Composites>

Composites>

This

week our assignment wasto

design, make a 3D mold, and create a fiber composite part out of it. This was a

busy week, and 3D printing a mold of the size I wanted would have taken too

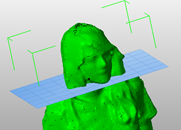

long. I decided to use a 3D scan of my face. First, I gathered my materials. I

decided to use resin first, since I had used it before, and was familiar with

the mixing process. Stiff white cotton was my first choice of fiber. I was

thinking it might be neat to illuminate my composited face, so I only did a few

layers. I didn't have any plastic wrap on hand, but a plastic bag worked out

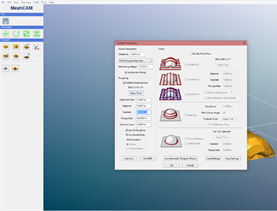

just fine as a release fabric. For my cast, I brought my 3D face into MeshCAM,

a great program to compose new 3D models from old ones. There I scaled my file

to the correct size of Styrofoam I would mill out. Here is my scaled file. Then I

brought that gcode file into Linux CNC, to send to our

big DIY CNC machine. Since I used a 1/4 inch ball end mill to drill the

styrofoam, I could go the machine's top speed of 60 inches per minute.The speed

of the dremel tool mounted in the CNC machine was 10000 RPM. After my face was

milled out I began the compositing process! I took care to keep my workspace

over a tray, as the resin was incredibly sticky, similar to honey. I cut up a

bunch of fabric squares, soaked them in resin, and pressed them onto my

styrofoam face. The resin/cotton was slippery, right away I got the impression

that this wasn't going to work, but continued in hopes that the pressured water

bag would do the trick. I placed my resin-soaked face in a small trash can, and

filled up a giant trash bag with water. 24 hours later I had a lumpy white

blob,

brought that gcode file into Linux CNC, to send to our

big DIY CNC machine. Since I used a 1/4 inch ball end mill to drill the

styrofoam, I could go the machine's top speed of 60 inches per minute.The speed

of the dremel tool mounted in the CNC machine was 10000 RPM. After my face was

milled out I began the compositing process! I took care to keep my workspace

over a tray, as the resin was incredibly sticky, similar to honey. I cut up a

bunch of fabric squares, soaked them in resin, and pressed them onto my

styrofoam face. The resin/cotton was slippery, right away I got the impression

that this wasn't going to work, but continued in hopes that the pressured water

bag would do the trick. I placed my resin-soaked face in a small trash can, and

filled up a giant trash bag with water. 24 hours later I had a lumpy white

blob,

resembling a face, but nowhere near

what I had hoped for! I also had made a few coupons of burlap and plaster. This

combination was super strong, and the plaster dried much faster than the resin.

I attempted to mold my face with cotton and plaster the second time around and

I was much more successful!

resembling a face, but nowhere near

what I had hoped for! I also had made a few coupons of burlap and plaster. This

combination was super strong, and the plaster dried much faster than the resin.

I attempted to mold my face with cotton and plaster the second time around and

I was much more successful!