Fab Academy 2014,

Masato Takemura

Weekly Assingments

class3: Parametric modeling, laser and vinyl cutting

Feb 12th,2014

Memo

In this week, I'v learned about "cutting". FABLAB recommend two way of cutting. One is vinyl cutter that cut materials like a sheet. Anothre is Laser cutter that cut board made by acrylic, wood, carboads etc...

Assignment

This assignment required to design "joints" with laser cutter. In addition it should be designed by any prametrical design tools.

I made joint made by carboard. They are designed by FABMODULE. It can edit sizes by each paramater, such as material thickness, or laser spot diamater.

fig.1 left:material thickness=5.5mm, right:material thickness=2.5mm

fig.2 left:material thickness=5.5mm, right:material thickness=2.5mm

fig.3 left:material thickness=5.5mm, right:material thickness=2.5mm

Second, I tried to make press fitting construction kit.

I used Illustrator for design. For cutting, I sort them.

I cut out 40 parts by laser cutter. Laser parameter is power:60w*30%, speed:10mm/sec

I made flower with this kit.

We can create any object. It's fun!!

*Illustrator(.ai) data is here

Next, I made a box for coffee mill. Because I lost the box...

I used Illustrator CS3 for designing. First, I measure the coffee mill. And I wrote the development.

You can download data from here.

After I cut out the parts by laser cutting, I constructed them. It was fit to my coffee mill !!

fig.3 left:material thickness=5.5mm, right:material thickness=2.5mm

Parametrical Design tools

Description

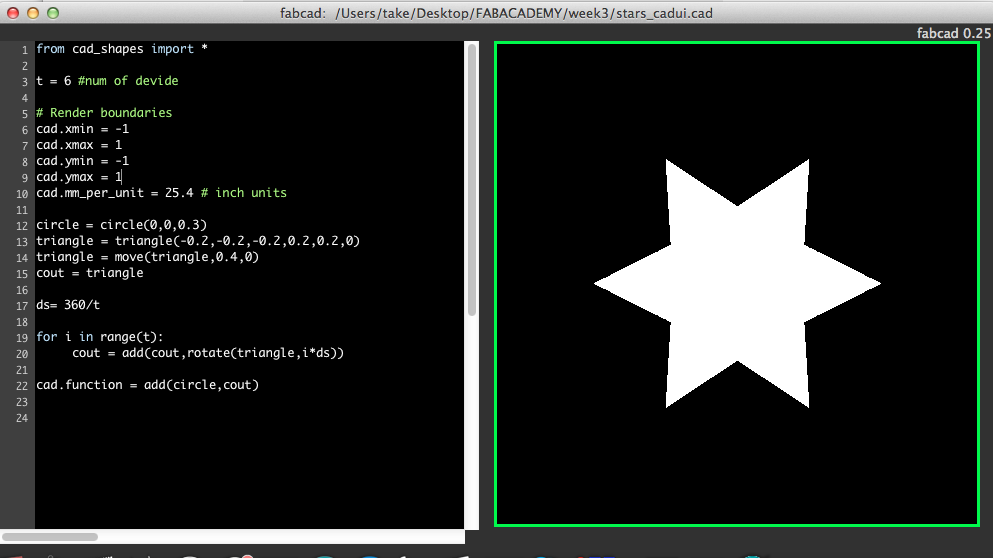

I used FAB MODELU as a Parametrical Design tool. It makes any shapes by code. The advantage is that we can edit shapes by just changing value of each parameter.Installation

refer to URL "FAB Module"My road

I wrote a code bellow as an exercise.

from cad_shapes import *

t = 6 #num of devide

# Render boundaries

cad.xmin = -1

cad.xmax = 1

cad.ymin = -1

cad.ymax = 1

cad.mm_per_unit = 25.4 # inch units

circle = circle(0,0,0.3)

triangle = triangle(-0.2,-0.2,-0.2,0.2,0.2,0)

triangle = move(triangle,0.4,0)

cout = triangle

ds= 360/t

for i in range(t):

cout = add(cout,rotate(triangle,i*ds))

cad.function = add(circle,cout)Machine

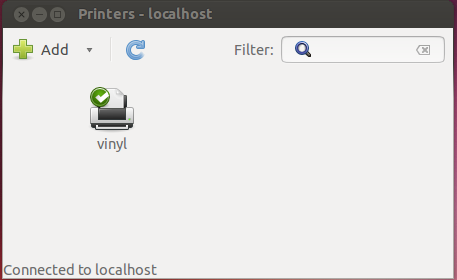

Our Vinyl cutter is "Roland CAMM-1 CX-12". We could not connect them with OSX. If you know how to connect Roland CAMM-1 to OSX via FAB Module, please contact me!

I could control Roland CAMM-1 with Fab module based on virtual simulated Ubuntu on OSX.

The setting was slightly hard work.

memo of installation

(on Ubuntu)- Add printer

- Name "vinyl" as a printer name

- select "GENERAL" as a make/model

- select output to "ROW"

- keep fab_send to bellow '.camm': 'printer=vinyl; lpr -P$printer "$file"',

I saw Roland camm like this on printer setting window.

I cut illustlation of alian Dr.Neil introduced us at Fab Academy.

[Reference]

- Tutorial of Rinoceros: It's easy to know how to make any shapes. It have sample 3d model also.

- HOW TO GET WHAT YOU WANT: It's exciting PCB.

- Tutorial of cad_ui: Helpfull.

http://wiki.fablab.is/wiki/Portal:BuildingBlocks

http://www.kobakant.at/DIY/?p=1132

http://fab.cba.mit.edu/classes/S62.12/people/keeter.matt/tutorials/basics.html

http://www.kobakant.at/DIY/?p=1132