Week 7: computer-controlled machining

assignment for this week

make something BIG !!

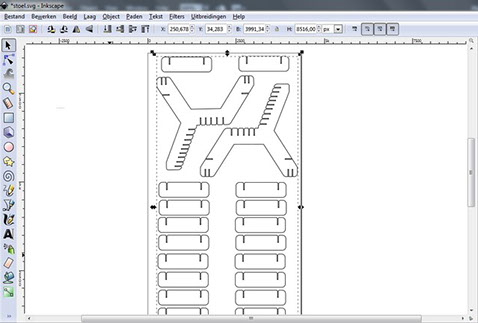

In week 3, computer controlled cutting I made a chair of cardboard and I was quite happy with this result, I made my design in Inkscape. I had never used it before so it was quite a challenge to try to get immedialte results. After struggling for a weekend, I managed to do and have some kind of a design.

For this week's assignment I decided to scale this model up to full size than hold a man's (my) weight.

First task was to scale up my Inscape model I already made but it was nowhere to be found on my laptop, probably overwritten or something or just deleted because maybe I thought I would be using it anymore.

Anyway I had to overdo my drawing in Inscape com completely and that took me an evening work at home, I made some strenghten improvements to the design I hoped.

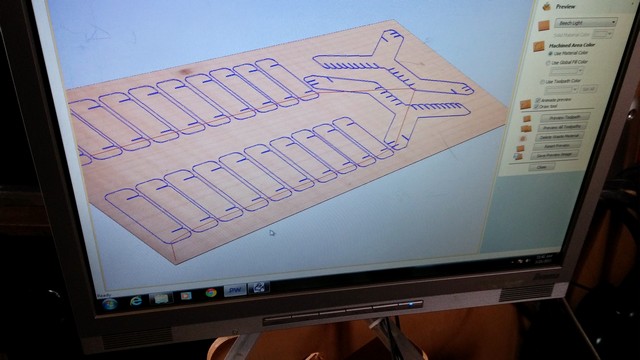

I had to think about the size and thickness of the wooden plate I would use. Round the corner at the Waag they have a woodshop and they sell lightweight 6mm plywood and I decided to buy that.

I is quite cheap, about 18 euro for a plate size 2.50 meter x 1.20 meter.

Detail of one (of many) cut outs I used. Hooks cut outs are to fit properly and the little circles are for the cnc machine to get better cut out results

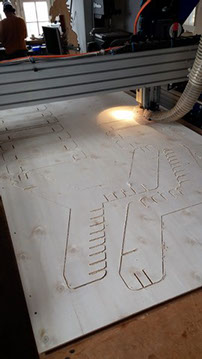

After my design was ready I save it as .svg file, exported it to a .dxf file and placed it on a USB stick to take it to the Waag and load it into the software of the Shopbot CNC machine.

Importing got me an error and the.dxf file could not be loaded, expert at the Waag gave me the advice to load the file .svg into Adobe Illustrator and save it as a .ai (adobe illustrator) file and than try to load this into the Shopbot software. This time all went well.

Together with one of the experts at the Waag we had to do a lot of settings and chamgements but in the end he gave it a go and the Shopbot machine was taking off. I was pleased with the result, had to do a lot of handsanding but pieces all fitted well and I was real happy with the result. To prove my chair can hold my weight, I added a picture.

dfsdfs

d

sdfs

sdfsd

Here some results of my fellow students at the Waag.