages

- OnShape: Browser based tool

- FreeCAD: Free software, NURBS based, targeted at mechanical design

- Blender: Free software, mesh based, targeted at video animations and rendering, very active community

- Inkscape: Free software, vector based, 2D drawing

Not having still settled on a final project I decided to use as exercise the idea to create a model of the FabLab logo.

My preference was to try Open Source tools first and to take a look at a couple of the commercial options.

I got a bit lost in using Blender, so I settled on FreeCAD and later tried to build the same in SolidWorks.

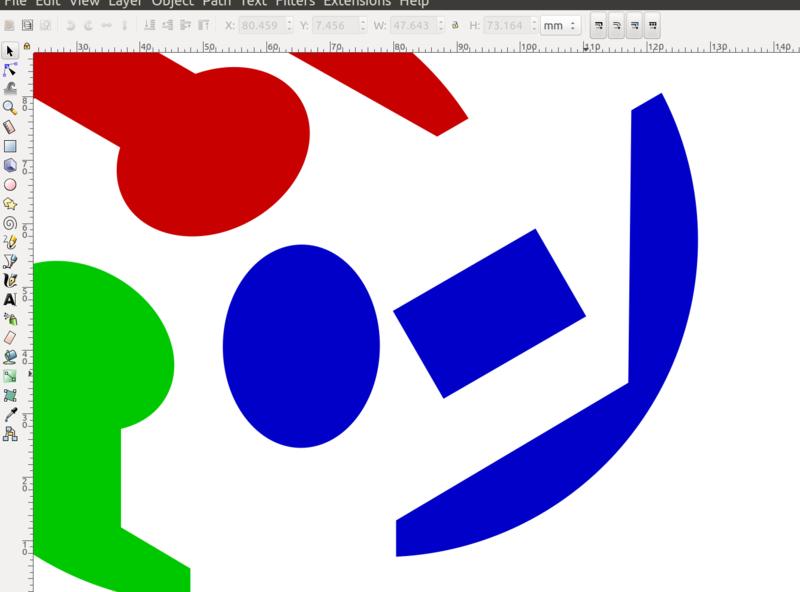

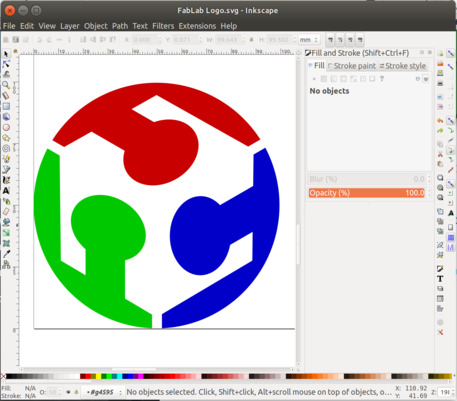

FabLab Logo in Inkscape

Inskscape is used to create 2D vector based images.

Download source file (.svg)

- Create circle for the puter shapes

- Create a concentric hexagon shape to subract from the circle

- On 2 corners of the hexagon I then subtracted rectangles: this way I got 1 third of the outside shape

- Then I added an ellipse and a rectagle: this way I got 1 third of the logo

- Finally I grouped all the parts, duplicated two times, rotated 120deg and coloured them separately.

Here is the final result:

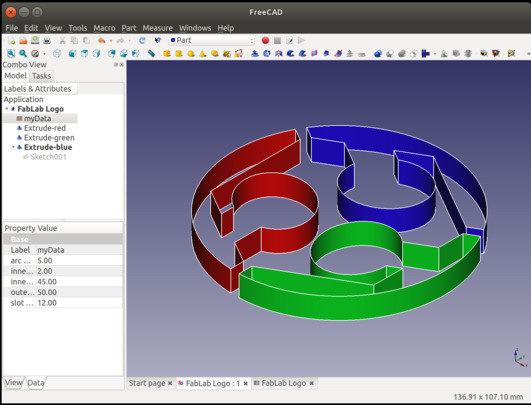

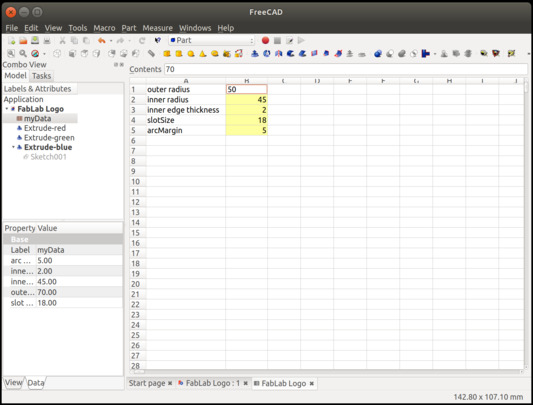

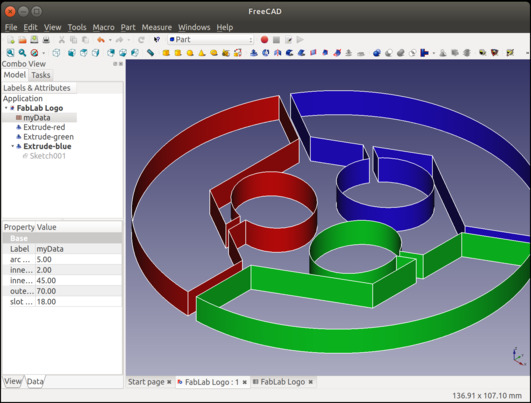

FabLab Logo in FreeCAD:

Download source file (.fcstd)

Here is the final result:

I also made the model parametric so different dimensions can be easily adjusted.

Working with FreeCAD I experienced recurring crashes (got used to save often :)) and sometimes struggled a bit in identifying elements that are not fully constrained or resolve constrains conflicts

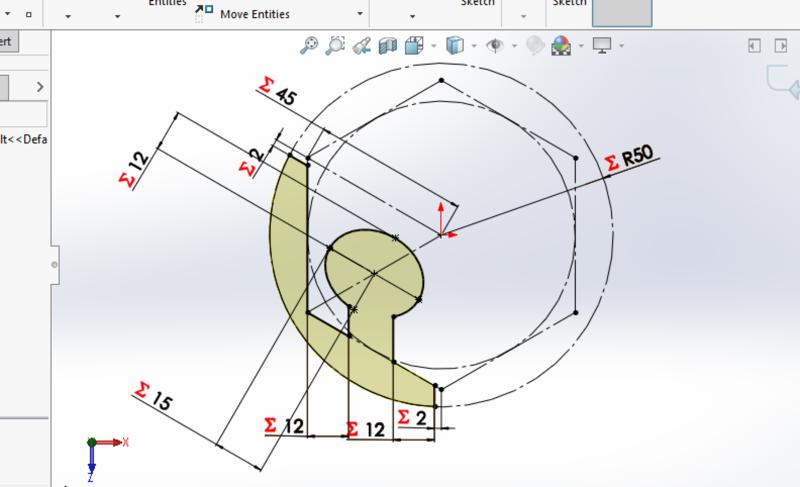

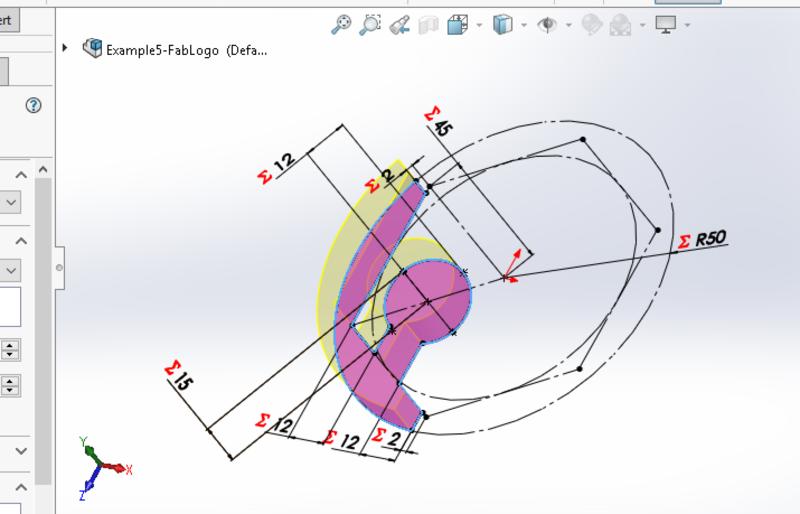

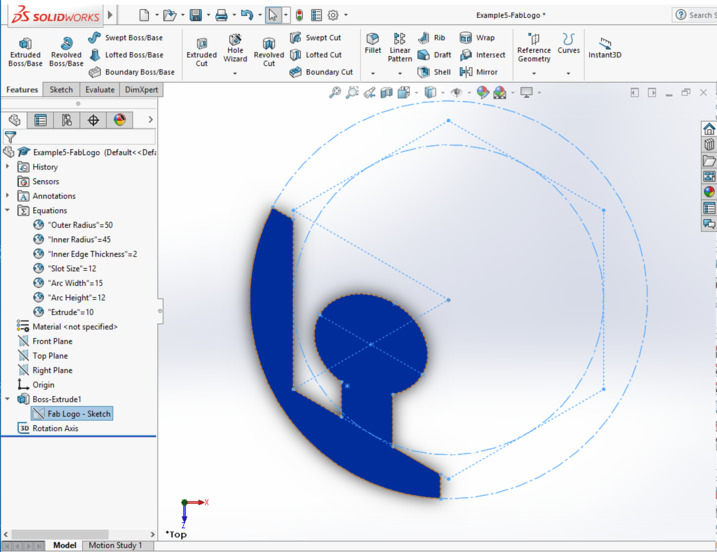

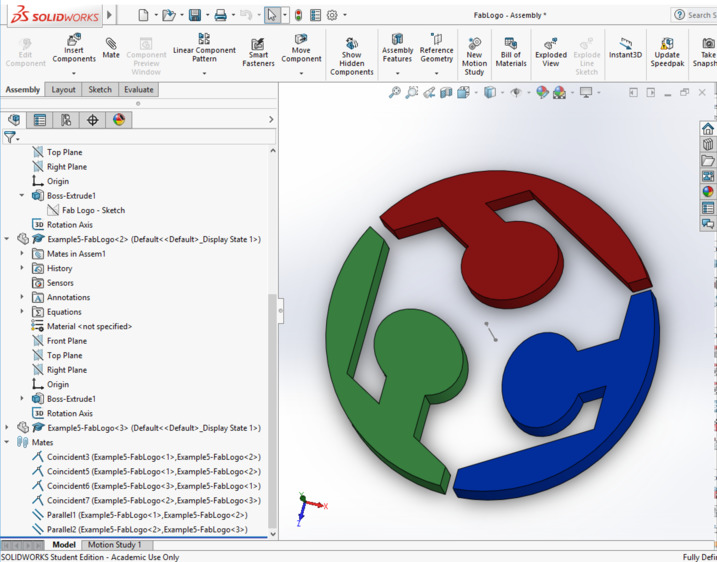

FabLab Logo in SolidWorks:

Download source Part file (.sldprt)

Download source Assembly file (.sldasm)

- First I created a single parametric sketch of 1 third of the Logo using a support circle, a concentric hexagon and then using constraints to create arcs, lines and ellipses.

- Then I extruded it on the vertical axis

- Finally I used the assembly feature, replicate the 3 simmetric elements and rotating them around an axis, so I reused the single part and reimported it 3 times.

The exprience with SolidWorks has been faster and more stable. Untile the very last moment… where it took me a while to separately colour the different parts :)

Note: being a Linux user I had to struggle a big in making Windows CAD tools running in a VM. Here you can find how to make SolidWorks run in a VirtualBox VM

Happy Computer Aided Designing! ![]()