09 -

Molding and casting

In this week, the assignment is that design a 3D mold, machine it, and cast parts from it. At the begining I had no idea about what to design. I spent serveal days on figuring out what to do for the assignment. I tried to design something from the features of material, and finally I think I can made someting bendable.

The 1st exercise

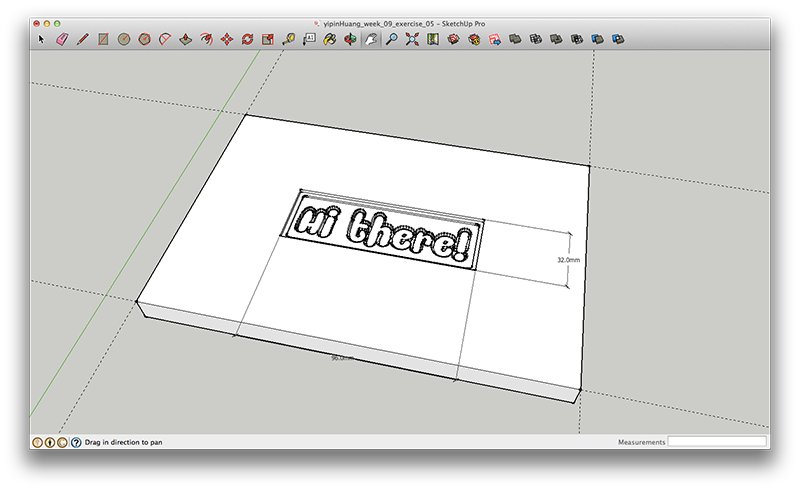

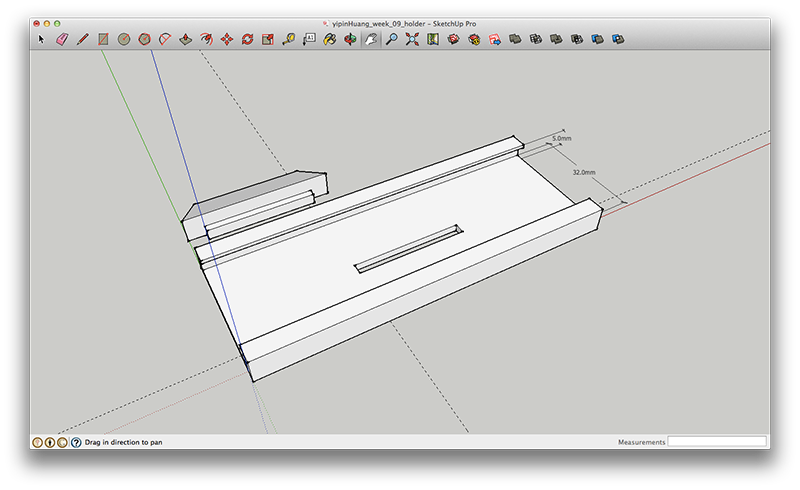

The is an exercise on makeing a stamp. First of all, I created a 3D model in Sketchup. That was the words I wanted to stamp.

Molding

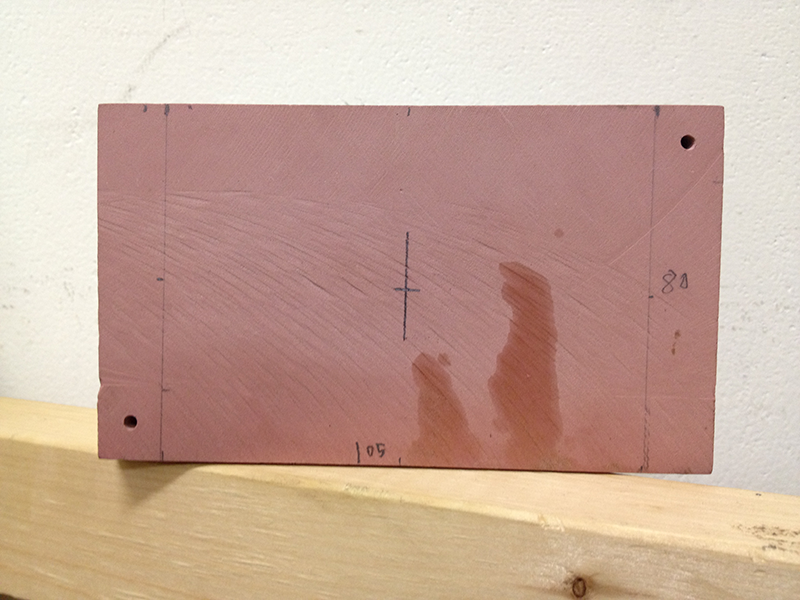

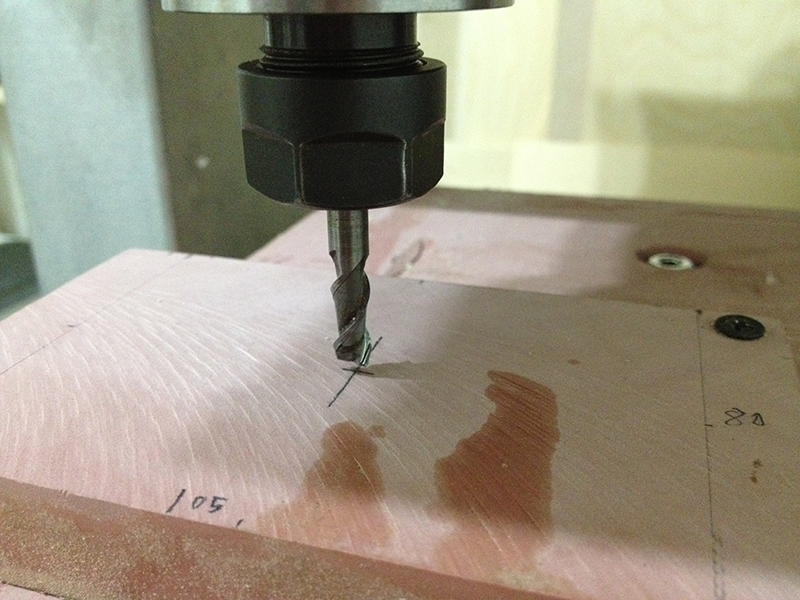

Milling out the 3D form from Epoxy Tooling board. I used Roland MDX-540 and SRP player. For aligning the coordinate, I marked x, y 0, 0 on the epoxy tooling board.

The tooling board was small. I have to make sure the end mill will not hit the screw when milling (see what I learned from previous work ), so I checked the end mill traveling path serveral times.

SRP player setting. Size of my tooling baord can be different from end mill working size.

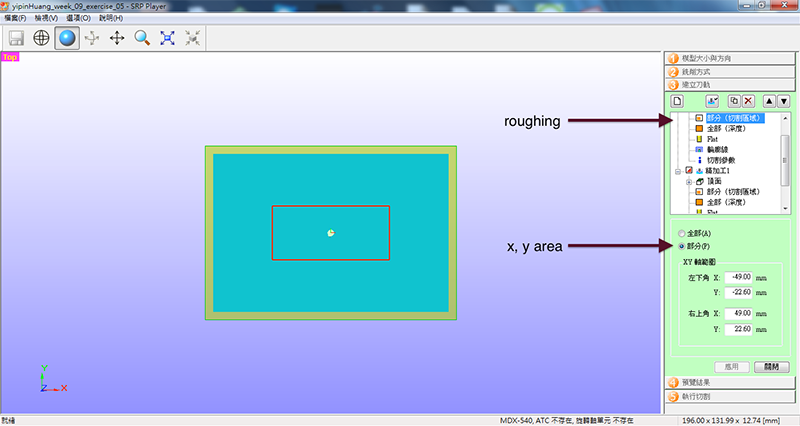

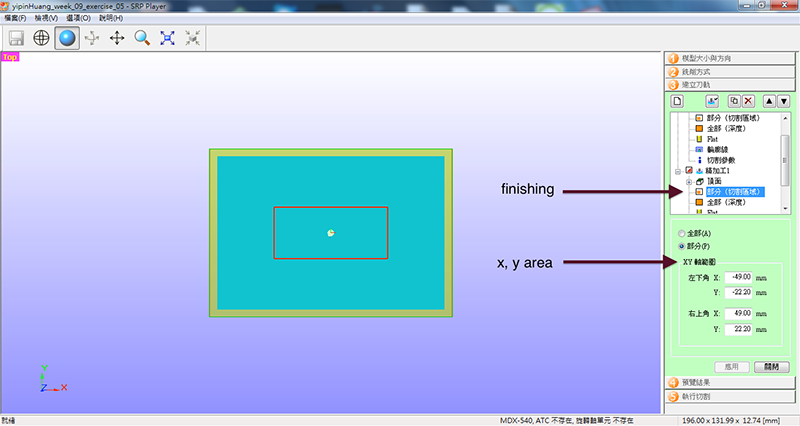

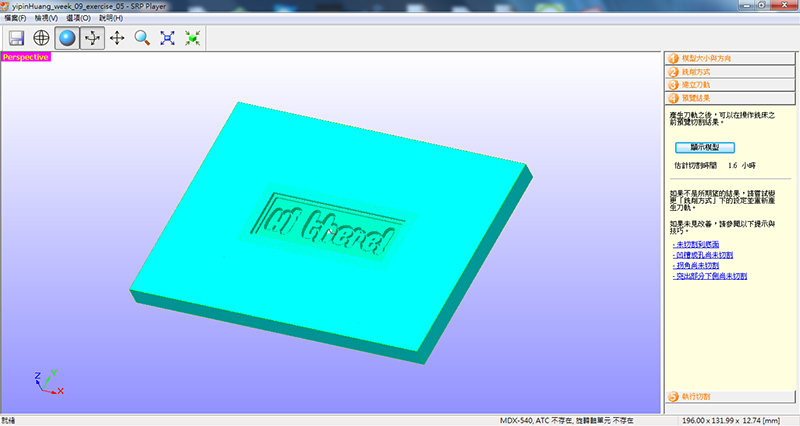

It is important to preview the result in SRP player. In the picture below, I can see both 2 milling stages (roughing and finishing) on the screen.

I used 6 mm end mill for roughing, and 1 mm end mill for finishing. The quality was OK this time.

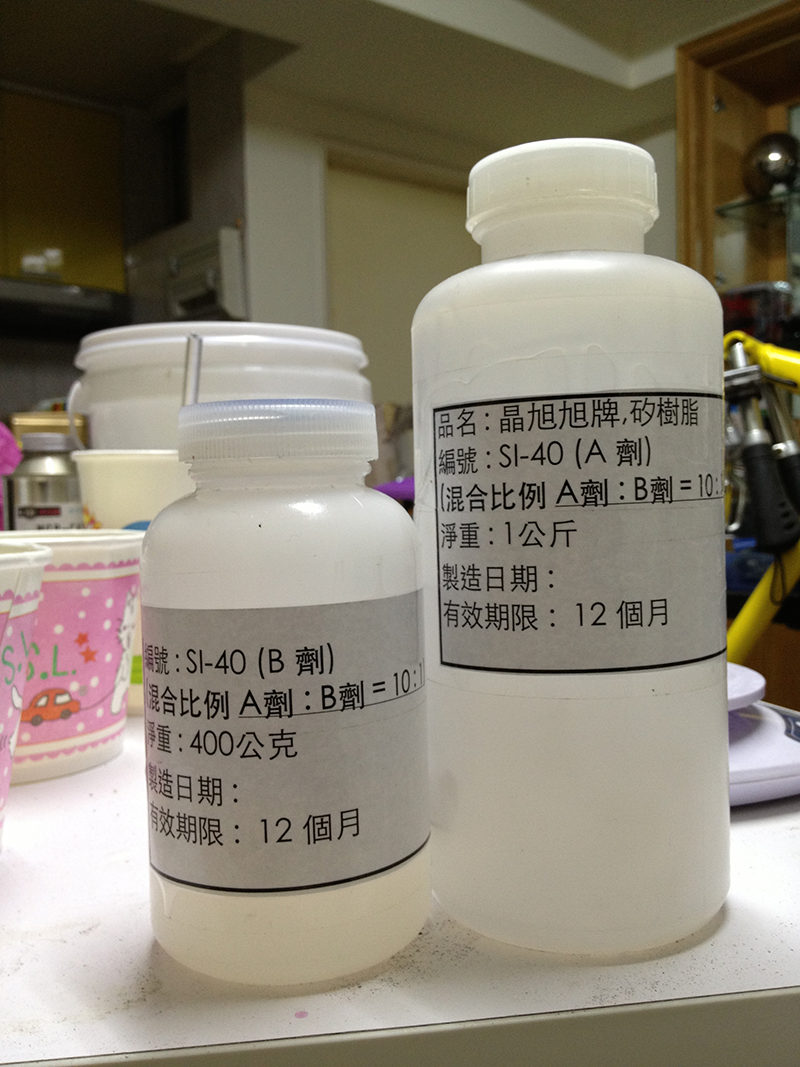

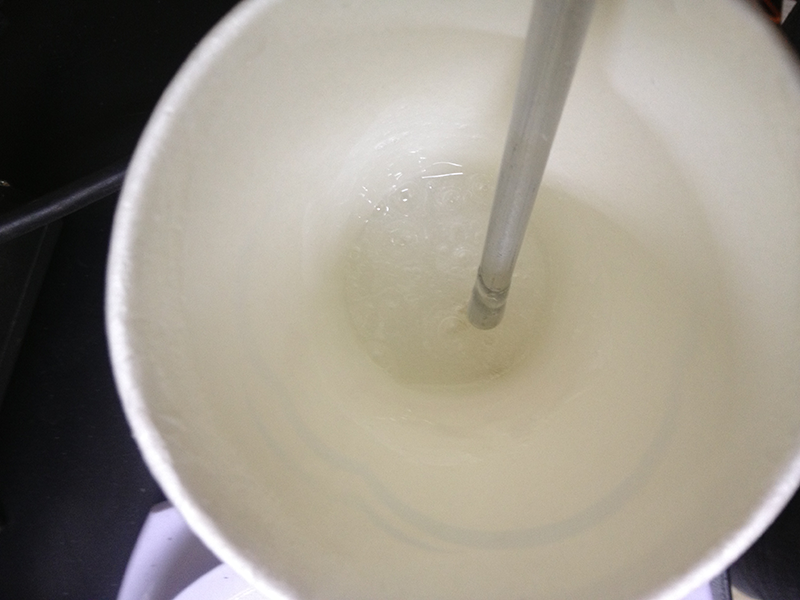

Then prepared silicone materials and mixed. We can easily get the material in chenimical shop.

For cleaning all bubbles, I used vacuum chamber.

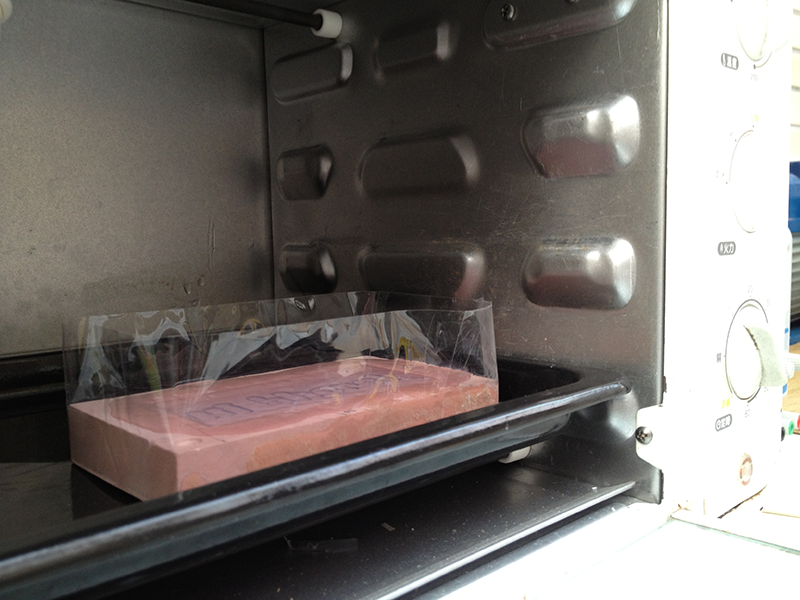

Baking 40 minutes in 80 °C for full cure faster.

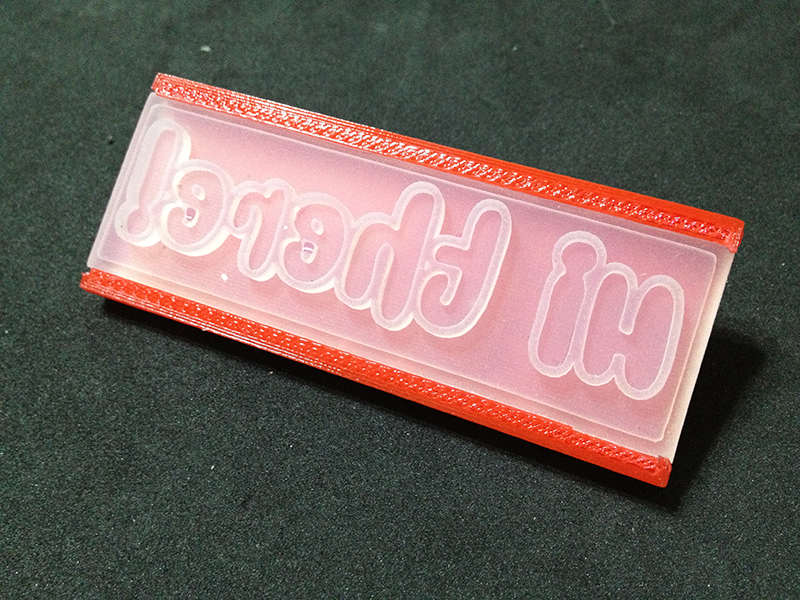

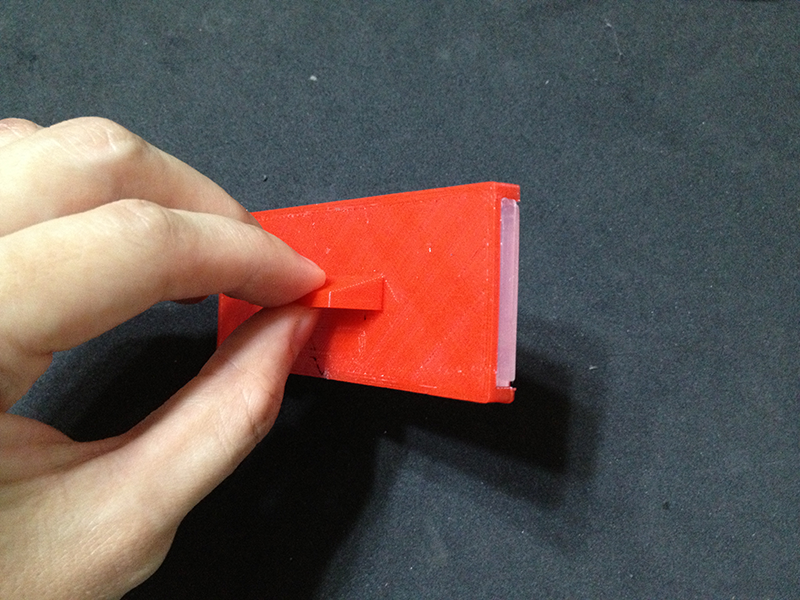

Then, I wanted to make a base to hold the stamp. I 3D print the parts.

3D print results. Because of I did not clean all balck PLA on heat bed, some balck material melt with the red material. It was hard to remove the imperfection detail.

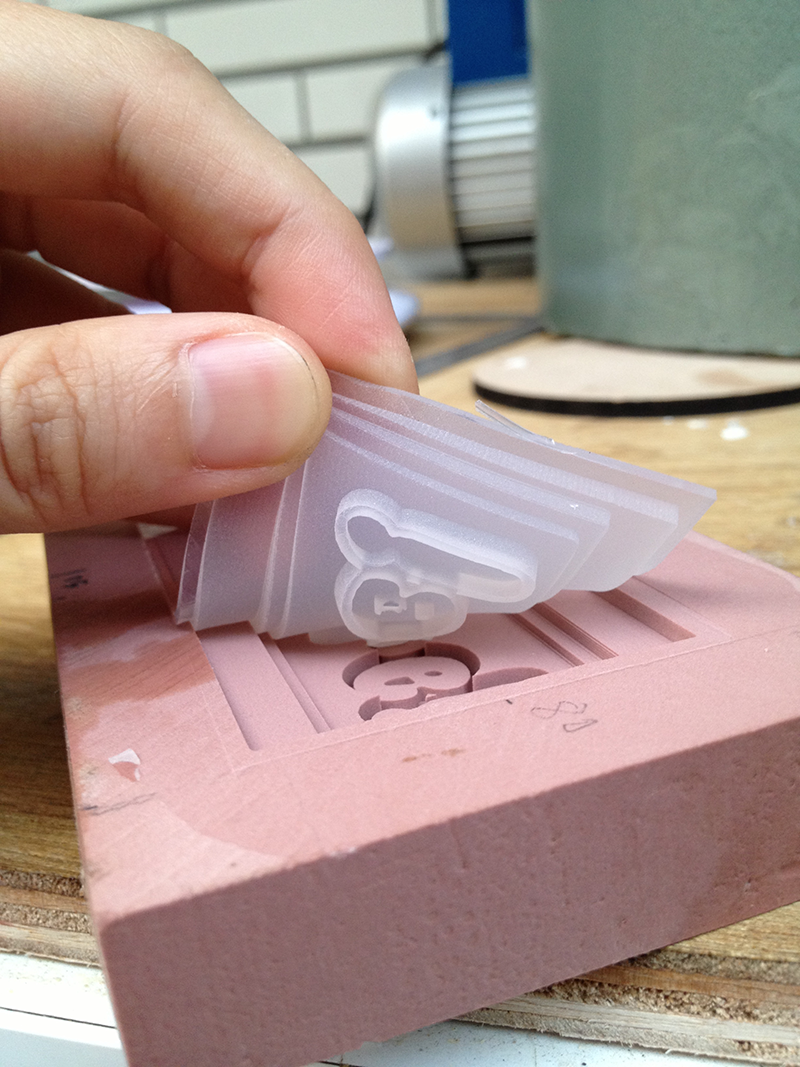

Pushing the silicon to the latch of 3D printed stamp base,

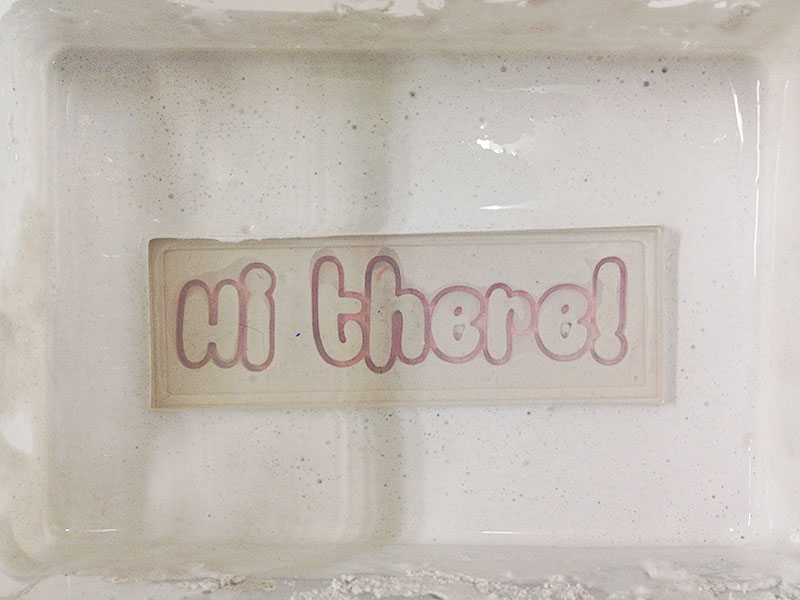

Plaster

Then I made a 3D mold by plaster. I've played with plaster when I was a child. That is the material I am familiar with.

First of all, I mixed some plaster with water. A better working procedure is that pouring some plaster to the container, and add some water. If the water is not enough, add some again.

Push the cast into plaster slowly:

Plaster cures so fast. It only takes 4 to 5 hours:

Finally I get anothermold:

Source files:

- molding: exercise_05

- stamp base holder: holder

[home]