CONCEPT

Why a rotational casting machine

Everything starts within one of my activities as a maker: Propmaking

A prop (abbreviative for property) is an object used on a movie set. A gun, a mobile phone, a book, a lightsaber, anything that an actor might have to use or touch is considered a prop and it has to be found and colected by the Prop Master or made from scratch by the Prop Maker. In my spare time I run a small propmaking lab with its own small webcomunity called Spaghetti Prop. One thing i usually make, are hollow casts made with silicone mold and cast with polyurethane resin.

What does a rotational casting machine do

You can check details about Industrial Rotational Moulding or Casting here. Industrial production uses various types of plastic that melts inside a mold that rotatets for a long time in a owen. What I will be doing is a machine that can work with silicon rubber molds and polyurethane resin for the cast.

The Rotocasting Machine is loaded with a closed silicon rubber mold containing a certain amount of premixed two component polyurethane resin. The machine rotates the mold in every direction so that the liquid resin inside keeps moving while it covers the inside walls of the mold. In a lapse of 10 minutes the resin hardens and at the end you have a hollow, durable and lightweight cast.

Previous attempt

In 2012 I designed and fabricated a traditional two frame machine featuring 3D printed gears, lasercut pulleys and cnc'ed bearings holder, I presented it at Rome's European Maker Faire, but never completed it with a motor.

My approach

The double squared frame system works pretty well, but it has been done so many times I decided to try something different. With any luck it will even be more efficient to fabricate and operate.

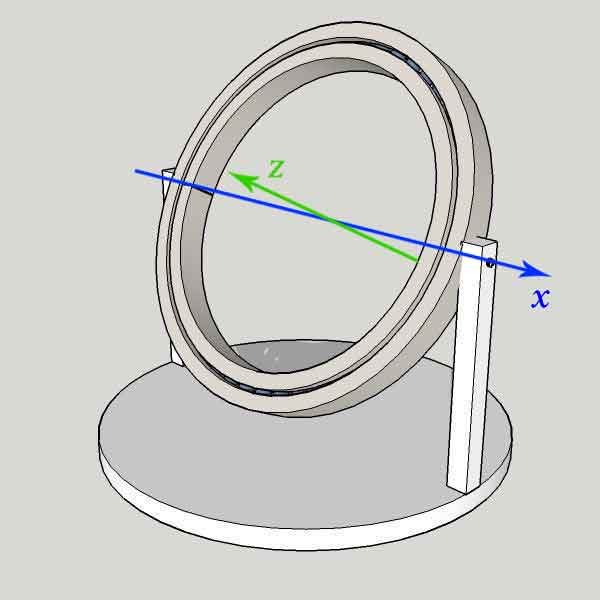

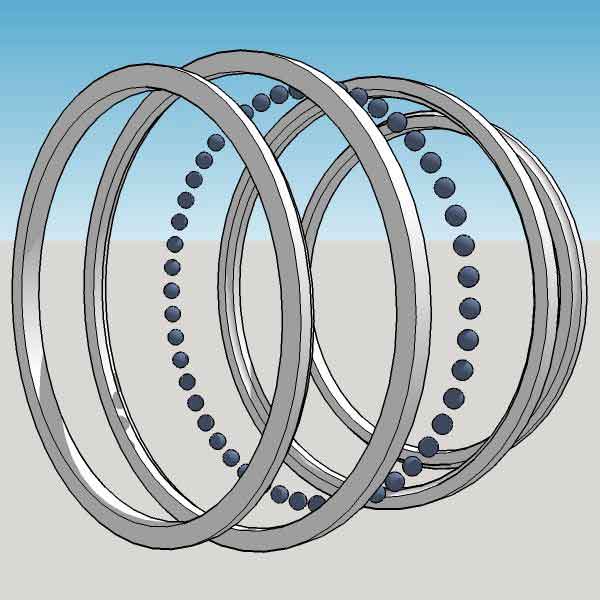

My idea is to make a double ring. The outer is connected on the x axis on a support base and it is connected to the inner ring by a circular array of steel balls so that the inner ring can rotate inside the outer one on the z axis. It is basically a huge Ball Bearing.