Week III

Lesson February 11th 2015

Review February 18th 2015

Computer-controlled cutting

The third lesson had regularly place on february 11th at 3 p.m.. During the first hour Neil reviewed some of our works, then he surprised the students, asking them to talk about their final project. At 4 p.m. We began the lesson with an overview about the available technologies used to cut, from the average to the more expensive practices, also talking about the more popular machineries in almost all the FabLabs. In Computer-controlled cutting page we can find the lecture input. The first machinery we introduced is Vinilcut. Neil showed us some of the raw materials and how to place the blade; then he gave us other informations to use the fab moduls with vinilcut.

Assignment

Design, make, and document a press-fit construction kit

Today we started to prepare the assignment for the next week. First of all we took a quick look at the works of the other students, then some of the examples of press fit on Instructables.

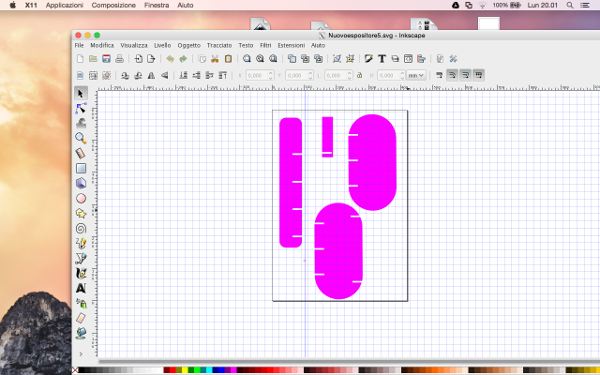

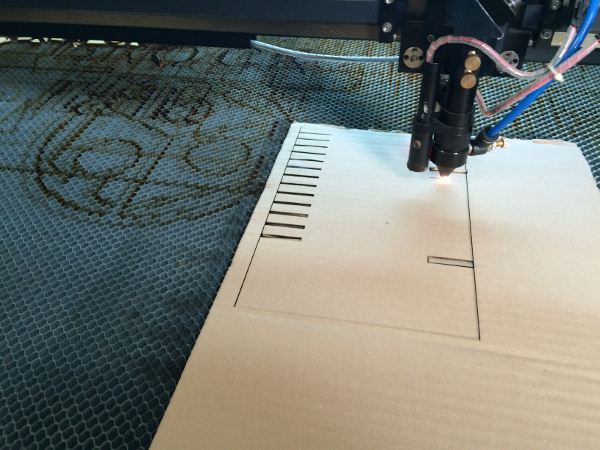

The first step was the inkscape reproduction of a file from Lorenzo's pc (our local tutor) and the uploading to the machine for the cutting. After 2 hours of work and layout creations on the Inkscape file, I exported the dxf file to the lasercut, but it was not readable, probably because of an exporting Inkscape problem.

Exercise n1: Vinil Cutting, stickers

I think that the cutting plotter is among the tools easier to use, any plotter has its reference software and ours is a SummaCut, with the counterpart software SUMMACUT. Depending on the material used is very important to set the weight of paper to be cut.

For my exercise I set 185gr weight, inserting a vinyl adhesive white, when you do this you need to lift the lever behind the plotter to allow the insertion of the card, when you lower the lever, the plotter automatically aligns itself seeking the his home. The home you can manage it automatically as the source, or it can be set with the custom parameters, this also allows you to use scraps of paper or comunuqe perform different operations.

To better understand what weight we need you can also make on the test, the machine recorded a small square and from there we can tell whether or not size.

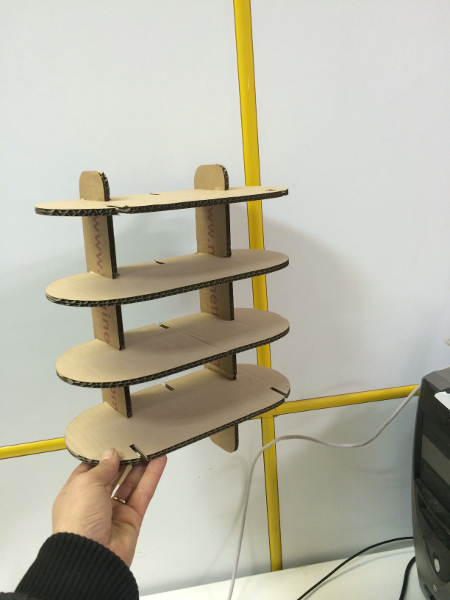

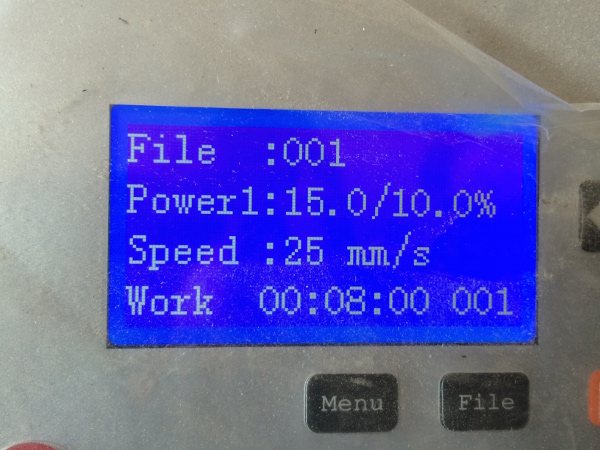

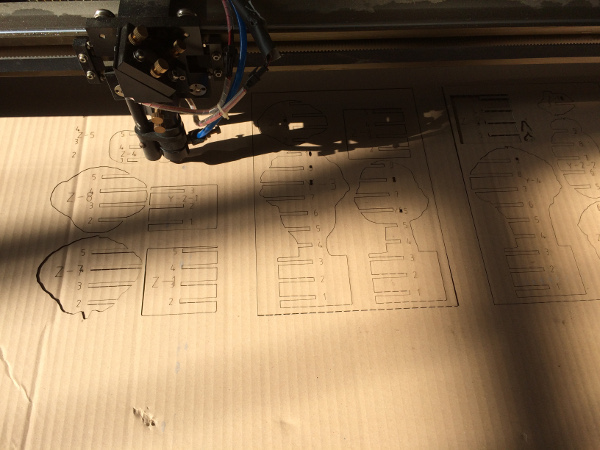

Exercise n2: Lasercutting, press-fit

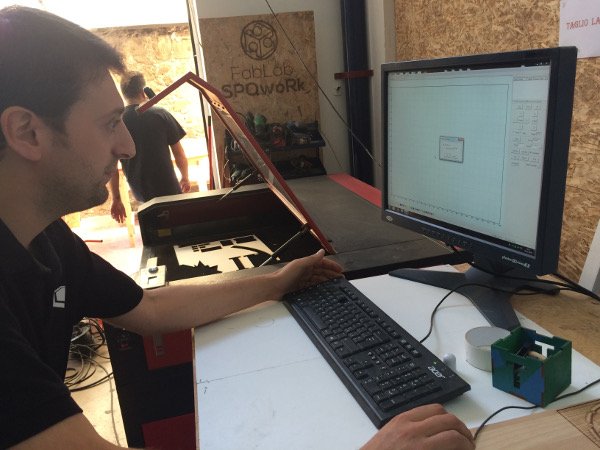

Fortunately i am are very practical with the use of Lasercut, can cut various materials without problems, I am less skilled in the use of software.

I must say that I have not much experience with the card-board because here is just used for prototyping, playwood is much cheaper and easily available.

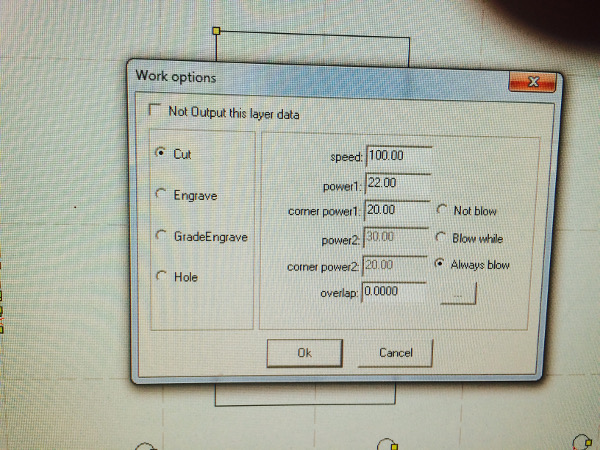

For this exercise, I followed the instructions of my Local instructor, so the first thing I made a comb to test the joints, once you choose the best fitting I started drawing the object to be achieved.

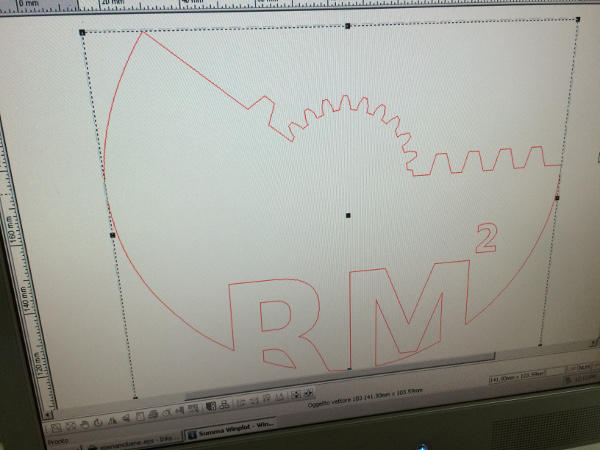

I made a drawing of a door desk objects, using Inkscape first and then Corel Drow. I often happens that when drawing file with Inkscape then the software Lasercut not accept the file, and does not allow me to see some parts of the project, but if I export the file from Inkscape as dxf and the amount of Corel Drow, then I problems, but you need to make a pass on Corel Drow before reaching the software machine.

I think this is a limitation of using this software that has many bugs, fortunately during Fabacademy I learned to use very well for both Solid Worksk file 2d 3d for those who, for lasercut is sufficient to export the file from Solid Works DXF and is immediately accepted by the machine program. This allowed me to accomplish everything necessary for my projects.

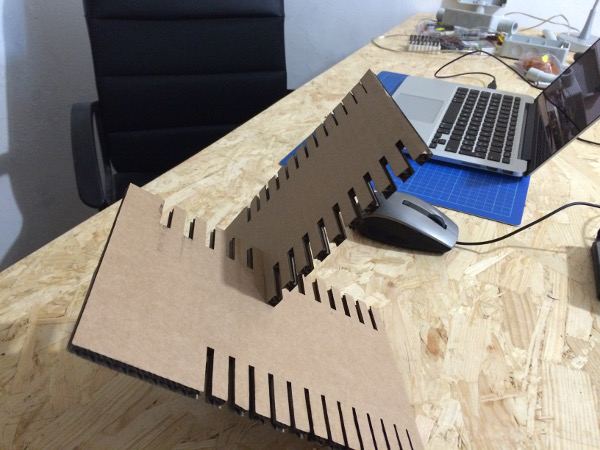

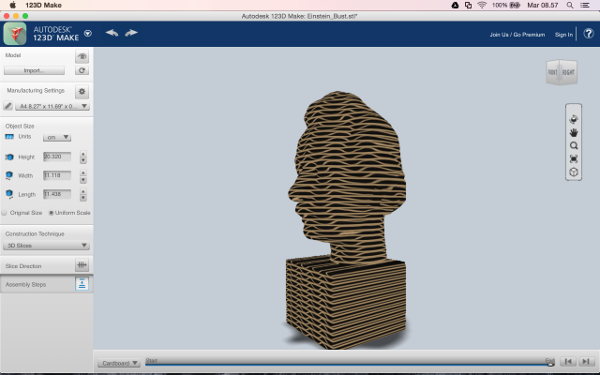

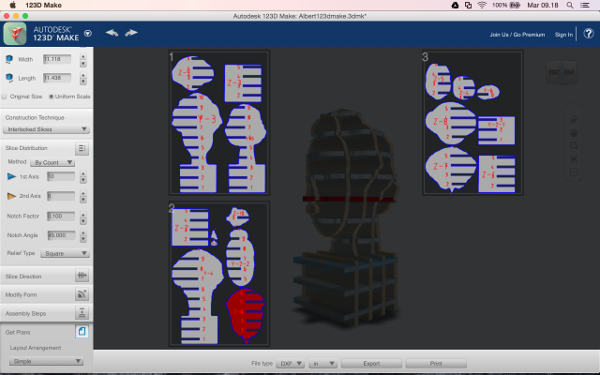

Exercise n3: Software 123D Make, cutting 3d models

During this week I also wanted to try another exercise , I have seen many videos and images of the achievements made with the card - board, by using 3D models then laser cut .

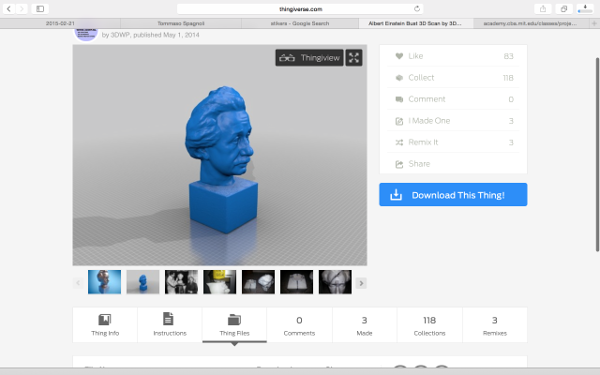

I downloaded a file from 3d Thingiverse , then I imported the file on

123D Make , the software allows you to choose whether to sections vertical or horizontal , you can choose the type of material and thickness .

Unfortunately I was unable to fit puzzle pieces because the card - board at my disposal was not stiff enough and the pieces among themselves struggled to get stuck .

I think this is a good exercise to make the three-dimensional creations with laser cutting .

Dowload file sitckers

Dowload file pressfit 01

Dowload file pressfit 01