Mechanics

The mechanic design of the machine is actually pretty easy, but it can be a little tricky to explain/understand. Here is a step by step explanation:

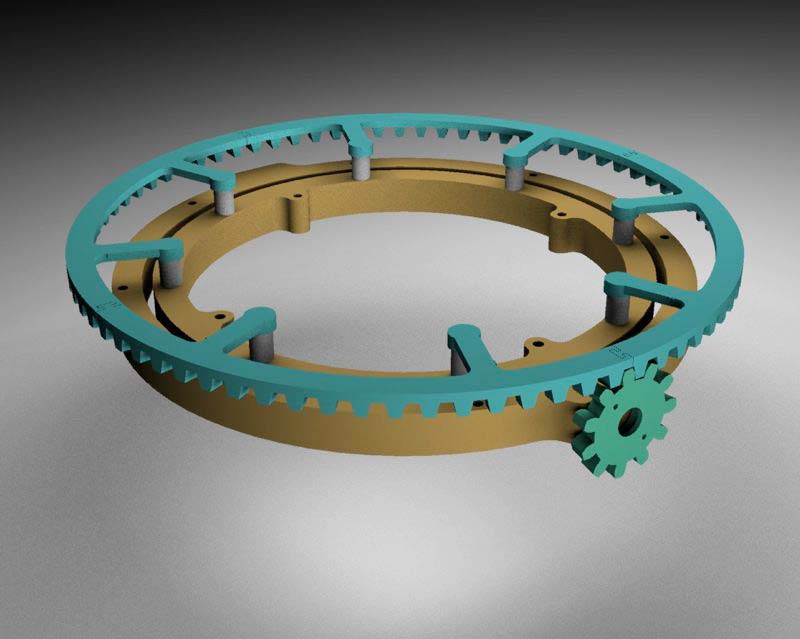

Bevel Gear and Pinion

The gears were designed in Rhinoceros starting by a very useful Gear Generator on which I calculated two normal gears. Then I imported the pdf in Rhino and used it as a reference to draw the actual pinion and bevel gear. The pinion has 11 teeth, while the Bevel gear has 77, thus making it a 1/7 ratio.

3D printing the bevel gear

The bevel gear was way too large to fit in any 3D printer I had available at the Fab Lab, so I had to split it in fourth. I designed a joint that would make the gear consistent once assembled, and I put pairs of little bulges (from one to four) on each side of the parts as a reference to find the right couples.

Assembling the bevel gear

The bevel gear rise for 1,5mm over the inner ring to match the size of the pinion, that's why the inner ring is assembled using longer M6 bolts. Two 5mm lasercut acrylic spacer are placed on every bolt, then the bevel gear is layed on the bolts and secured with nuts.

Motor housing and Decoupling Ring

The motor is kept in place inside the turret with four 100mm long M6 bolts and it is connected to the M8 shaft with a custom connector. In the beginning the connector was a single piece with a M8 nut housing on one side and a custom housing on the other. The problem was that when the motor was off, it couldn't rotate because of the warm gear inside and so couldn't the machine. So I came up with a decoupling ring whit two different housing element and one ring that can slide connecting or deconnecting the two.